High-energy tamping machine

A technology of tamping machine and liquid gunpowder, which is applied in the direction of sheet pile walls, blasting, construction, etc., can solve the problems of shallow tamping depth, low tamping frequency, large impact vibration, etc., and achieve full combustion, small pollution, and high force Delivers the effect of great depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

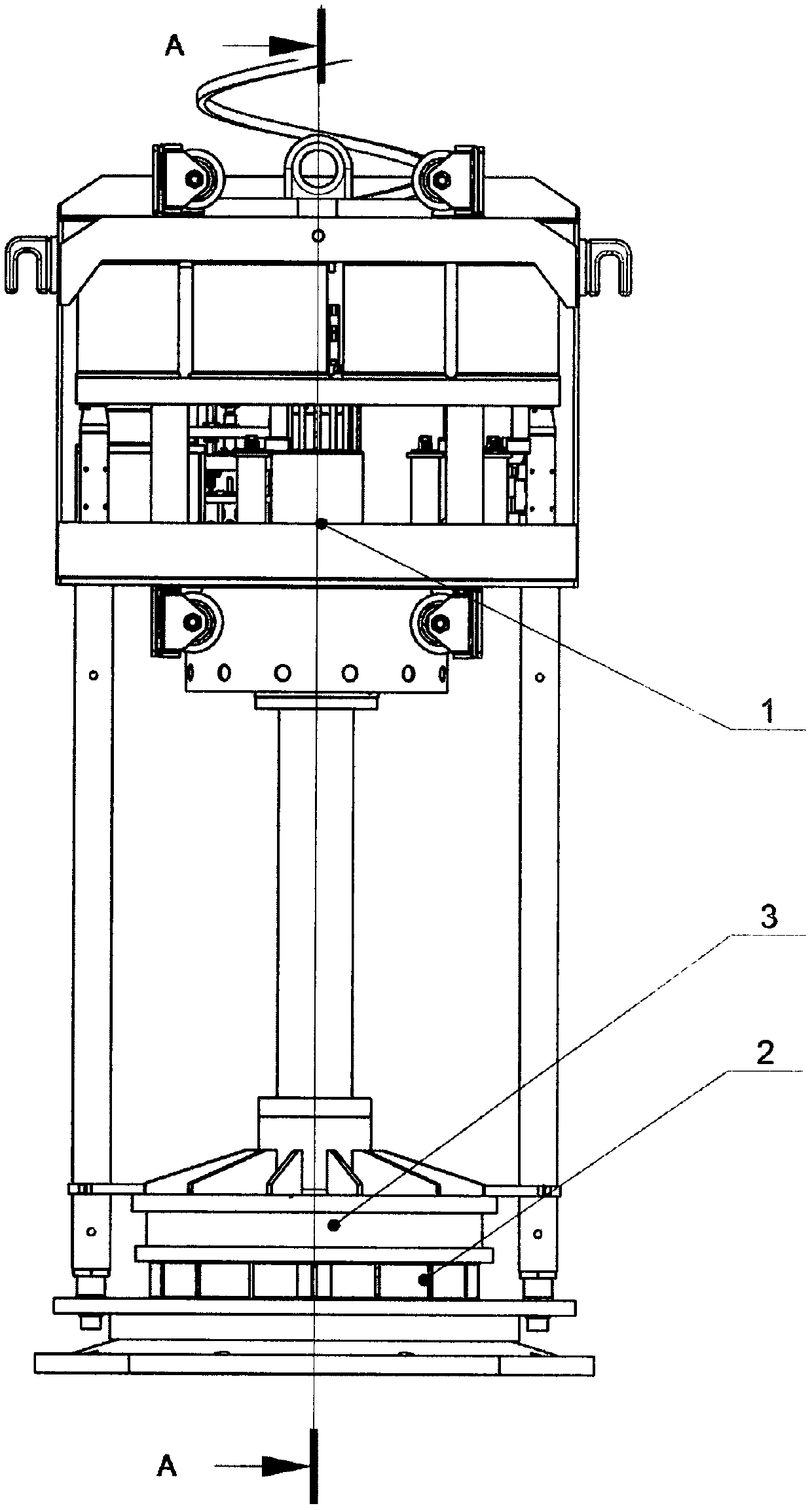

[0016] figure 1 It is a general diagram of a high-energy rammer. It consists of an impact part 1, a pressure part 2 and a buffer 3. The impact part 1 is a moving part up and down, which includes a container for holding liquid gunpowder, a pump for delivering liquid propellant, a one-way valve for injecting liquid gunpowder, a combustion chamber and a hollow tube equivalent to a gun barrel, and a muffler for reducing plosive sound. Hydraulic system and linkage devices, etc.; the pressure part 2 is in contact with the ground, and the force transmitted from above acts on the ground to make the ground compact; the buffer 3 is located in the buffer between the impact part 1 and the pressure part 2 Components, in the static state, the weight of the impact part is borne by the buffer, and the weight of the impact part is transferred to the pressure part, and the pressure part transfers the overall weight to the ground.

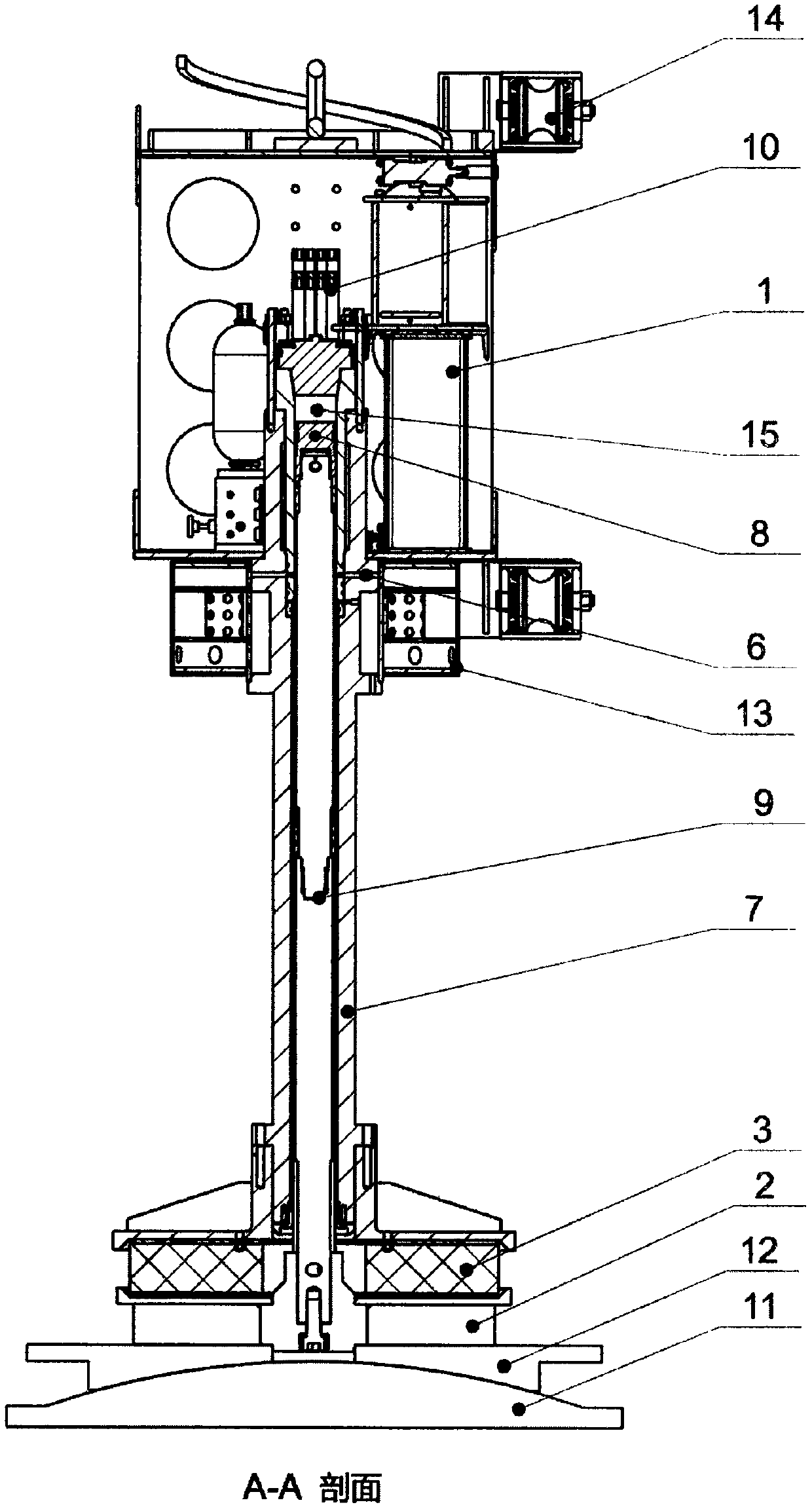

[0017] figure 2 yes figure 1 The A-A section in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com