Multi-pulse combined fracturing device for perforation of coalbed methane reservoir

A multi-pulse and combined technology, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve problems that cannot meet the requirements of high and stable production of coalbed methane wells, the inability to realize multi-layer transformation at one time, and low energy utilization rate. Advanced problems, to achieve the effect of improving operability and practicability, expanding the effective desorption range, and improving the seepage channel of coalbed methane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

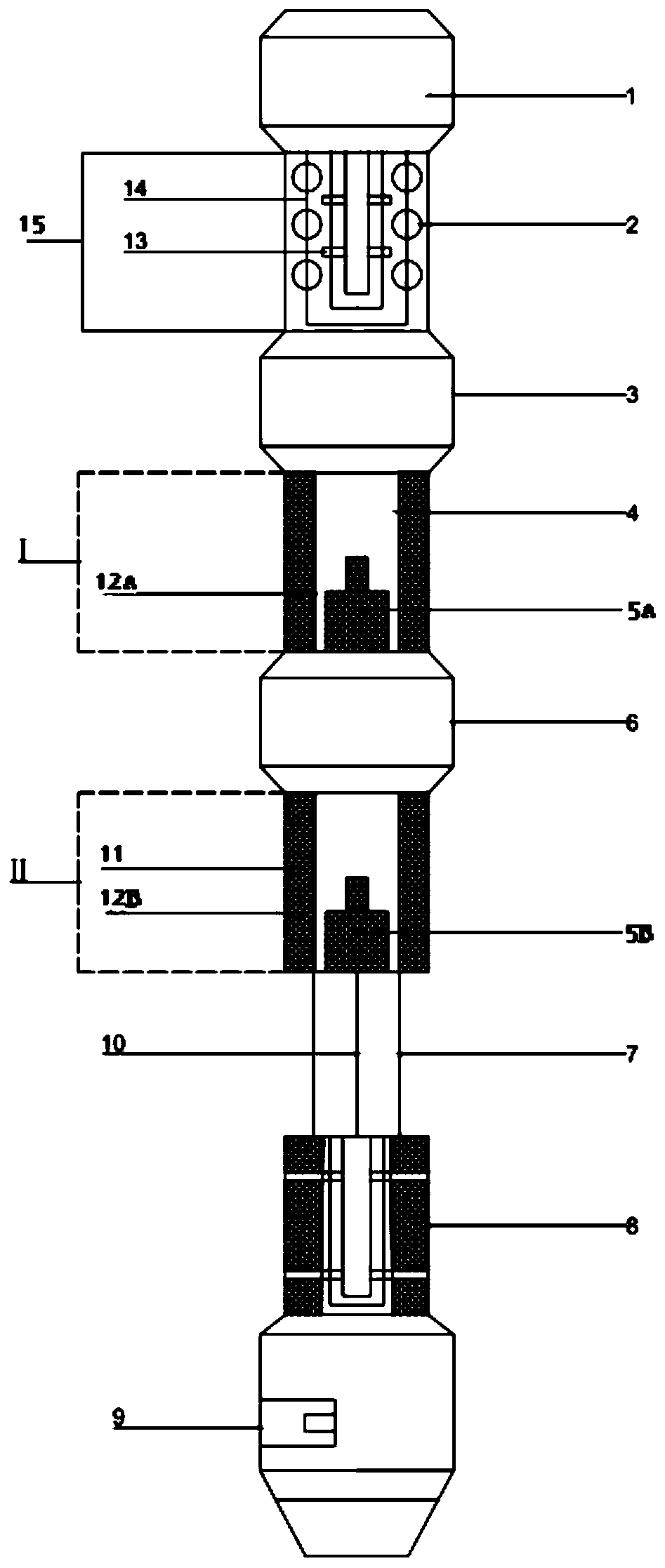

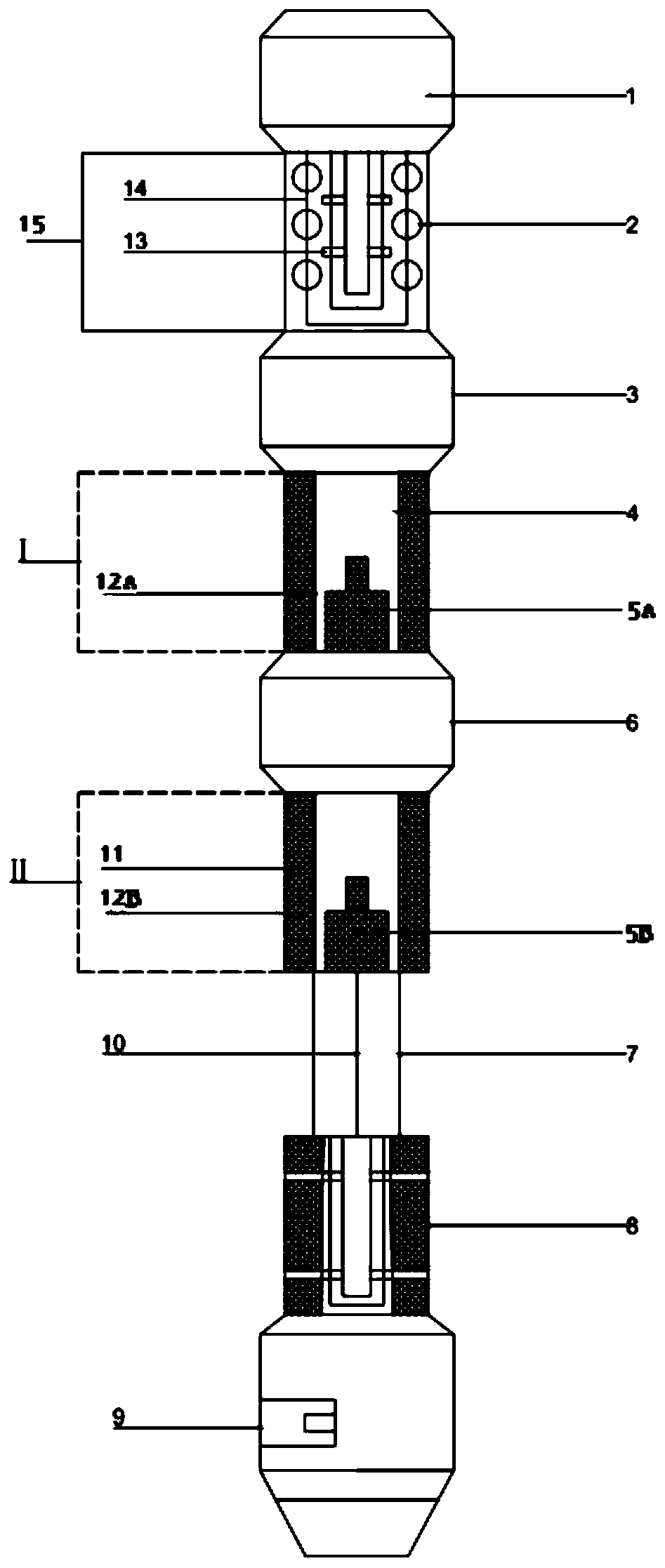

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0013] see figure 1 , a multi-pulse combined fracturing device for coalbed methane layer perforation, including a percussion detonator 1, the lower part of the percussion detonator 1 is connected to a perforating gun barrel 14, and a frame-shaped ammunition rack 13 is arranged inside the perforating gun barrel 14. The ammunition rack 13 is loaded with perforating bullets; the groove of the perforating barrel 14 is embedded with a capsule-wrapped low-detonation velocity liquid explosive 2, and the perforating bullet and the low-detonation velocity liquid explosive 2 are separated by a capsule, thereby realizing the low-detonation velocity liquid explosive 2; the perforating gun barrel 14, the frame-shaped ammunition rack 13, and the low-detonation velocity liquid explosive 2 jointly constitute a composite perforator 15; the lower part of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com