Double pallet fork rectangular coordinate robot stereoscopic warehouse

A rectangular coordinate and three-dimensional warehouse technology, applied in the field of cargo storage and transportation, can solve the problems that the efficiency of warehouse storage and transportation machinery cannot be improved synchronously, the efficiency of warehouse storage and transportation will not be improved, and the capital investment will be increased, so as to achieve short transfer period and high operating efficiency Improvement, the effect of large throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

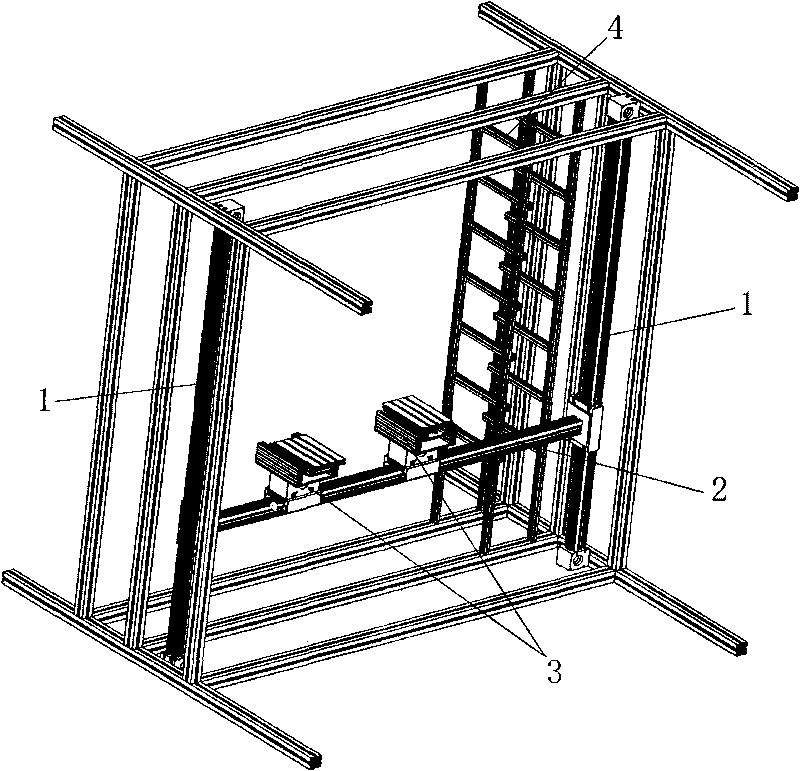

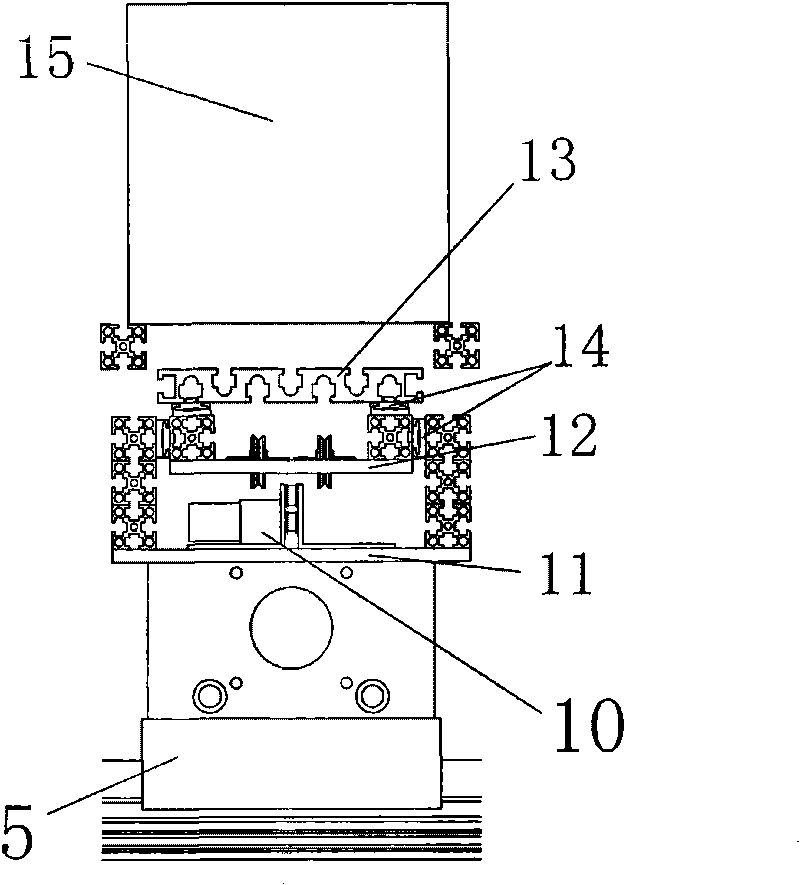

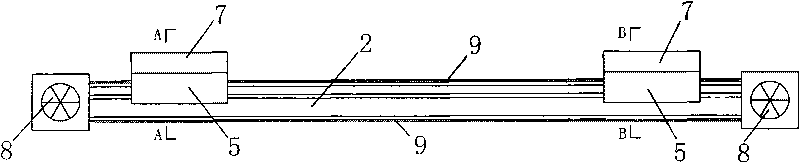

[0026] see figure 1 , this two-fork Cartesian robot three-dimensional warehouse of the present invention includes a multi-storey shelf 4, a stacking crane motion system and an incoming and outgoing mechanism, and the shelf 4 is arranged in the form of a single-lane double-row shelf. The movement system of the stacking crane includes a vertical beam 1 arranged at both ends of the single roadway, a cross beam 2 between the vertical beams 1 and a stacking crane 3, and the two ends of the cross beam 2 are respectively buckled on the vertical beam 1 and can be 1 slides vertically in the axial direction, and more than two stacking cranes 3 are arranged on the beam 2, and a crane driving mechanism is also arranged on the beam 2, and the crane driving mechanism drives the stacking crane 3 to slide along the beam 2. Both the vertical beam 1 and the cross beam 2 are industrial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com