High-temperature-resistant easy-to-form PC/PCTG material and preparation method thereof

A technology of high temperature resistance and antioxidant, applied in the field of PC/PCTG materials and their preparation, can solve the problems of poor flowability of PC materials, poor processing and forming performance, poor secondary processing performance, and PC is difficult to process, and achieves excellent secondary processing performance. , The effect of high fluidity and short molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

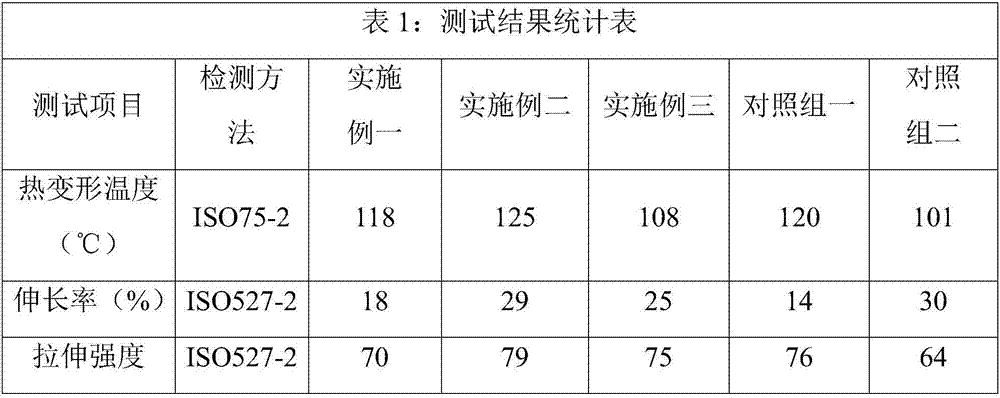

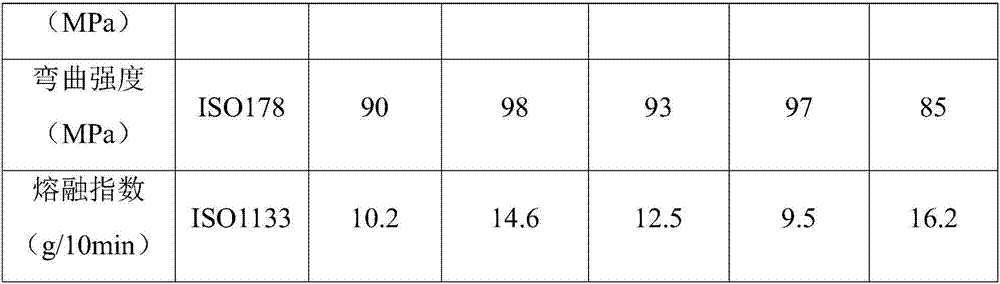

Embodiment 1

[0023] The high-temperature-resistant and easy-to-shape PC / PCTG material is composed of the following components by mass percentage: PC 70%; PCTG 29.6%; lubricant 0.1%; antioxidant 0.3%.

Embodiment 2

[0025] The high-temperature-resistant and easy-to-form PC / PCTG material is composed of the following components by mass percentage: PC66.5%; PCTG33.1%; lubricant 0.1%; antioxidant 0.3%.

Embodiment 3

[0027] The high-temperature-resistant and easy-to-form PC / PCTG material is composed of the following components by mass percentage: PC60%; PCTG39.6%; lubricant 0.1%; antioxidant 0.3%.

[0028] control group one

[0029] The high-temperature-resistant and easy-to-shape PC material is composed of the following components by mass percentage: PC 99.5%; lubricant 0.1%; antioxidant 0.3%.

[0030] control group two

[0031] The high-temperature-resistant and easy-to-form PCTG material is composed of the following components by mass percentage: PCTG 99.5%; lubricant 0.1%; antioxidant 0.3%.

[0032] In the above embodiments, PC is bisphenol A polycarbonate, PCTG is polyethylene terephthalate-1,4-cyclohexanedimethanol, the lubricant is polyethylene wax, and the antioxidant is mass A compound of hindered phenol antioxidant 1076 and phosphite antioxidant 168 in a ratio of 1:2.

[0033] The preparation method of the high-temperature-resistant and easy-to-shape PC / PCTG material is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com