Pearl real time detection and classifying system based on mechanical vision

A machine vision and grading system technology, applied in photogrammetry/video measurement, instruments, sorting and other directions, can solve the problems of slow speed, inability to uniformly classify smoothness and flaws, and high missed detection rate of pearl surface defects. The effect of improving production efficiency, improving product quality and competitiveness, and improving automation and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and embodiment

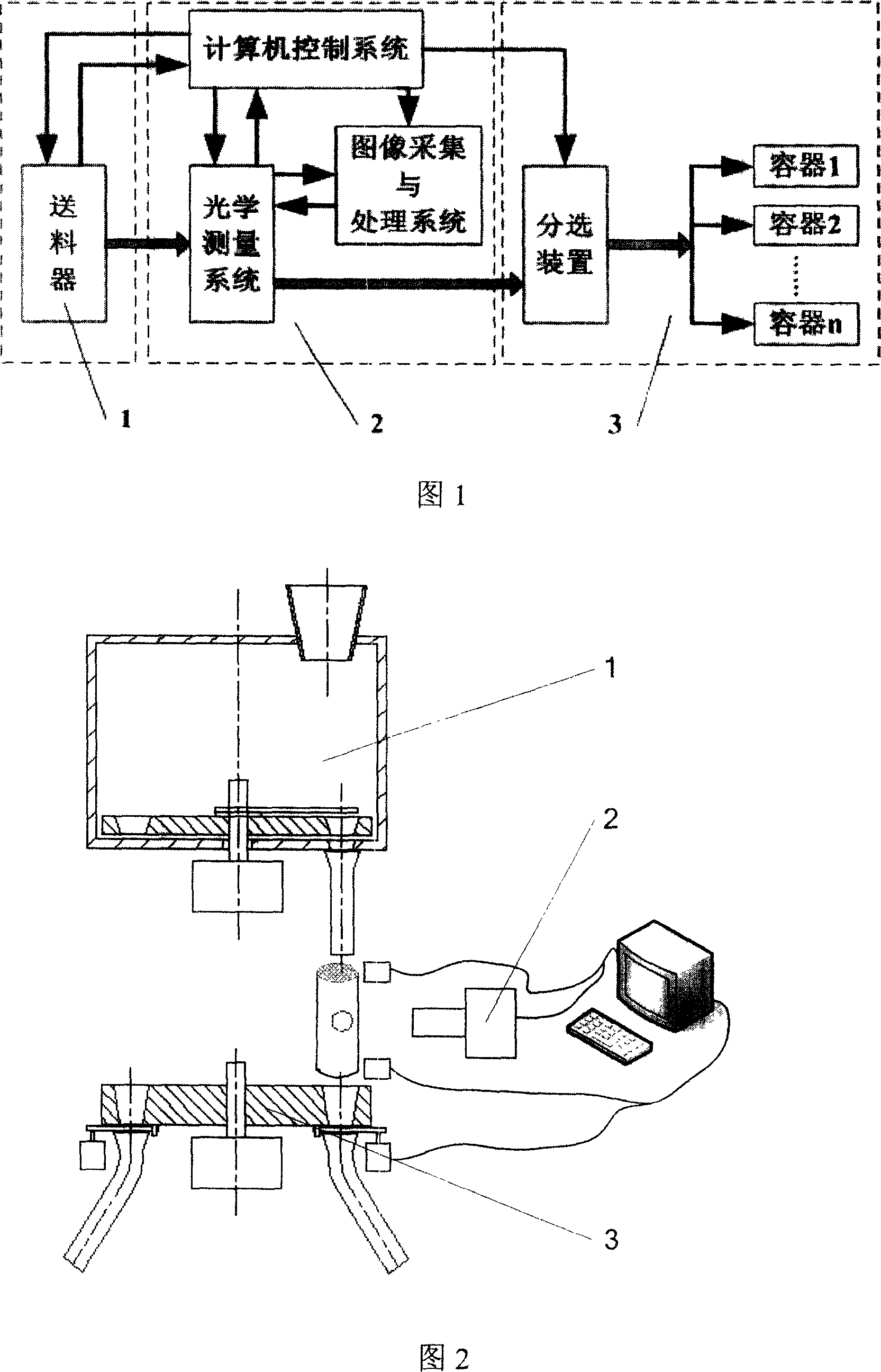

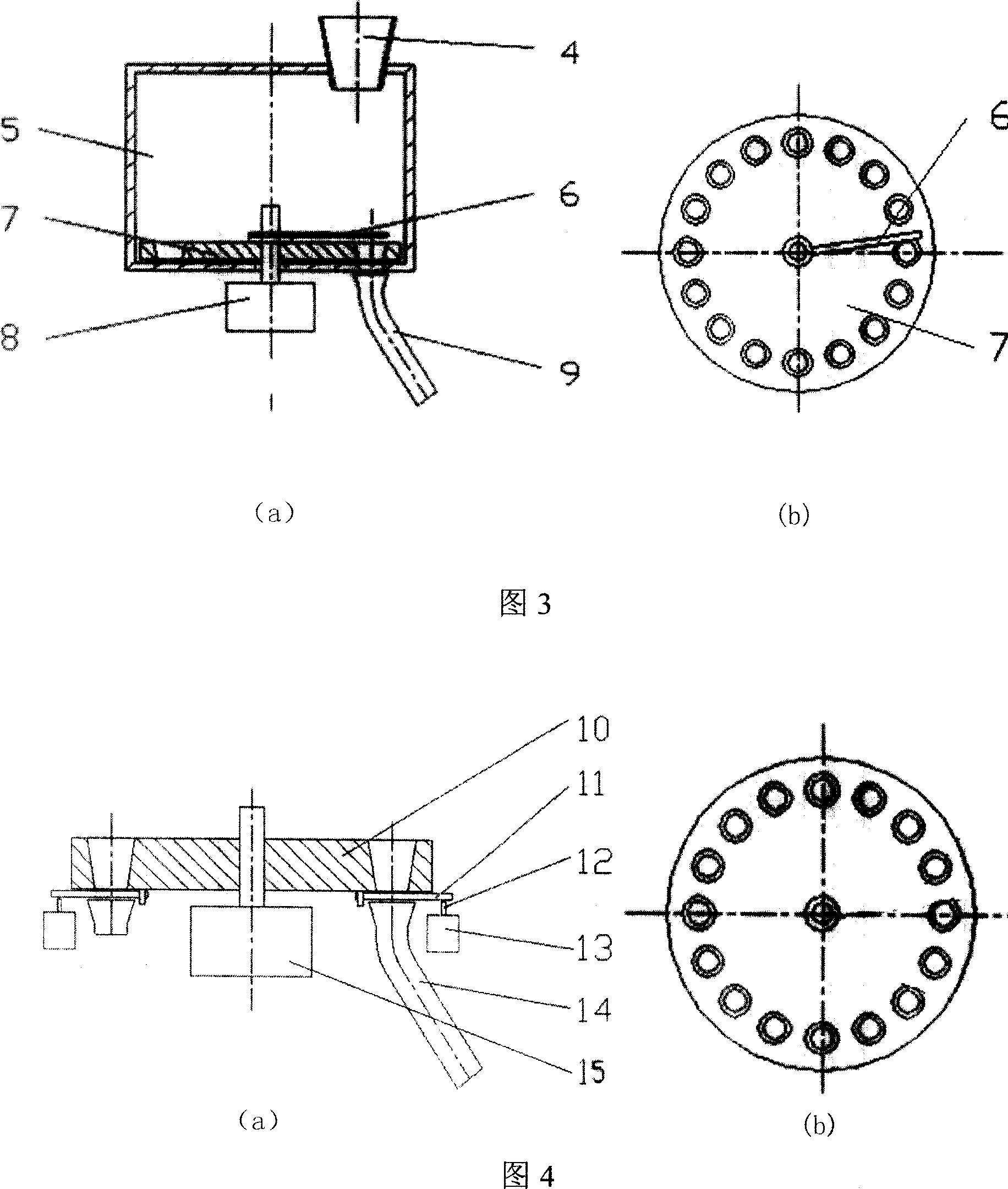

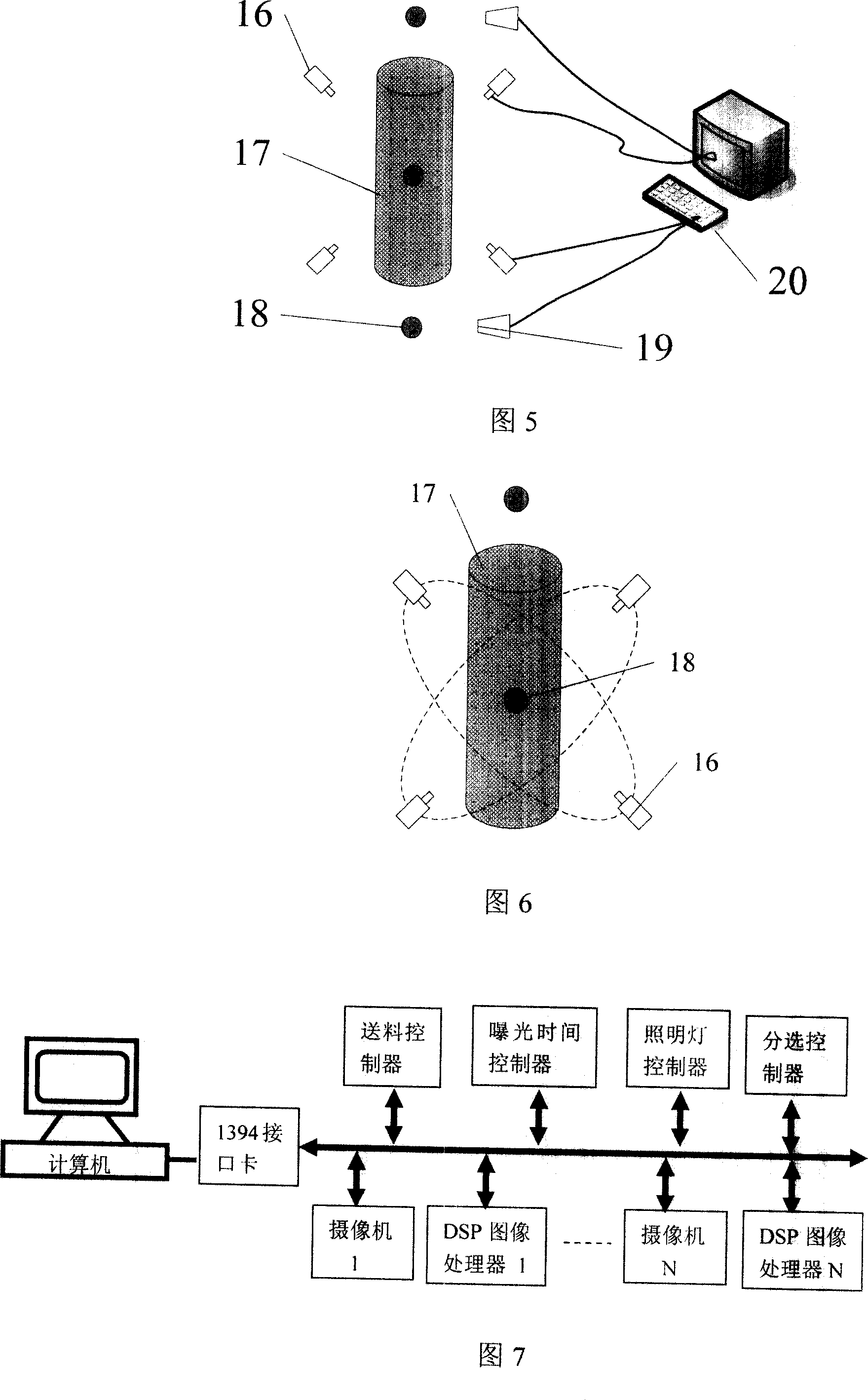

[0021] As shown in FIGS. 1 and 2 , the present invention consists of a pearl feeding device 1 , a computer vision recognition component 2 , and a pearl mechanical grading device 3 . A computer vision recognition unit 2 is arranged below the feeding conduit 9 of the pearl feeding device 1 , and a pearl sorting device 3 is arranged below the computer vision recognition unit 2 . The designed feeding device 1 allows the pearls to enter the imaging area in a free-fall manner, which can ensure that the subsequent computer vision recognition component 2 obtains an image of the entire surface of the pearls. Its working process is: when the pearl falls from the feeding conduit of the feeding device 1, the position sensor 19 is triggered, and the trigger signal is transmitted to the image acquisition unit, and the grading processing software in the computer processes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com