Process for producing polyester industrial yarns by liquid-phase tackified melts in multi-end direct spinning manner

A polyester industrial yarn, liquid phase tackifying technology, applied in the directions of melt spinning, stretch spinning, textiles and papermaking, etc., can solve the problems that the polyester industrial yarn process has not yet appeared, and achieve high production efficiency, increased production capacity, material The effect of short turnaround times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

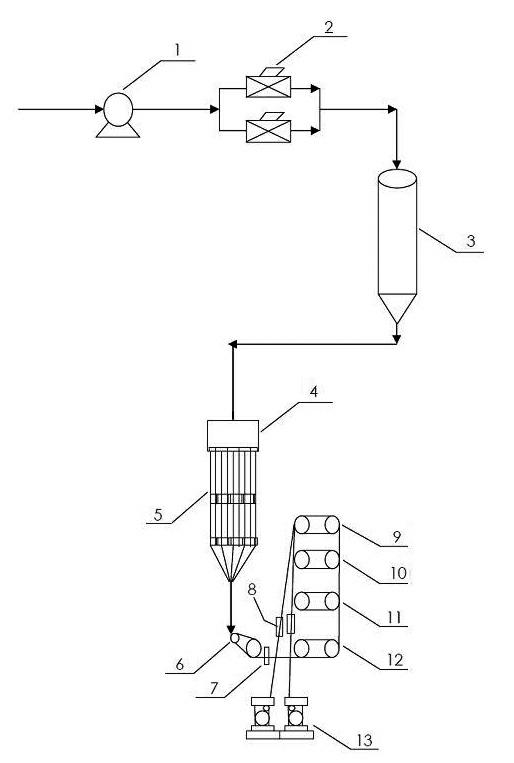

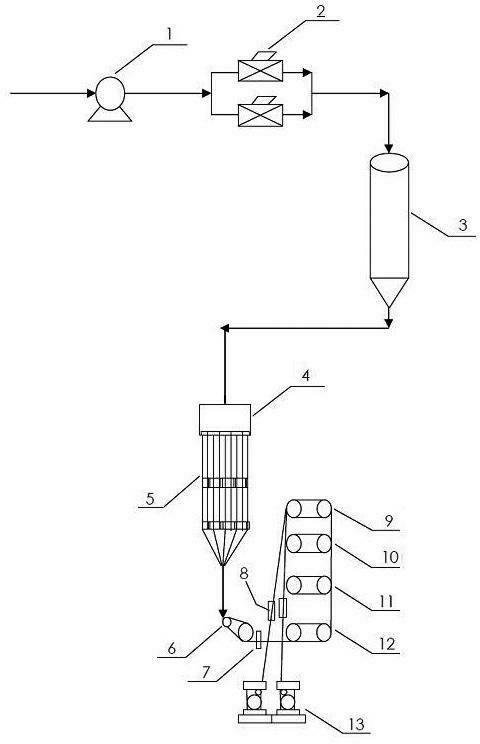

[0028] Example 1: Melt 16 ends of direct spinning 1000D high-strength polyester industrial yarn.

[0029] (1), liquid phase viscosity increase:

[0030] The low-viscosity polyester melt with an intrinsic viscosity of 0.64-0.69dl / g is obtained through melt polycondensation. The low-viscosity polyester melt is boosted by booster pump 1, filtered by duplex filter 2, and transported to the vertical liquid The top of the phase thickening reactor 3 flows down evenly in the vertical liquid phase thickening reactor 3 due to the natural film formation by gravity. After ~90 minutes, a high-viscosity polyester melt with an intrinsic viscosity of 0.90-1.10 dl / g was obtained.

[0031] (2), multi-head spinning:

[0032] The high-viscosity polyester melt after liquid-phase thickening is transported to the spinning box 4 of each spinning position. Each spinning position adopts 16 direct spinning. After being metered and filtered by the metering pump, the body is sprayed out from the spinne...

Embodiment 2

[0039] Example 2: Melt 16 head direct spinning 1000D low shrinkage polyester industrial yarn.

[0040] (1) Liquid phase thickening:

[0041] A low-viscosity polyester melt with an intrinsic viscosity of 0.64-0.69dl / g is obtained by melt polycondensation. The low-viscosity melt is boosted by a booster pump, filtered, and then transported to the top of a vertical liquid-phase viscosifying reactor. The film is formed and flowed down evenly, the temperature in the reactor is 270-290° C., the pressure is 50-130 Pa, and after 60-90 minutes, a high-viscosity polyester melt with an intrinsic viscosity of 0.90-1.00 dl / g is obtained.

[0042] (2), multi-head spinning:

[0043]The liquid-phase viscosified melt is transported to the spinning box of each spinning position. The temperature of the box is 290-300°C. Each spinning position contains two parallel spinning boxes. Each box is equipped with 4 Planetary pumps, planetary pumps contain 1 melt inlet and 4 melt outlets, and each box i...

Embodiment 3

[0049] Example 3: Melt 24 ends of direct spinning 500D high-strength polyester industrial yarn.

[0050] (1) Liquid phase thickening:

[0051] A low-viscosity polyester melt with an intrinsic viscosity of 0.64-0.69dl / g is obtained by melt polycondensation. The low-viscosity melt is boosted by a booster pump, filtered, and then transported to the top of a vertical liquid-phase viscosifying reactor. The film is uniformly flowed down, the temperature in the reactor is 270-290° C., the pressure is 50-130 Pa, and after 60-90 minutes, a high-viscosity polyester melt with an intrinsic viscosity of 0.90-1.10 dl / g is obtained.

[0052] (2) Multi-head spinning:

[0053] The liquid-phase viscosified melt is transported to the spinning box of each spinning position. The temperature of the box is 290-300 ° C. Each spinning position contains two parallel spinning boxes. Each box is equipped with 4 Planetary pumps, planetary pumps contain 1 melt inlet and 6 melt outlets, and each box is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com