Patents

Literature

69 results about "Liquid explosives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid nitro explosives are mainly liquid nitro-containing aliphatics, aromatics and alcohols. Among these compounds, nitro alkane is a very important liquid explosive, which has a certain explosive power.

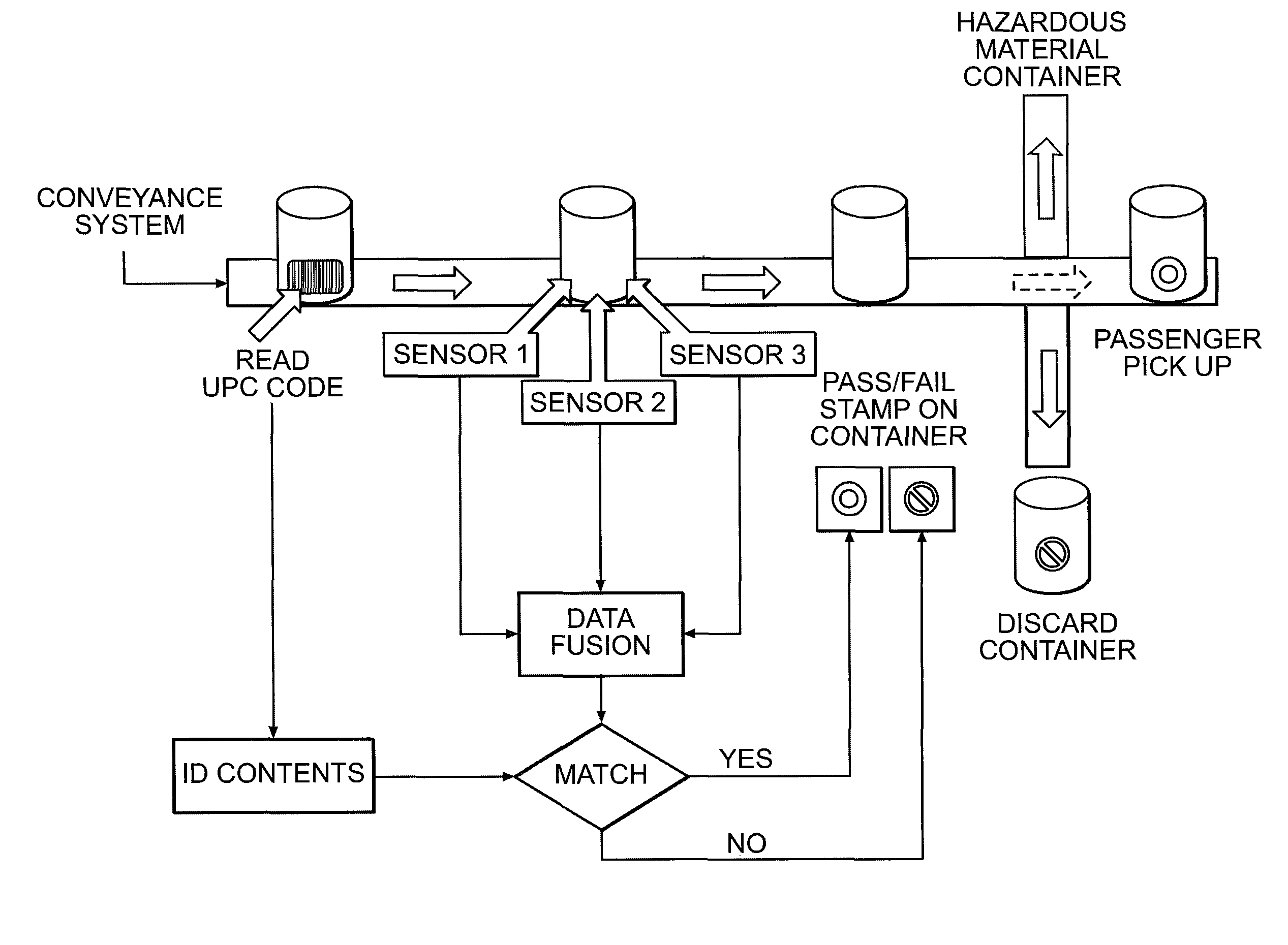

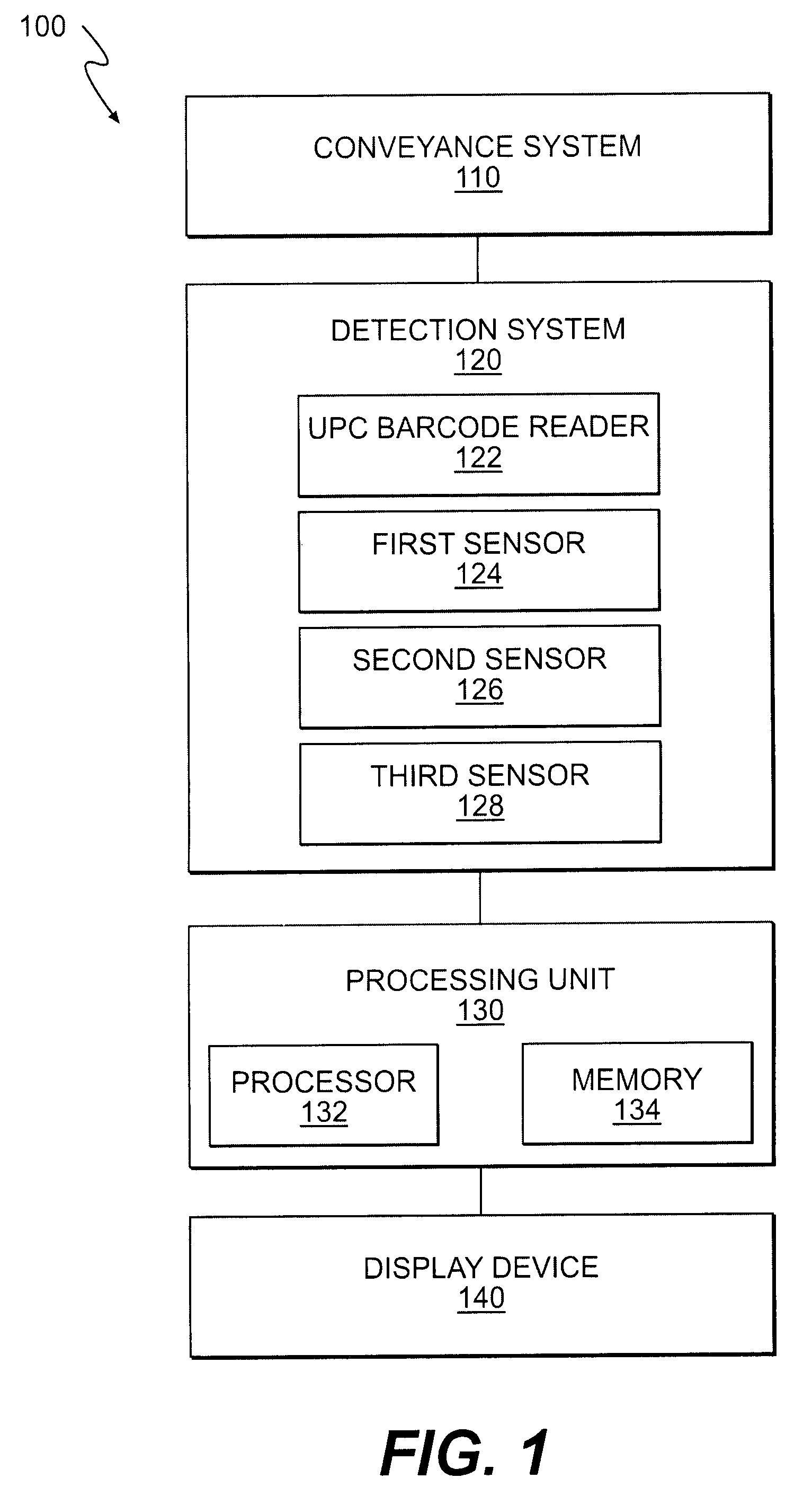

Devices and methods for detecting hazardous materials

ActiveUS20080312768A1Digital data processing detailsFuel testingHazardous substanceProcess engineering

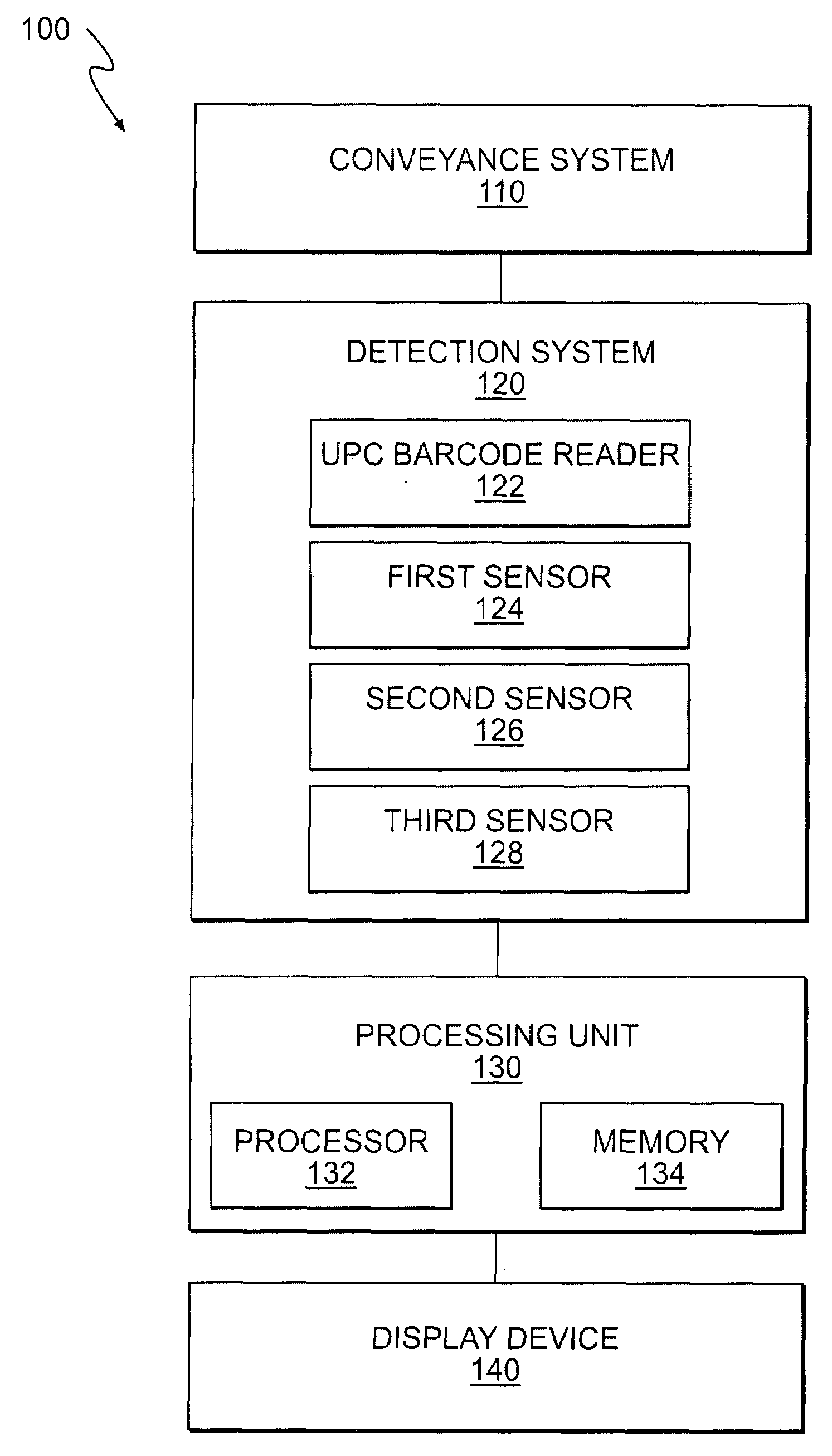

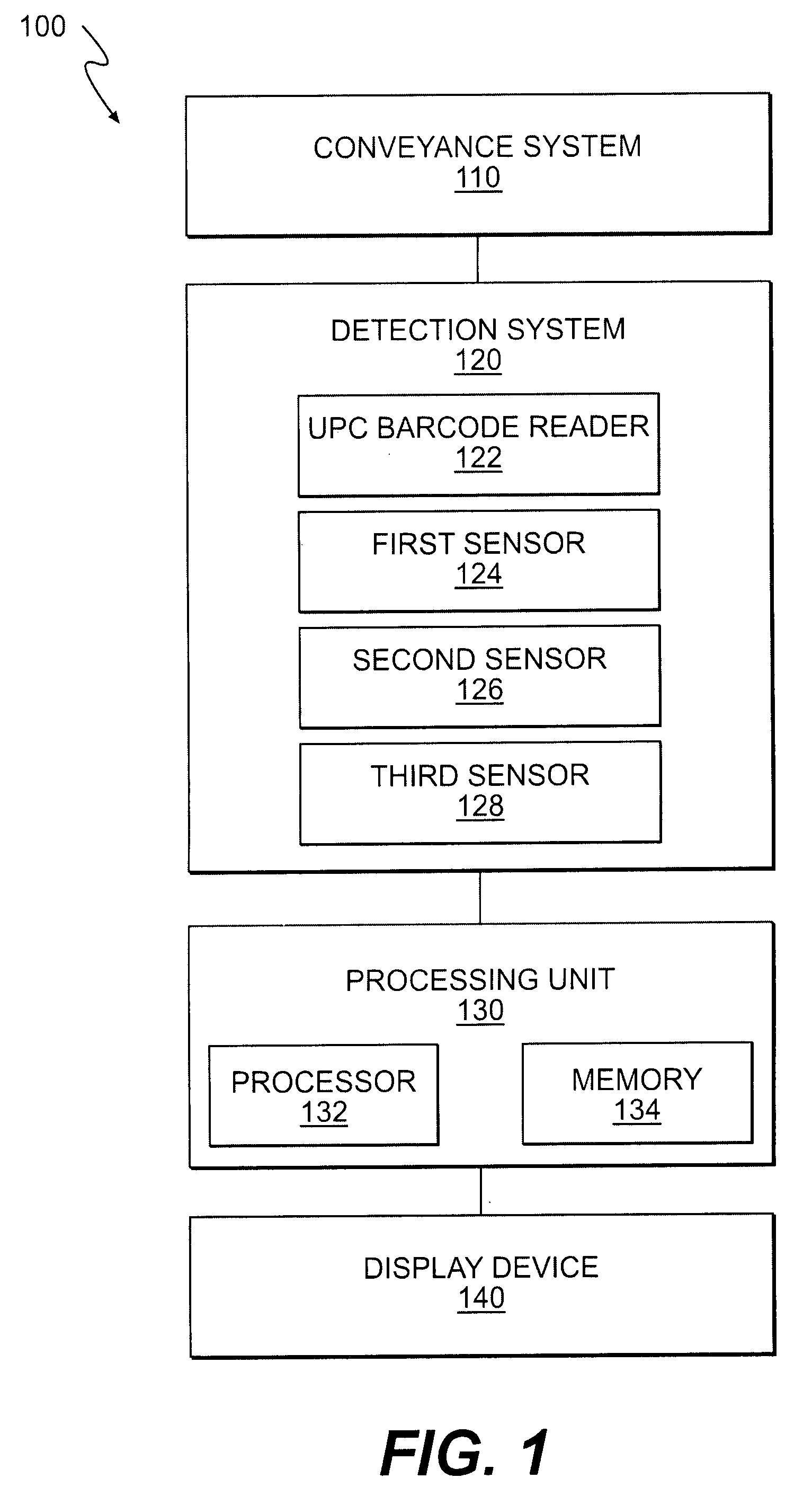

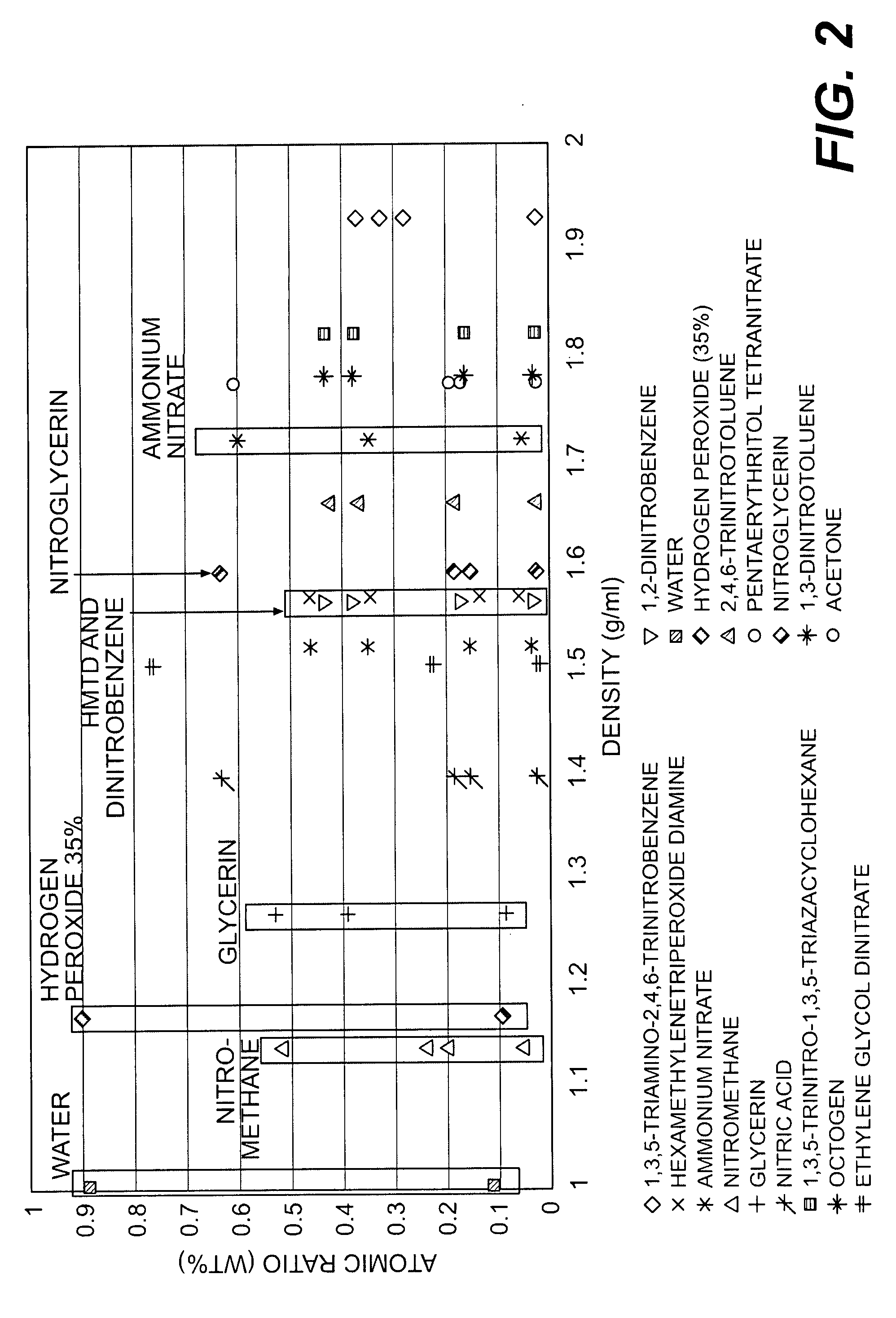

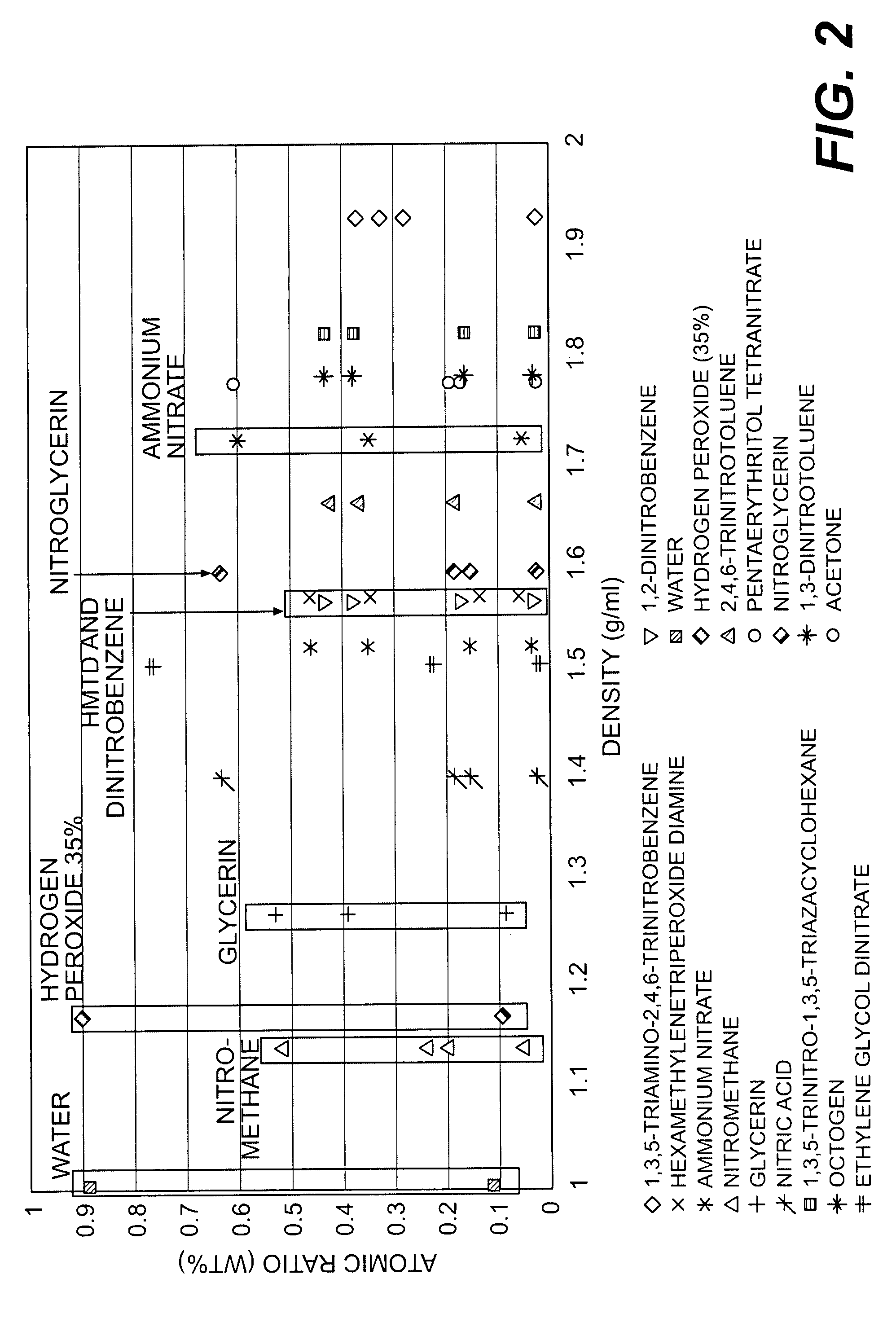

A container screening system that uses multiple orthogonal sensors for detecting hazardous materials, such as liquid explosives and precursors of liquid explosives, in sealed containers. The container screening system comprises a first sensor that detects materials inside the container using a first detection technology, a second sensor that detects materials insider the container using a second detection technology, and a data processing unit that processes data from the first and second sensors and generates a screen result. The system reduces false positives and increases probability of detection by matching the relative strengths and weaknesses of each technology.

Owner:NORTHROP GRUMMAN SYST CORP

Energetic ionic liquids

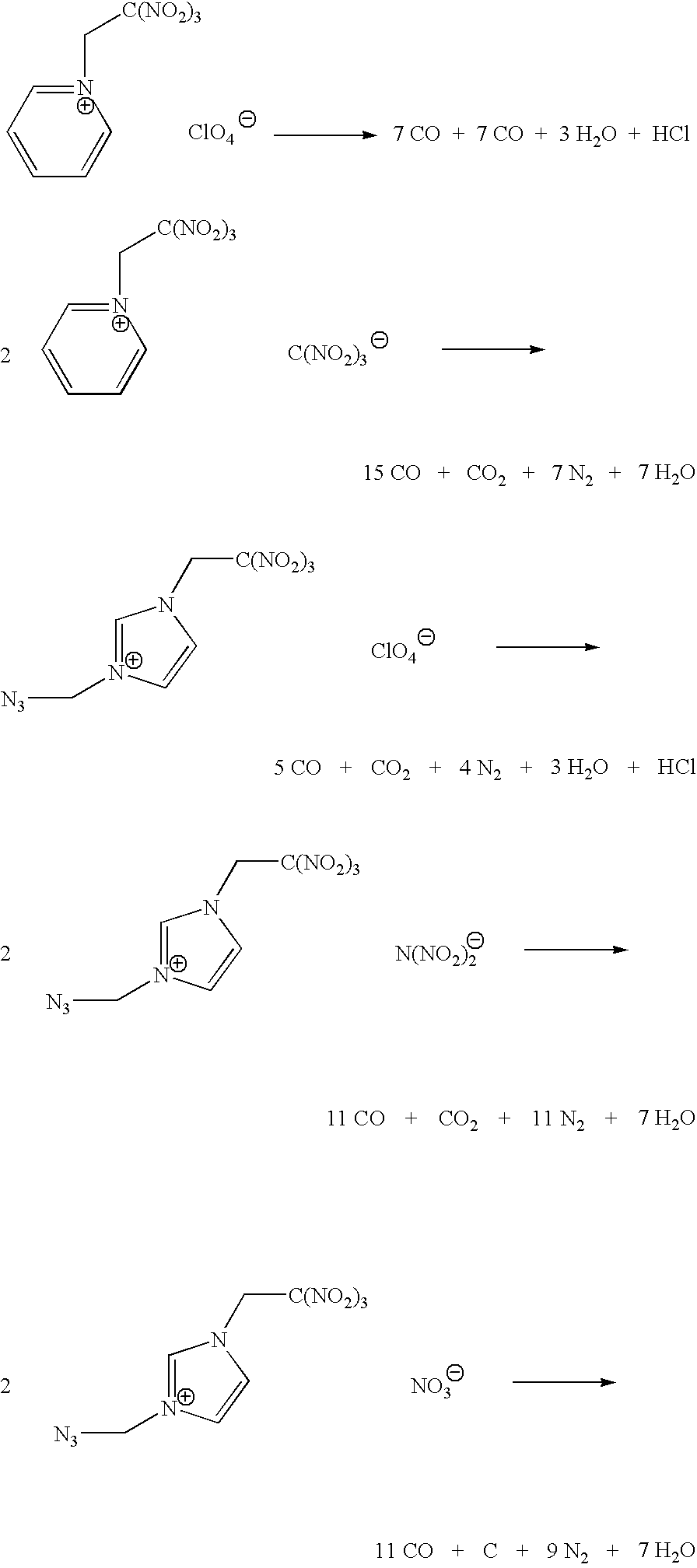

Provided are energetic materials of low vapor pressure in the form of ionic liquids having fuel and oxidizer ions including, substituted pyridinium or imidazolium cations paired with nitrato-, perchlorato-, or nitramido-based anions, to form such ionic liquids or salts. The salts of the present invention are low melting and have essentially little or no vapor pressure over a wide temperature range. The salts of this invention are thus an important breakthrough since they can serve as high-performing monopropellants which are not complex mixtures and have no vapor toxicity. Such salts also find use as munitions, liquid explosives, reaction media for the synthesis of other high-energy materials, and as plasticizers.

Owner:GOVERNMENT OF THE UNITED STATES OF AMERCIA AS REPRESENTED BY THE SEC OF THE AIR FORCE

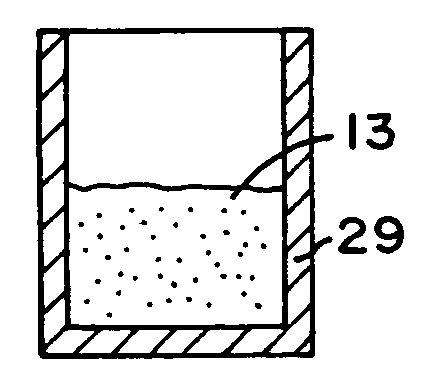

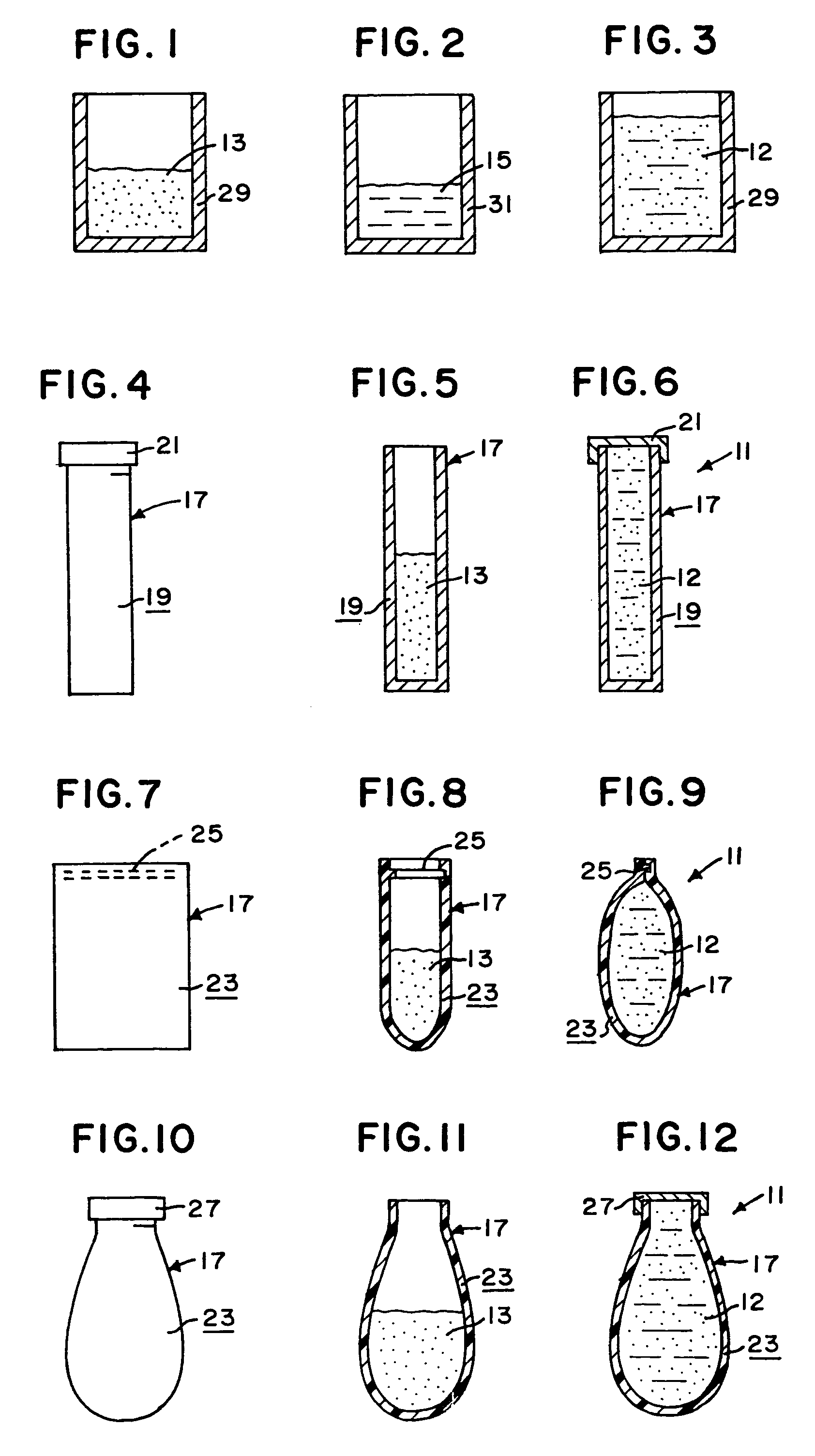

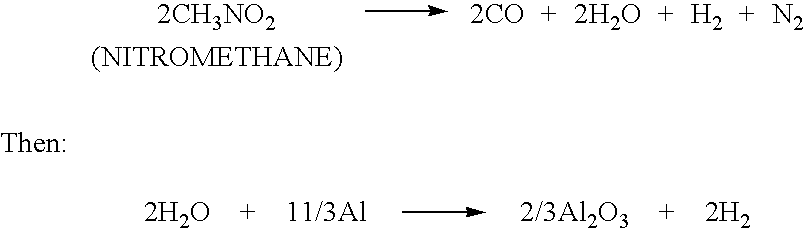

Multi-component liquid explosive composition and method

InactiveUS6960267B1Extended shelf lifeLoomsNitroparaffin explosive compositionsNitromethaneSquare meter

A multi-component liquid explosive composition and method of mixing thereof. The steps include (a) providing a powder consisting of aluminum preferably having an average particle size of 5 to 50 microns and a surface area of 0.5 to 2 square meters per cubic centimeter containing 0.1 to 5% stearic acid by weight; (b) providing a liquid consisting of nitromethane; and (c) mixing said aluminum powder with the nitromethane to form a liquid explosive formulation detonable at a wide range of temperatures and diameters with a standard commercial number 8 blasting cap.

Owner:NIXON III WILLIAM P

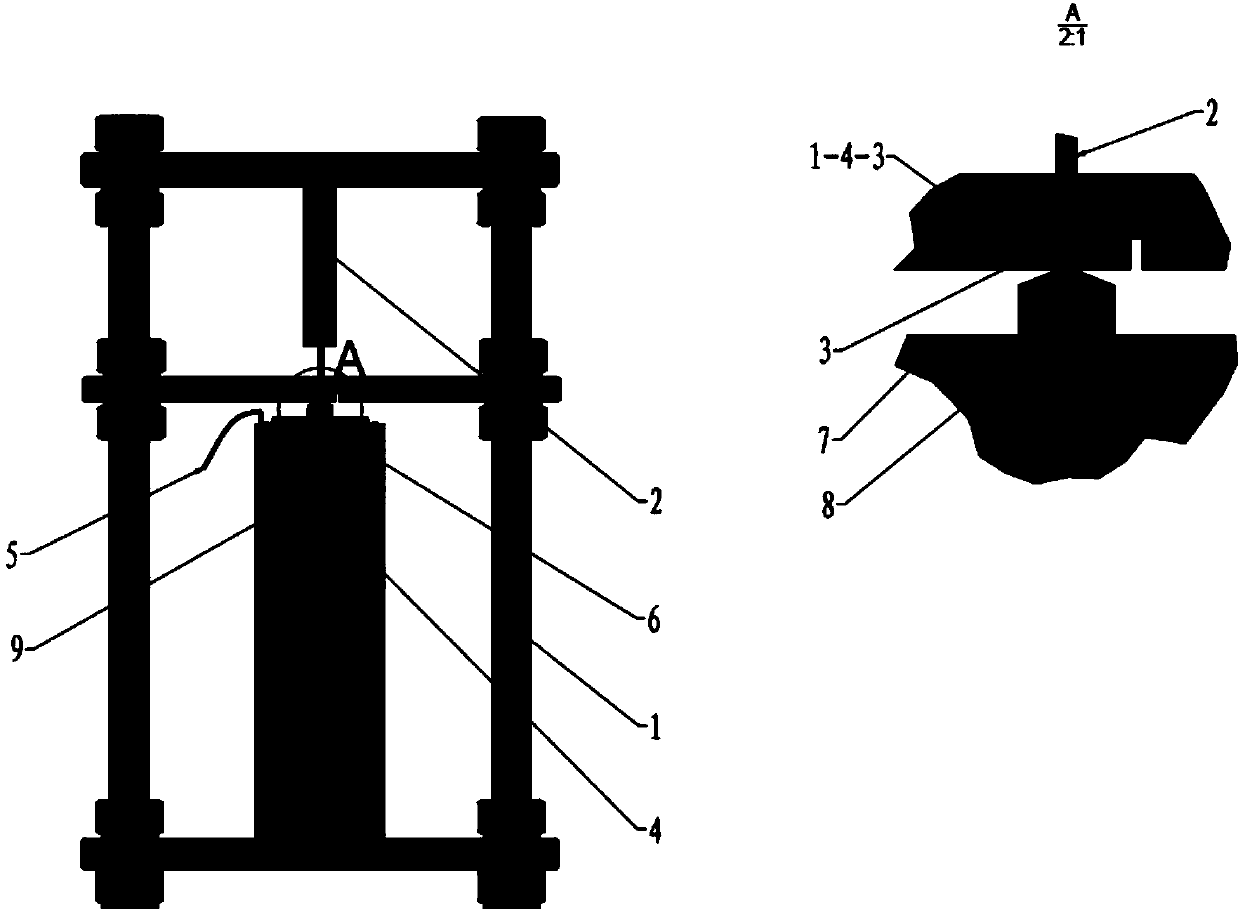

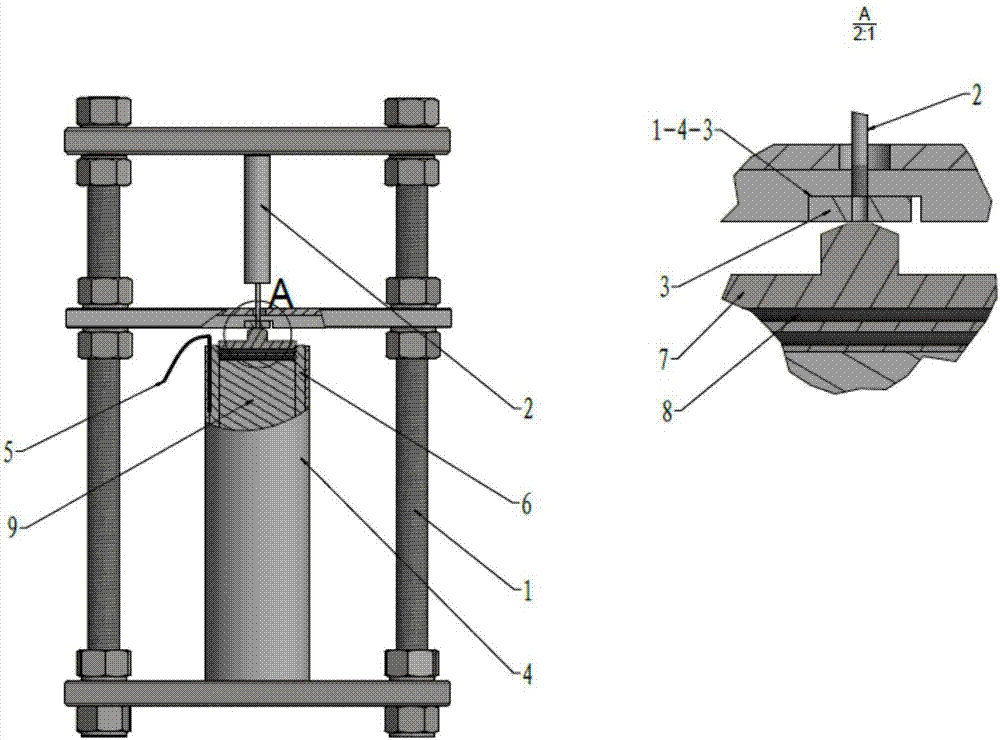

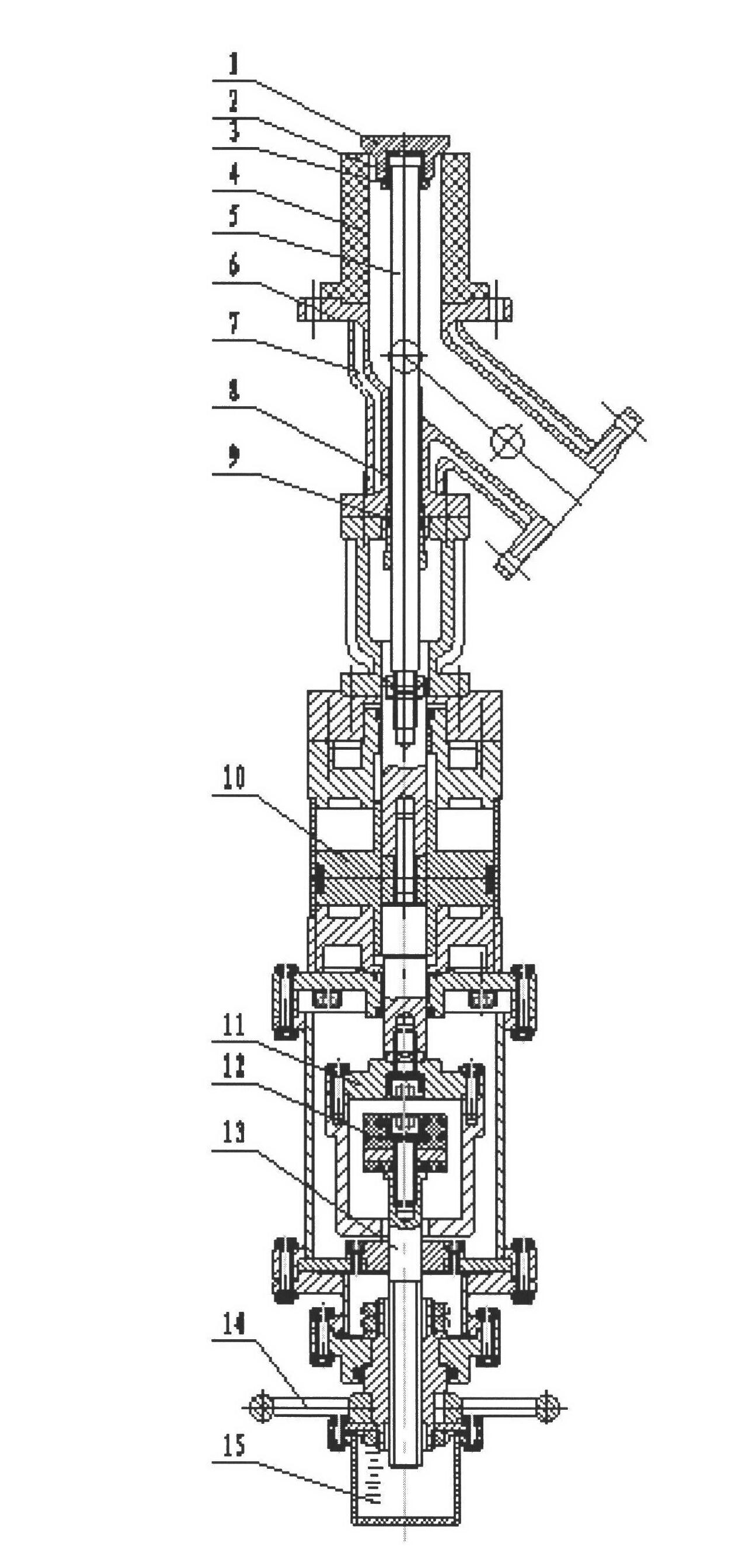

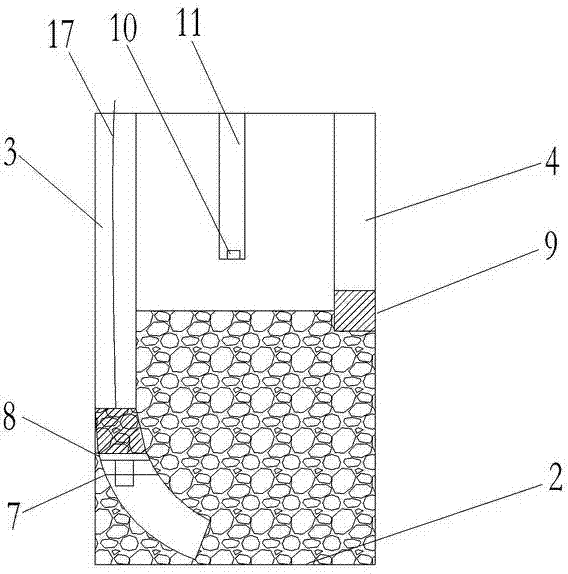

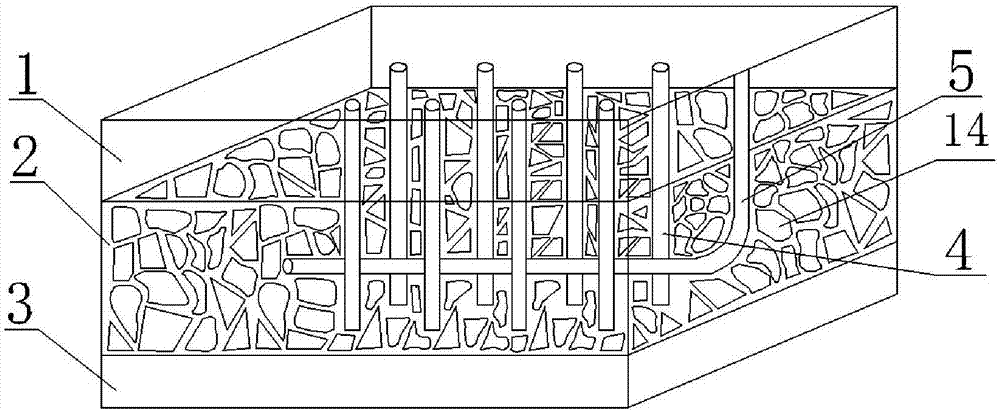

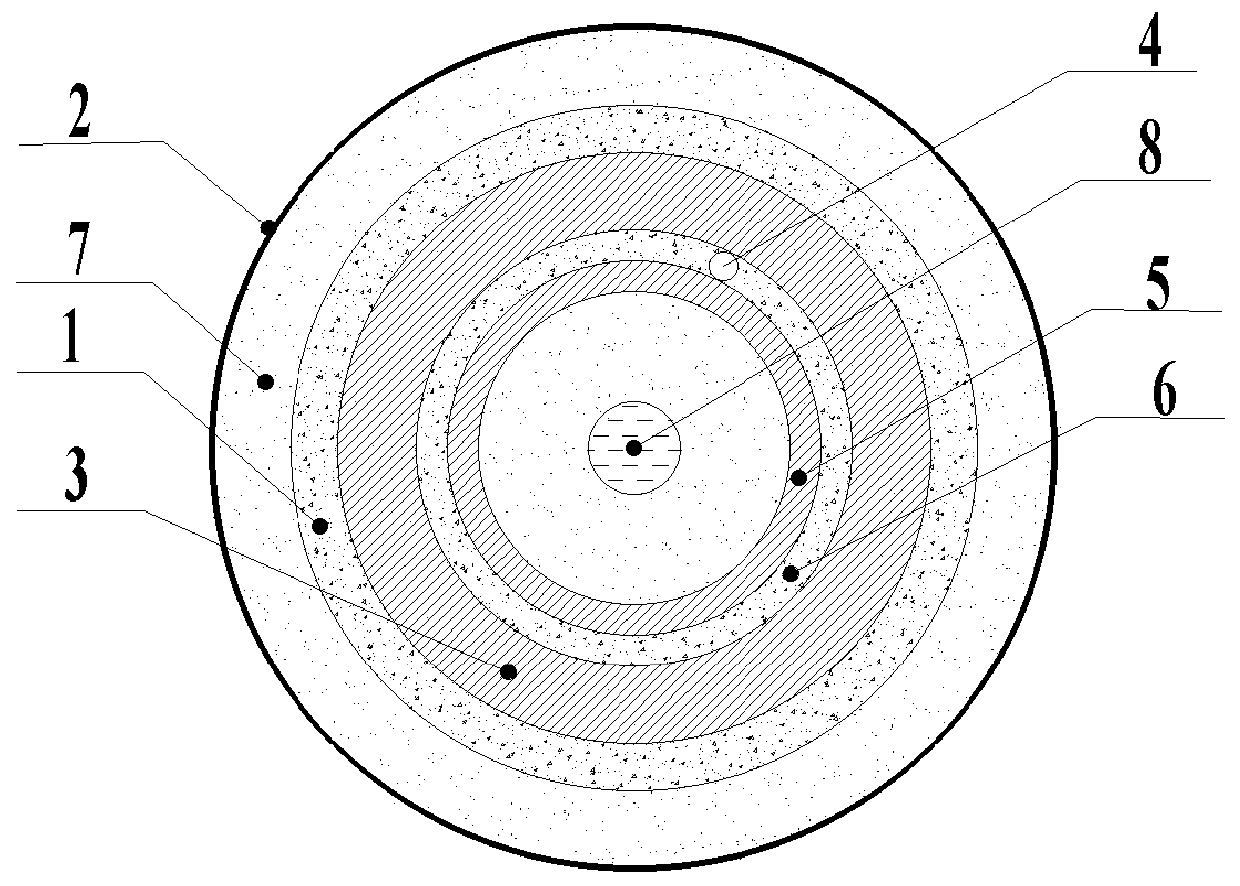

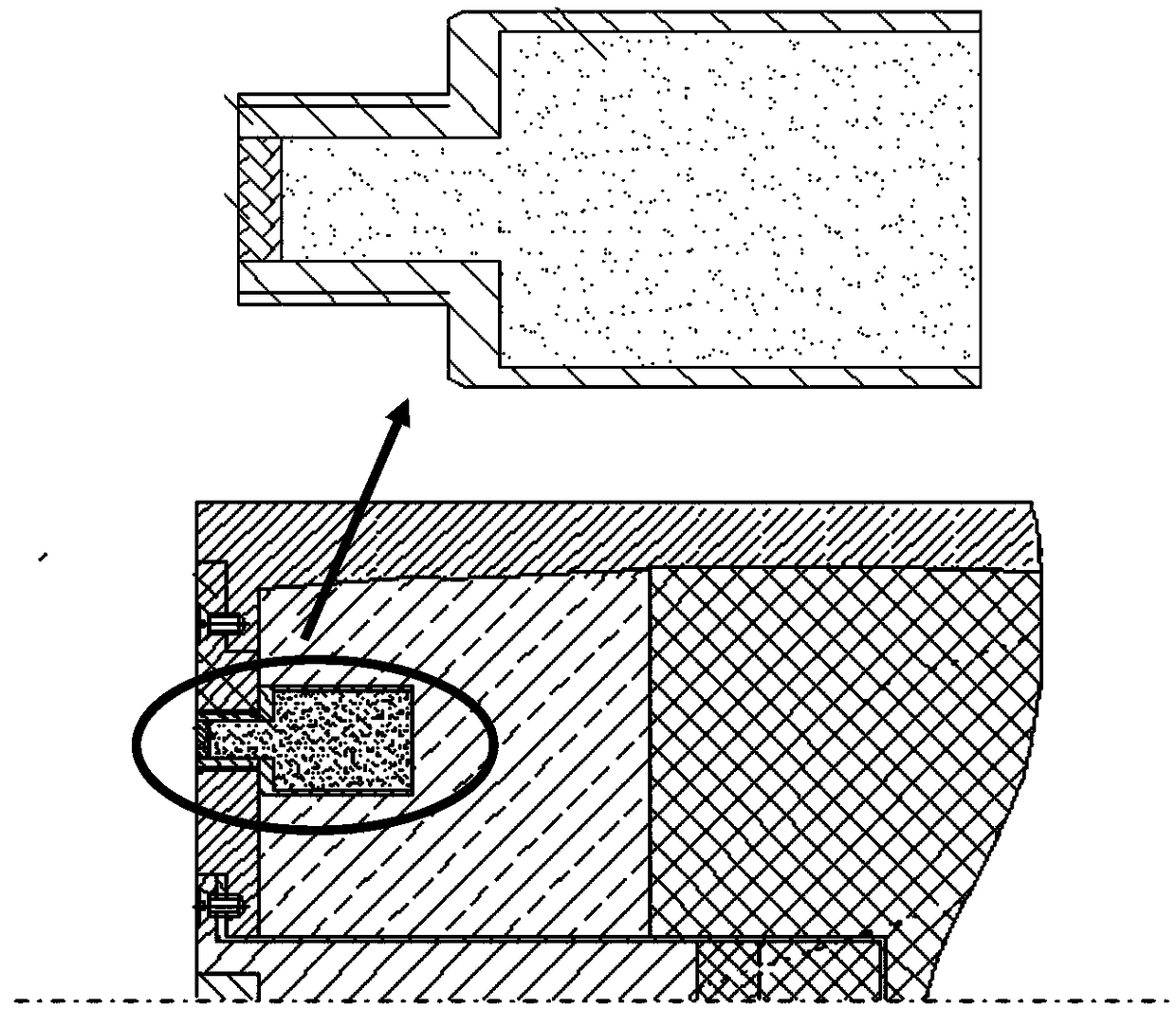

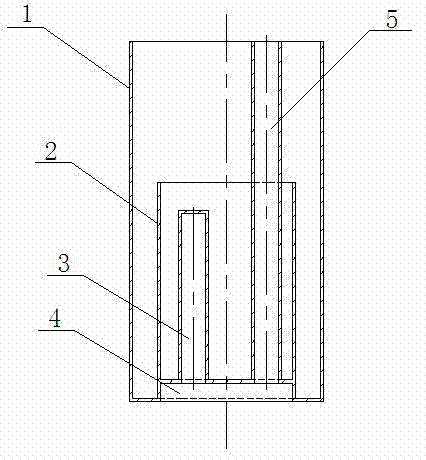

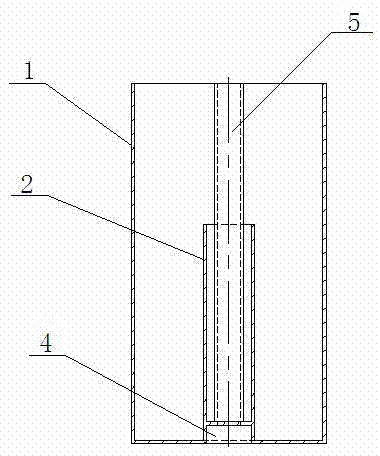

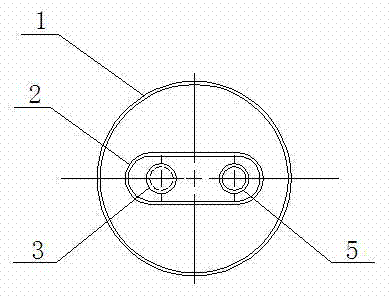

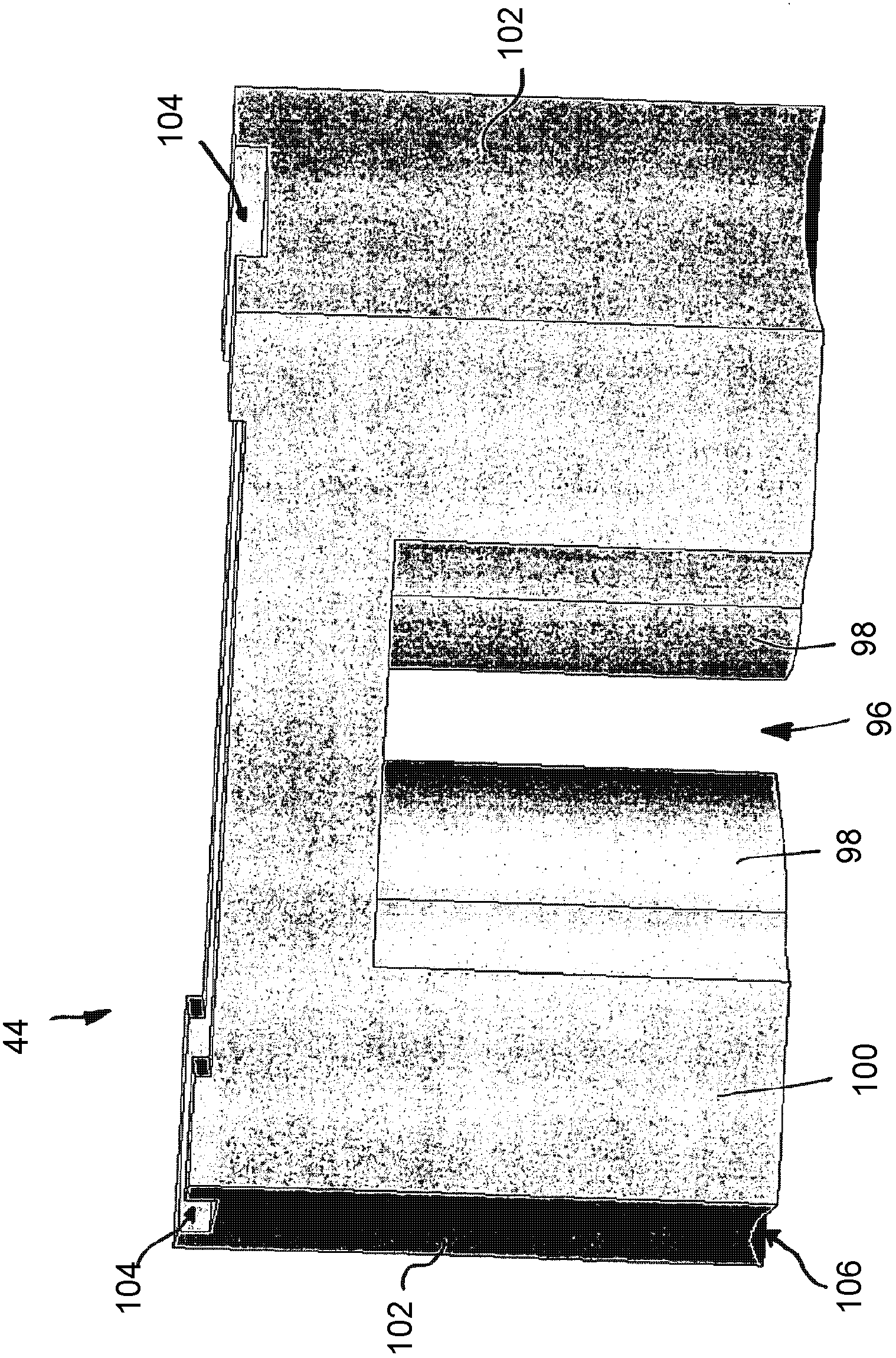

High-energy explosive expansion characteristic parameter measuring device

ActiveCN107655933AAccurate acquisitionEfficient acquisitionMaterial thermal coefficient of expansionComplete dataHigh energy

The invention discloses a high-energy explosive expansion characteristic parameter measuring device. A problem that the thermal expansion characteristic parameter of solid explosive charge cannot be measured by existing test devices is solved. The basic principle of the measuring device is characterized in that explosive charge is heated to a certain temperature by using a heating sleeve, the temperature of the explosive is measured in real time by using a thermocouple, the pressure generated by the heating expansion of the explosive charge is measured by using spring steel having a known deformation coefficient, a displacement sensor positioned above the spring steel is pushed through the deformation of the spring steel to obtain displacement data, and a three-dimensional relational graphamong the temperature, the expansion force and the expansion size of the explosive charge is established. The high-energy explosive expansion characteristic parameter measuring device has the advantages of strong versatility, high accuracy and low cost, can simultaneously meet requirements of the expansion parameter measurement of liquid explosives, slurry explosives and all-solid explosives, andprovides complete data support for the design of middle-large ammunition charge.

Owner:XIAN MODERN CHEM RES INST

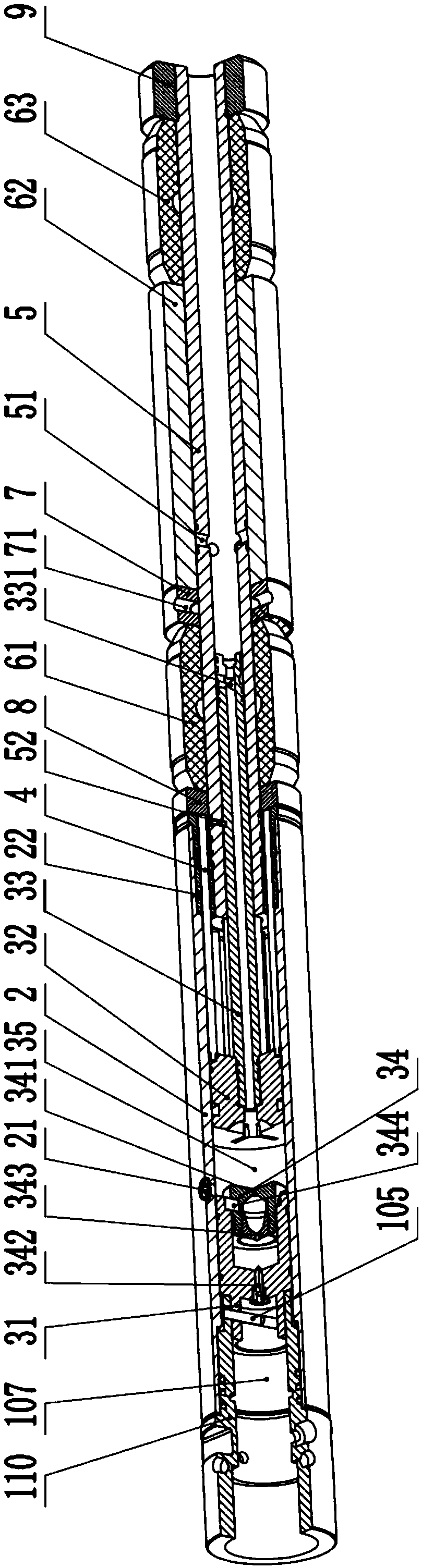

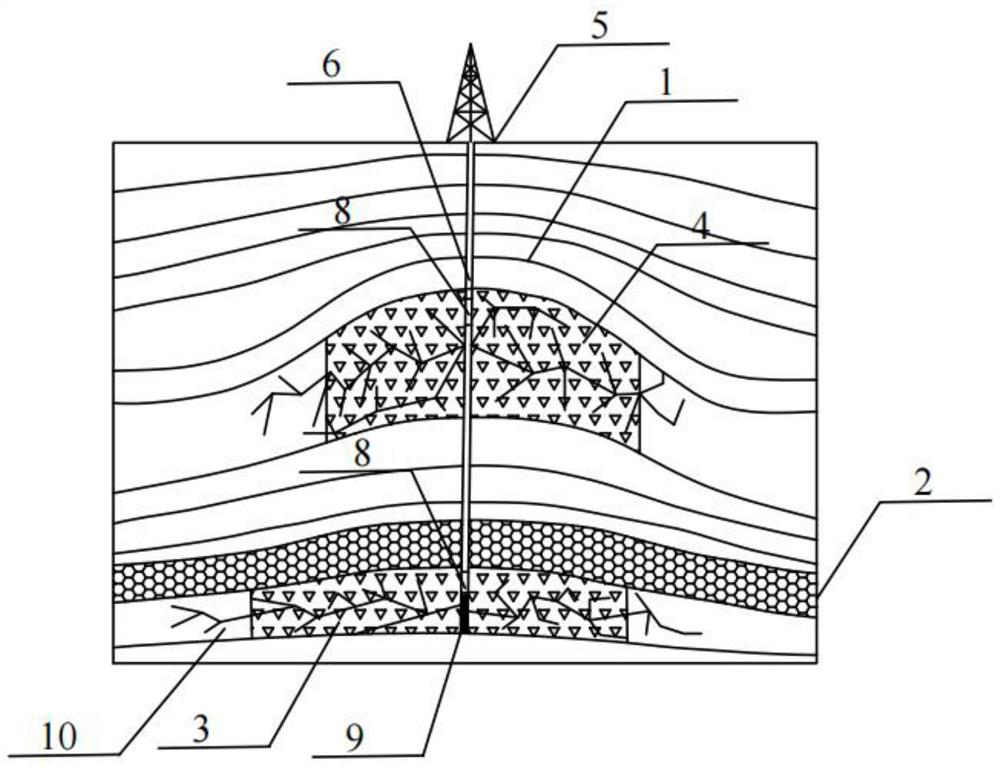

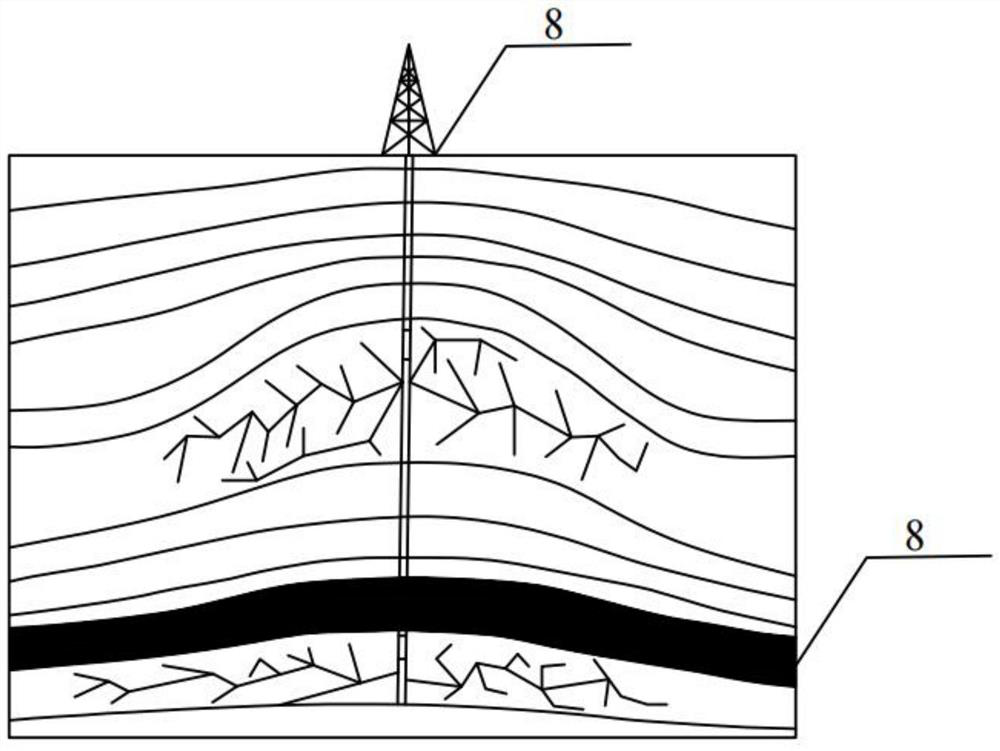

Environmental protection type under-well formation fracturing device

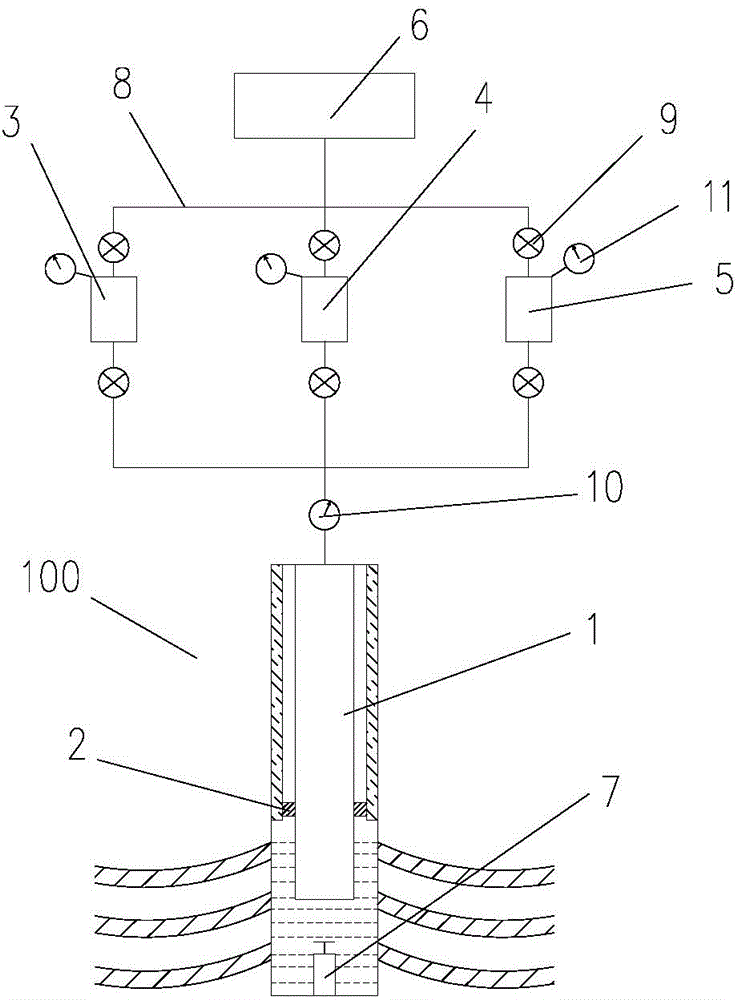

The invention relates to an environmental protection type under-well formation fracturing device, belonging to the technical field of permeability improvement fracturing for horizontal wells, inclined shafts and vertical wells. The device comprises a wellhead plugging device, an under-well tugger, in-well packers, a high-pressure hose, an in-well armored cable, a high-strength cable, an operating control mechanism and a sensor assembly. The under-well tugger is operated through the operating control mechanism to drag the two in-well packers to a set position and form a set under-well fracturing formation space, then the high-pressure hose is controlled to respectively pour spacer fluid, a liquid explosive and a primary explosive into an under-well space to be fractured according to the proportion of formula, and the in-well cable is controlled for electronic ignition to carry out the high-energy high-pressure gas fracturing formation operation; through such manipulation, repetitive or non-repetitive formation fracturing operation in different formation spaces and under different formation conditions is realized. The efficient, economic and environmental-protection formation fracturing device is provided for coal bed gas / shale gas mining, the operation fracturing effect is good, fracture extension can form a wide range of fracture system, the permeability and the desorption rate of a reservoir can be increased, and the purpose of increasing production is achieved. The device is worthy of adoption and promotion.

Owner:ZHONGBEI UNIV

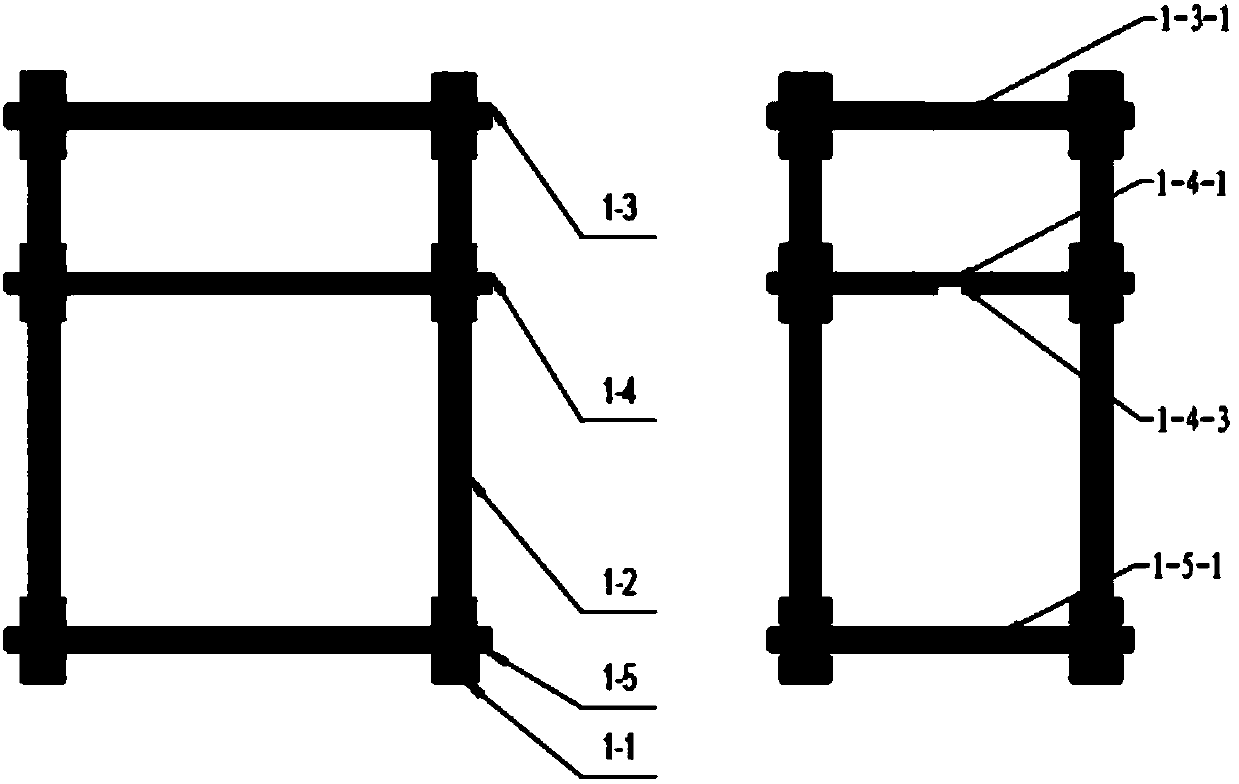

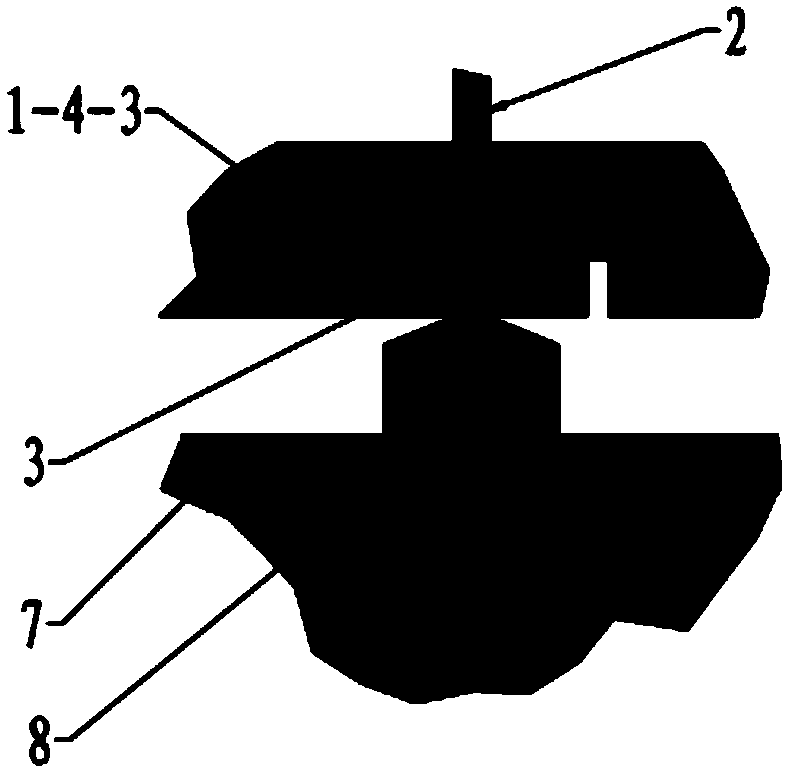

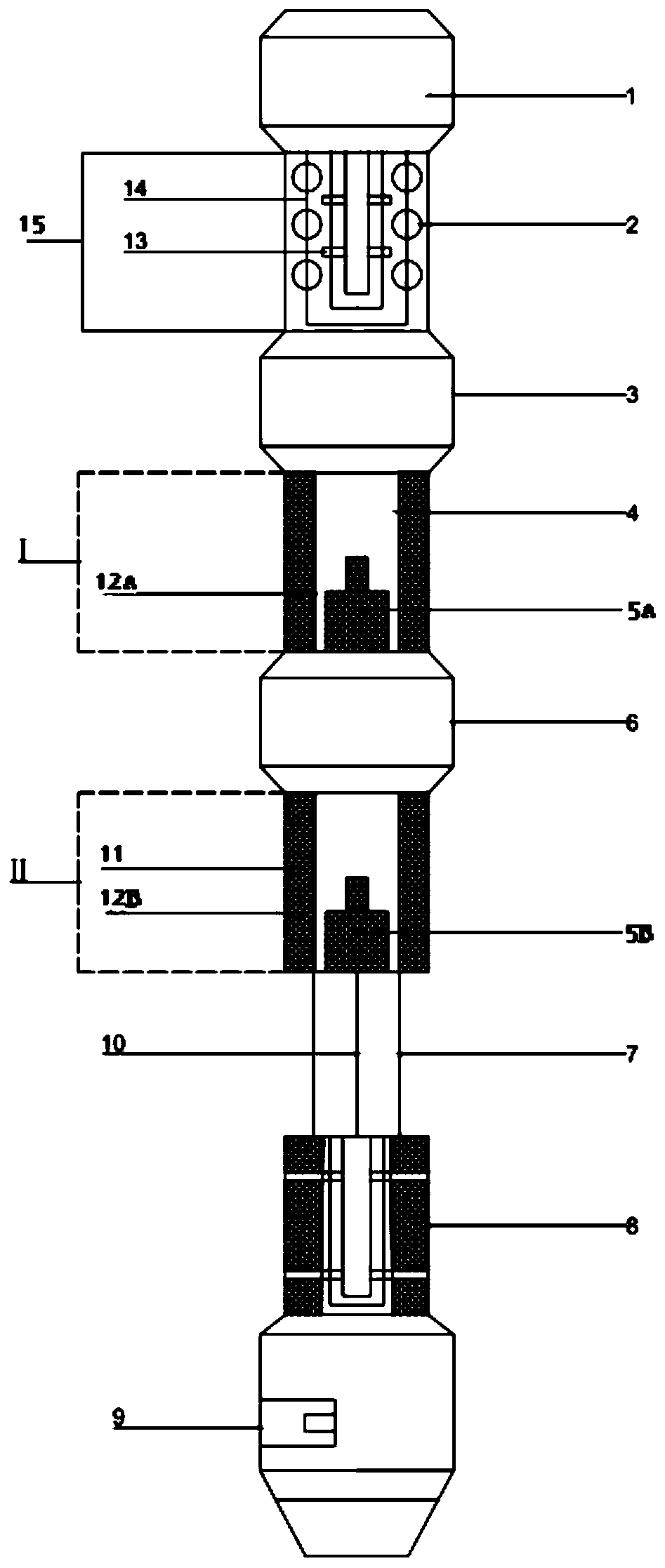

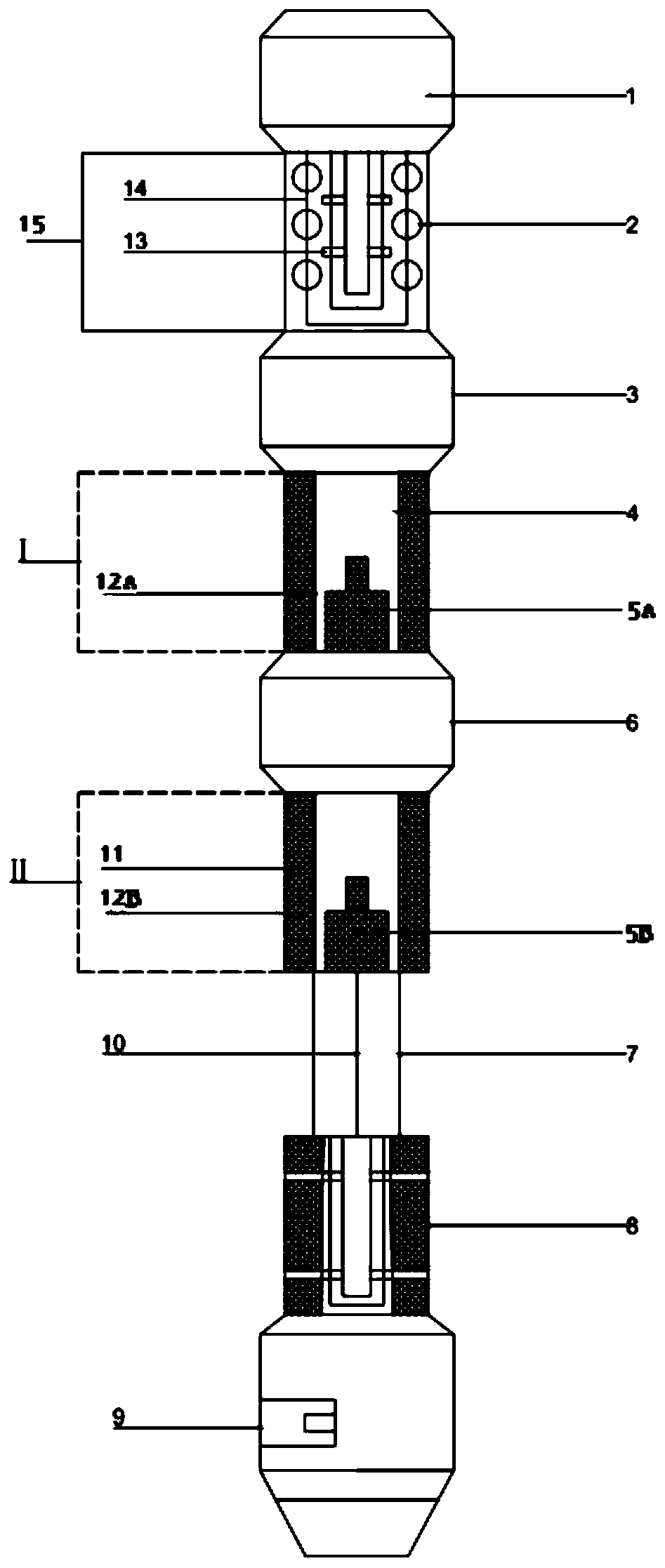

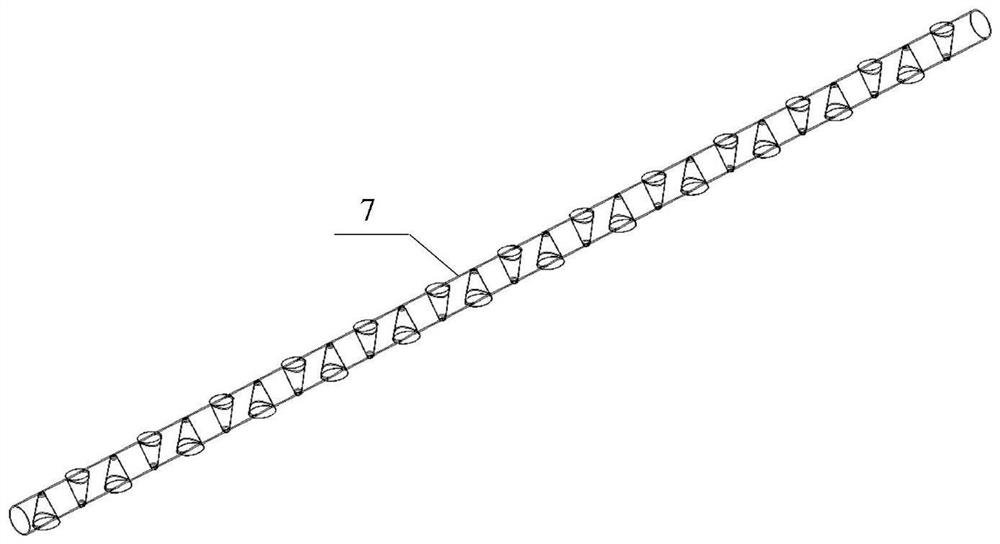

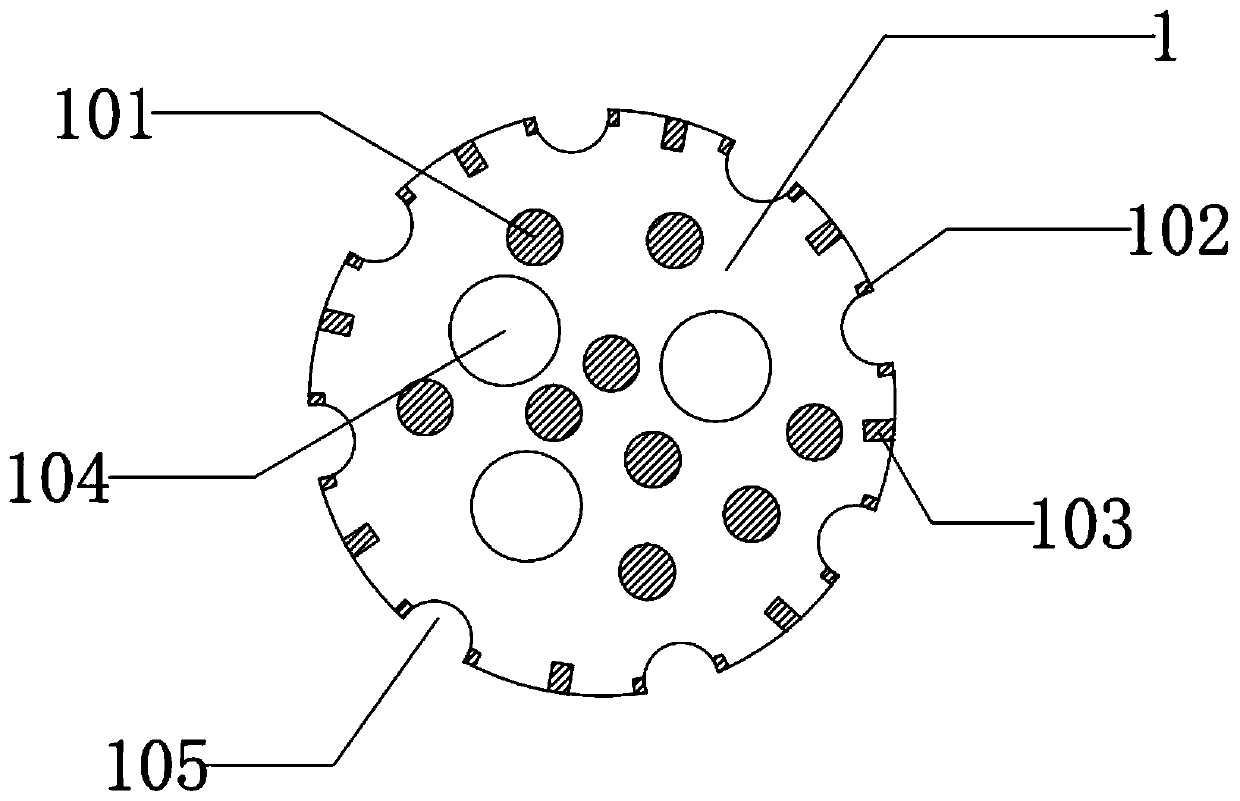

Multi-pulse combined fracturing device for perforation of coalbed methane reservoir

PendingCN109915080AOrderly and rapid extensionAchieve security isolationFluid removalEngineeringDeflagration

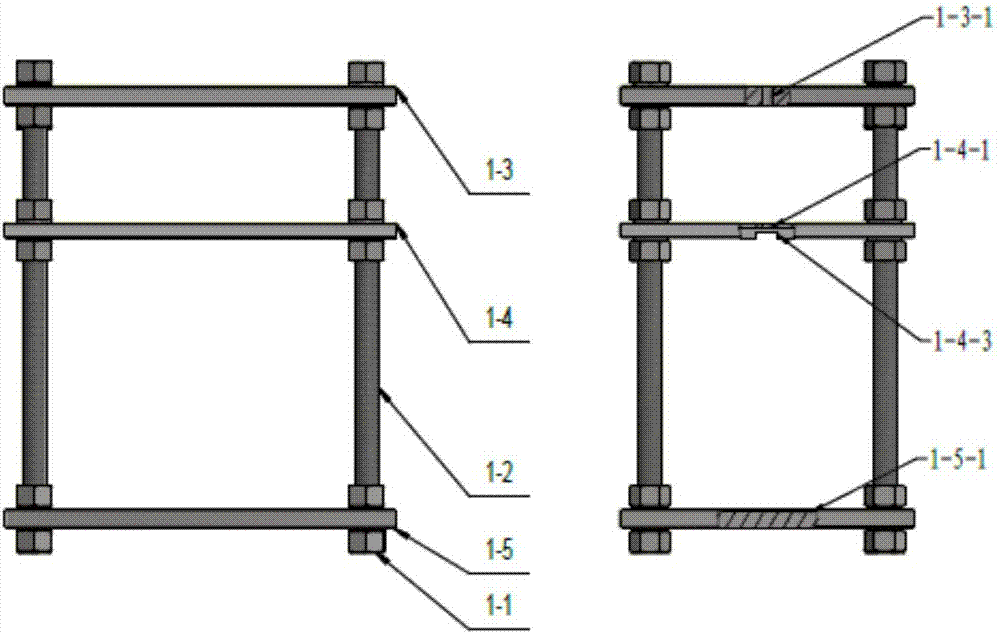

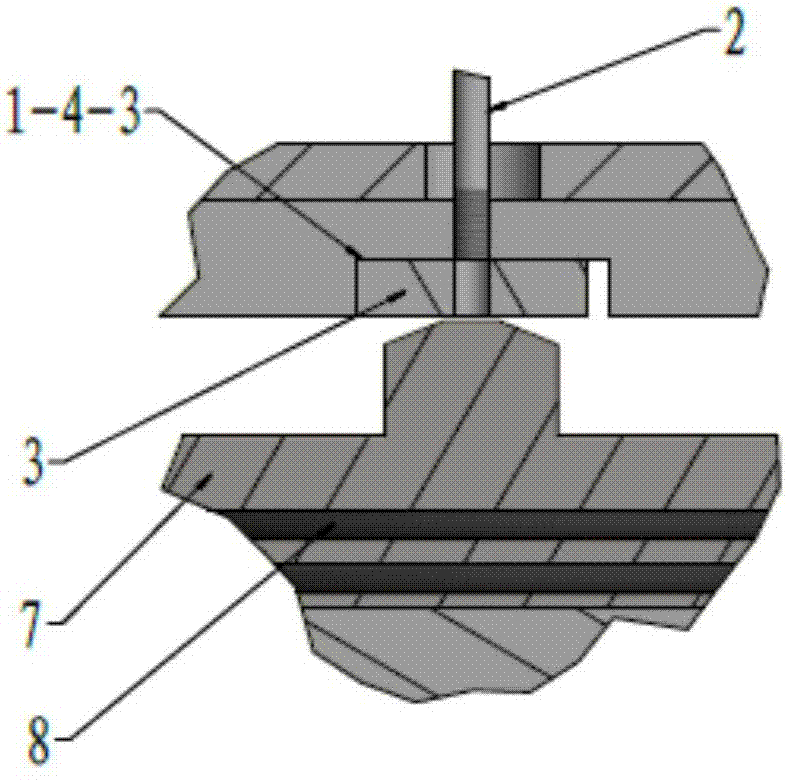

The invention relates to a multi-pulse combined fracturing device for perforation of coalbed methane reservoir, comprising a percussion initiator; the lower part of the percussion initiator is connected with a perforating barrel; the perforating barrel is internally provided with a frame type ammunition rack, and perforating bullets are loaded on the frame type ammunition rack; the perforating bullets are isolated from low-explosive-velocity liquid explosive by means of capsules, so that the low-explosive-velocity liquid explosive can be safely detonated; the lower part of the composite perforator is connected with a detonation convertor, the lower part of the detonation convertor is connected with a first-stage propulsion device, a central aluminum pipe is positioned in the center of thefirst-stage propulsion device, the lower part of the central aluminum pipe is connected with a delay ignition device, and the lower part of the delay ignition device is connected with a second-stage propulsion device; when the temperature of the outer wall of the central aluminum pipe reaches the ignition point of a propellant, a great deal of high-temperature and high-pressure gas produced by thepropellant acts on the coalbeds in a pulse loading way, thus enabling cracks to rapidly extend; the lower part of the second-stage propulsion device is connected with a connecting rod, a detonating cord is arranged in the connecting rod, the lower part of the connecting rod is connected with a perforator, and the perforator is connected with a pressure measurement tail plug, so that the deflagration pressure change of gunpowder in a fracturing process is reflected; the multi-pulse combined fracturing device has the advantages of treating the multiple coalbeds at a time, and being high in energy utilization rate and cost-saving.

Owner:XI'AN PETROLEUM UNIVERSITY

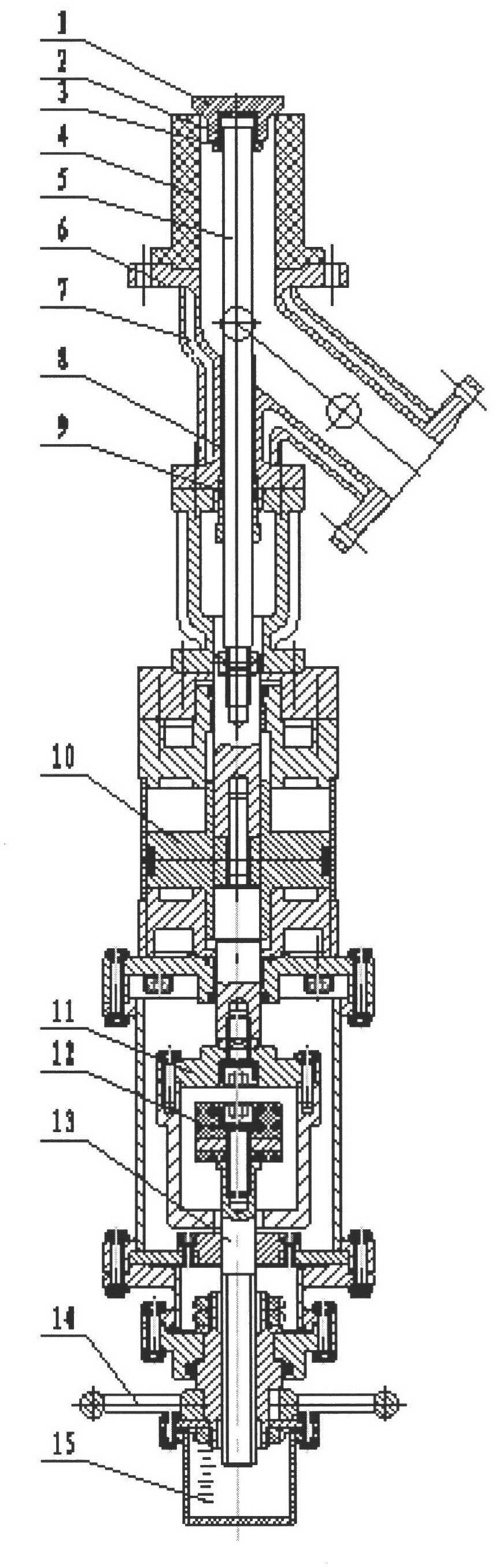

High-energy dynamite charging thermal expansivity measuring device and method

ActiveCN107389725AAccurate acquisitionEfficient acquisitionMaterial thermal coefficient of expansionAll solid stateDynamite

The invention discloses a high-energy dynamite charging thermal expansivity measuring device and method. The problem that an existing test device fails to measure solid state dynamite charging thermal expansion characteristic parameters is solved. According to the basic principle of the device and method, a heating jacket is used for heating dynamite charging to a certain temperature, a thermocouple is used for measuring a dynamite temperature in real time, spring steel with a known deformation coefficient is used for measuring pressure generated when the dynamite charging is heated and expanded, meanwhile, deformation of the spring steel is used for pushing a displacement sensor located above to obtain displacement data, and thus, a three-dimensional relational graph of the temperature, the expansibility and the expansion size of the dynamite charging is established. The device and method provided by the invention have the advantages of high universality, high accuracy and low cost, the requirements for measuring expansion parameters of liquid explosives, slurry explosives and all-solid-state explosives can be met simultaneously, and a more comprehensive data support is provided for middle-large sized ammunition charging designs.

Owner:XIAN MODERN CHEM RES INST

Intrastratal explosive fracturing ignition ball and fracturing construction method

The invention discloses an intrastratal explosive fracturing ignition ball and a fracturing construction method; the method is applied after hydrofracture is finished; the ignition ball is added between a liquid gunpowder slug and a liquid explosive slug; all liquid explosive enters the inner side of a hydraulic fracture through a perforation tunnel; the diameter of the ignition ball is slightly bigger than that of the perforation tunnel, so the ignition ball is clamped in the perforation tunnel; pressure is built in a shaft; under internal and external differential pressure mechanical force effect, solid gunpowder in the ignition ball starts to ignite, thus further igniting the liquid gunpowder; liquid explosives in the fracture can be continuously detonated under the liquid gunpowder combustion heat effect, thus completing the intrastratal explosive fracturing process. The method needs no other detonation tool in the well, and liquid explosives can be timely ignited and detonated after fully entering the hydraulic fracture, thus preventing shaft internal explosive residual in a detonation process, and maximumly reducing shaft damages in the blast process.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method and device for explosive fracturing of sidetracking well

The invention relates to a method and a device for explosive fracturing of a sidetracking well. The method for explosive fracturing of sidetracking wells includes: step 1: running a pipe string into the wellbore, so that the lower end of the pipe string extends into the reservoir; The spacer isolates the reservoir; step 3: pump liquid explosives through the pipe string, so that the liquid explosives enter the sidetracked well; step 4: pressurize the liquid explosives in the pipe string to the upper interface of the reservoir; step 5: pass the pipe string The column is lowered into the detonator and detonated at regular intervals. By adopting the method, the permeability of the reservoir can be improved, the effective oil and gas recovery radius and the effusion area of the oil and gas well can be expanded, and the purpose of increasing the output of the oil and gas well can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Automated liquid explosive discharging device

InactiveCN102305298AWith hot water heat preservation functionWith heat preservation functionValve members for heating/coolingLift valveEngineeringFlange

The invention provides a liquid explosive discharging device technology, which can realize automatic safety discharge of liquid explosive as well as manual emergency discharge and flow control in case of emergency power-off. In the invention, a valve body is of a sandwich structure, two ends of the sandwich structure are provided with a water inlet and a water outlet, high-temperature hot water is introduced into the sandwich structure so as to realize heat preservation function and prevent the liquid explosive from being solidified; a valve core is movably and hermetically connected with a valve rod so that reliable sealing property can be still kept in the event that the valve rod and the valve body are not concentric; the valve core and the valve body are sealed by a Teflon sleeve flange so as to ensure sealing reliability; and meanwhile the valve rod and the valve body are sealed by using Teflon packing, and the sliding part between the stainless steel valve rod and the valve body is isolated by a Teflon sleeve, which effectively prevents metal friction during the movement process of the valve rod, avoids sparks and shock and prevents explosion.

Owner:中国兵器工业集团第五五研究所

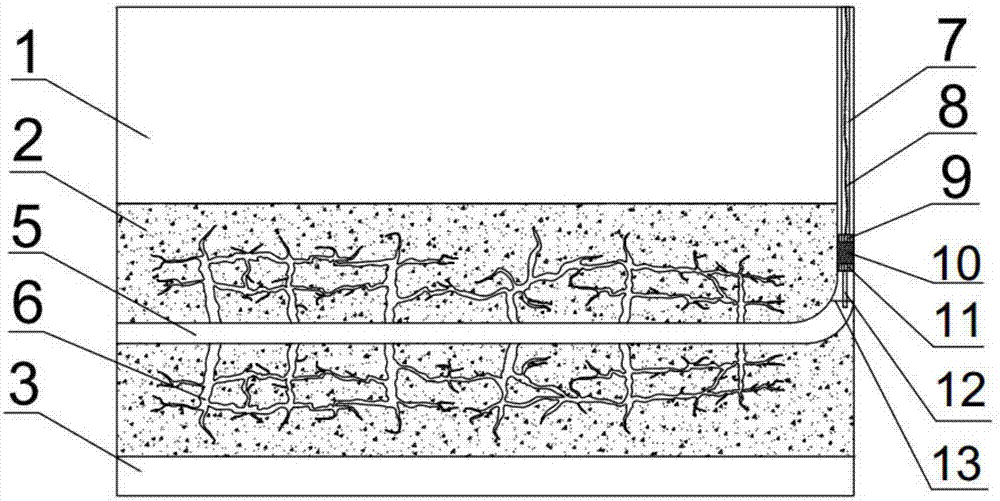

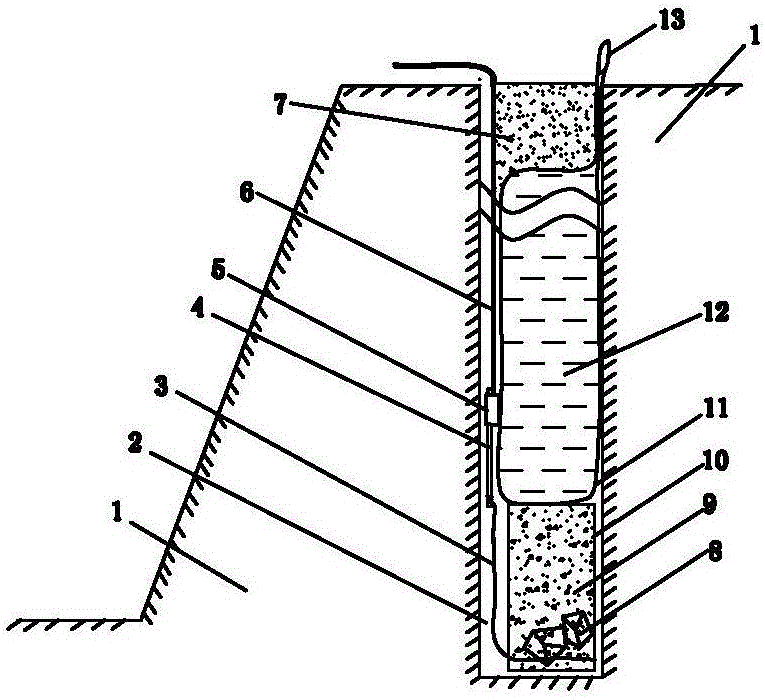

Method for artificial building of hot dry rock heat storage layer

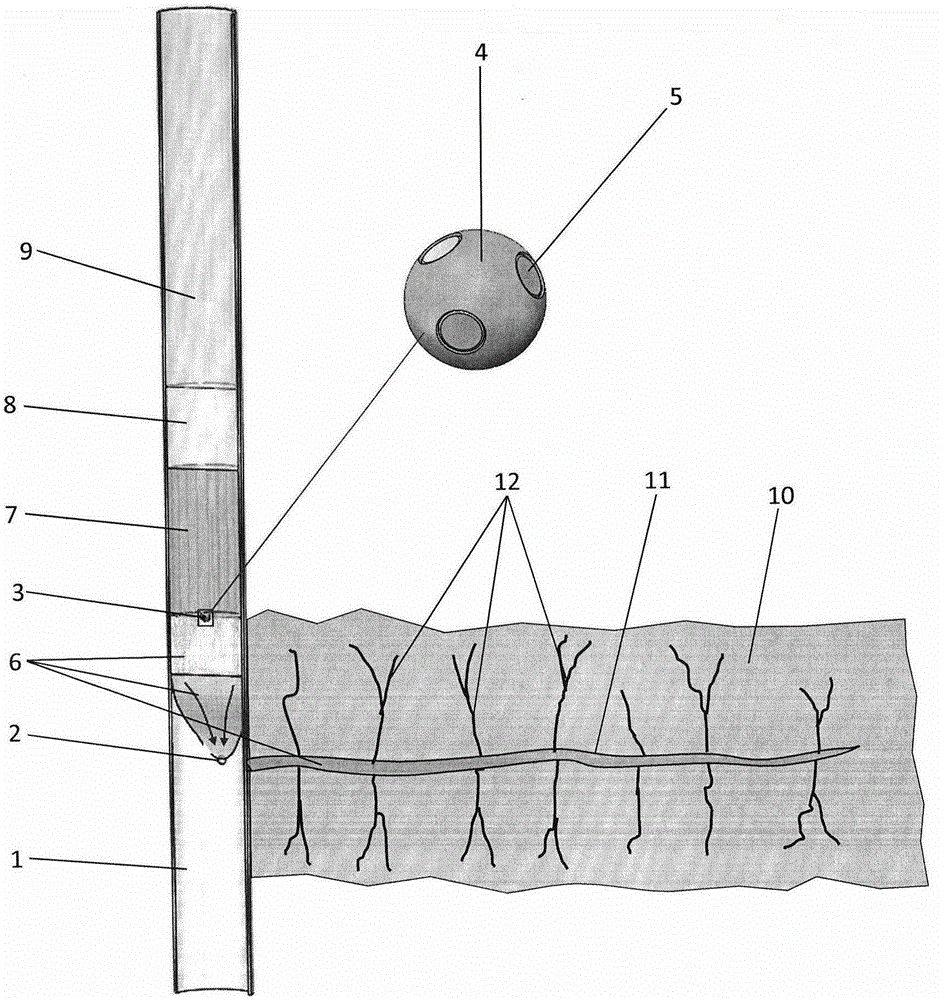

The invention discloses a method for artificial building of a hot dry rock heat storage layer. Heat storage layer joint forming is conducted through the layered segment blasting joint forming mode. A plurality of cavities with certain widths are formed in a horizontal well segment at equal intervals through a high-pressure pulse jet flow drill tool, liquid explosives are injected into a horizontal well, and then an electromagnetic initiator is put down from an injection well. Then rock powder is backfilled to a production well and the injection well correspondingly, and the well hole sealing effect is achieved. Meanwhile, a microseismic monitoring device is put down from a monitoring well to monitor the blasting joint forming effect. After blasting is implemented, when cracks are sufficiently developed, blasting operation can be implemented again. When artificial crack swarms meet the design requirements, blasting operation can be stopped. According to the method for artificial building of the hot dry rock heat storage layer, the joint forming quality can be improved, the large-size artificial crack swarms are formed, meanwhile large hydraulic fracturing is not needed, increasing of the utilization rate of a hot dry rock layer is facilitated, and conditions are provided for achievement of commercial use of hot dry rocks.

Owner:JILIN UNIV

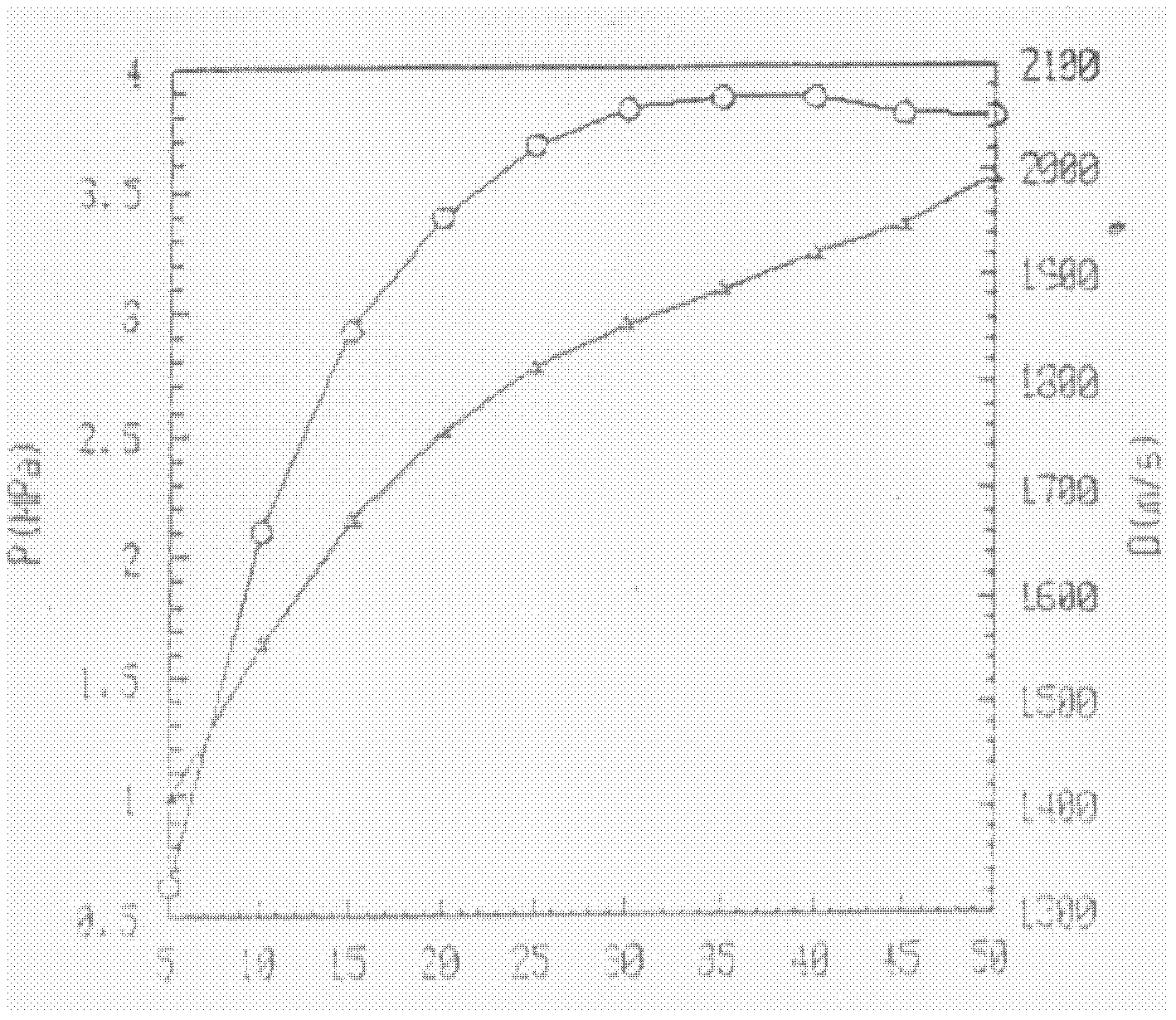

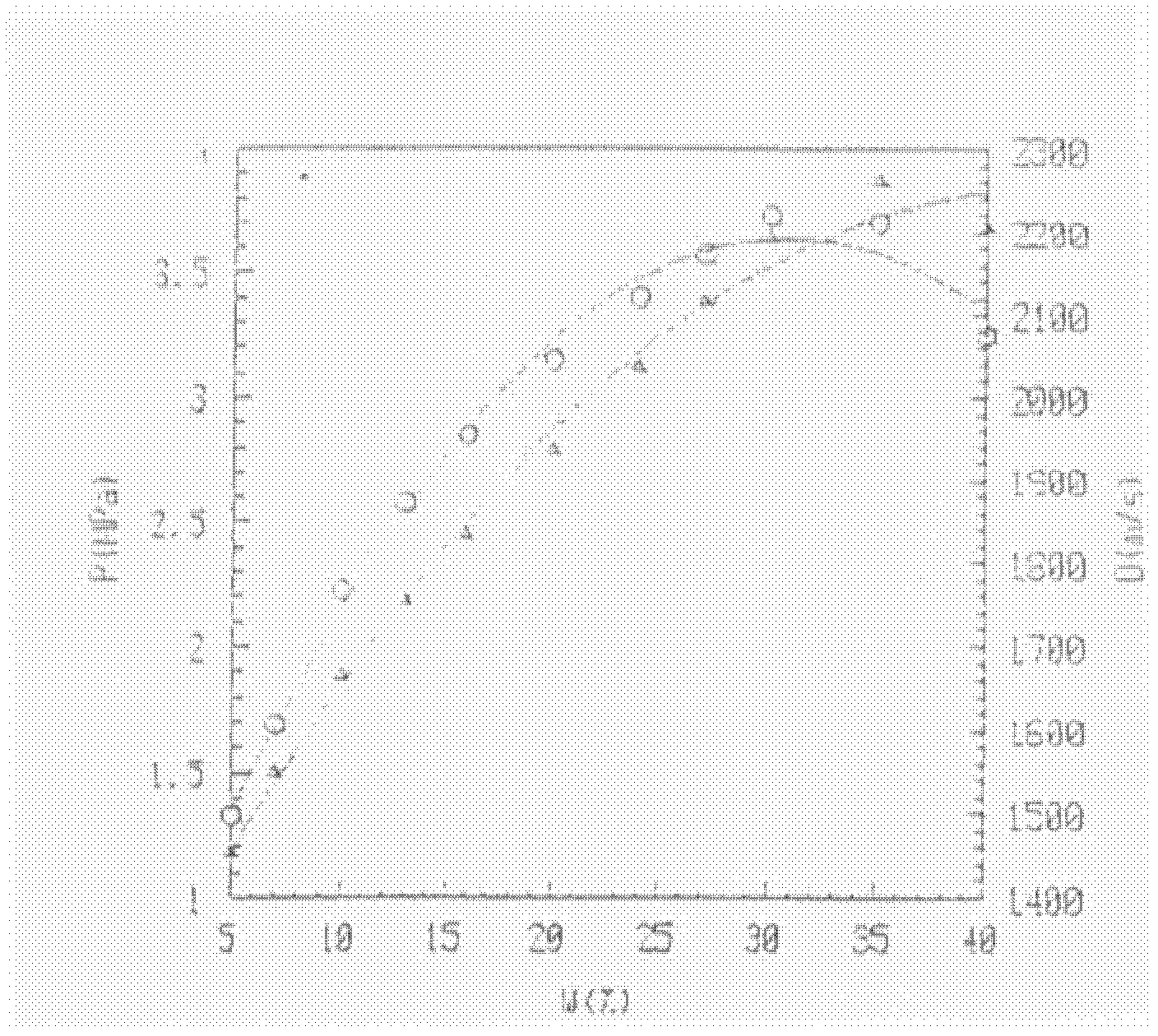

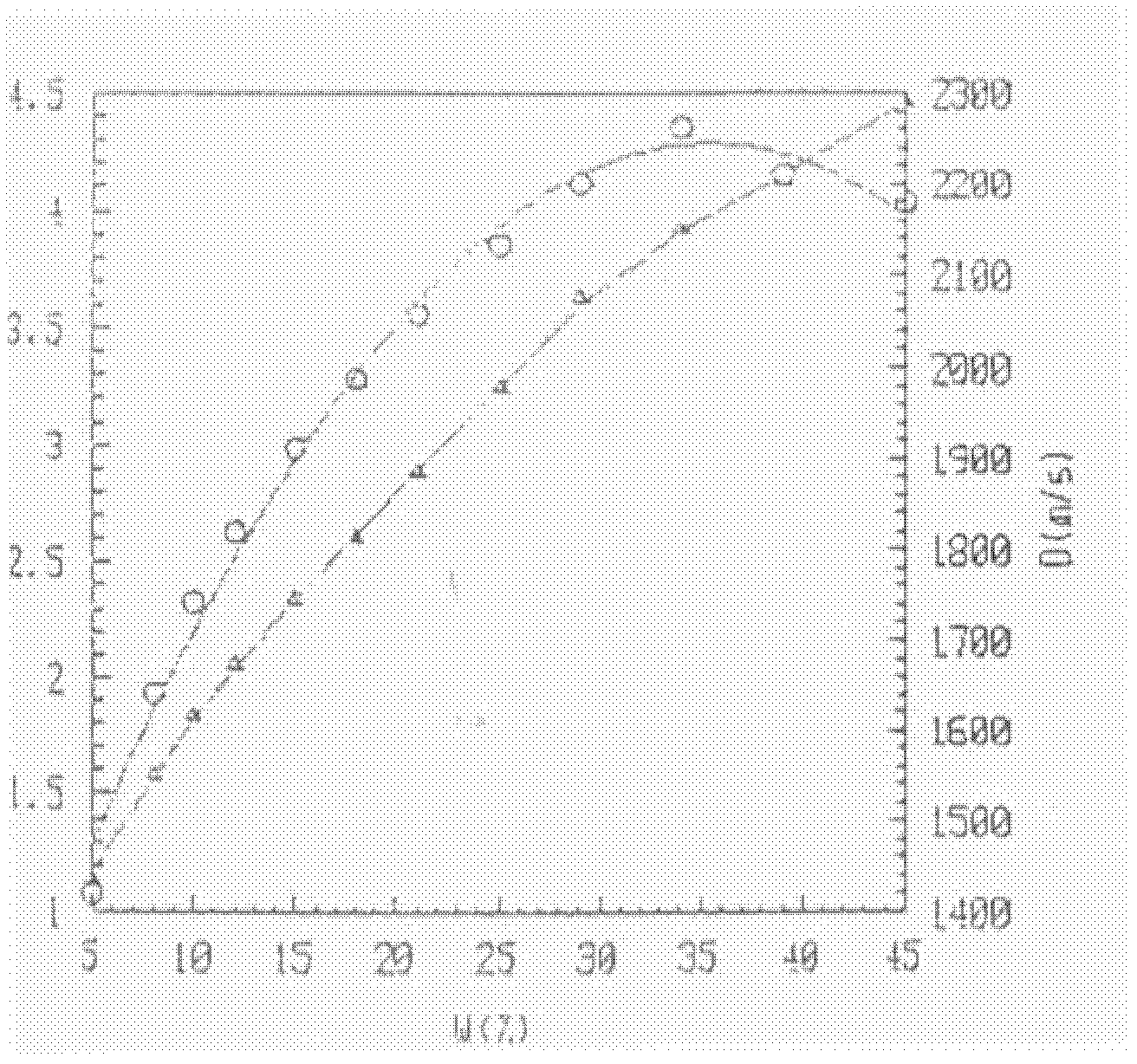

Method for determining detonation parameters of liquid explosive

The invention relates to detonation parameters of liquid explosive and provides a method for calculating CJ detonation pressure, detonation speed, detonation temperature and specific volume of the liquid explosive through a thermodynamic function of compounds and a minimal free energy method, and the invention belongs to the technical field of energetic materials. A VLW program is created on the basis of a BKW program and is used for calculating such function relations of the liquid explosive as CJ detonation pressure, detonation speed, detonation temperature, specific volume and the like through the thermodynamic function of compounds by utilizing the minimal free energy method.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

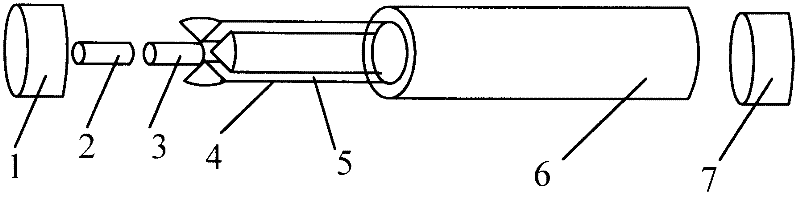

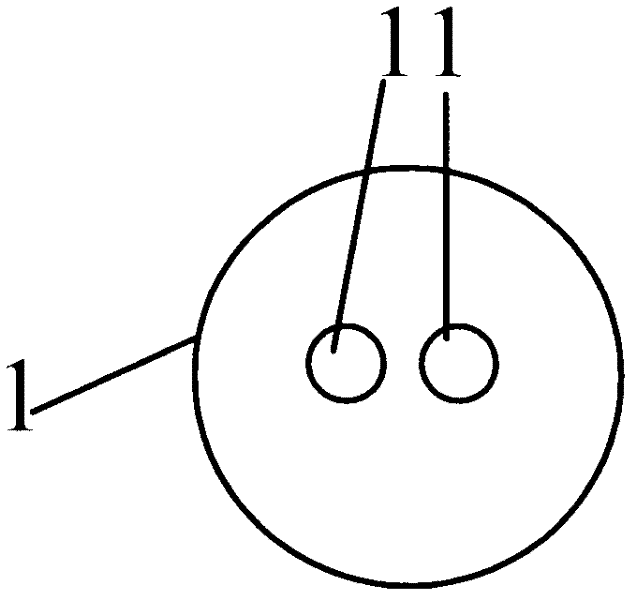

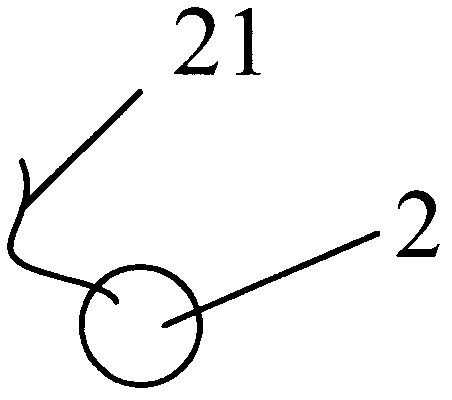

Micro-fracture explosion propagation device for interlayer explosion laboratory study

The invention discloses a micro-fracture explosion propagation device for interlayer explosion laboratory study. The device comprises first bakelite, a detonator, an explosion propagation explosive, an aluminum inner core, an aluminum inner core groove, a bakelite pipe body and second bakelite, wherein the detonator is fixed on the first bakelite; the first bakelite is adhered at one end of the bakelite pipe body; the aluminum inner core is provided with a central hole; the explosion propagation explosive is filled in the central hole of the aluminum inner core; the aluminum inner core groove is formed on the aluminum inner core; the aluminum inner core is sleeved in the bakelite pipe body; and the second bakelite is adhered at the other end of the bakelite pipe body. The device is convenient to use, has a smaller volume, saves materials and can be used for accurately measuring explosion propagation data of a suspension explosive and a liquid explosive in an underground micro-fracture in the process of imitating underground perforation fracturing operation and interlayer explosion and indirectly measuring pressure and temperature variation numerical values from a wellhead to an operation layer.

Owner:XI'AN PETROLEUM UNIVERSITY +1

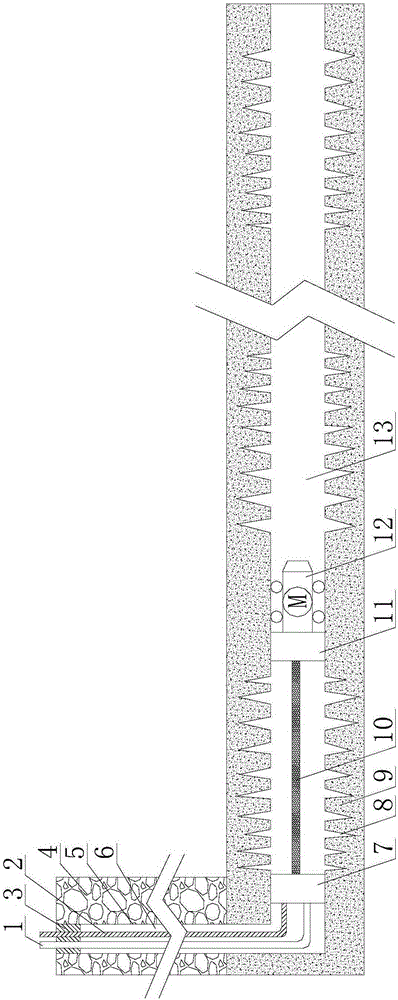

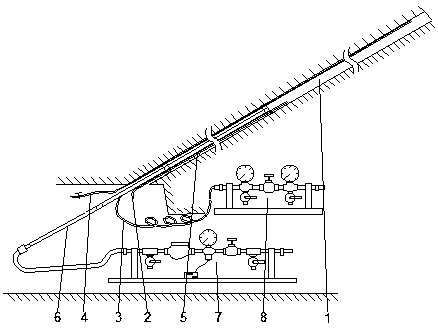

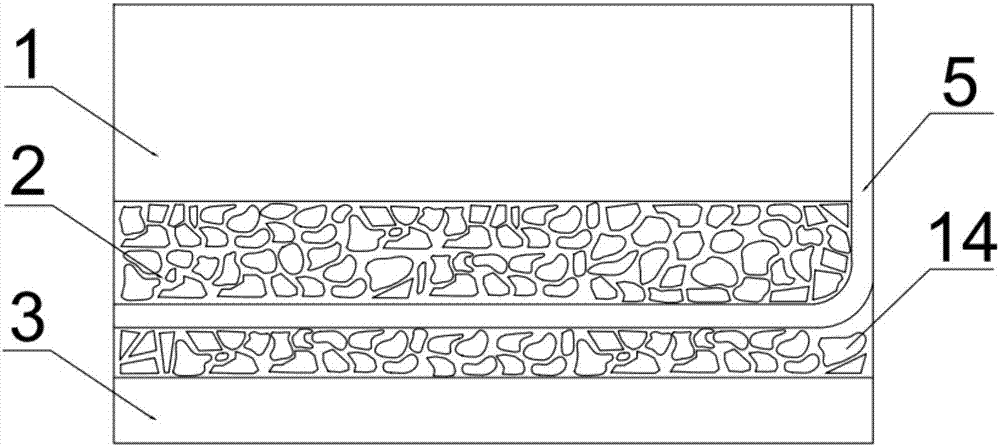

Coal-rock blasting pre-splitting method and device based on packing blasting of liquid explosive in long hole

The invention discloses a coal-rock blasting pre-splitting method based on packing blasting of liquid explosive in a long hole, comprising: drilling a long hole in coal-rock mass, preliminarily addinga detonating instrument in the long hole, packing the long hole with a packer having liquid injection and exhausting functions, pumping the liquid explosive into the long hole by means of hydraulic pumping after packing slurry congeals, closing an exhaust pipe stop valve when a continuous flow of the liquid explosive occurs to an orifice exhausting pipe, stopping a liquid explosive pump from pumping, closing a liquid injection pipe orifice stop valve, removing a liquid injection pump delivery pipe from a liquid injection pipe orifice, and connecting wires to allow detonating. Compared with common solid explosives in a long hole, the method has the advantages that the detonating critical dimeter of the liquid explosive is small, delivering is performed conveniently via pumping, explosive charging is not affected by borehole collapse, failure detonation can be avoided, engineering blasting vibrations are slight, static rock breaking is provided under blasting super dynamic load, and themethod is widely applicable to pre-splitting, anti-reflection, pressure relief, impact resistance and other conditions of coal rock.

Owner:CHINA UNIV OF MINING & TECH

Method for manually building oil shale underground broken bodies

ActiveCN107339091AImprove seam qualitySolve the problem of difficult accurate fracturing of deep buried thin oil shaleFluid removalPorosityHeat conducting

The invention provides a method for manually building oil shale underground broken bodies and relates to the technical field of oil shale underground in-situ transformation. The method comprises the following steps: drilling a horizontal well; after drilling the horizontal well, performing staged fracturing on the horizontal well by a hydraulic fracturing method; after fracturing, injecting a liquid explosive into the horizontal well, enabling the liquid explosive to enter a stratum fracture formed by staged fracturing, and further reinforcing the underground oil shale layer by using the energy generated by explosion to generate the broken body; enhancing the porosity and the permeability of the oil shale exploiting layer to form an underground in-situ transformation broken body; and drilling a plurality of vertical wells, wherein the oil shale layer between the horizontal well and the vertical wells generates sufficient heat transfer area at the moment. By the method, the cost is reduced, the rubblization of the oil shale layer can be improved, the effect is better as compared with that of the conventional fracturing method, the heat-conducting capability of the oil shale stratum can be improved obviously, development of an oil shale in-situ process is benefited, and conditions are provided for realizing commercial use of the oil shale.

Owner:JILIN UNIV

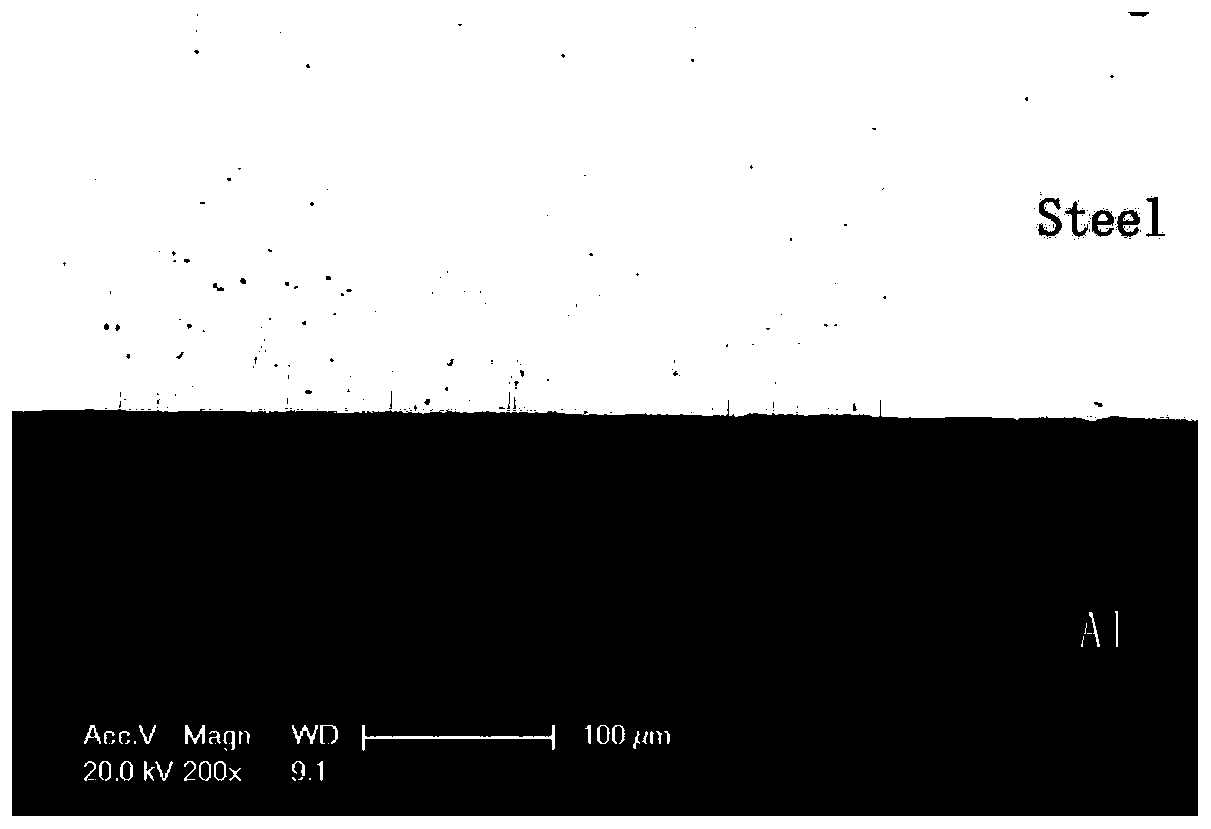

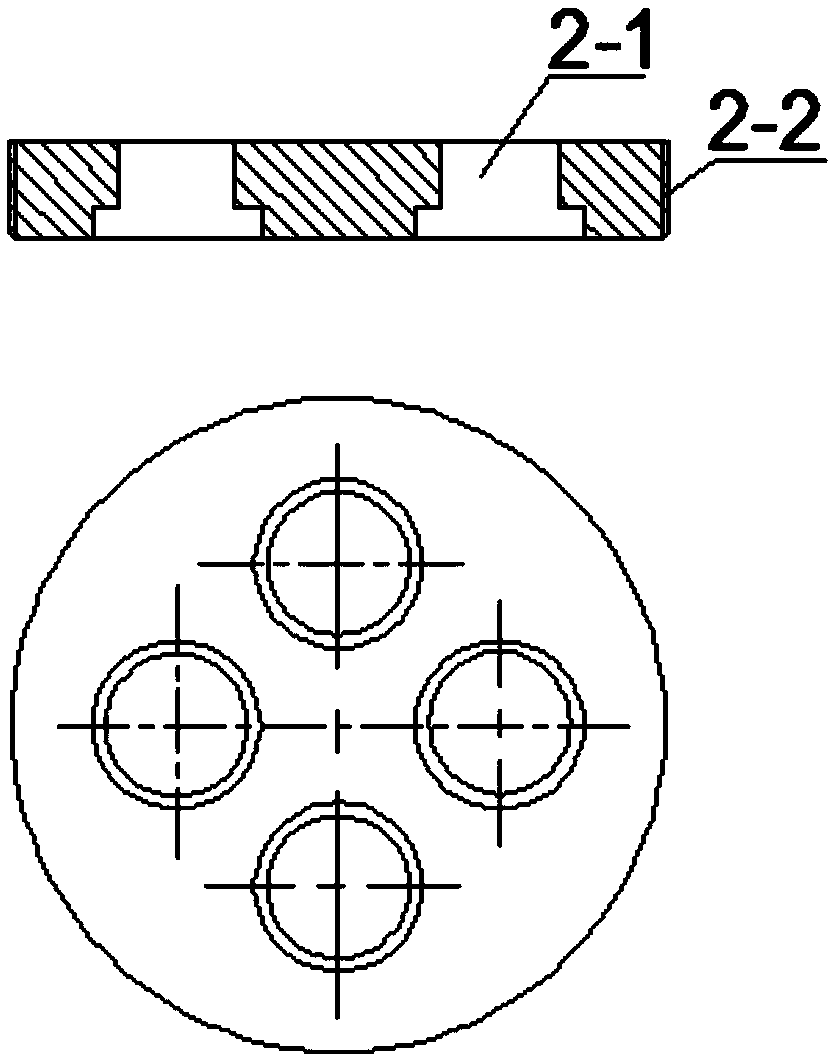

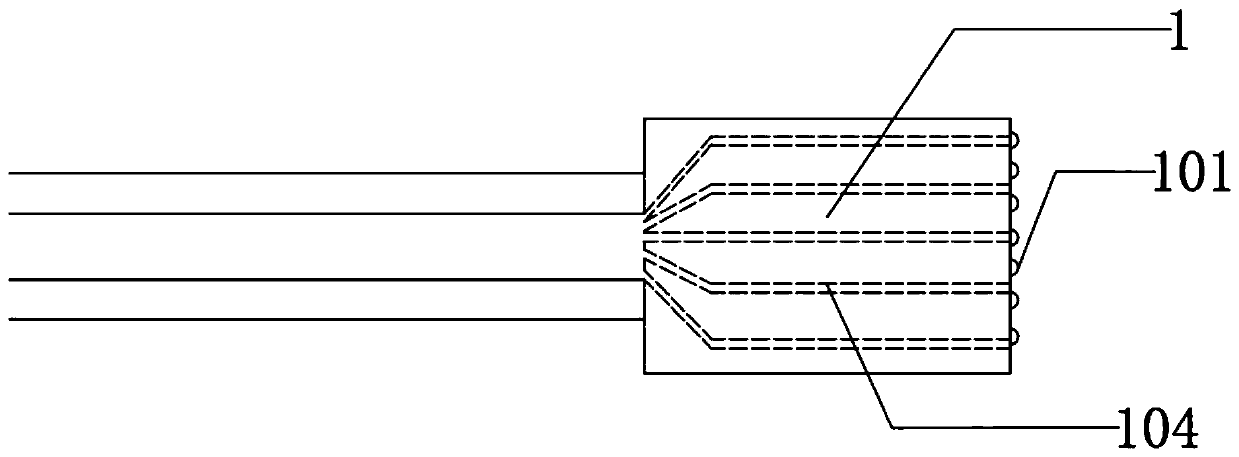

Manufacturing process of explosive composite pipe with negative pressure cavity based on liquid explosive

ActiveCN111085769AIncrease binding rateImprove welding qualityNon-electric welding apparatusTEX-explosivePipe

The invention provides a manufacturing process of an explosive composite pipe with a negative pressure cavity based on a liquid explosive. The manufacturing process comprises the following steps thata covering pipe and a base pipe are sequentially and coaxially mounted on a soft base from inside to outside, the explosive amount is calculated according to the specification of a to-be-composited pipe blank, and meanwhile an inner pipe dose adjusting water column is mounted; the upper end of an annular cylindrical gap between the covering pipe and the base pipe is sealed through a sealing ring,and an annular cylindrical cavity is sealed after being pumped into negative pressure through a vacuum pump; and the assembled to-be-composited pipe blank and a container are coaxially arranged, and then liquid explosive is injected, and the explosive is ignited so that a metal composite pipe can be obtained. According to the manufacturing process, the production efficiency can be greatly improved, explosive charging is uniform, the bonding rate of the composite pipe is high, the welding quality is good, and a constraint mold does not need to be applied in the welding process, so that the production cost can be greatly reduced; and meanwhile, the vacuum pump is adopted for pumping the cylindrical cavity into negative pressure, the influence of air on explosive welding is greatly reduced, the bonding quality of the composite pipe is improved, and the use amount of explosives can be reduced.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Devices and methods for detecting hazardous materials

InactiveUS8019466B2Digital data processing detailsSpecial data processing applicationsHazardous substanceProcess engineering

A container screening system that uses multiple orthogonal sensors for detecting hazardous materials, such as liquid explosives and precursors of liquid explosives, in sealed containers. The container screening system comprises a first sensor that detects materials inside the container using a first detection technology, a second sensor that detects materials insider the container using a second detection technology, and a data processing unit that processes data from the first and second sensors and generates a screen result. The system reduces false positives and increases probability of detection by matching the relative strengths and weaknesses of each technology.

Owner:NORTHROP GRUMMAN SYST CORP

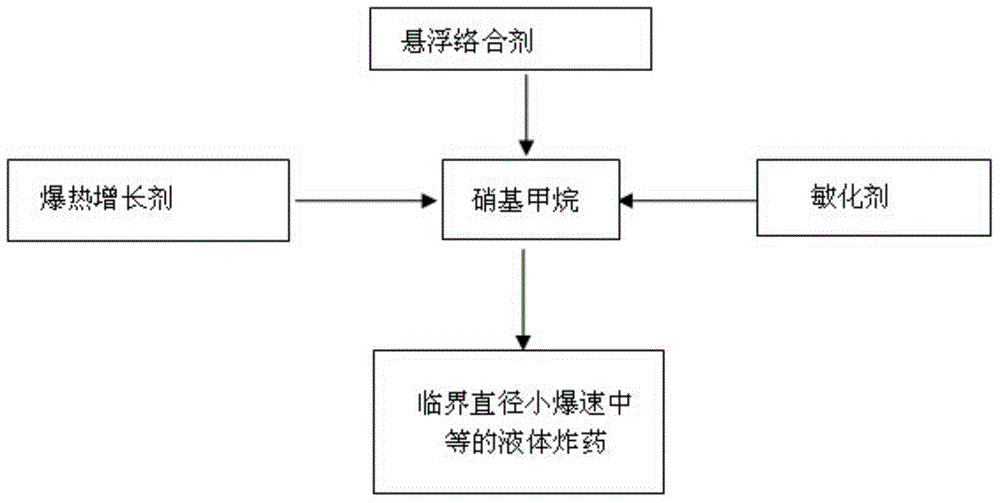

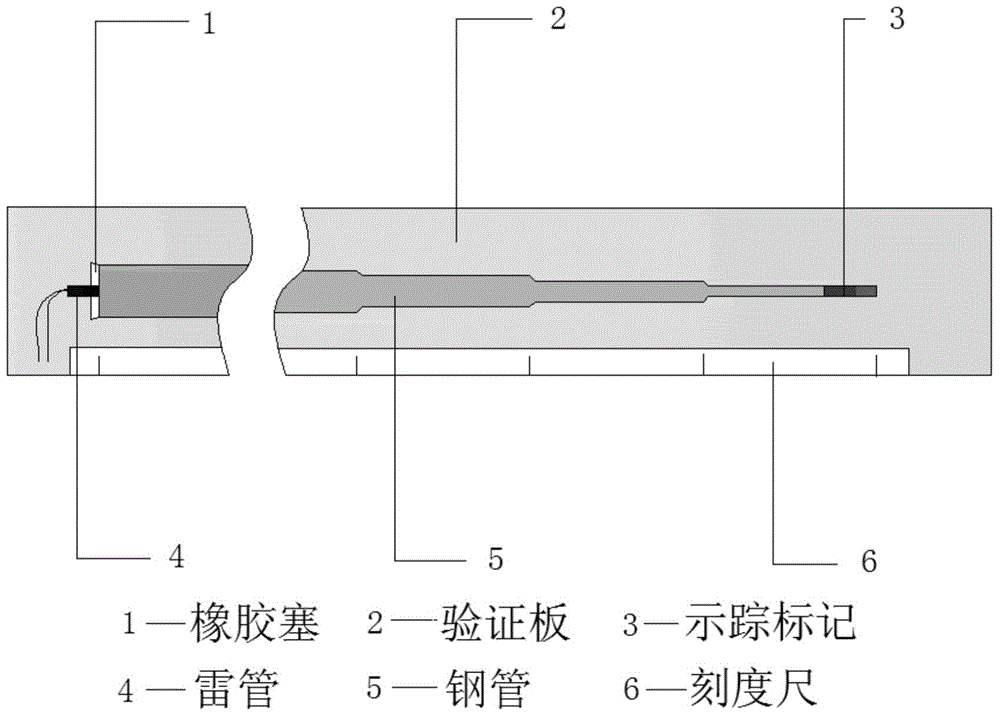

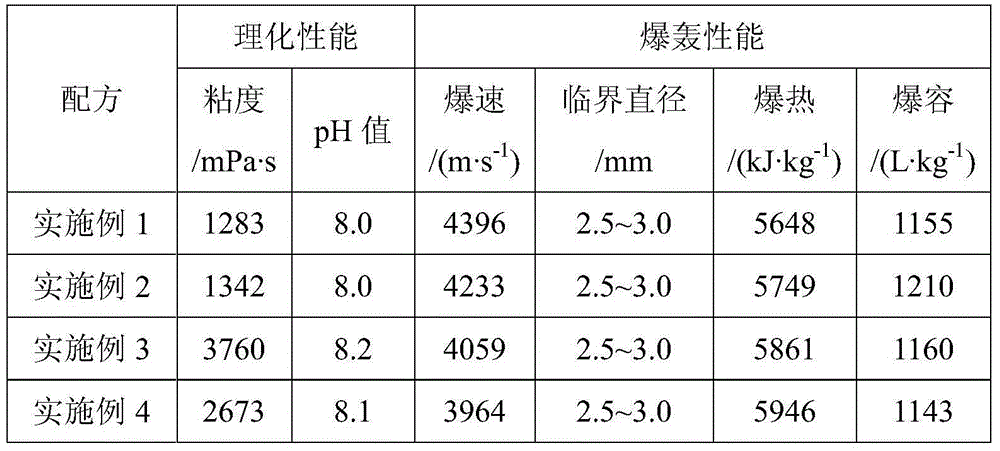

Liquid explosive with small critical diameter and medium detonation velocity and preparation technology thereof

InactiveCN105712808ALow detonation velocityReduce critical diameterNitroparaffin explosive compositionsNitromethaneBuffering agent

The invention discloses a liquid explosive with a small critical diameter and medium detonation velocity and a preparation technology thereof. The liquid explosive is composed of the following components in percentage by weight: 60 to 90% of nitromethane, 3 to 10% of sensitizing agent, 5 to 20% of performance buffering agent, and 2 to 10% of complexing agent. The liquid explosive has the following characteristics: (1) the mechanical sensitiveness is low, and the operation is safe; (2) the detonation is reliable, the critical diameter is small, and the energy is proper; (3) the fluidity is good, and thus the liquid explosive is suitable for long distance pumping; (4) the whole system is in a weak alkali state and is non-corrosive to metals; (5) the preparation method is simple, the price is low, and the liquid explosive can be mixed onsite before using. The liquid explosive is applied to oil and gas exploitation and is especially suitable for oil and gas exploitation in low permeable hard rock areas.

Owner:NANJING UNIV OF SCI & TECH +1

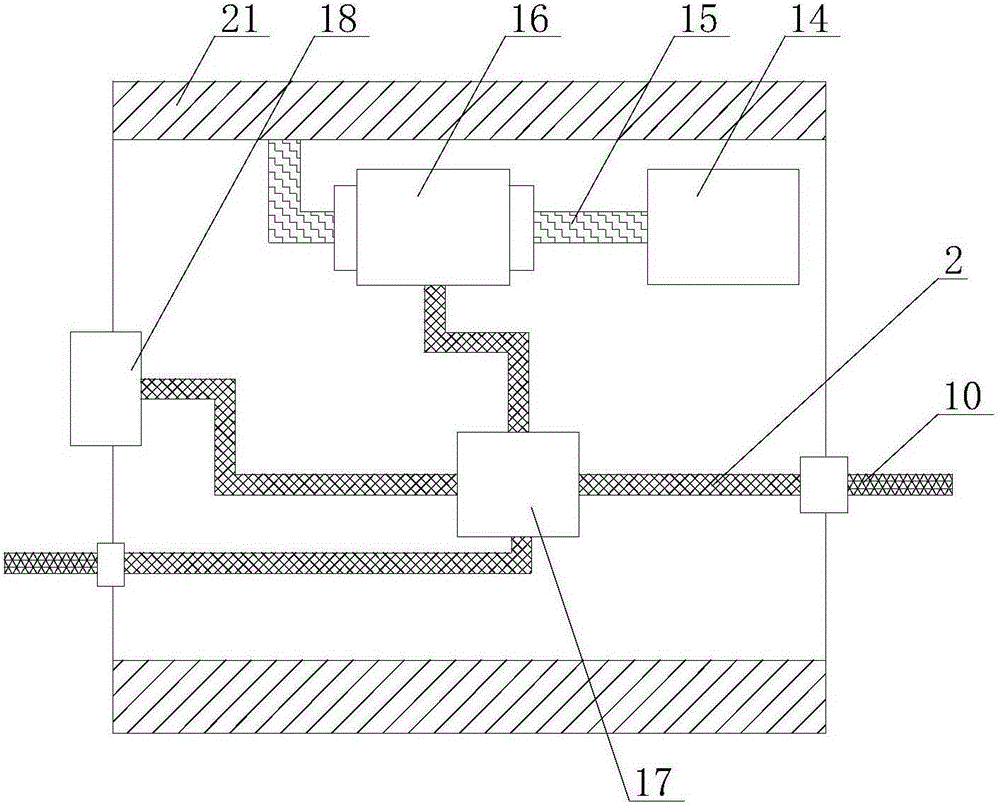

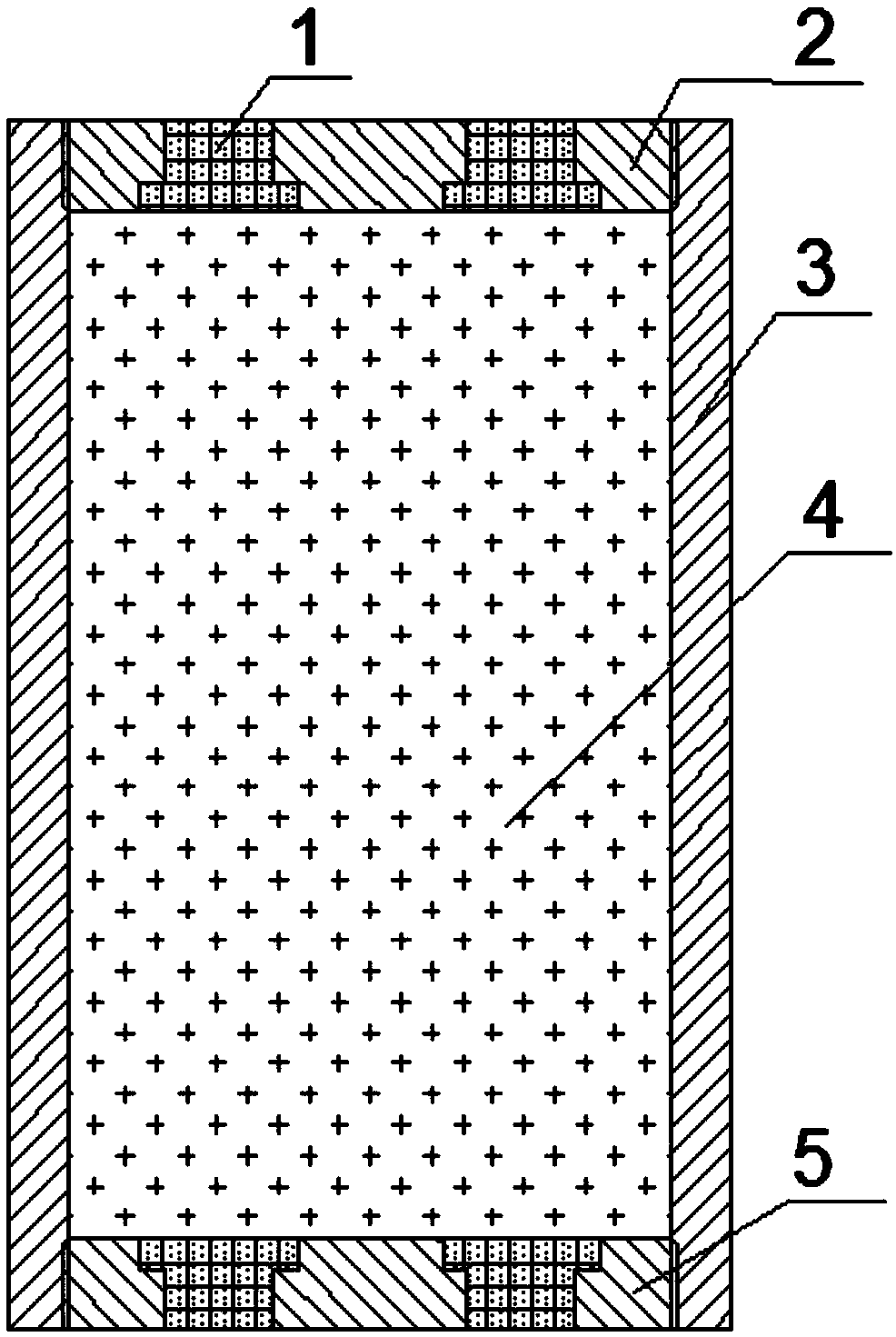

Constant-temperature melting pressure release slow-release system of missile warhead

InactiveCN109282711AVarying intensityChange damage performanceSelf-propelled projectilesCooking & bakingInternal pressure

The invention discloses a constant-temperature melting pressure release slow-release system of a missile warhead. The system is composed of a shell, a front end cover, pressure releasing modules, a filling object and a rear end cover; and four pressure releasing modules are installed on the front end cover and the rear end cover respectively, and the front end cover and the rear end cover are coaxially assembled at the two ends of the shell through threads. According to the system, when the missiles suffer from accidental thermal stimulation caused by slow baking, in the process that the temperature of the missile warhead is increased, the fusible metal inlaid in the pressure releasing modules which are installed on the front end cover and the rear end cover are gradually softened, finallya pressure releasing channel is formed after melting; when the explosive does not reach a temperature threshold value of local ignition, the effectively discharging of the melted liquid explosive andthe gas released by explosive thermal decomposition can be guaranteed; and the increase of the pressure in the bullet body is inhibited, so that the reaction rate of the explosive is not increased sharply, the slow baking response grade of the warhead is reduced, and the slow baking safety of the ammunition is improved.

Owner:XIAN MODERN CHEM RES INST

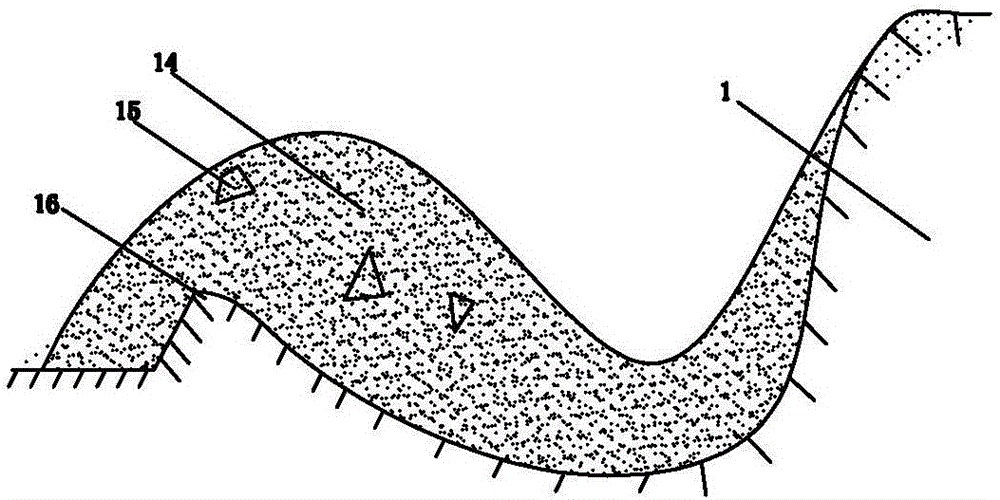

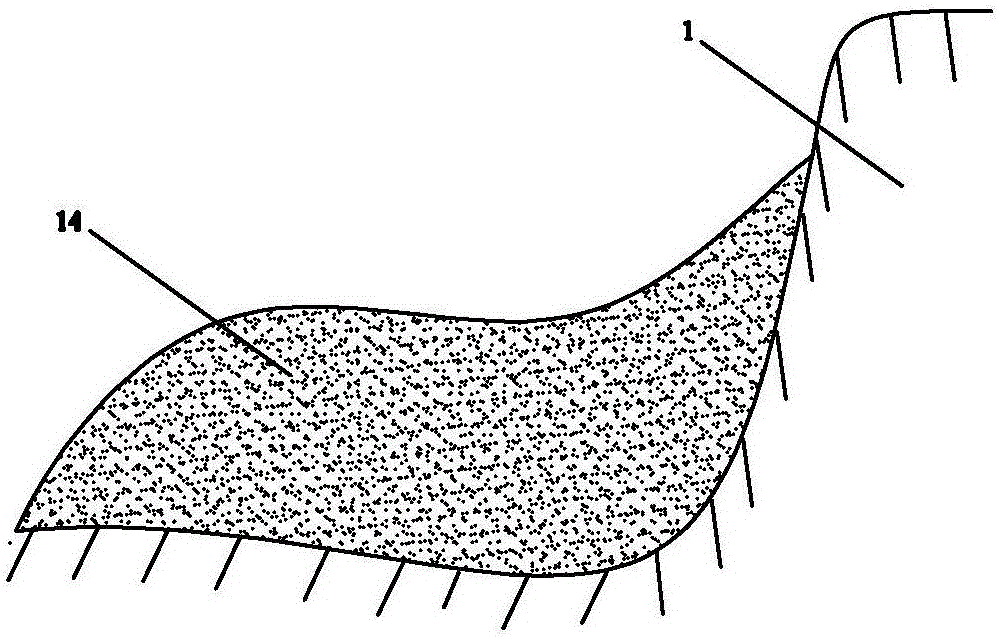

Liquid explosive detonating method adopting hole bottom air cushion

A liquid explosive detonating method adopting a hole bottom air cushion comprises the following steps that a medium-length hole is drilled in an appropriate position of rock; an air cushion bag loaded with light-weight foaming filler and soil-rock blocks is placed into the hole bottom of the medium-length hole, a detonating cord is fixed to the upper end of the air cushion bag, a detonator is bound to the detonating cord, and a detonating tube is connected to the detonator and extends over the ground; a plastic film barrel with the bottom sealed is placed into the medium-length hole; liquid explosives are injected into the plastic film barrel; the portion, above the liquid explosives and the outside the plastic film barrel, inside the medium-length hole is filled with pulverized soil; and an igniter is used for igniting the detonating tube, the detonator is ignited through the detonating tube, the detonating cord is ignited through the detonator, and then the liquid explosives at the bottom of the medium-length hole are ignited through the detonating cord. The liquid explosive detonating method adopting the hole bottom air cushion has the advantages that the explosive energy utilization rate is high, the rock is evenly crushed, blast heaps are centralized, bedrock is prevented, the use quantity of the detonating cord is decreased, the blasting cost is lowered, a few of flying stones are produced and the safety is high; and the liquid explosive detonating method adopting the hole bottom air cushion is mainly used for occasions, where blasting is conducted on medium-length holes of ore and rock, of mines, repaired roads, quarries and the like.

Owner:SUZHOU CHUANGMING SOFTWARE TECH CO LTD

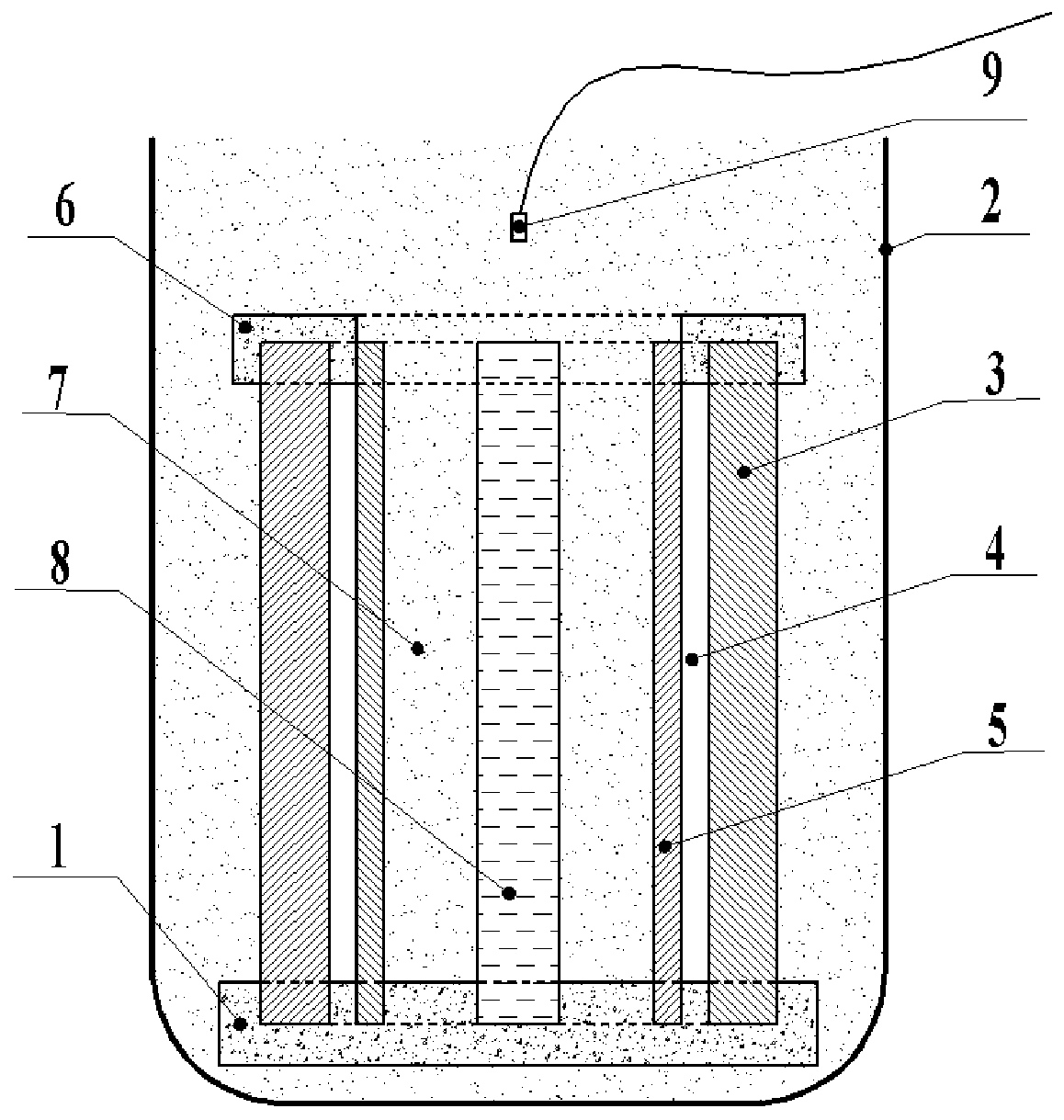

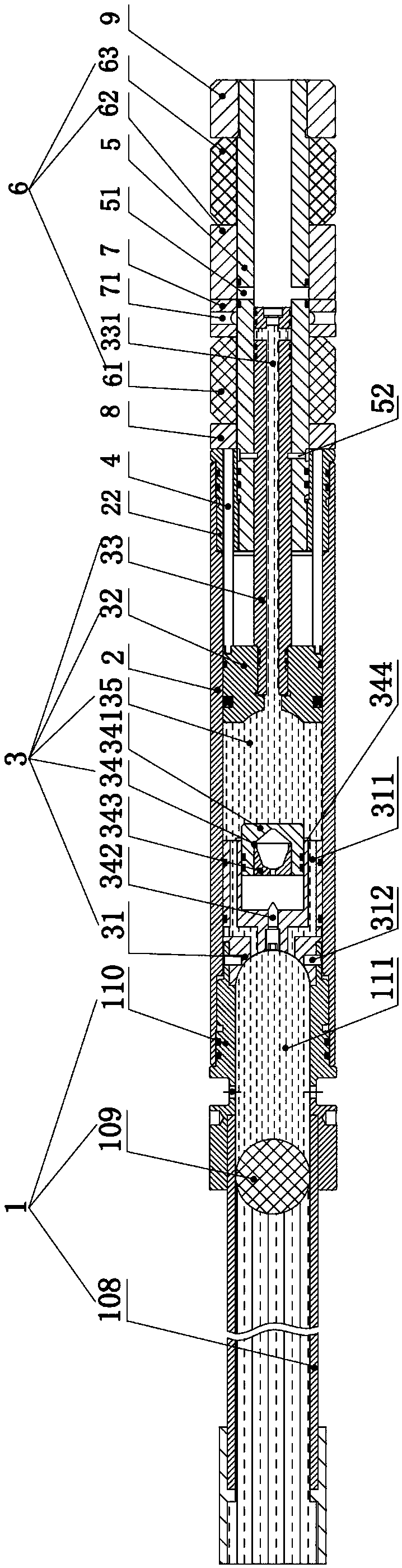

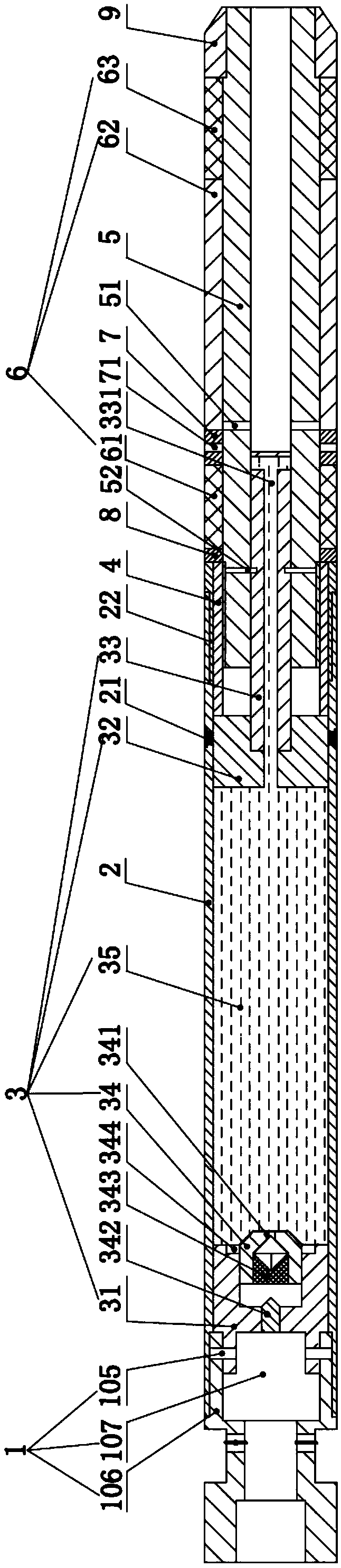

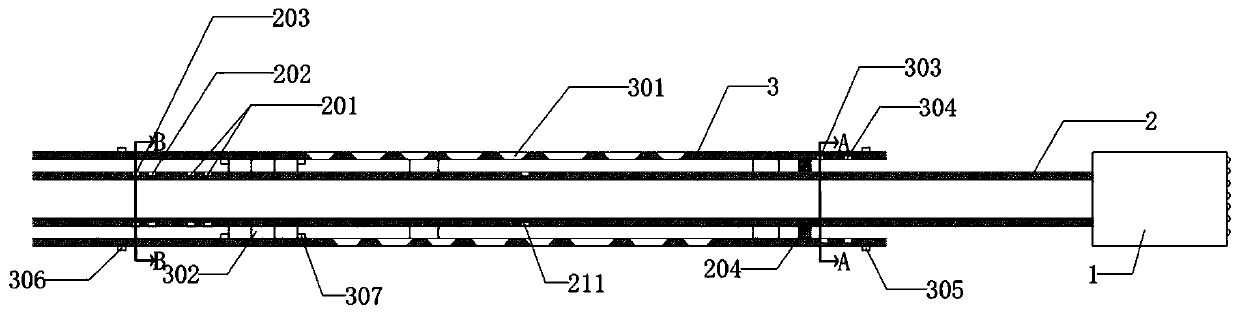

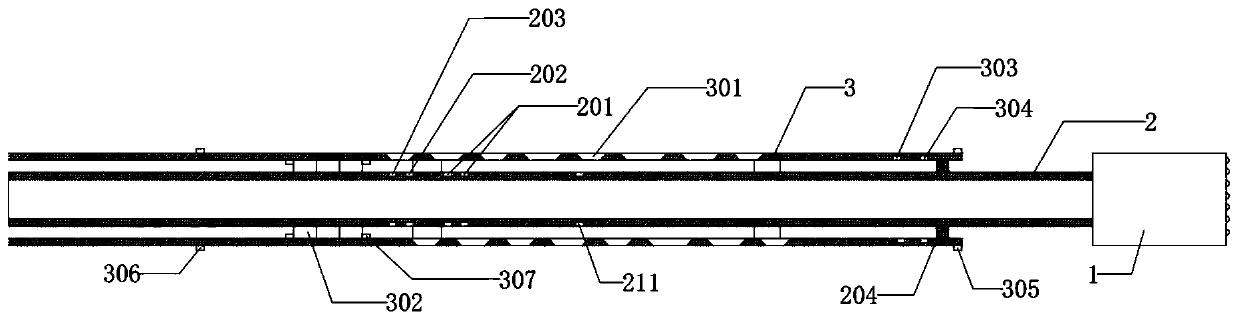

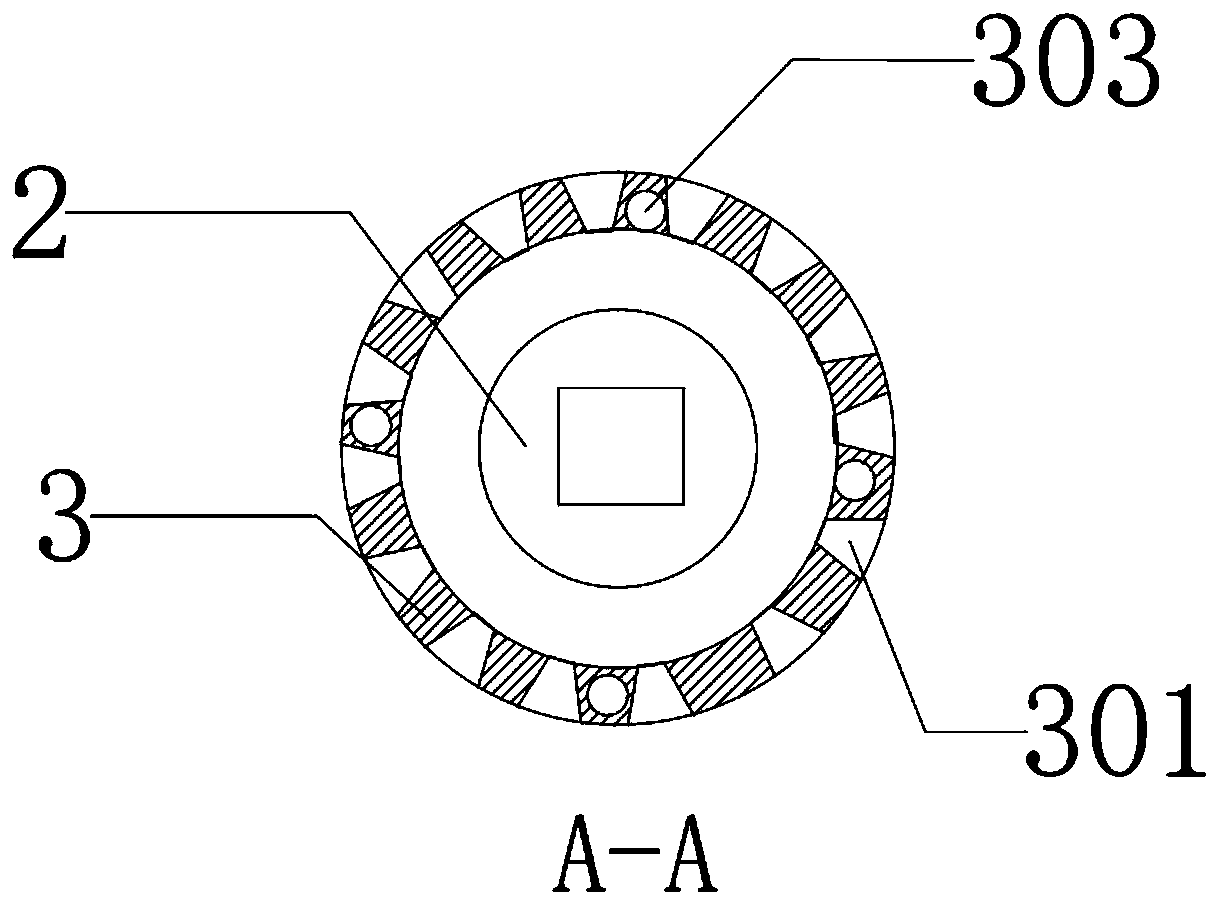

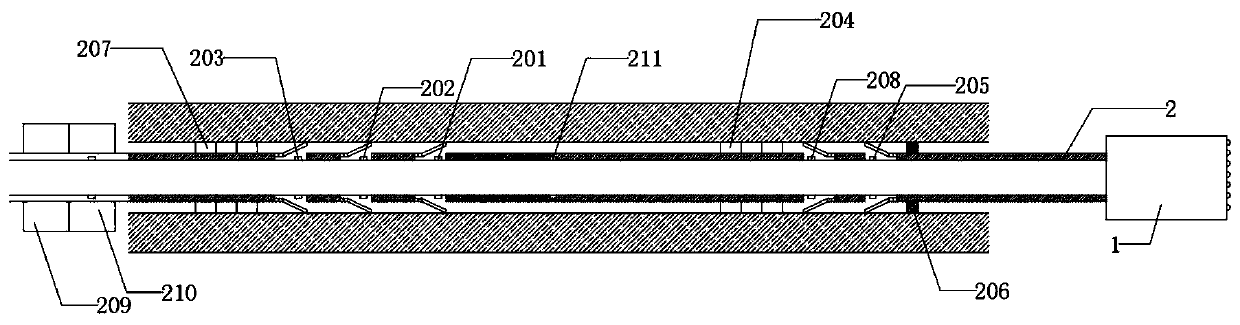

Liquid explosive injection and detonation device for explosion fracturing of oil and gas reservoir

The invention discloses a liquid explosive injection and detonation device for explosion fracturing of an oil and gas reservoir. The liquid explosive injection and detonation device comprises a driving unit, a cylinder barrel, a liquid explosive injection and detonation unit, a driving pressure transferring unit, a central steel column, a perforation section elastic sealing unit and a first pressing ring. The driving unit is located in the left end of the cylinder barrel; the cylinder barrel is fixedly connected with the central steel column; the liquid explosive injection and detonation unitis located in the cylinder barrel; the perforation section elastic sealing unit and the first pressing ring are both arranged outside the central steel column in a sleeving mode; and the driving pressure transferring unit is located between the liquid explosive injection and detonation unit and the first pressing ring and penetrates through the junction of the cylinder barrel and the central steelcolumn. After a target perforation section is sealed through the driving unit, a liquid explosive is injected into a stratum in a high pressure mode through a perforation hole channel; and after theexplosive with the required amount is injected into the stratum and the instantaneous state of the injection pressure is maintained, the liquid explosive injected into the oil and gas stratum is automatically detonated immediately, and the oil and gas stratum is internally exploded to be fractured.

Owner:屈波

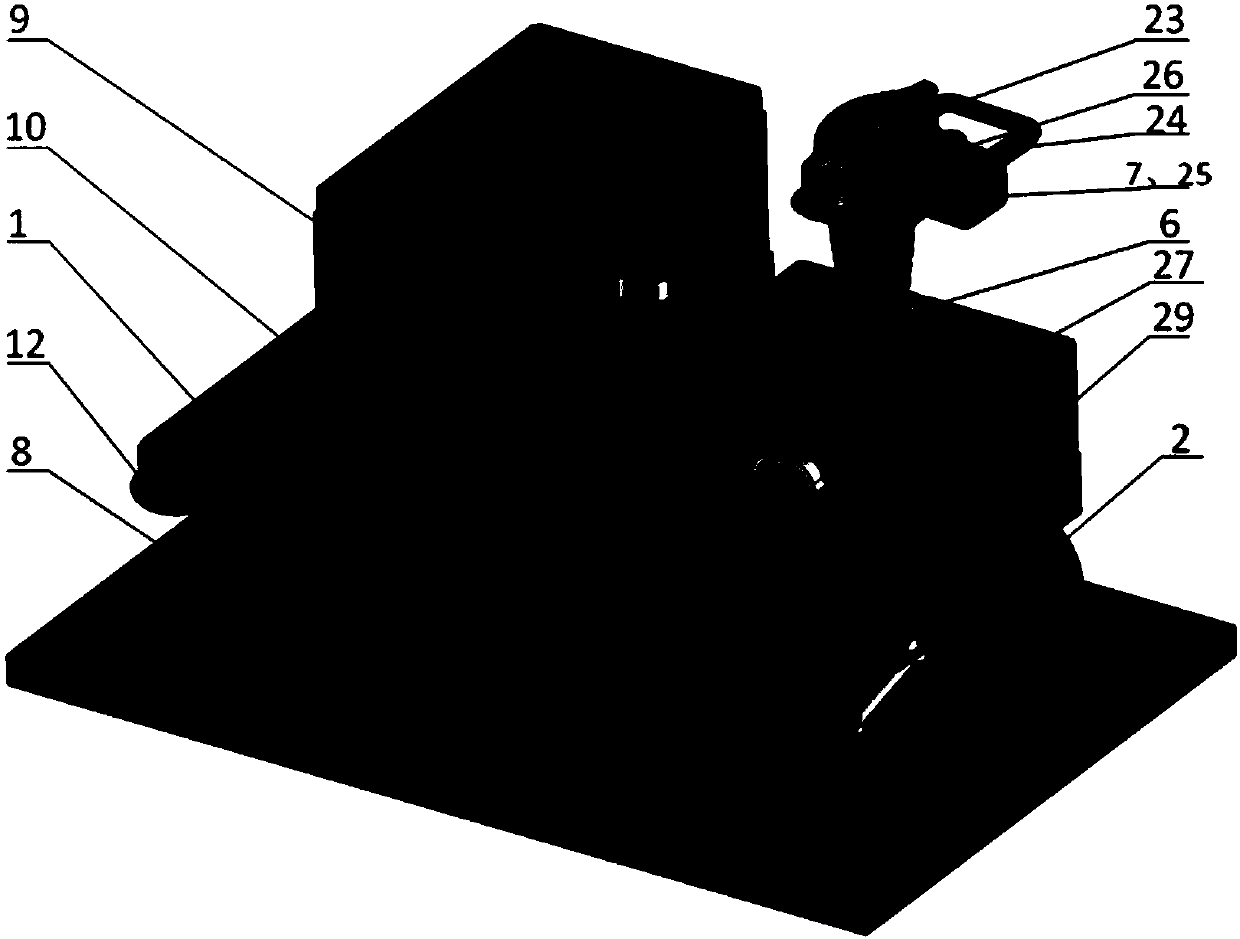

High-energy tamping machine

InactiveCN110700257AStressfulLarge transfer depthBlastingBulkheads/pilesCombustion chamberEngineering

The invention discloses a high-energy tamping machine. According to the high-energy tamping machine, a liquid explosive is adopted as tamping energy, the upper portion serves as an impacting part, thelower part serves as a pressing part, and a buffer is arranged between the impacting part and the pressing part. A combustion chamber with a downward opening is arranged on the impacting part, the upper end of the combustion chamber is closed, a closed combustion space is formed from the upper end face of a piston to the closed upper end of the combustion chamber, the liquid explosive is injectedinto the combustion chamber through a check valve and is ignited through electric ignition or chemical ignition, and high-pressure fuel gas is generated; on one hand, the piston, a piston rod and thepressing part are pushed downwards, and the ground below the high-energy tamping machine is compacted; on the other hand, the impacting part is pushed to move upwards; and the impacting part falls under the action of the gravity or a reset spring, the buffer is compressed, buffering force and tamping force are generated, and secondary tamping is formed.

Owner:郑州鑫美高能打桩机有限责任公司

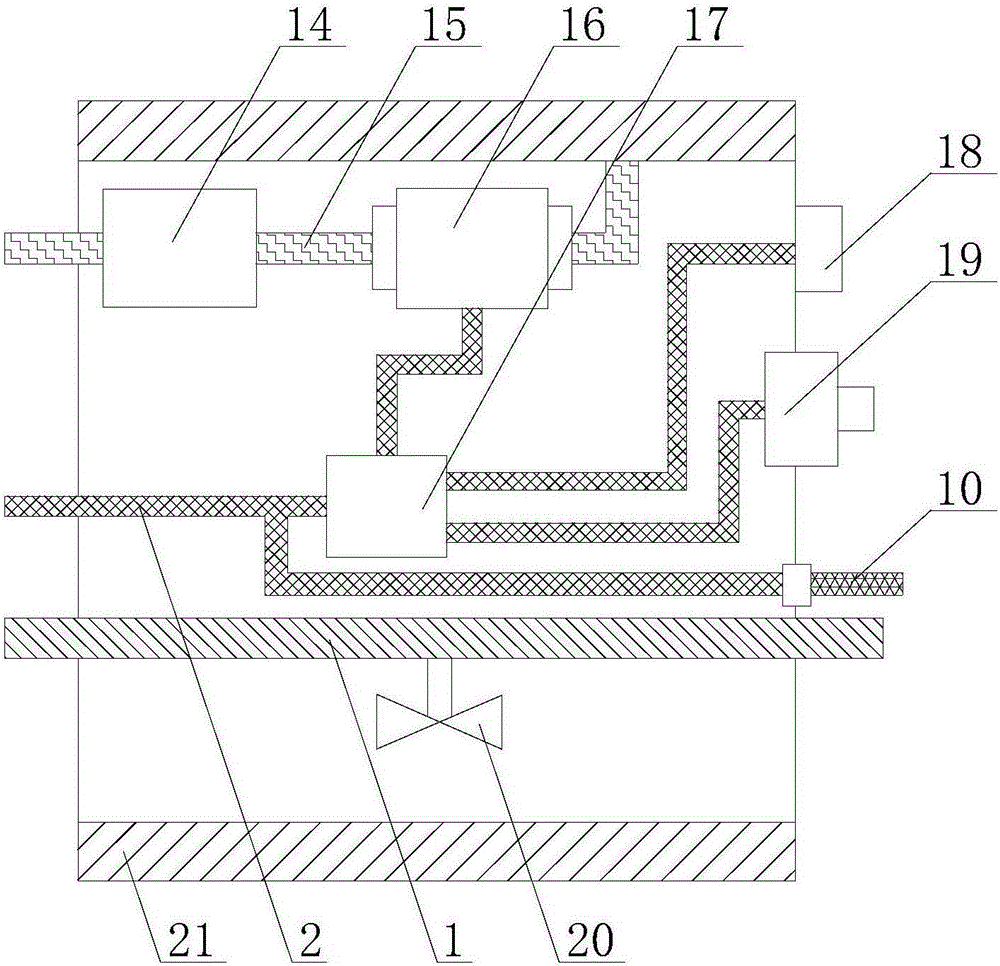

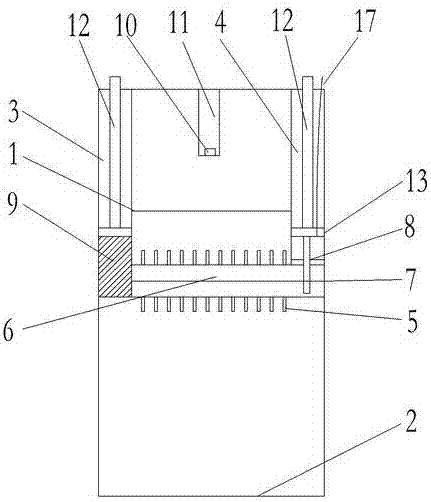

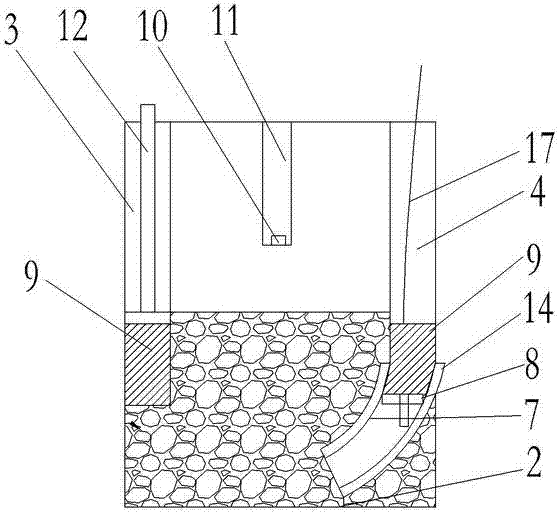

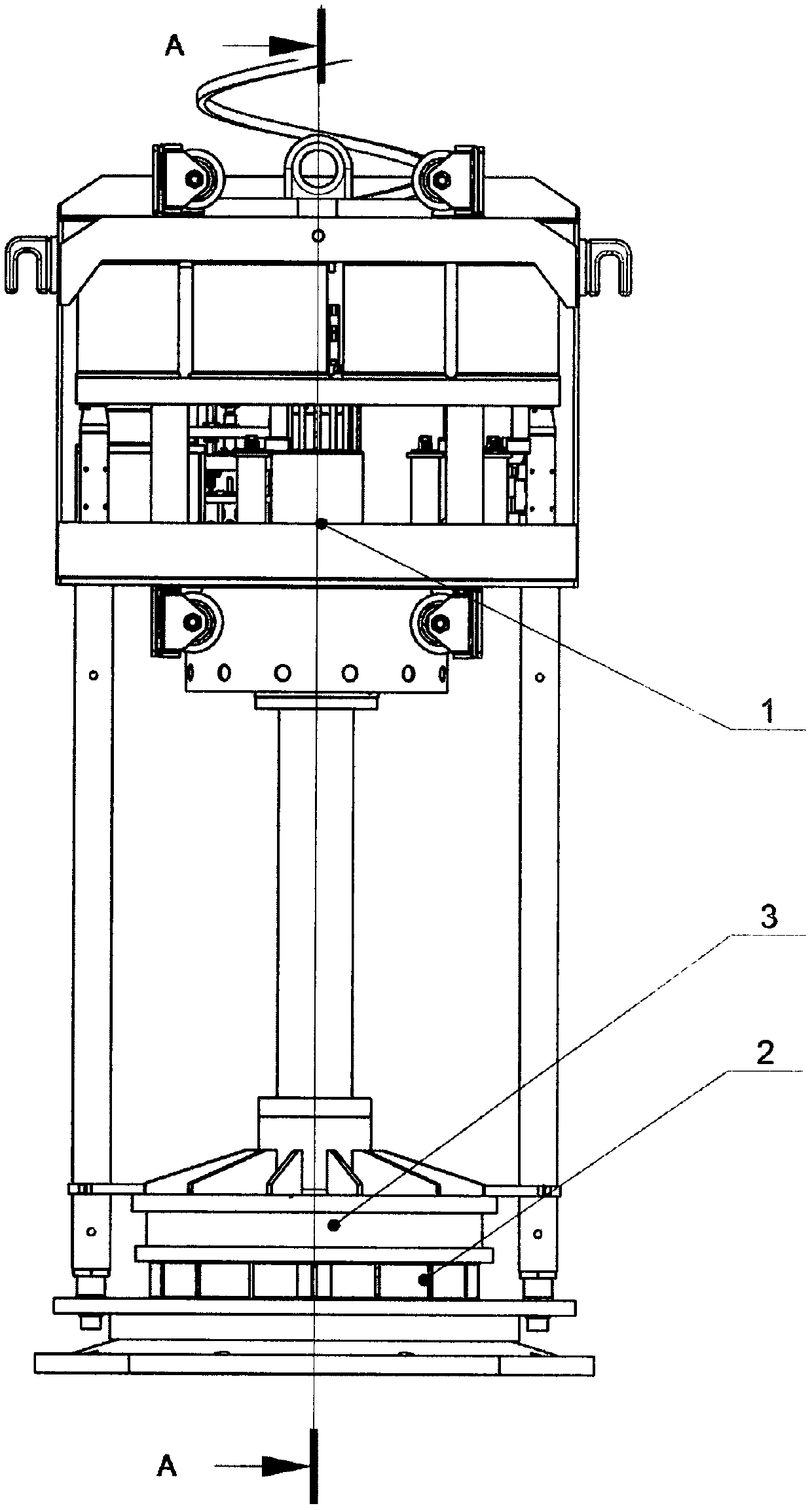

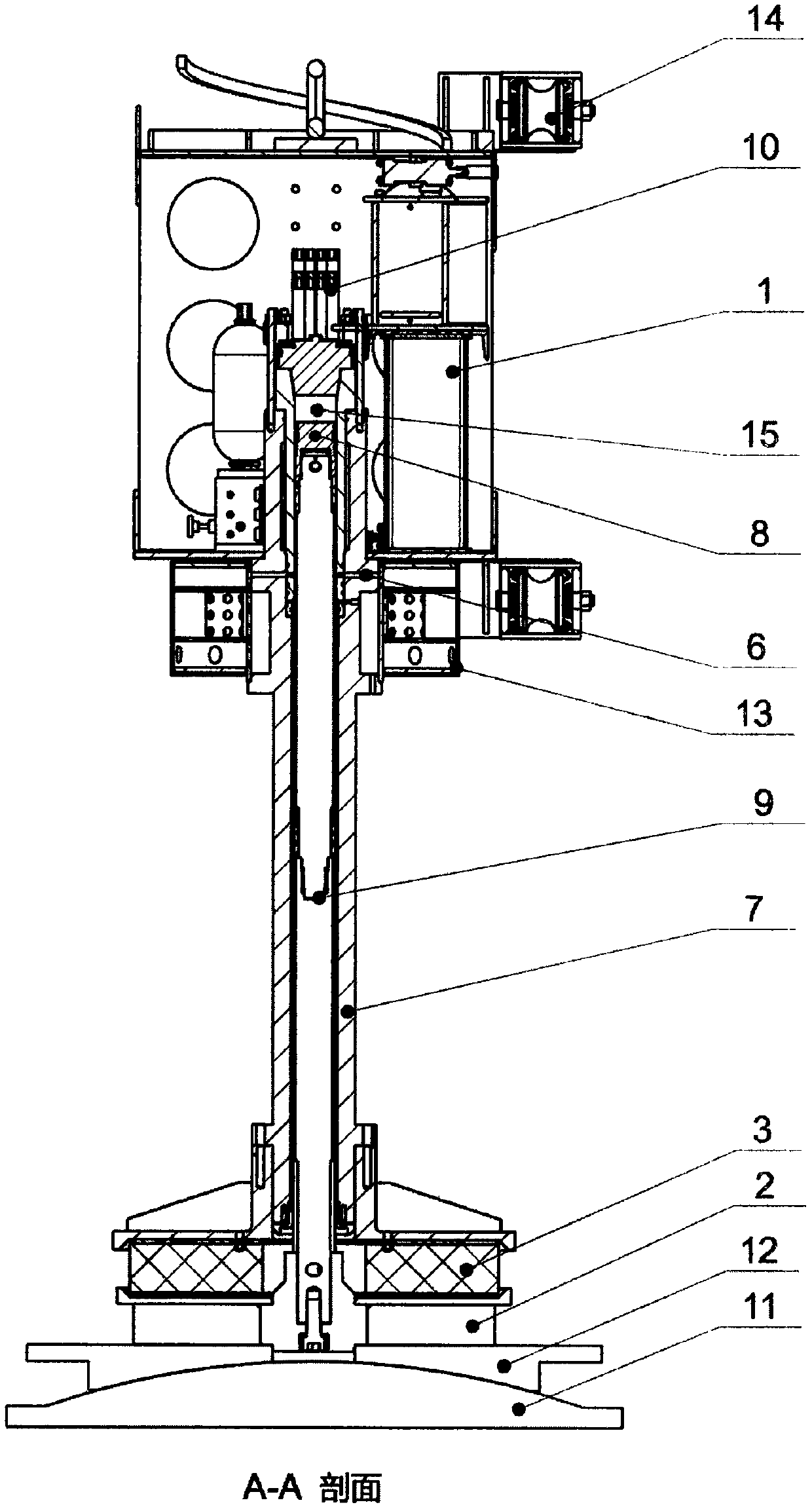

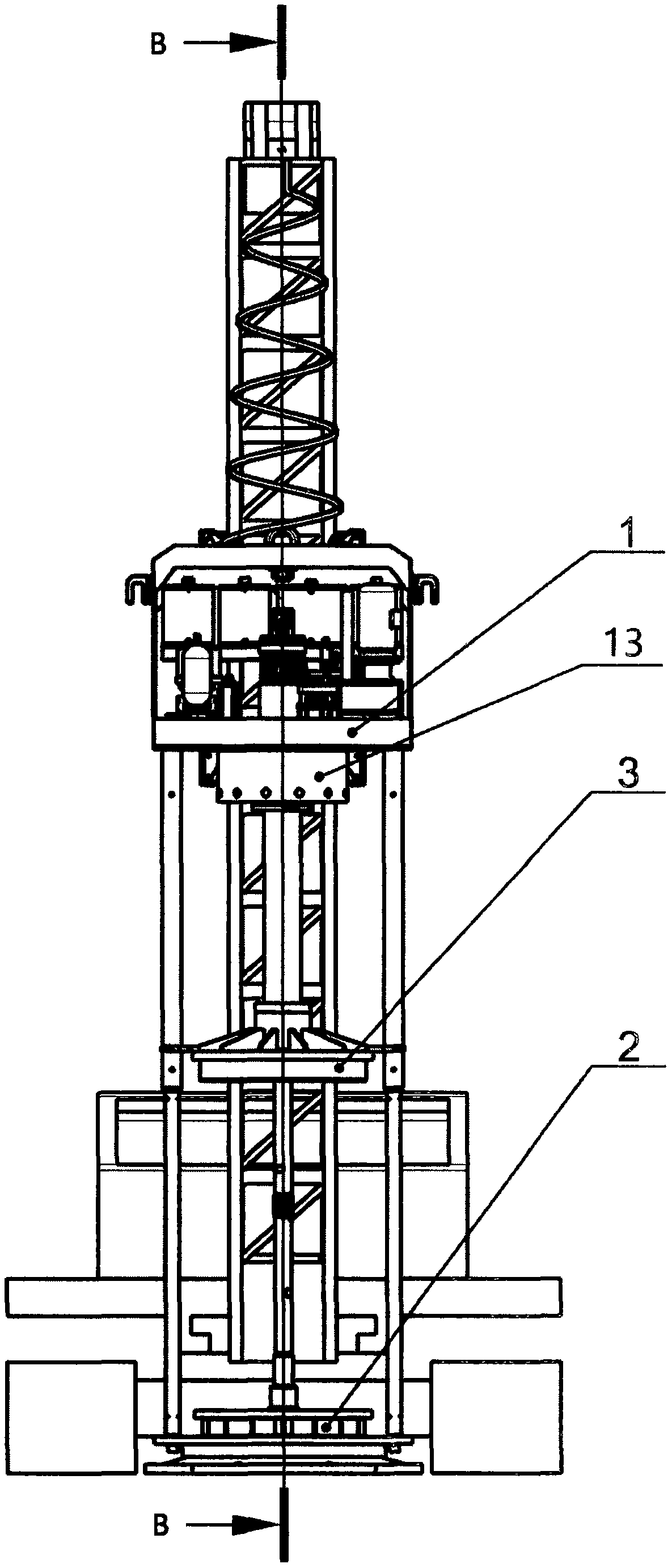

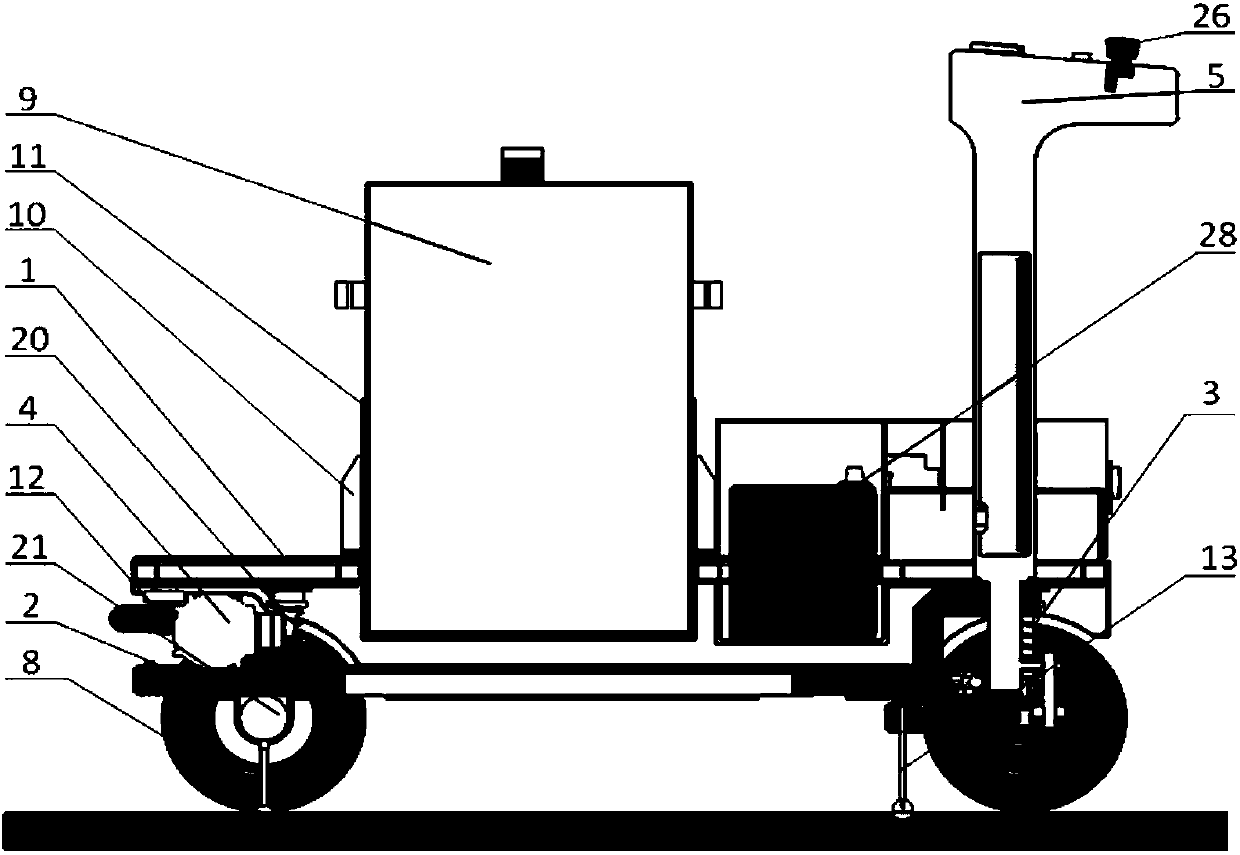

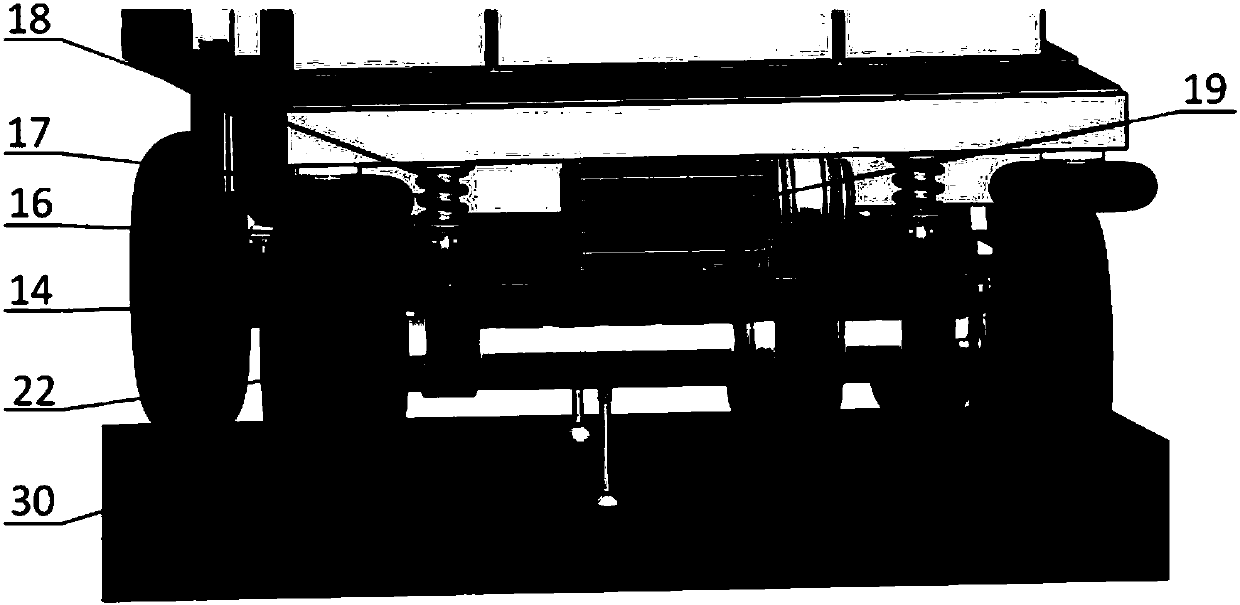

Shock-absorption electric vehicle for transferring liquid-state explosives between workshops

ActiveCN107696856AFirmly connectedGuaranteed temperatureItem transportation vehiclesResilient suspensionsLiquid stateControl system

The invention discloses a shock-absorption electric vehicle for transferring liquid-state explosives between workshops. The shock-absorption electric vehicle comprises the parts of a vehicle body 1, avehicle axle 2, a shock-absorption system 3, a driving system 4, a control system 5, a power supply system 6, a braking system 7, a wheel set 8, a thermal container 9 and the like. The shock-absorption system 3 adopts a shock-absorption spring 17 and a guiding column 18, the resonant frequency of the vehicle is calculated through the deadweight capacity and the sensitivity of the explosives, andfurther a model needed by the spring is determined; and multiple protection measures are taken, and an explosion-proof electric machine, reliable grounding, the thermal container, an anti-collision wheel, electroconductive rubber and the like are included, explosive-proof treatment is conducted on an electric control part, and therefore the electric control part can be suitable for transferring the liquid explosives. According to the shock-absorption electric vehicle for transferring the liquid-state explosives between the workshops, the structure is simple, maintenance is simple and convenient, vibration is controllable, and the shock-absorption electric vehicle can adapt to different deadweight capacities and different sensitivity requirements of the liquid explosives by adjusting the model of the spring.

Owner:XIAN MODERN CHEM RES INST

Casting process for high-explosive primer

The invention discloses a casting process for a high-explosive primer. The casting process comprises the following steps of: firstly, manufacturing shells of the primer, and mixing and heating to melt solid explosive raw materials in a melting tank; installing a mold provided with the shells onto a tooling plate on a triple-speed chain, moving the shells to reach a primary explosive injection station, and automatically metering by a first explosive injection tank to inject a high-energy composite explosive into the cavity of an inner shell; after explosive injection is completed, driving the shells to move forwards by the triple-speed chain, and cooling the high-energy composite explosive in the inner shell; moving the shells to reach a secondary explosive injection station, and then, automatically metering by a second explosive injection tank to inject a conventional composite explosive into the cavity of an outer shell to complete explosive injection for the second time; driving the shells to move forwards by the triple-speed chain, and cooling the conventional composite explosive in the outer shell; enabling the shells to enter a mold retreating station to complete a mold retreating operation; and solidifying to shape the liquid explosive, and then, entering a packaging process to form a finished product. The casting process for the high-explosive primer is simple, can be easily operated and is low in production cost, and automatic and continuous production is realized.

Owner:QIANJIN IND EXPLOSIVES CO LTD

Liquid explosive blaster

The invention discloses a liquid explosive blaster. The liquid explosive blaster comprises a blasting box, wherein a moving cavity is formed in the blasting box; a motor is arranged in the blasting box; a first thread rod is fixedly connected to the right-side end surface of an output shaft facing the right, of the motor; a first bevel gear is fixedly installed on the first thread rod; a first limit baffle is fixedly installed on the first thread rod and at the right side of the first bevel gear; first fixed plates are fixedly installed on the left inner wall and the right inner wall of the moving cavity; a straight-line groove penetrating through the upper end surface and the lower end surface is formed in each first fixed plate; a first thread slide block is installed on the top end surface of each first fixed plate in a manner of slide fit; a first thread hole with an opening facing the left is formed in each first thread slide block; each first thread hole and the first thread rodare installed in a manner of thread fit; and a first spring plate is fixedly installed on the left-side inner wall of the moving cavity.

Owner:兰溪德比电子科技有限公司

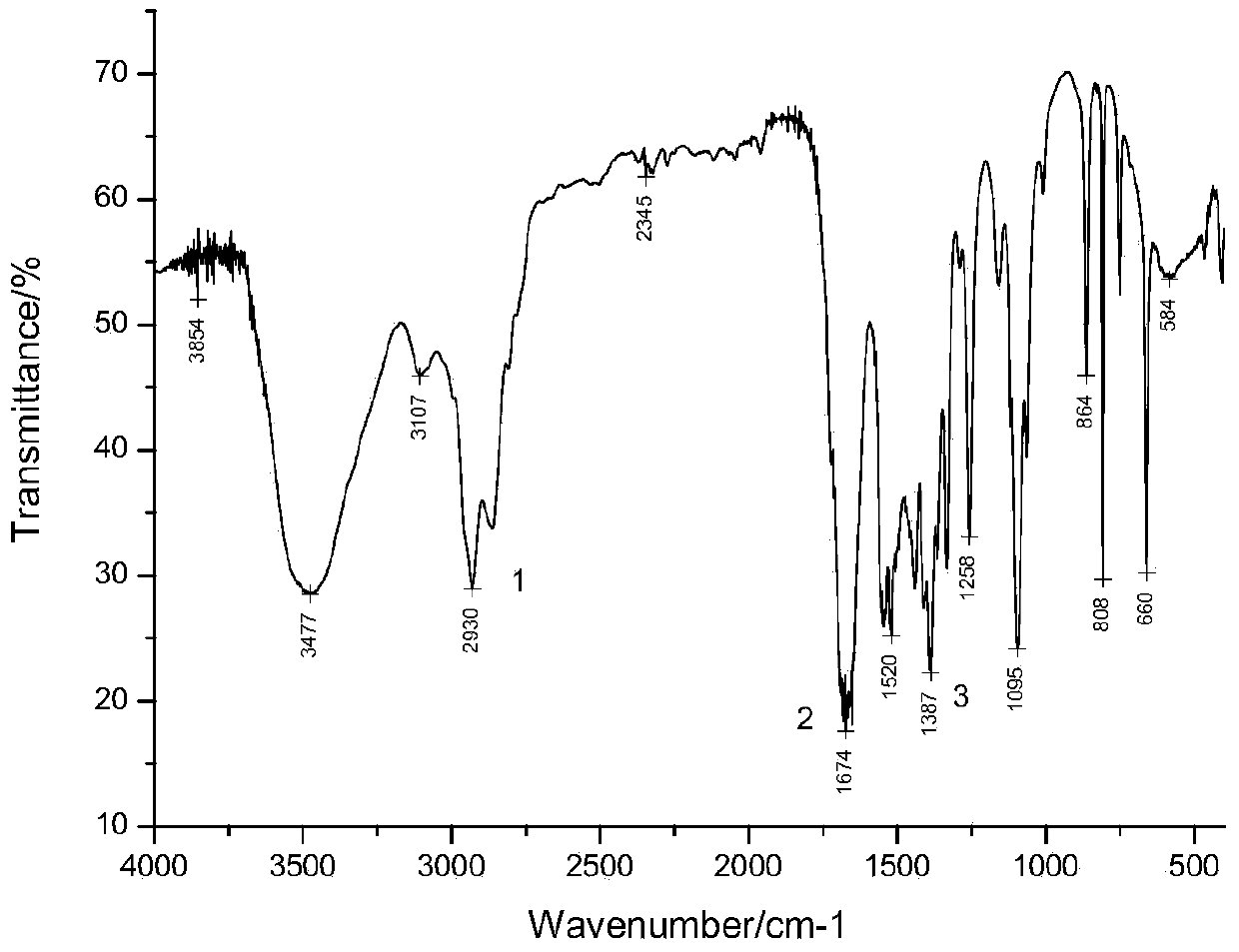

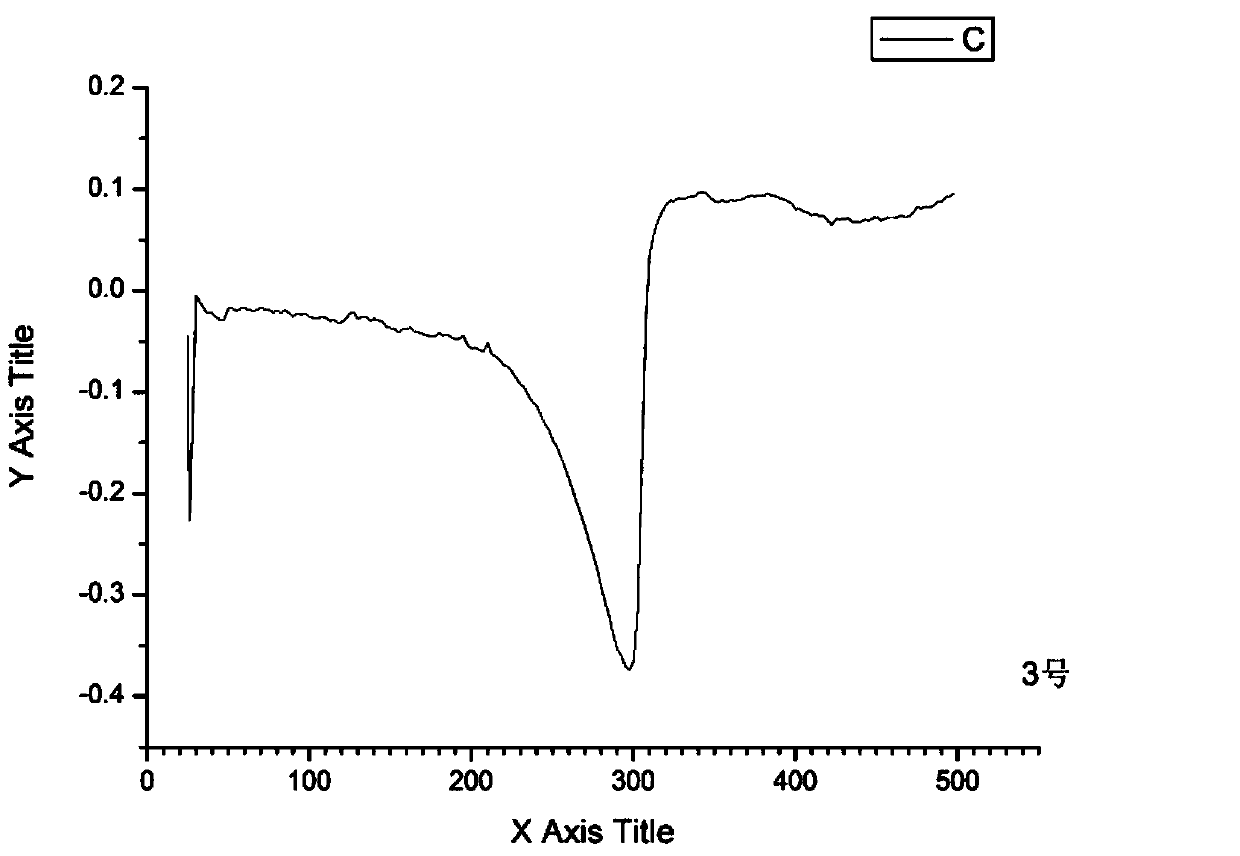

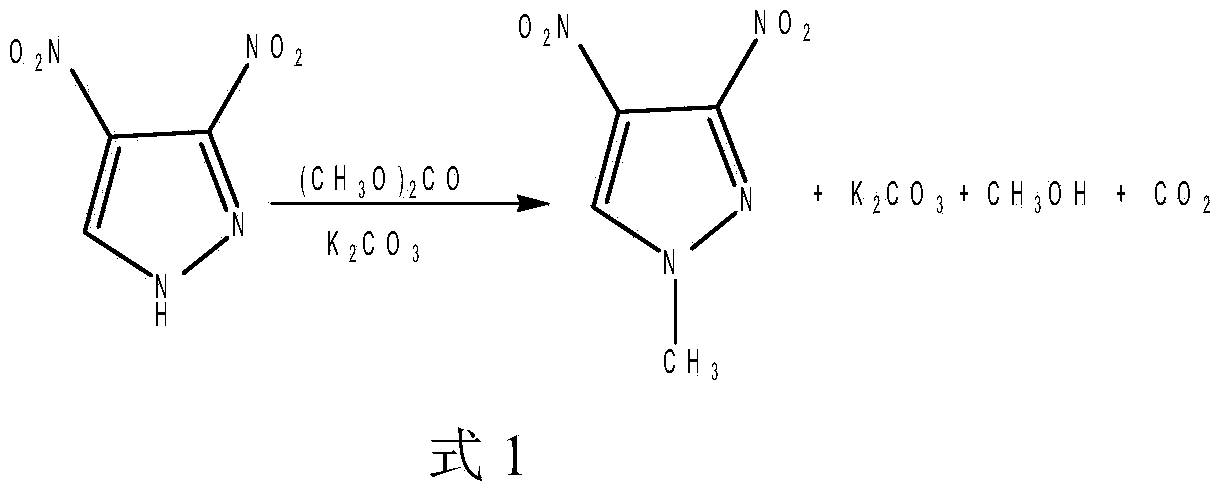

Preparation method of 1-methyl-3,4-binitro pyrromonazole

The invention relates to a preparation method of 1-methyl-3,4-binitro pyrromonazole. The 1-methyl-3,4-binitro pyrromonazole prepared through the method disclosed by the invention is high in energy and desensitization and lower in melting point and is a normal-temperature liquid explosive. The preparation method is mainly used for solving the technical problems of high cost, low yield, and the like of the traditional preparation method of the 1-methyl-3,4-binitro pyrromonazole. The technical scheme is as follows: the preparation method comprises the following steps: weighing raw materials according to the condition that the ratio of the amount of substance of 3,4-binitro pyrromonazole:anhydrous potassium carbonate:dimethyl carbonate:N,N-dimethyl formamide is 1:1.5:(5-13):20-25); dissolving the 3,4-binitro pyrromonazole into the N,N-dimethyl formamide at the low temperature of 0-5 DEG C, and then sequentially adding the anhydrous potassium carbonate and the dimethyl carbonate; reacting at 60-110 DEG C for 4-10 hours; pouring reaction liquid into distilled water; extracting for multiple times by using dichloromethane (CH2Cl2); merging organic phases; carrying out reduced pressure distillation; removing a solvent to obtain a 1-methyl-3,4-binitro pyrromonazole product. The preparation method disclosed by the invention has the advantages of safety and low toxin content of the raw materials, simple synthetic process, high yield and high purity of products and easiness for industrialization.

Owner:ZHONGBEI UNIV

Fold rock burst control method based on ground fracturing and liquid explosive blasting

ActiveCN113818922AReduce structural stressReduce labor intensityFluid removalGas removalTectonic stressTEX-explosive

The invention discloses a fold rock burst control method based on ground fracturing and liquid explosive blasting. An emulsion explosive is used as a rock burst dangerous position of a fracturing fluid fracturing fold tectonic area; a crack and the emulsion explosive in a vertical well are detonated, a crushing pressure relief zone is formed in the rock burst surrounding rock area to control the rock burst, the tectonic stress of the fold tectonic area can be effectively reduced, the probability of rock burst occurrence is reduced, and meanwhile the method has the multiple advantages that the control range is large, and multiple working faces can be controlled at a time; the labor intensity of workers is low; and normal production is not influenced.

Owner:CHONGQING UNIV

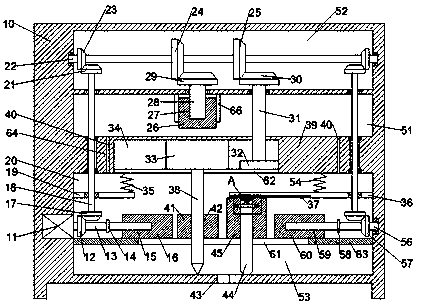

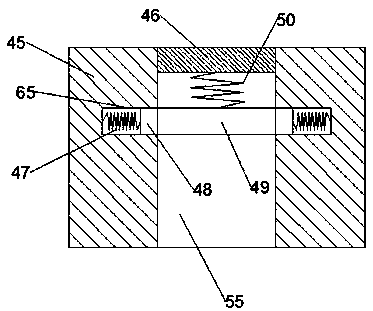

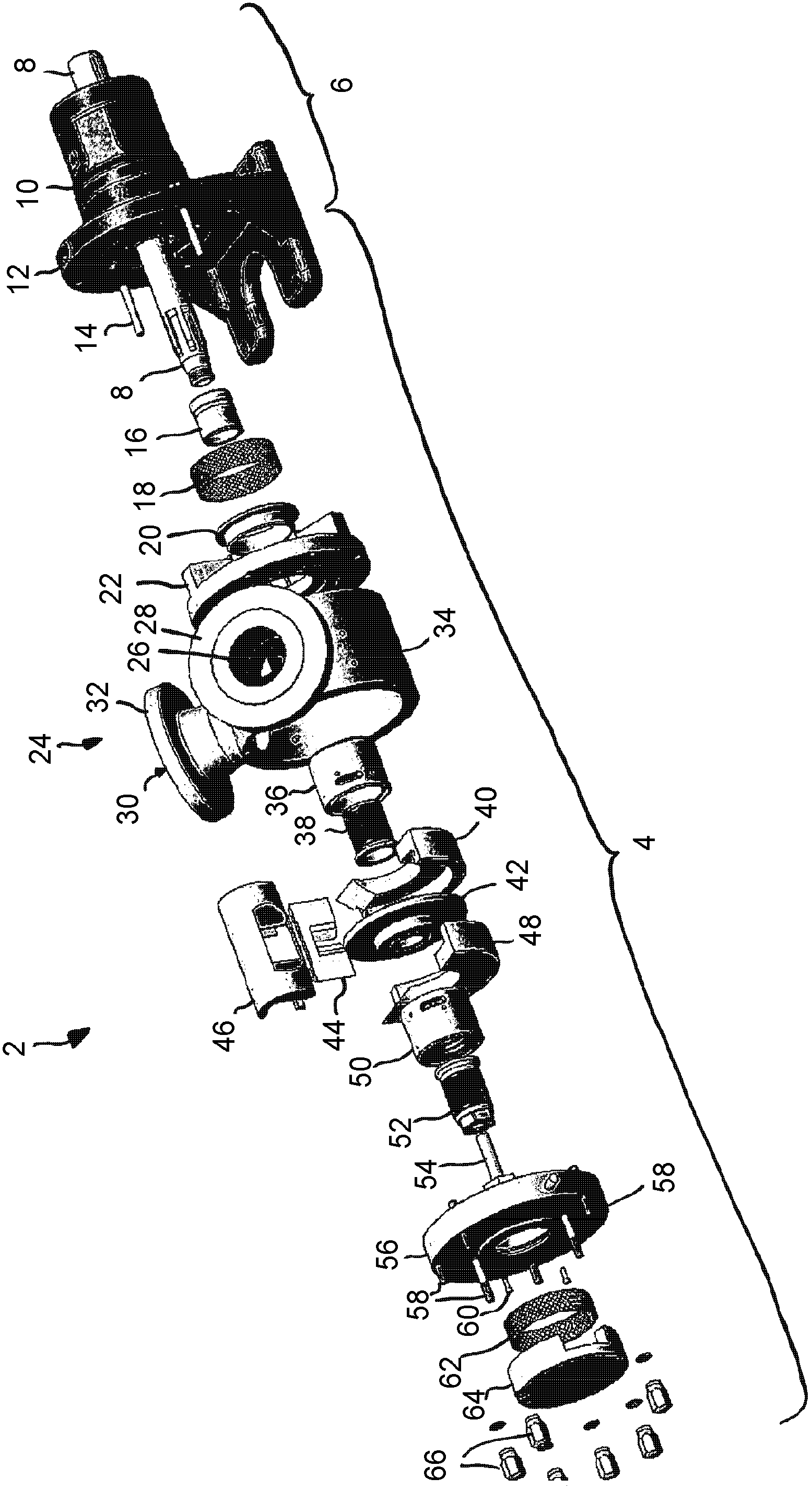

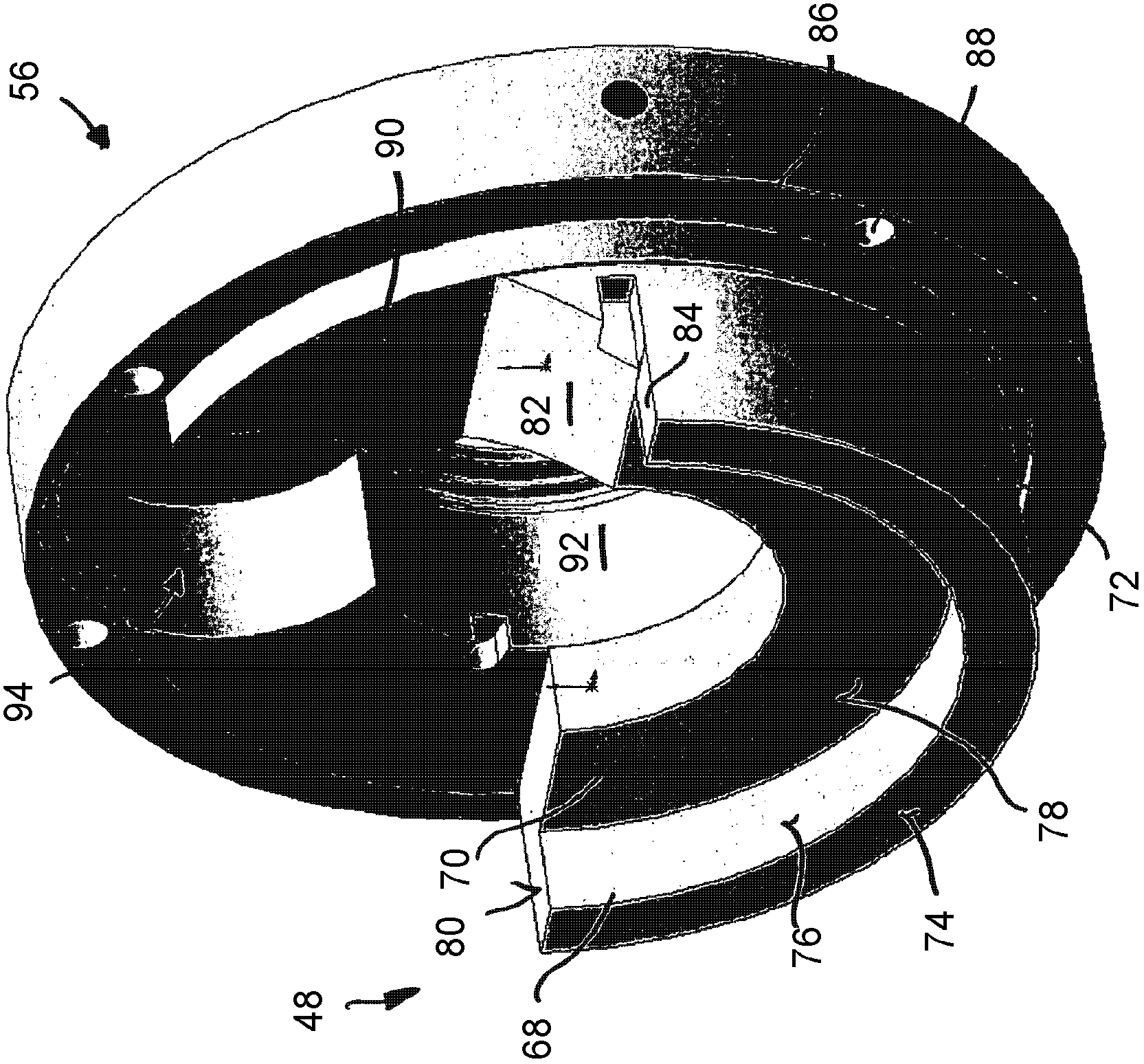

Rotary displacement pump for pumping solids emulsions, especially liquid explosives

A rotary displacement pump of an undulatory disk type; with a pump housing (24) comprising a front end plate (56) and a rear end plate, the pump housing enclosing a stator (40, 48), a rotor (42), a scraper (44) and a scraper guide (46), a shaft (8) extending through at least the rear end plate; the stator including a generally semi-circular arc-formed first stator member (40) and a generally semi-circular arc-formed second stator member (48), the stator, the pump housing and the scraper together with the scraper guide defining an inlet and outlet chamber, wherein at least part of the end faces of the first and second stator members being situated in the outlet chamber are oblique so as to provide an obtuse-angled transition to the inner faces of the front end plate and the rear end plate.

Owner:WATSON MARLOW

Continuous blasting drilling method

InactiveCN111578799ACan control the blasting directionImprove blasting effectDrill bitsBlastingExplosive AgentsMechanical engineering

Owner:李天北

Rapid blasting drilling method

InactiveCN111578800AImprove blasting effectImprove drilling efficiencyDrill bitsBlastingExplosive AgentsPetroleum engineering

The invention provides a rapid blasting drilling method. The rapid blasting drilling method comprises the following steps that S1, simultaneously injecting mud to the front end and the rear end of a detonation section along a rock drilling direction is carried out through a rapid blasting device to respectively form a front mud column and a rear mud column; S2, blasting powder is injected betweenthe front mud column and the rear mud column through the rapid blasting device; S3, sand is injected into the front end, in the rock drilling direction, of the front mud column and the rear end, in the rock drilling direction, of the rear mud column at the same time through the rapid blasting device, a front sand section and a rear sand section are formed respectively; and S4, the blasting powderis ignited through the rapid blasting device, and blasting is implemented. According to the rapid blasting drilling method, liquid explosive can be filled so that blasting can be carried out, so thatthe blasting effect is good, blasting and rock drilling are carried out at the same time; and explosive filling can be continued without taking out a drill bit, so that the drilling efficiency is high.

Owner:李天北

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com