Constant-temperature melting pressure release slow-release system of missile warhead

A warhead and pressure relief technology, applied to self-propelled bombs, projectiles, offensive equipment, etc., can solve the problems of increasing danger, weakening the structural strength of the warhead, destroying the charge structure of the warhead, etc., and achieving the goal of ensuring safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, it should be noted that the present invention is not limited to following specific embodiment, all equivalent transformations carried out on the basis of the technical solution of the present invention are all within the scope of protection of the present invention.

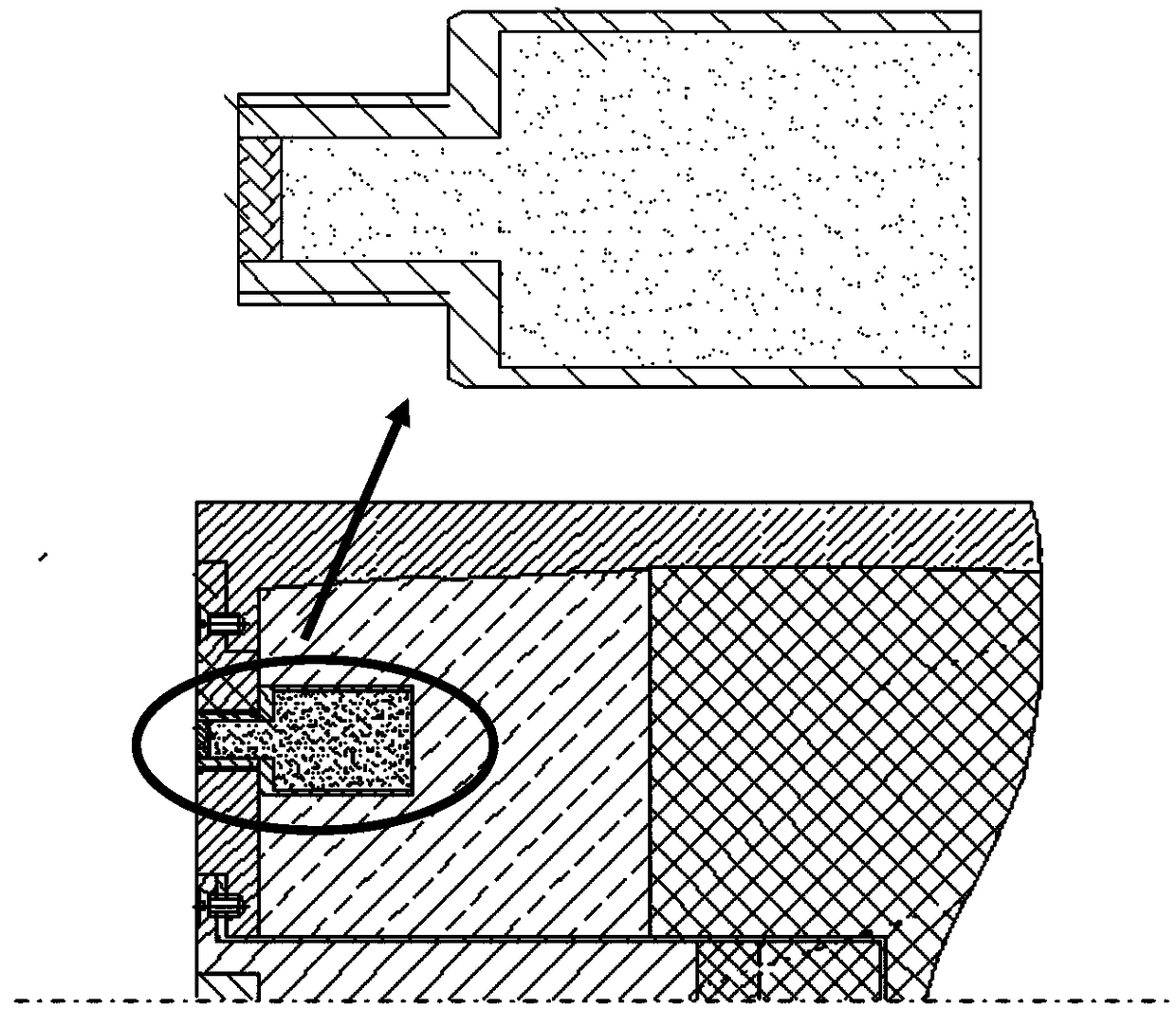

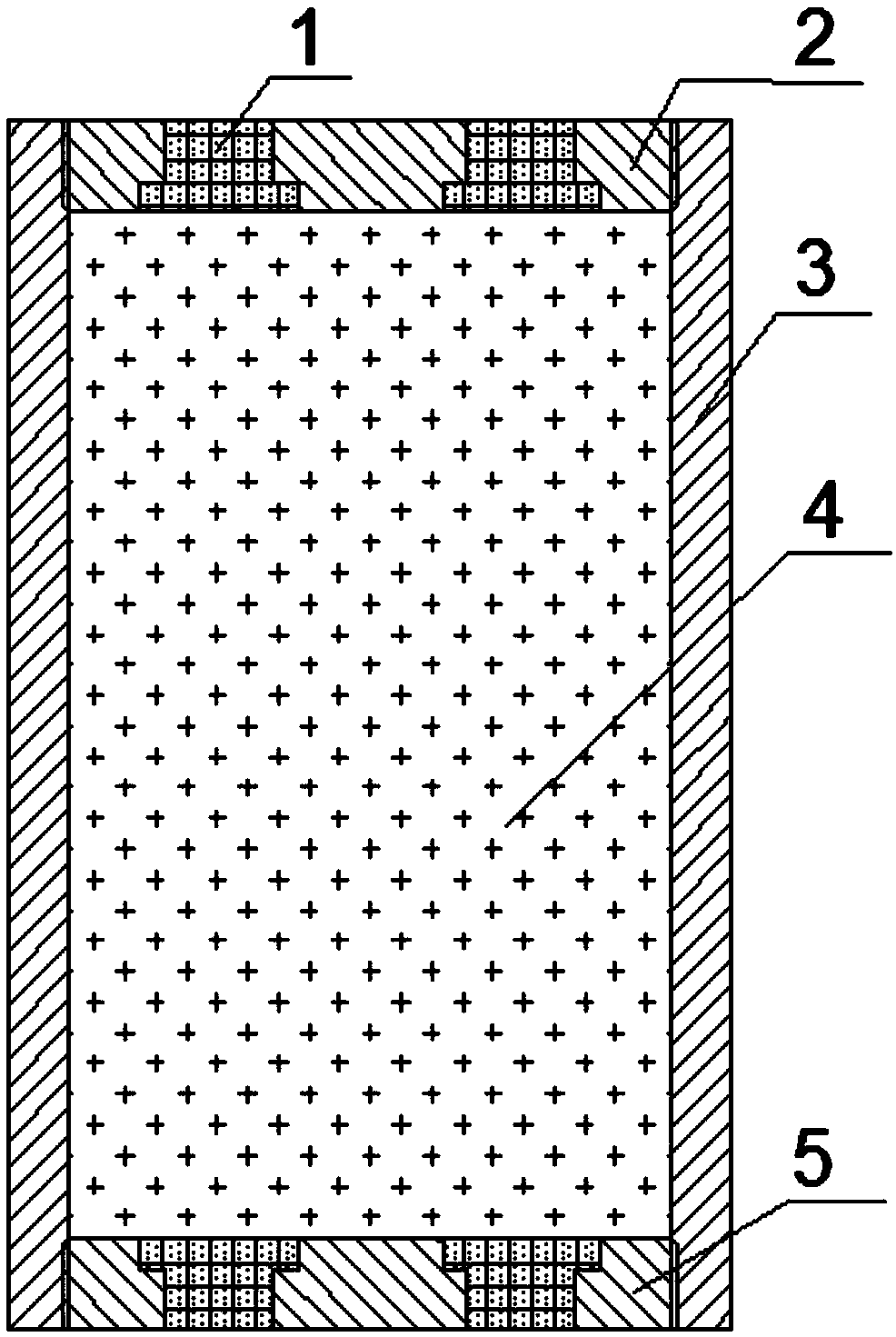

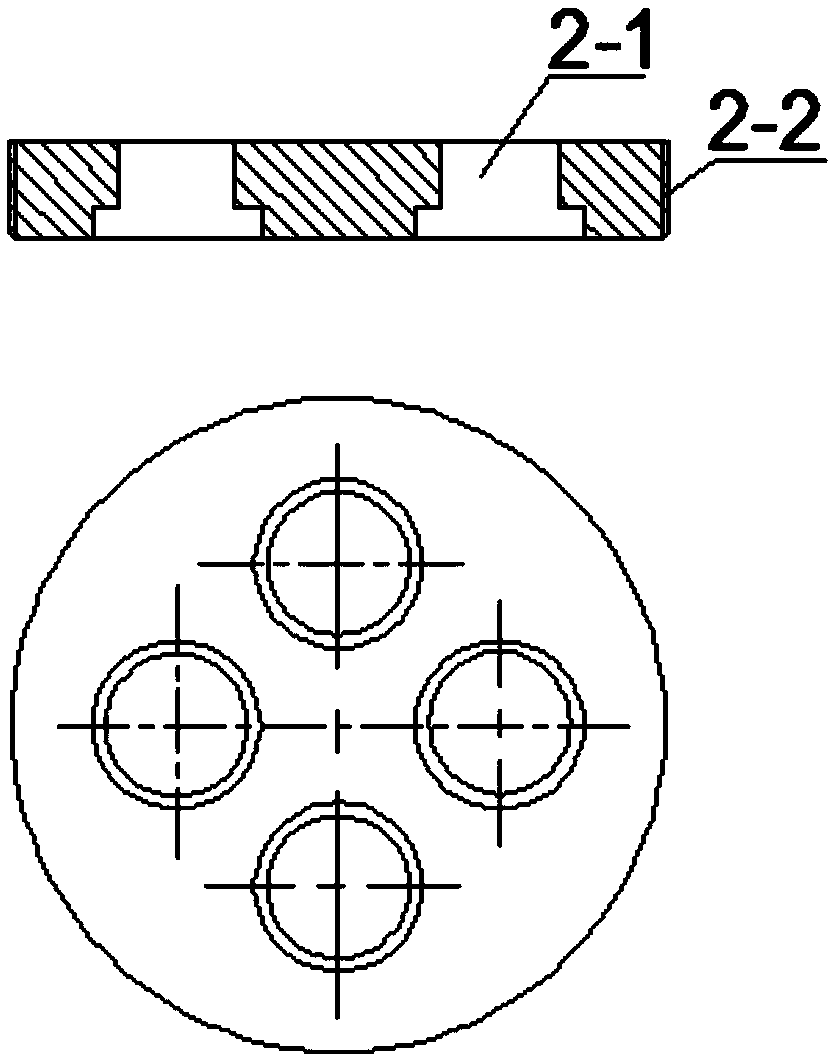

[0017] Comply with the above technical solutions, such as Figure 2-5 As shown, this embodiment provides a missile warhead constant temperature melting pressure relief structure, including a housing 3, a front end cover 2, a pressure relief module 1, a filling 4, and a rear end cover 5; it is characterized in that the housing 3 is a cylindrical sleeve of first-class wall thickness, with a thickness of 6mm, an inner cavity diameter of 125mm, and a height of 260mm. The material is LY12 duralumin. There is an internal thread 1 at one end of the shell 3, and an internal thread 2 at the other end; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com