High-energy dynamite charging thermal expansivity measuring device and method

A technology of thermal expansion coefficient and high-energy explosives, which is applied in the experimental field of explosives performance parameters, can solve the problem that the correlation curve of expansion displacement, temperature and pressure cannot be obtained, the performance evaluation methods of explosives cannot meet the research needs, and cannot be directly used to guide the charging of explosives. Drug design and other issues to achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

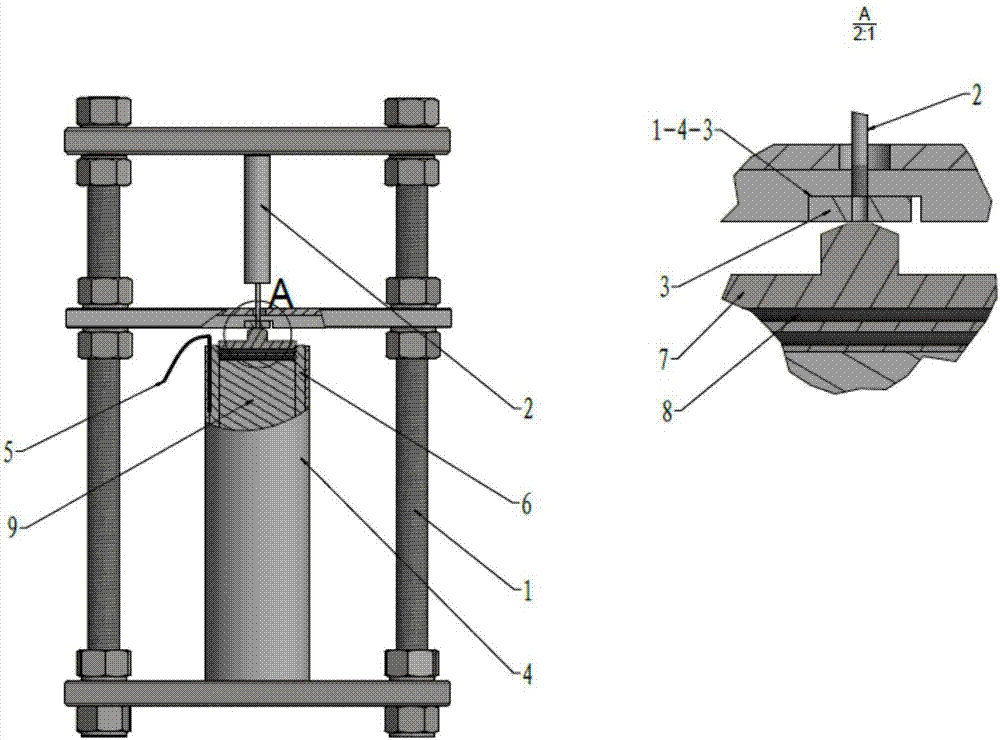

[0033] In this embodiment, the expansion displacement of PBXN-109 explosive (no curing agent added, similar to slurry semi-fluid) is measured. The diameter of PBXN-109 explosive is 60mm and the length is 180mm.

[0034] Displacement sensor 6 adopts LP804 of OMEGA Company, and the sensor resolution is 0.00127mm; plate spring 2 is made of 5mm thick 60Si2Mn steel, and is heat treated, and the elastic coefficient K of the middle plate is calibrated before use; bracket 1, piston 3 and sample tube 4 are all made of 35Mn processing and heat treatment; the sealing ring 5 is a V-shaped sealing ring made of silica gel.

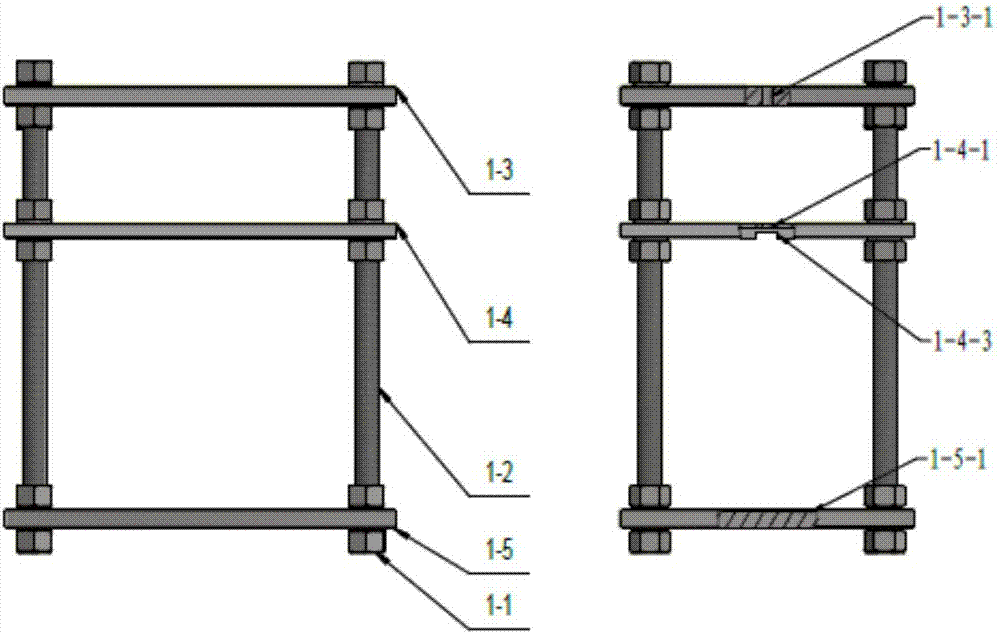

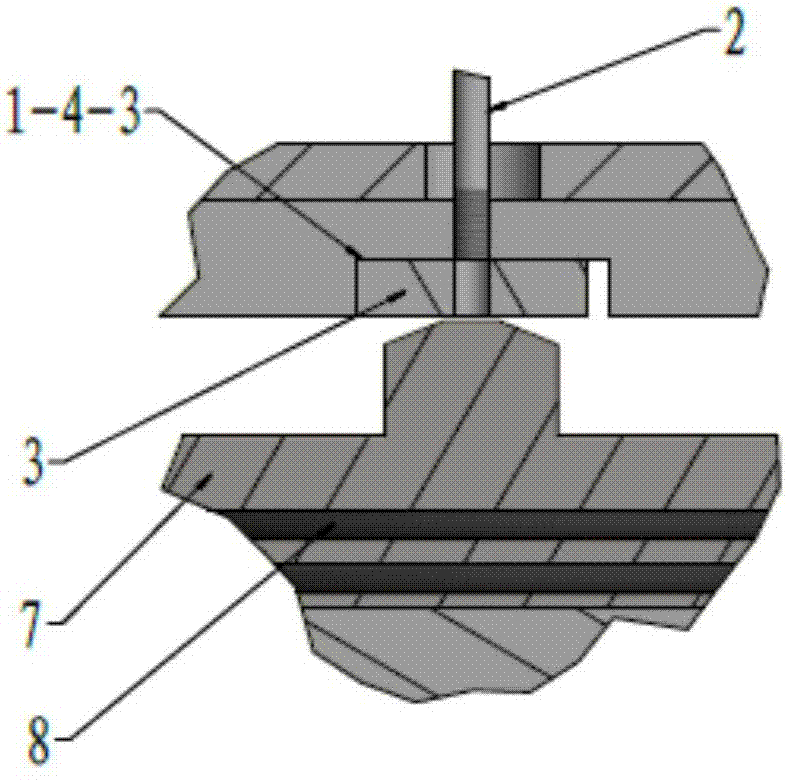

[0035] The design and installation of the sample device are as follows. The device includes a bracket 1, a displacement sensor 2, a leaf spring 3, a heating jacket 4, a thermocouple 5, a sample tube 6, a piston 7, a sealing ring 8 and a sample 9. The device as a whole It is a two-layer board house structure, the displacement sensor 2 is installed on the second layer, and ...

Embodiment 2

[0044] In this embodiment, the expansion displacement of RL-F explosive (solid press-packed explosive) is measured.

[0045] Displacement sensor 6 adopts LP804 of OMEGA Company, and the sensor resolution is 0.00127mm; plate spring 2 is made of 5mm thick 60Si2Mn steel, and is heat treated, and the elastic coefficient K of the middle plate is calibrated before use; bracket 1, piston 3 and sample tube 4 are all made of 35Mn processing and heat treatment; the sealing ring 5 is a V-shaped sealing ring made of silica gel.

[0046] The design and installation of the sample device are as follows. The device includes a bracket 1, a displacement sensor 2, a leaf spring 3, a heating jacket 4, a thermocouple 5, a sample tube 6, a piston 7, a sealing ring 8 and a sample 9. The device as a whole It is a two-layer board house structure, the displacement sensor 2 is installed on the second layer, and the sample tube 6 is installed on the bottom layer. The cover plate C1-5 consists of the cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com