Patents

Literature

109results about How to "Reduce structural stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

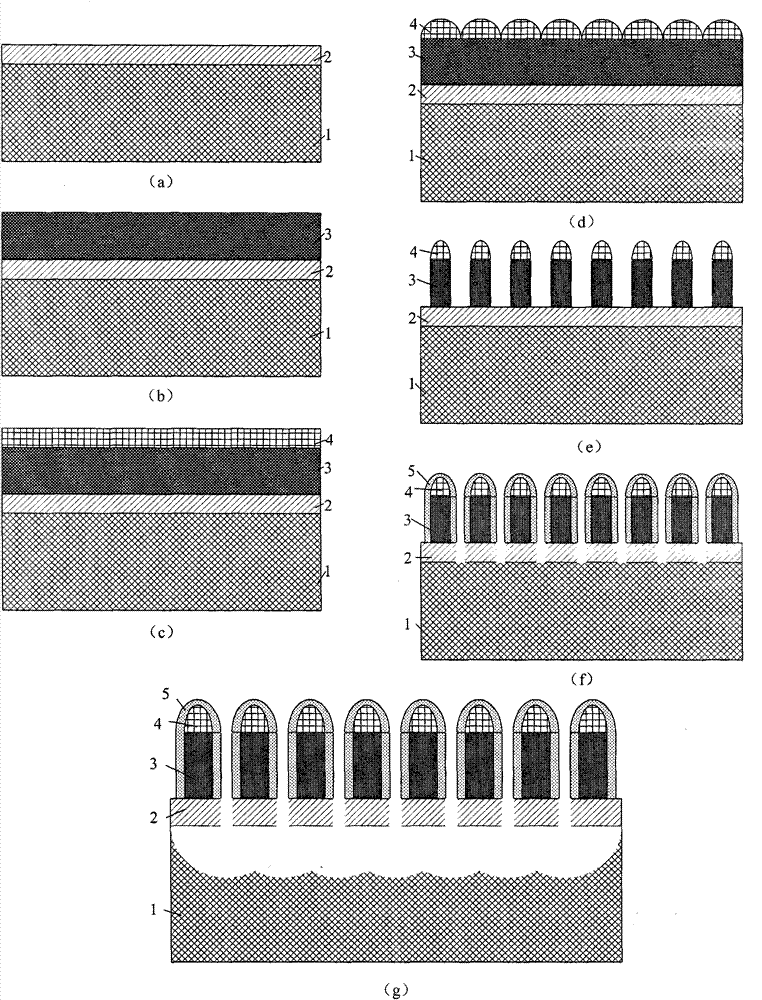

Microsilicon microphone and its preparing method

InactiveCN1684546AHigh strengthPrevent Waveform DistortionElectrets selectrostatic transducerCapacitanceCapacitor

This invention provides a micro-silicon microphone and its preparation method, in which, said microphone includes a monocrystal silicon film and polysilicon film as the capacitor pole plates, the polysilicon film is a movable pole plate, several release holes are set on the monosilicon film and rib reinforcement structures are formed on the polysilicon film, the rib reinforcement structure is corresponding to the release hole on the monocrystal silicon film and inlayed in the release holes. The preparation method utilizes ICP technology to carry out deep bar etching to either get the release holes or realize polysilicon films with the rib reinforcement structure.

Owner:PEKING UNIV

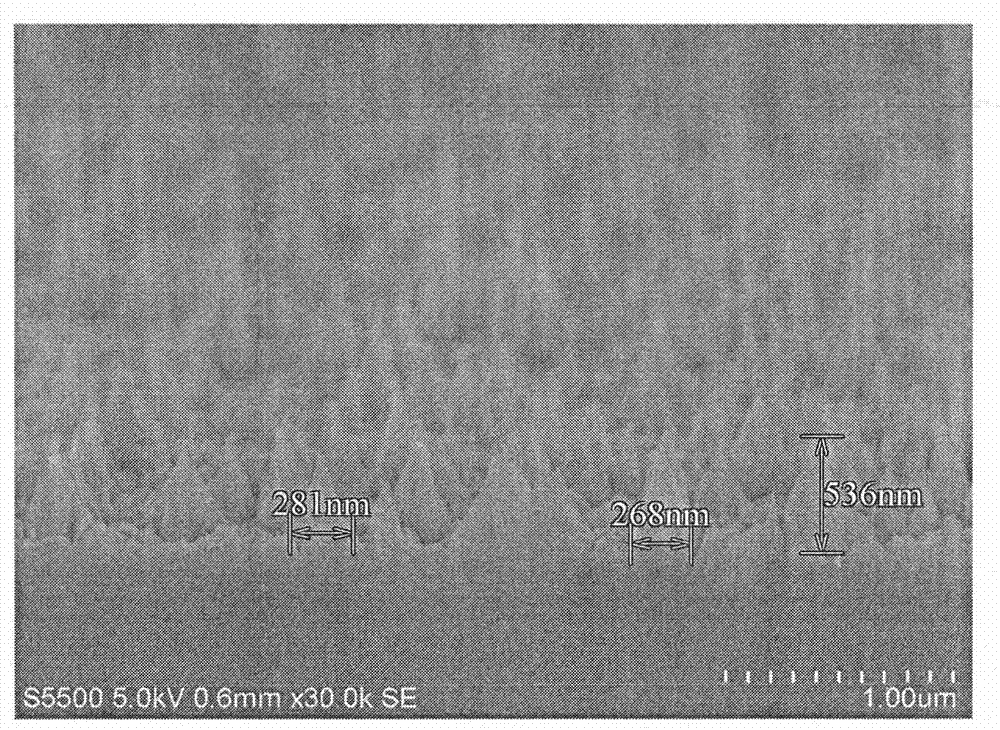

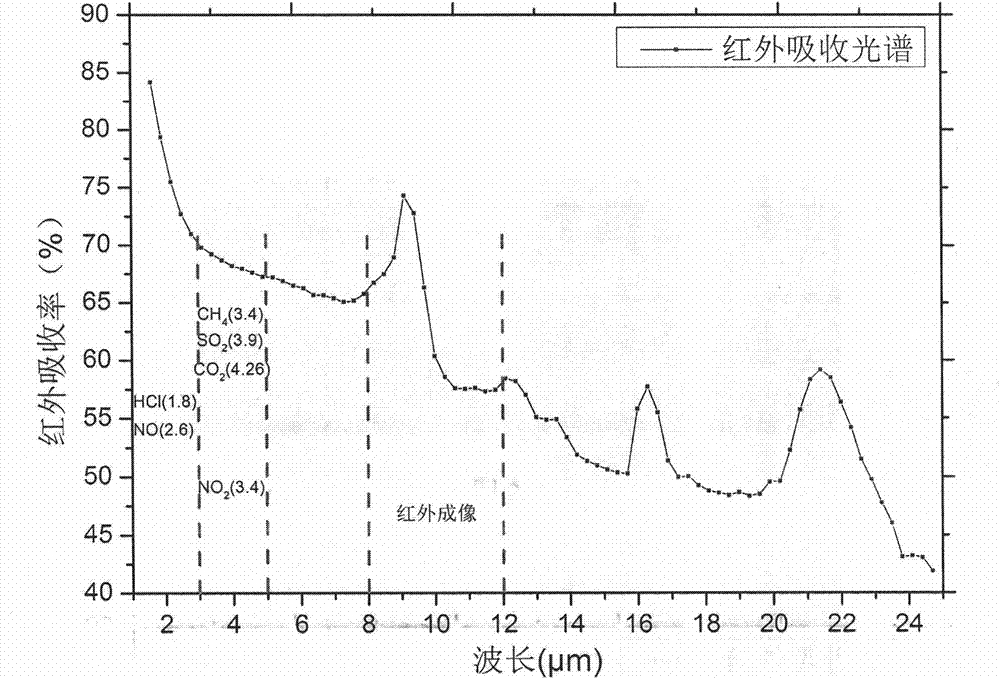

Integratable nanostructure infrared light source

ActiveCN103500788AReduce heat lossReduce structural stressTelevision system detailsImpedence networksManufacturing technologySurface plasmonic resonance

The invention discloses an integratable nanostructure infrared light source. According to the integratable nanostructure infrared light source, the surface of amorphous silicon is subjected to nano-modification processing by using an MEMS / CMOS (Micro-Electro-Mechanical System / Complementary Metal Oxide Semiconductor) process so as to form tapered nanostructures, and then, the tapered nanostructures are subjected to TiN cladding processing; finally, a silicon substrate is subjected to deep silicon etching by using a front XeF2 release technology, and a narrowband infrared light supply is separated from being in contact with the silicon substrate, so that the heat loss during Ohmic heating of silicon wires is reduced, and the operating power of the light source is increased. According to the integratable nanostructure infrared light source, an MEMS / CMOS light source manufacturing technology is adopted, the surface modification for the infrared light source is realized by using a metal-induced crystallization technology so as to obtain the tapered nanostructures, and the tapered nanostructures are subjected to surface TiN cladding processing, so that a surface plasma resonance technology for Si-TiN and TiN-Air is realized; micro cantilevers are formed by adopting a front release technology and support the infrared light source so as to reduce heat loss, and the structure stress is lowered through pre-burying a dielectric layer, namely silicon nitride, below a heating layer.

Owner:ZHONGBEI UNIV

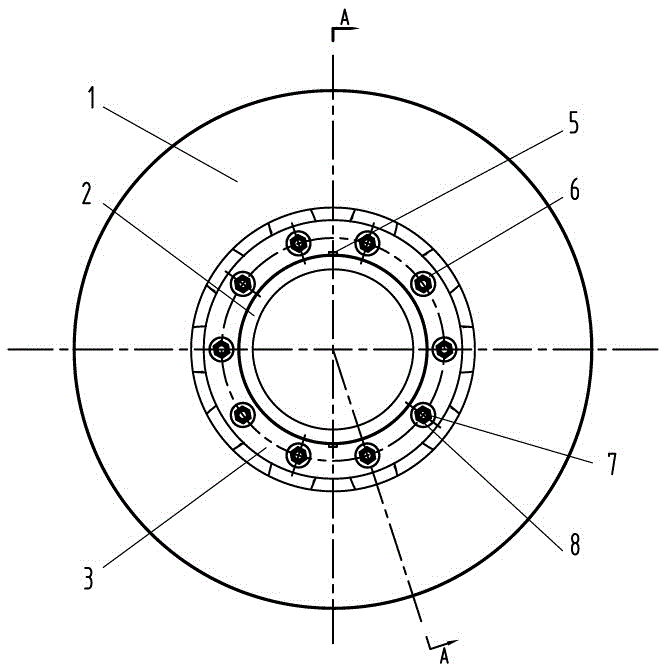

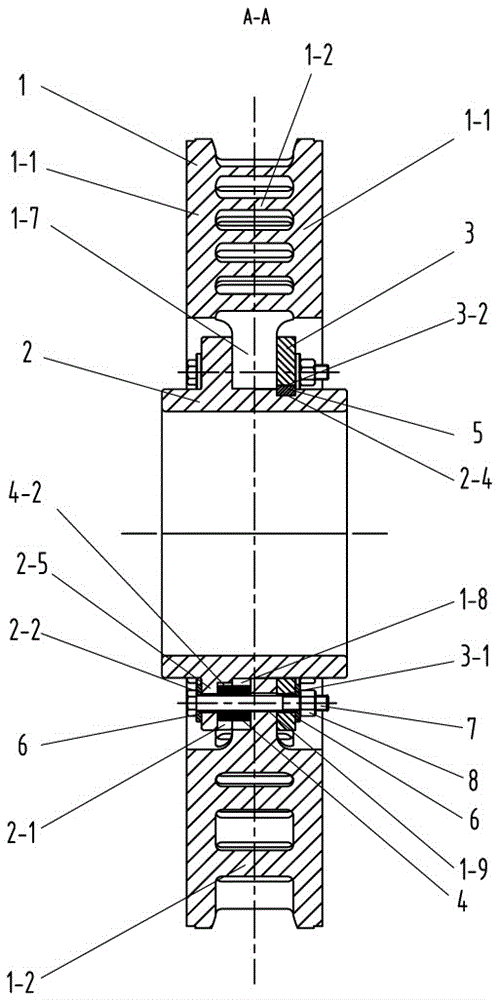

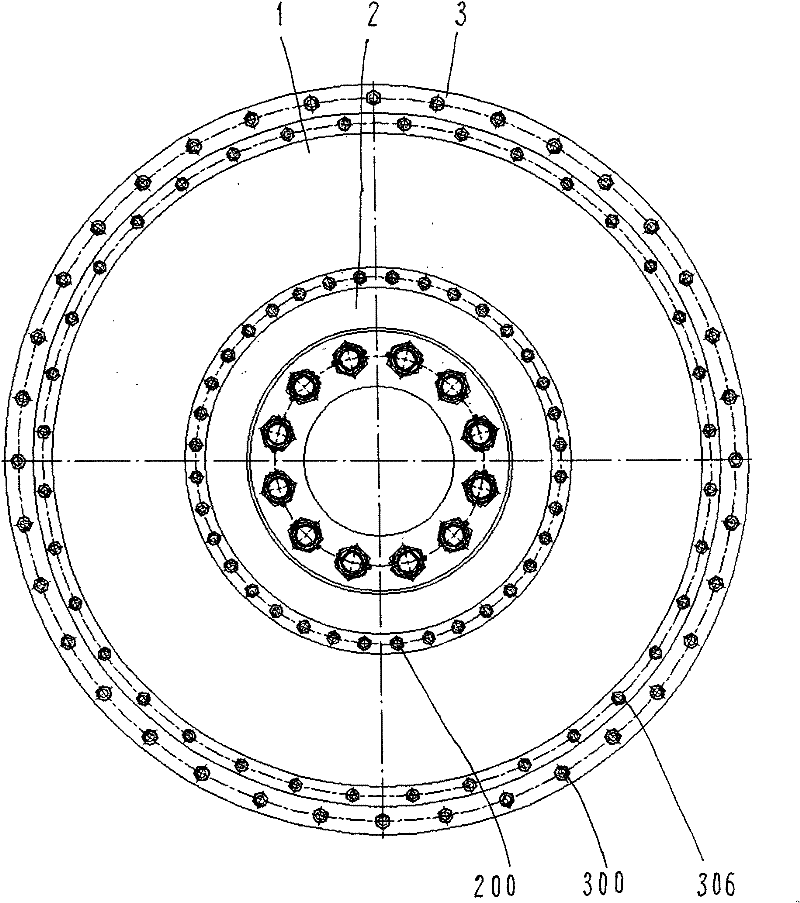

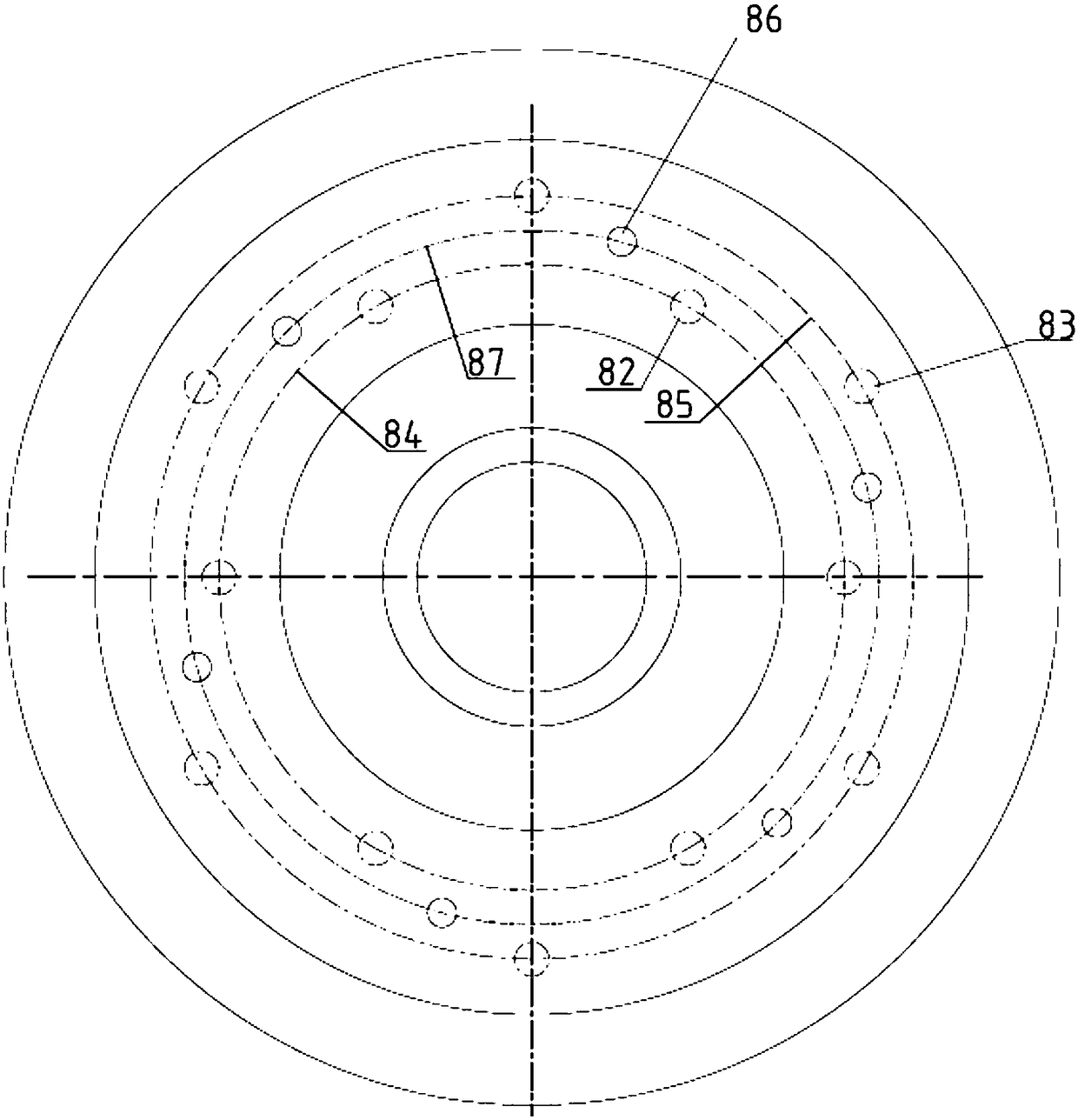

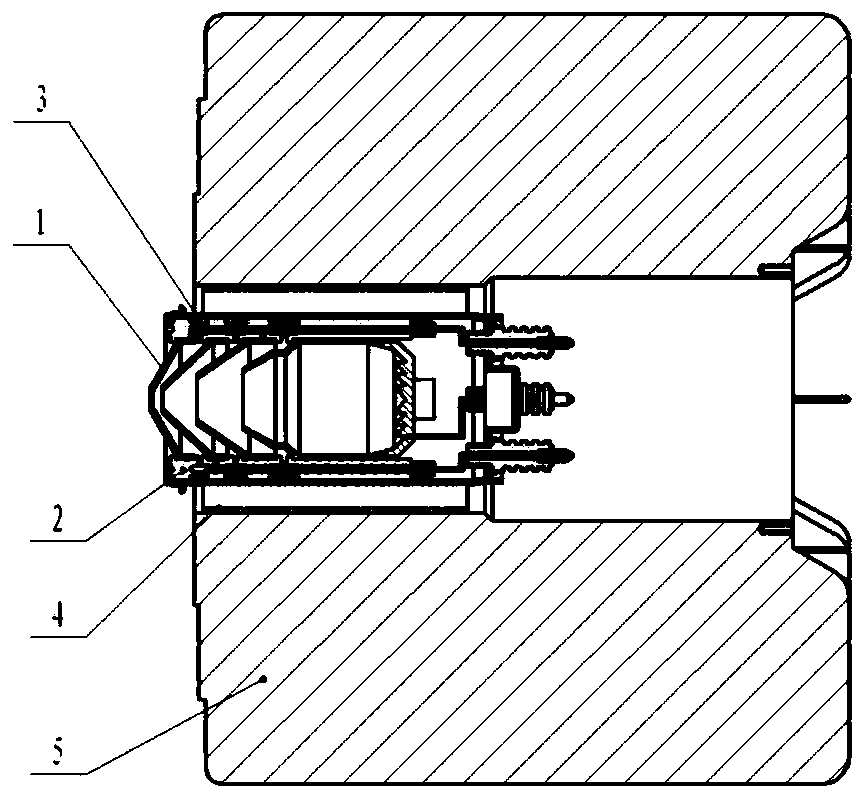

Shaft-mounted brake disc

The invention discloses a shaft-mounted brake disc used for a rail traffic vehicle. The shaft-mounted brake disc comprises a disc body, a hub, space rings, sliding blocks, locating keys, spacers, bolts and nuts; the disc body comprises two friction rings, radiation ribs and a plurality of connecting claws, wherein the radiation ribs are placed in the radial direction of the friction rings and arranged in multiple circles from inside to outside and the connecting claws are placed on the inner circles of the friction rings and arranged in the peripheral direction; each connecting claw is provided with a radial disc body sliding block groove; each hub flange is provided with a radial hub upper sliding block groove; the sliding blocks are correspondingly arranged inside the disc body sliding block grooves and the hub upper sliding block grooves; after installation, the sliding block force transferring faces of the sliding blocks are matched with the force transferring faces of disc body sliding blocks and the force transferring faces of hub upper sliding blocks; each bolt sequentially penetrates through various bolt holes in a loose fit mode and is locked through the corresponding spacer and the corresponding nut; and the shaft-mounted brake disc is high in connection reliability and good in ventilation and heat dissipation performance.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

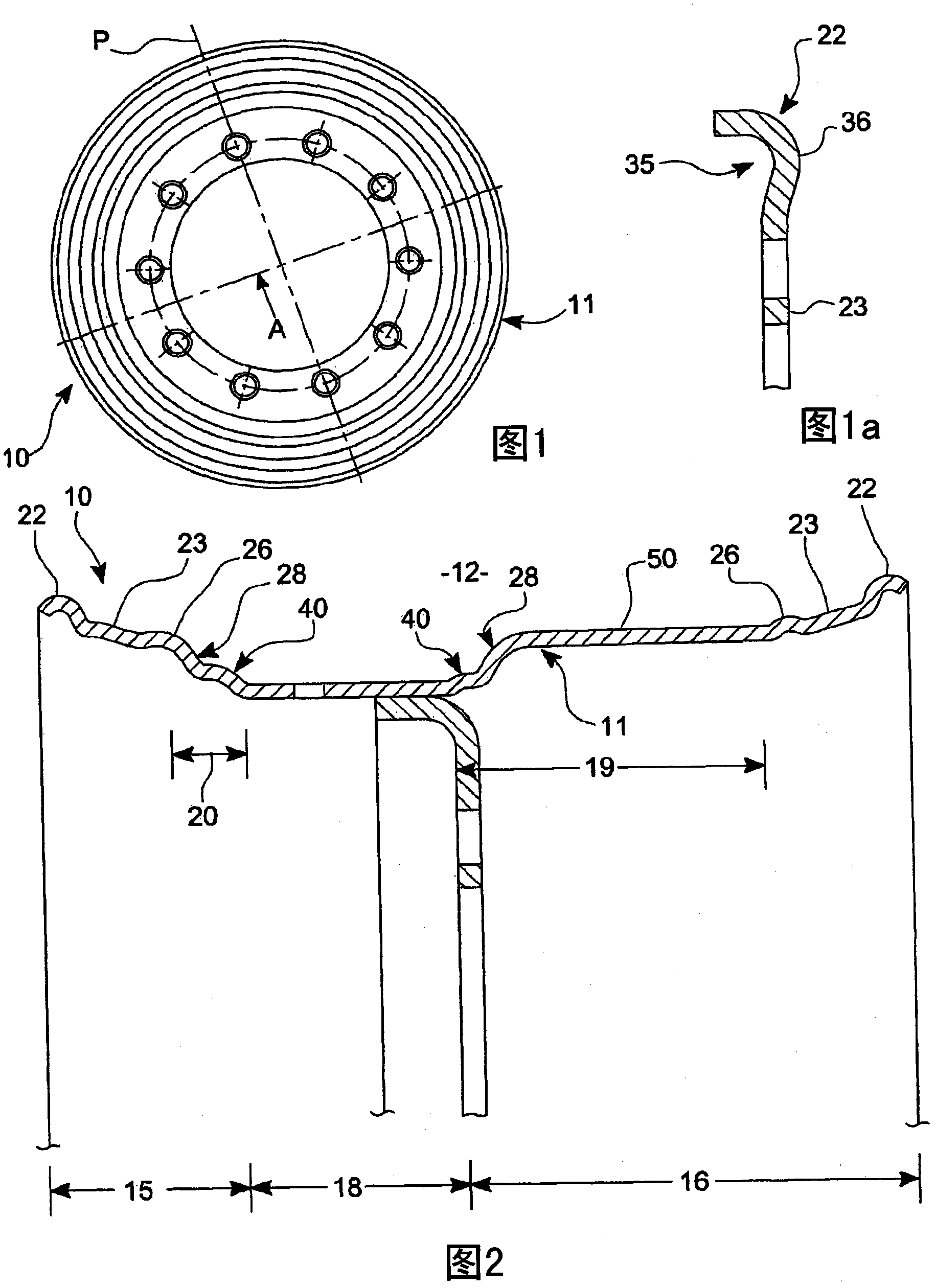

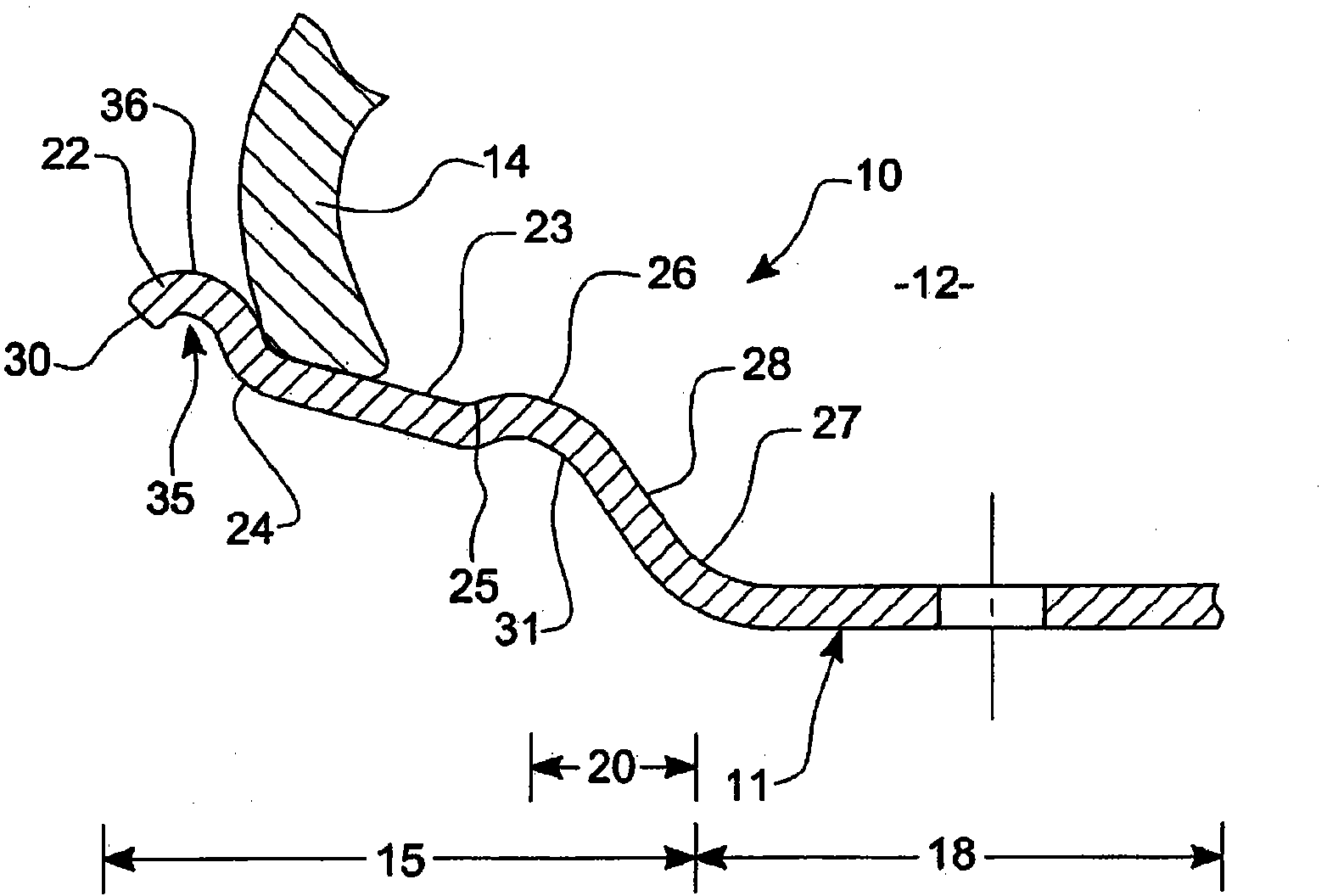

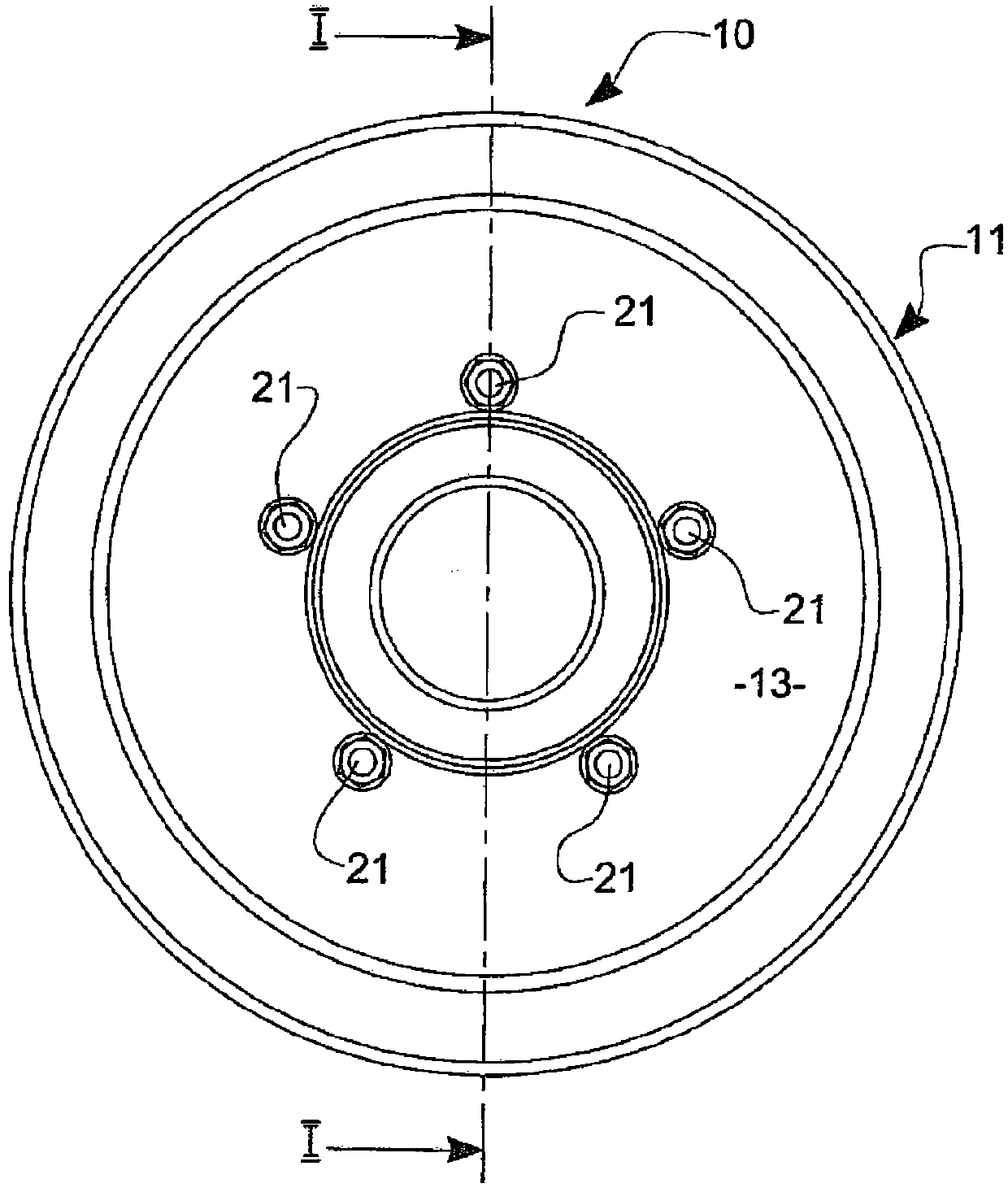

Wheel construction

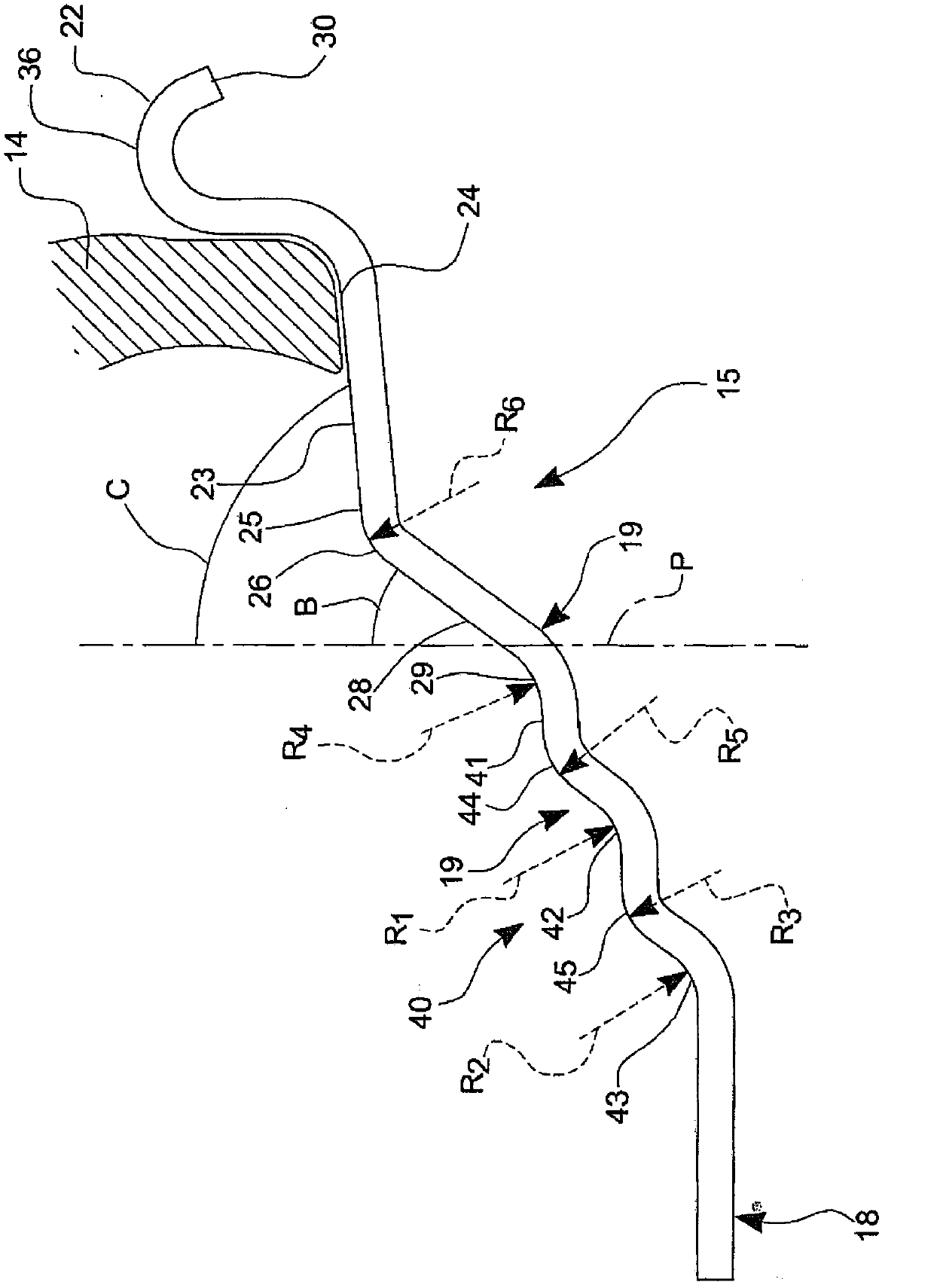

A wheel construction (10) includes a wheel rim (11) which in use receives a (tyre 14), the rim (11) having axially inner and outer portions (16, 15), and a mid-portion (18) between them, and each axially inner and outer portion (16, 15) providing a flange (22), a connecting surface (23) adjoining the flange (22) and extending axially towards the mid portion (18), the flange (22) and a part of theconnecting surface (23) providing a seat for a bead of the tyre (14), and there being a side part (19, 20) between the connecting surface (23) and the mid portion (18), and wherein for at least one of the inner and outer portions (16, 15), the connecting surface (23) is a frusto-conical having an axial end (24) of greatest radius and an axial end (25) of least radius, the connecting surface (23),at its axial end of greatest radius (24), adjoining the flange (22), and the axial end (25) of least radius adjoining a circumferentially extending convex surface (26) which extends radially outwardly of the wheel axis A beyond the end (25) of least radius of the adjoining frusto-conical connecting surface (23), and the side part (19, 20) of the at least one of the axially inner and outer portions (16,15) including a generally frusto-conical region (28) and a curved region (40), the curved region (40) including first and second axially spaced circumferentially extending concave surfaces (41, 42), and the curved region (40) adjoining the end of least radius of the frusto- conical region (28) and the mid-portion (18).

Owner:GKN OFFHIGHWAY LTD

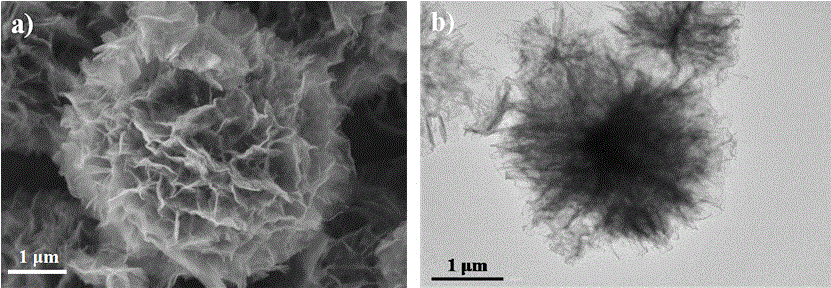

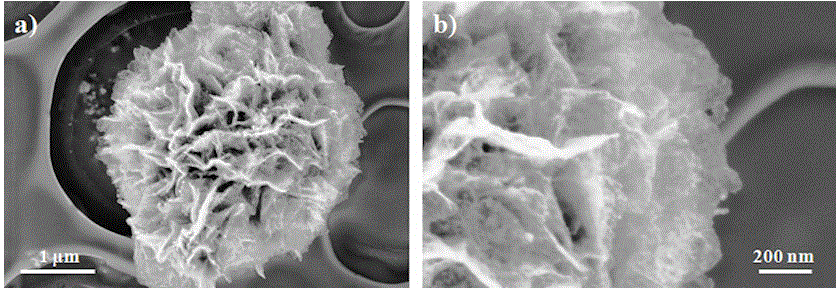

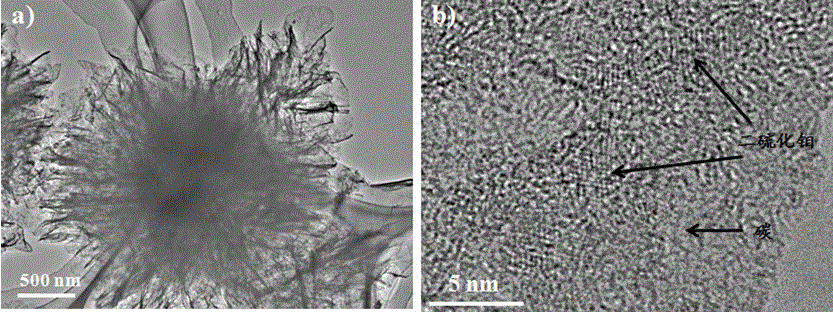

Composite material of flower-like carbon-loaded MoS2 nanoparticles and preparation method and application thereof

InactiveCN106058206AImprove cycle stabilityImprove current withstand capabilityCell electrodesSecondary cellsAcid etchingHigh energy

The invention belongs to the field of energy storing materials, in particular to a composite material for flower-like carbon-loaded MoS2 nanoparticles and a preparation method and application thereof. The preparation method comprises the following steps: performing high-temperature thermal treatment and acid etching by taking flower-like ZnO as a template and taking biomass as a precursor through a simple hydrothermal method to obtain a flower-like carbon substrate; performing solvent thermal treatment on flower-like carbon and ammonium tetrathiomolybdate to obtain the composite material in which the MoS2 nanoparticles are uniformly loaded on the flower-like carbon. The prepared composite material has high energy storing capacity, superior cycling stability and superior rate capability when being taken as a negative electrode material of a lithium battery. Biomass with a wide source is taken as the flower-like precursor, and a hydrothermal and solvent-thermal two-step method is adopted; the composite material has the advantage of easiness in operation, low production cost, low environmental pollution, easiness in bath production and large-scale production, good industrial production basis and wide application prospect.

Owner:FUDAN UNIV

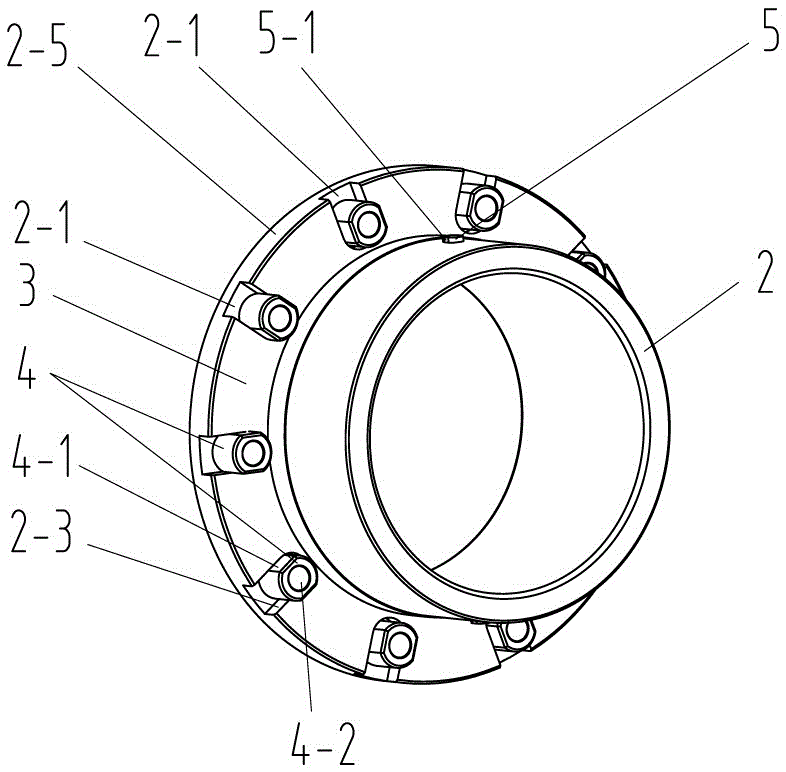

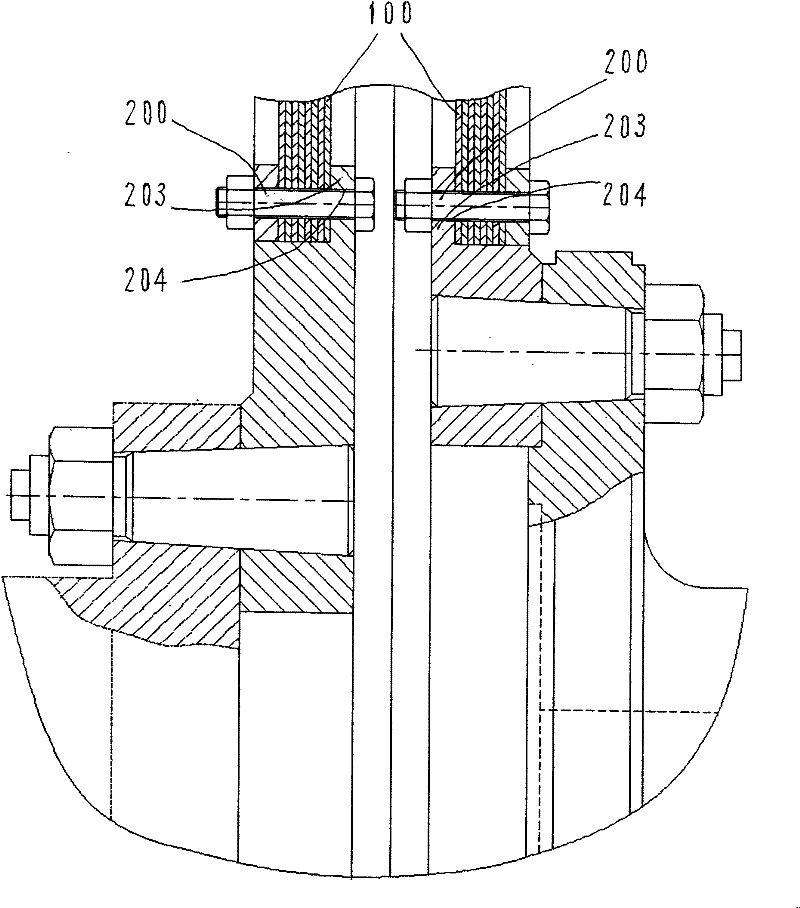

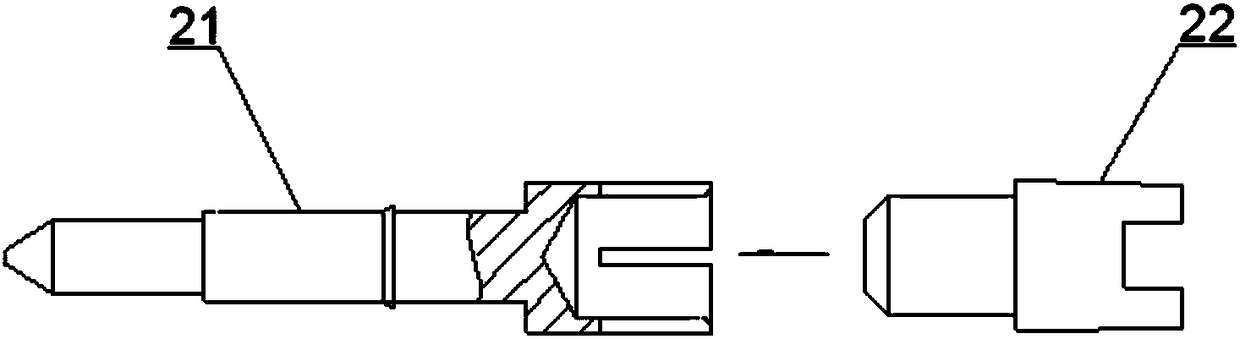

Low-stiffness large-torsion metal film type coupling

The invention relates to a low-stiffness large-torsion metal film type coupling, and the coupling is mainly used for improving the coupling compensation axis offset capability. The technical proposals adopted by the invention is as follow: the coupling is provided with at least two metal film sets, two inner flanges and two external clamping rings, wherein the inner edge of one metal film set is fixedly connected with one of the inner flanges and the outer edge of one metal film set is fixedly provided with one external clamping ring; the inner edge of the other metal film set is fixedly connected with the other inner flange and the outer edge of the other metal film set is fixedly connected with the other external clamping ring; and the two external clamping rings are fixedly connected into a whole so as to form one single-row low-stiffness large-torsion metal film type coupling, and the coupling is suitable for transmission of different types of large-torsion shaftings.

Owner:704TH RES INST OF CHINA SHIPBUILDING IND CORP

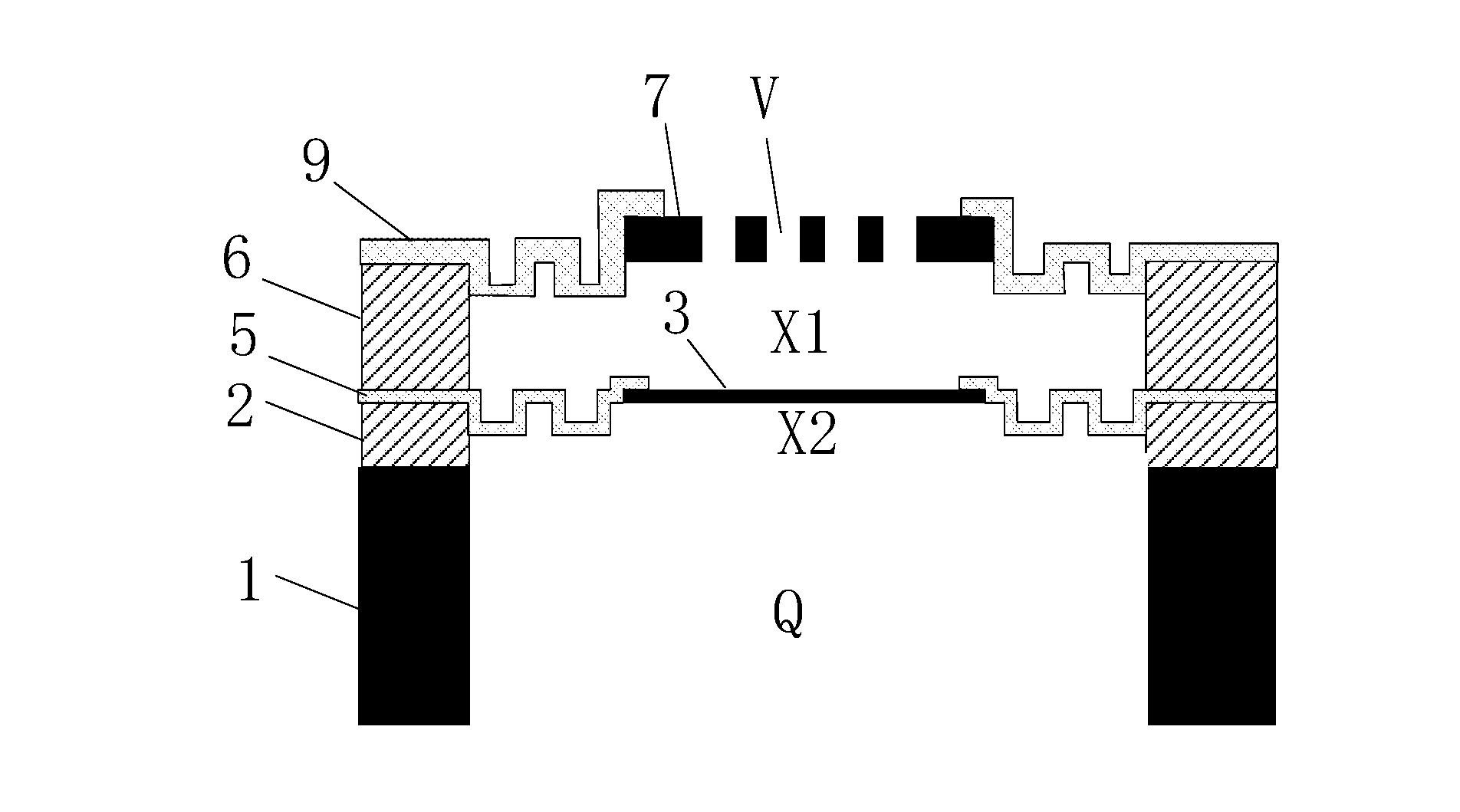

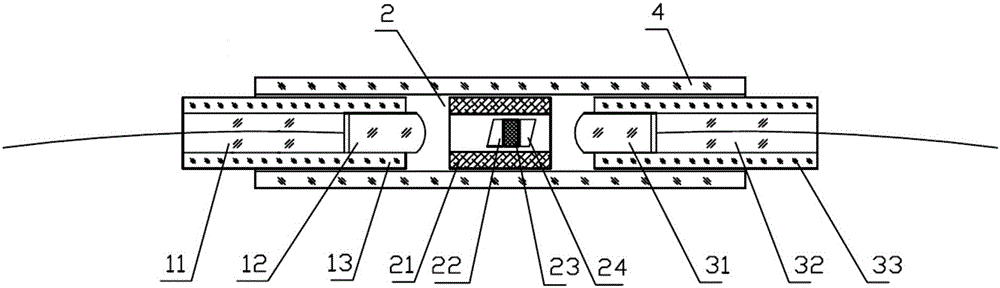

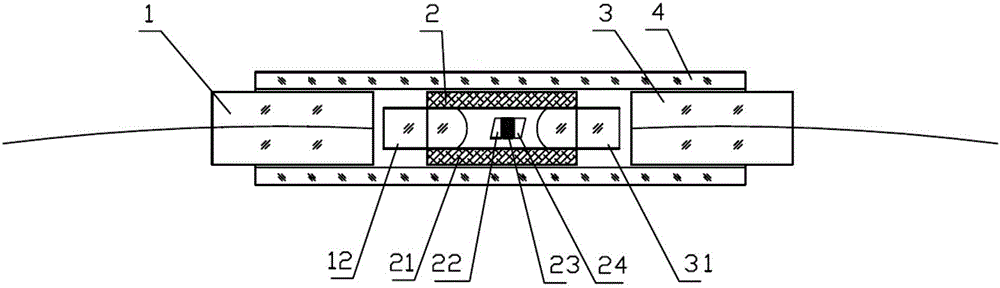

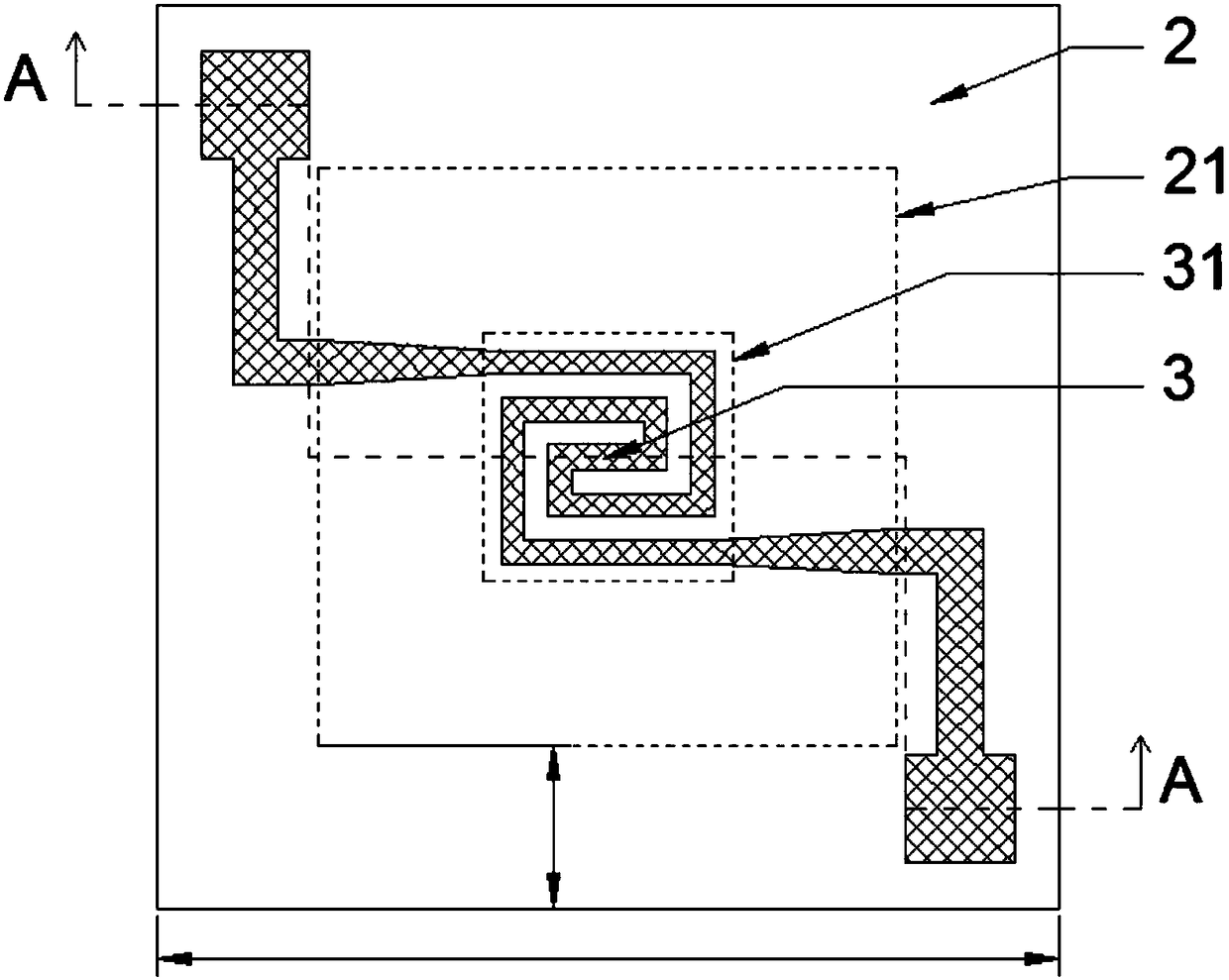

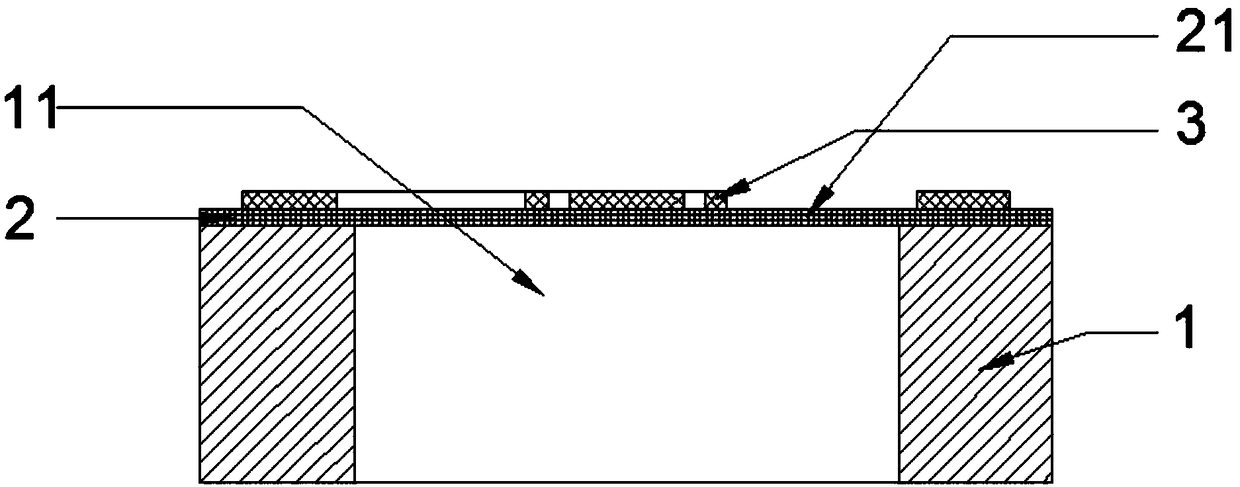

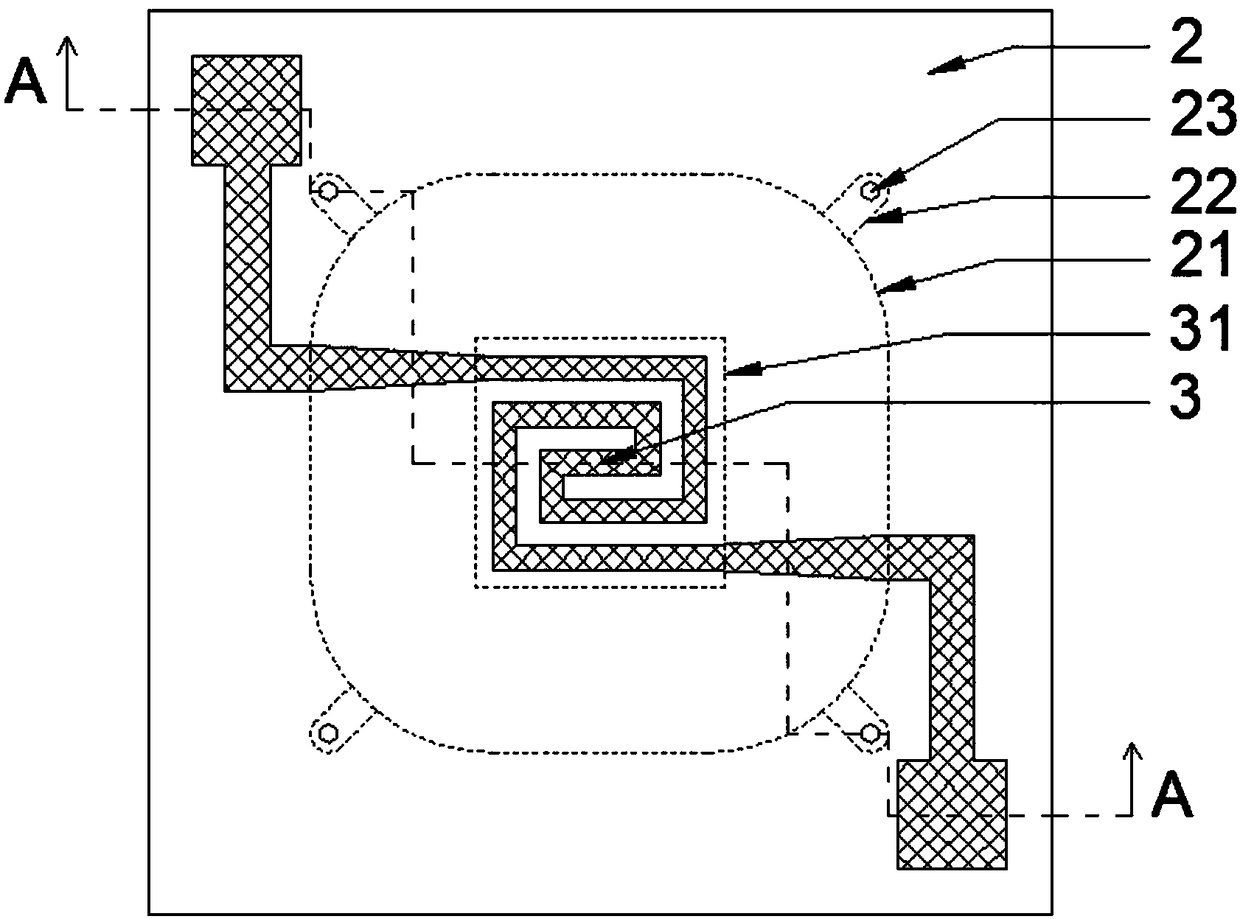

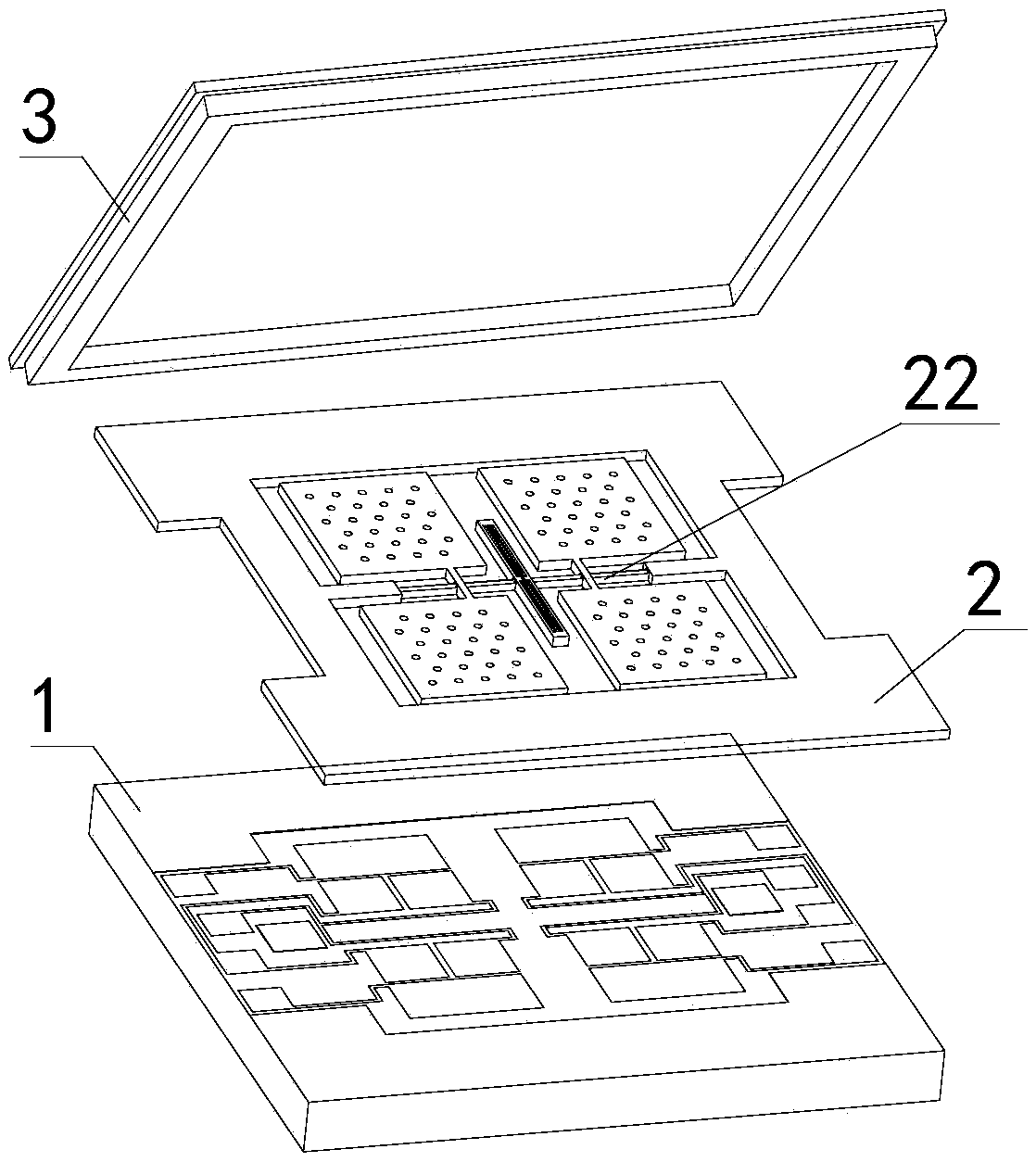

Capacitive silicon microphone and fabrication method thereof

ActiveUS20160286317A1Efficient releaseOvercome non-uniformity of stressMicrophonesLoudspeakersDielectric layerSilicon

A capacitive silicon microphone comprises: a first dielectric layer sets on a substrate with a back cavity, a lower polar plate which is located over the back cavity, a first elastic member of which an inner edge is connected with the edge of the lower polar plate and an outer edge is located on the upper surface of the first dielectric layer, a second dielectric layer which is located on the outer edge of the first elastic member and right above the first dielectric layer, an upper polar plate which has a plurality of release holes and is formed above the lower polar plate with an air gap in between, a second elastic member of which an inner edge is connected with the edge of the upper polar plate and an outer edge is located on the upper surface of the second dielectric layer.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

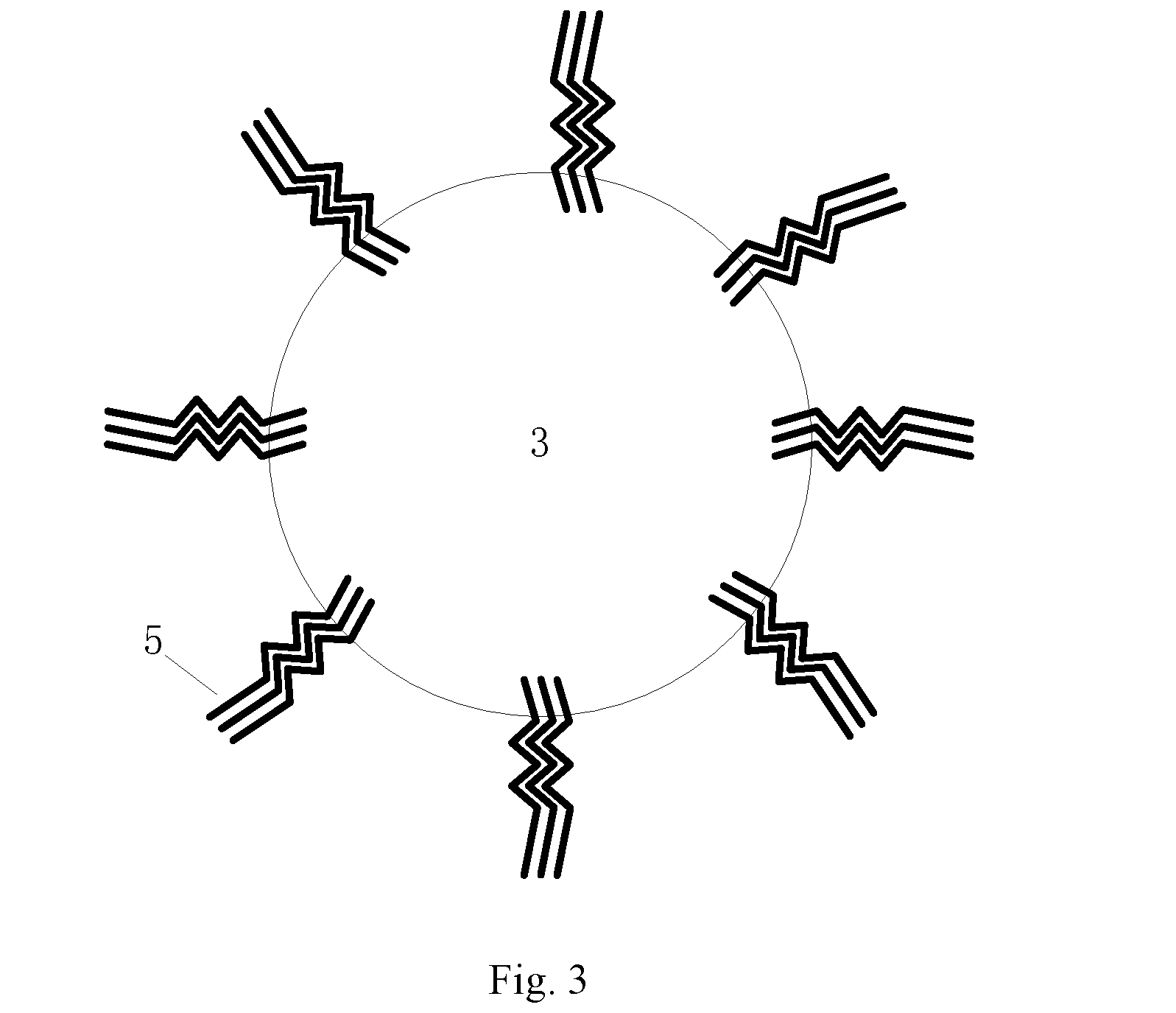

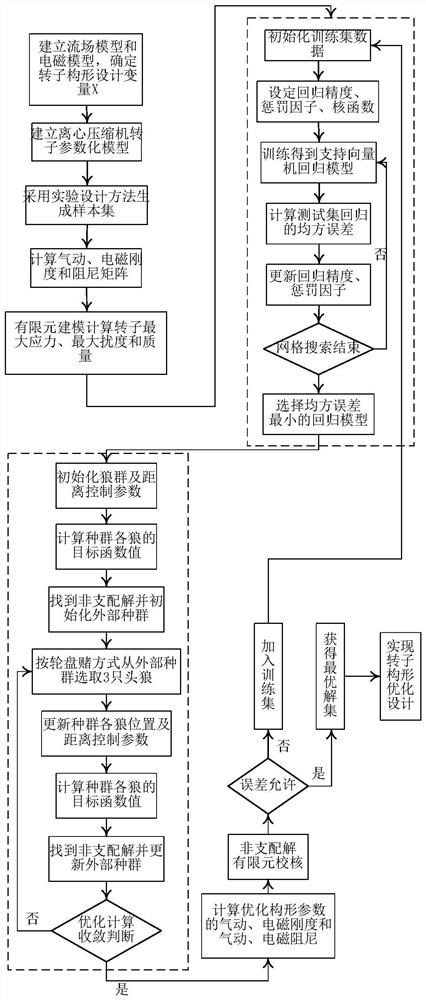

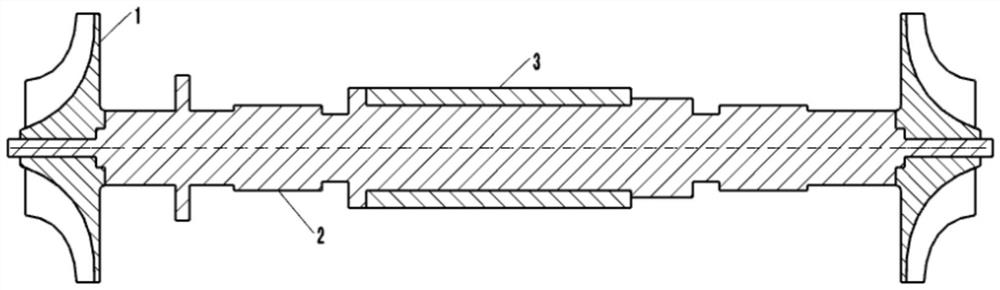

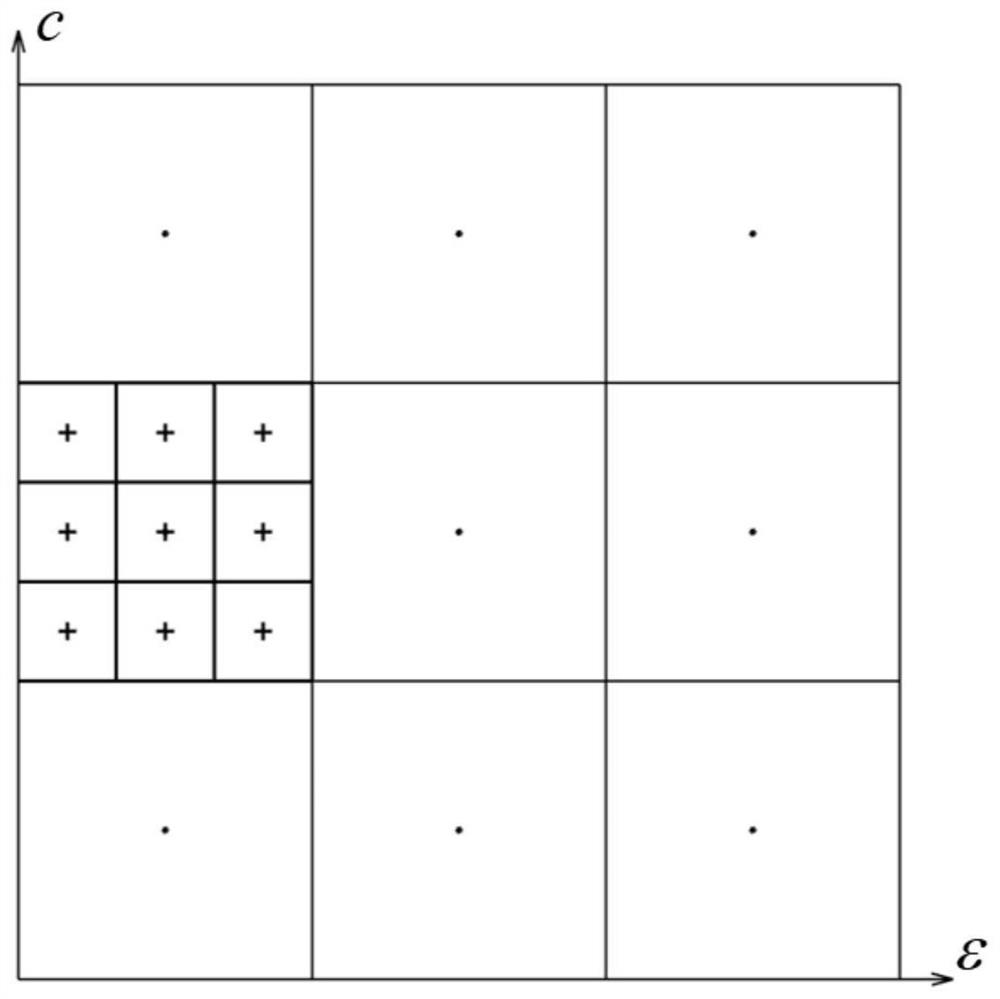

Fuel cell centrifugal compressor rotor configuration optimization design method

PendingCN111859730AAccurate shapeIn line with the actual work situationGeometric CADPump componentsFuel cellsConfiguration optimization

The invention belongs to the field of turbomachinery optimization design. The invention particularly relates to a fuel cell centrifugal compressor rotor configuration optimization design method. The method comprises the following specific steps: in the configuration optimization design process of the centrifugal compressor rotor, rotor aerodynamic stiffness, aerodynamic damping, electromagnetic stiffness and electromagnetic damping changes caused by fluid excitation of an impeller air gap, a bearing air film and sealing gas and electromagnetic excitation factors of a motor rotor are considered; and optimization calculation is performed on the rotor configuration parameters by using a support vector regression machine and an adaptive multi-target grey wolf algorithm, and thus finally obtaining uniformly distributed non-dominated solutions as the rotor configuration parameters. According to the invention, a flow field and electromagnetic excitation are included in dynamic response influence factors for a motor integrated direct drive structure and light weight requirements of the fuel cell centrifugal compressor rotor, the maximum stress and deformation of a rotor part are reduced under the condition that mass constraints are met, the structural dynamic reliability of the fuel cell centrifugal compressor is improved, and the service life of the fuel cell centrifugal compressor isprolonged.

Owner:HEFEI GENERAL MACHINERY RES INST

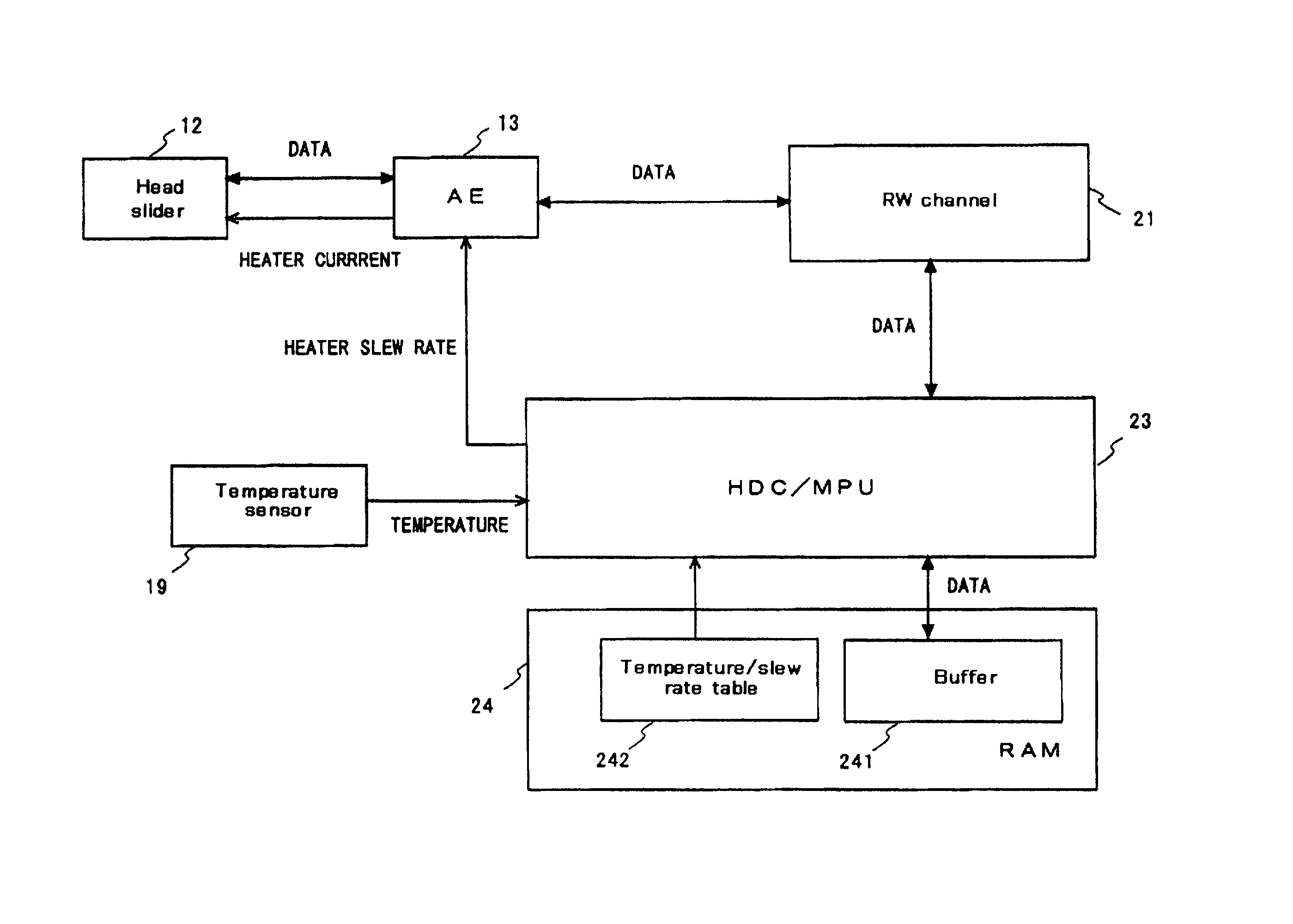

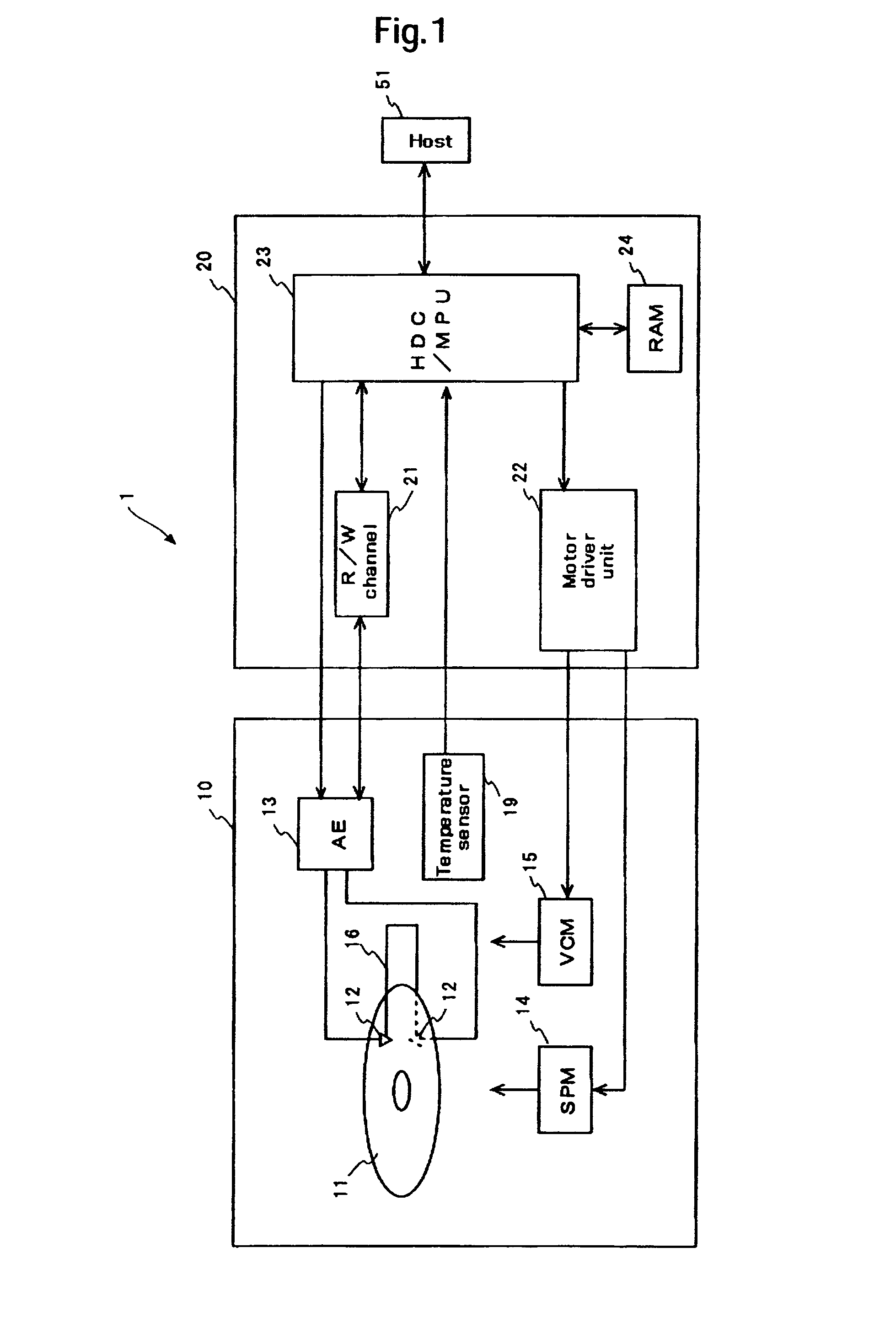

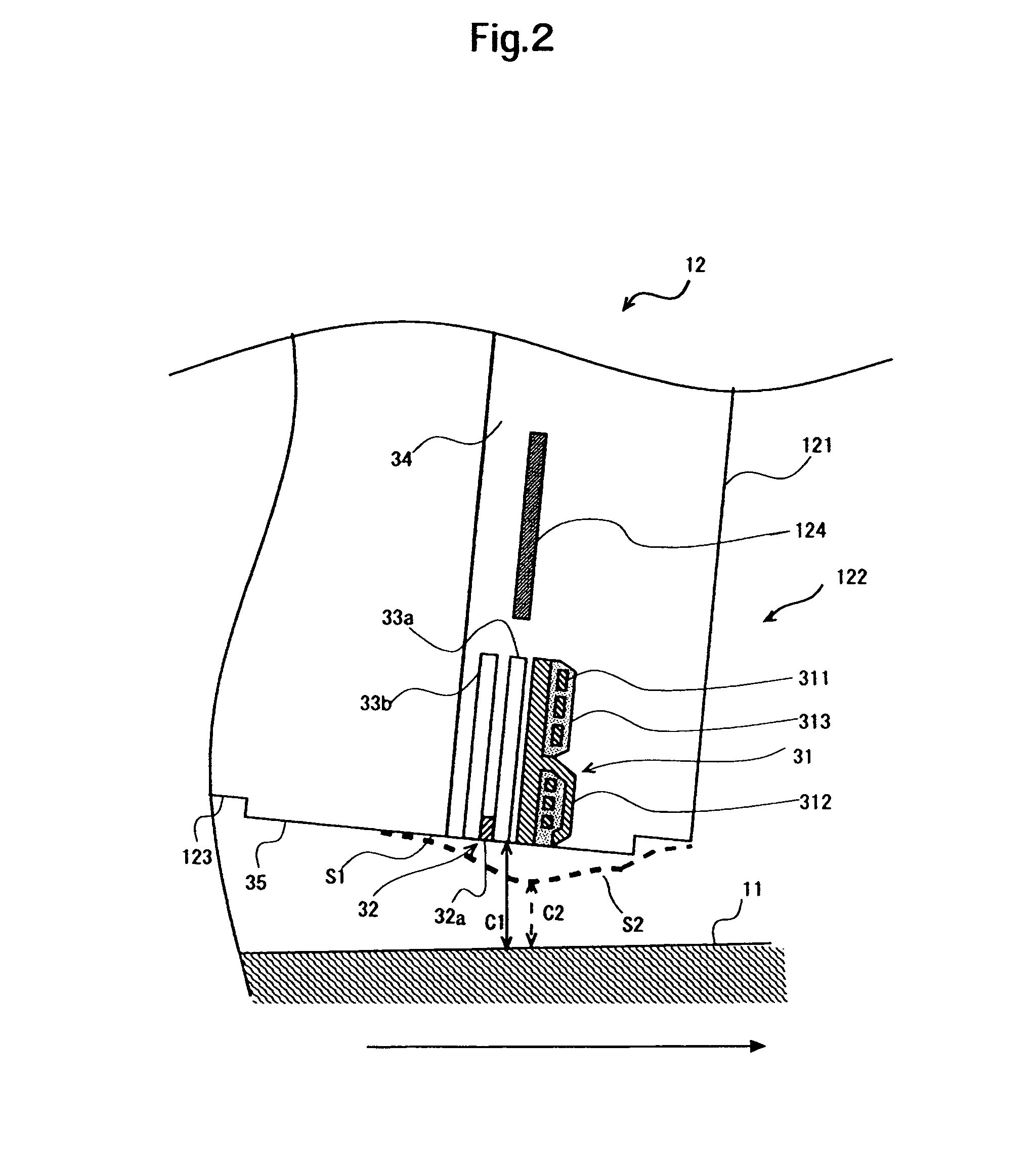

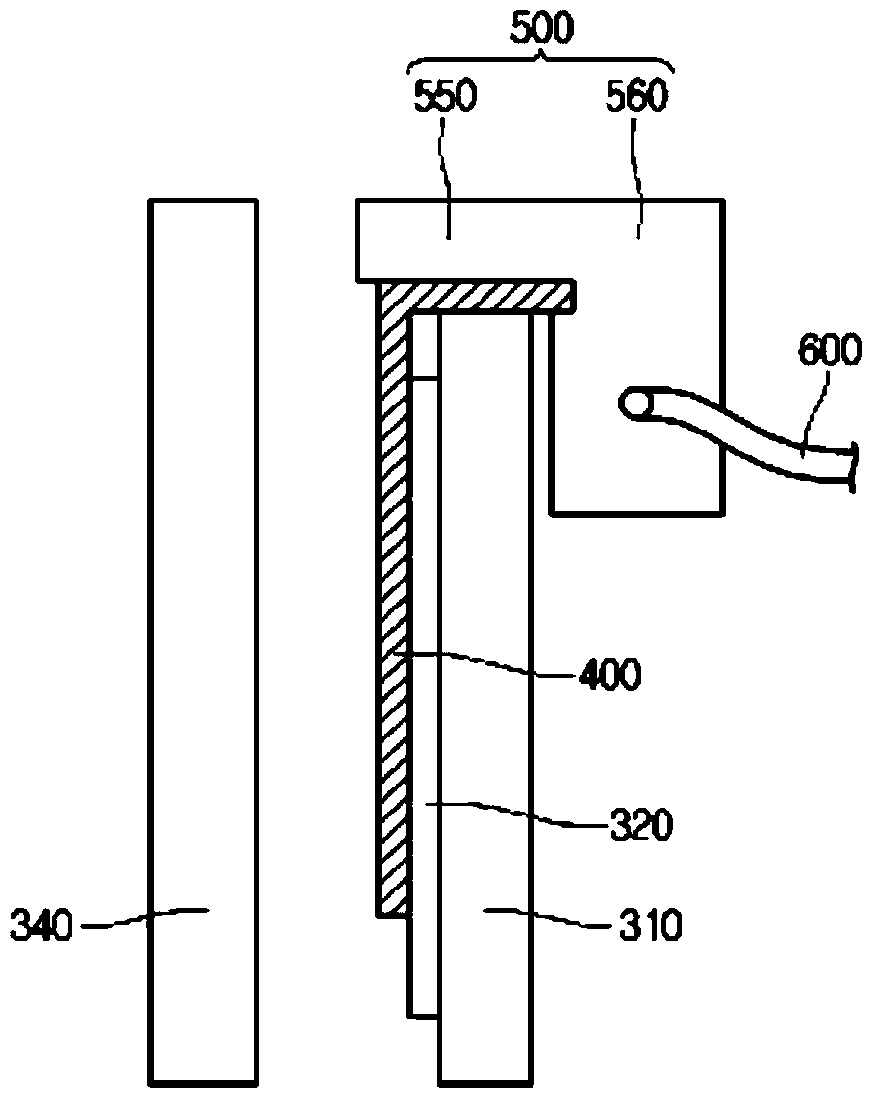

Disk drive and control method thereof

InactiveUS7969681B2Reduce structural stressReduce stressDriving/moving recording headsRecord information storageStructural stressSlew rate

Embodiments in accordance with the present invention reduce the structural stress applied to a head, and to achieve the effective control, when the clearance between the head and a disk is adjusted by using a heater. According to one embodiment, the hard disk controller / microprocessing unit (HDC / MPU) controls a slew rate of a heater at the time of TFC (Thermal Fly height Control). In response to processing conditions, a HDC / MPU changes a slew rate of the output of electric current / voltage applied to the heater. This makes it possible to reduce the head stress, and to achieve the effective TFC. To be more specific, with reference to a temperature / slew rate table, the HDC / MPU changes a slew rate in response to the temperature in the read / write processing.

Owner:WESTERN DIGITAL TECH INC

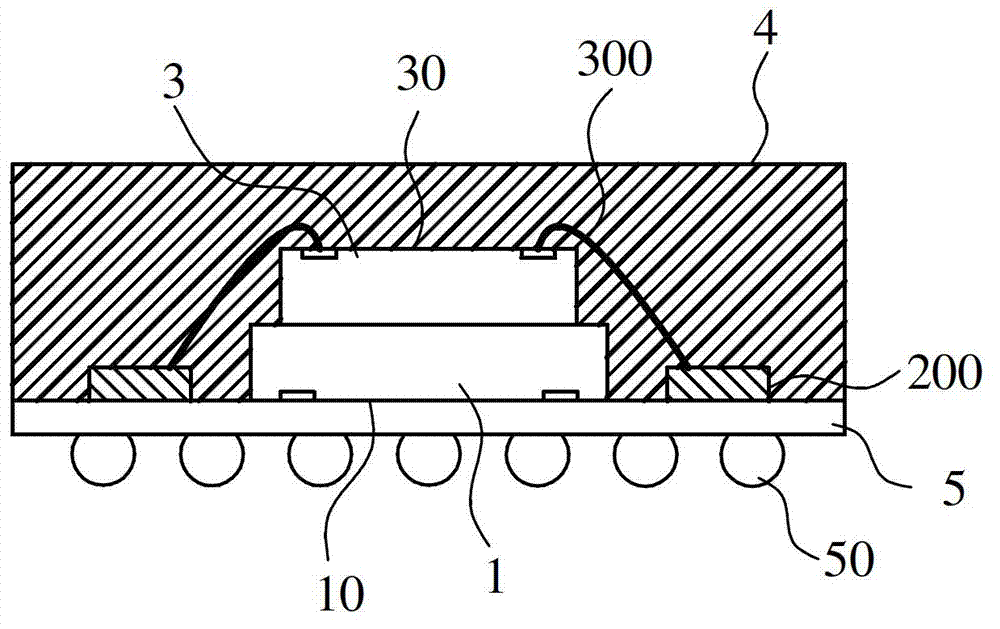

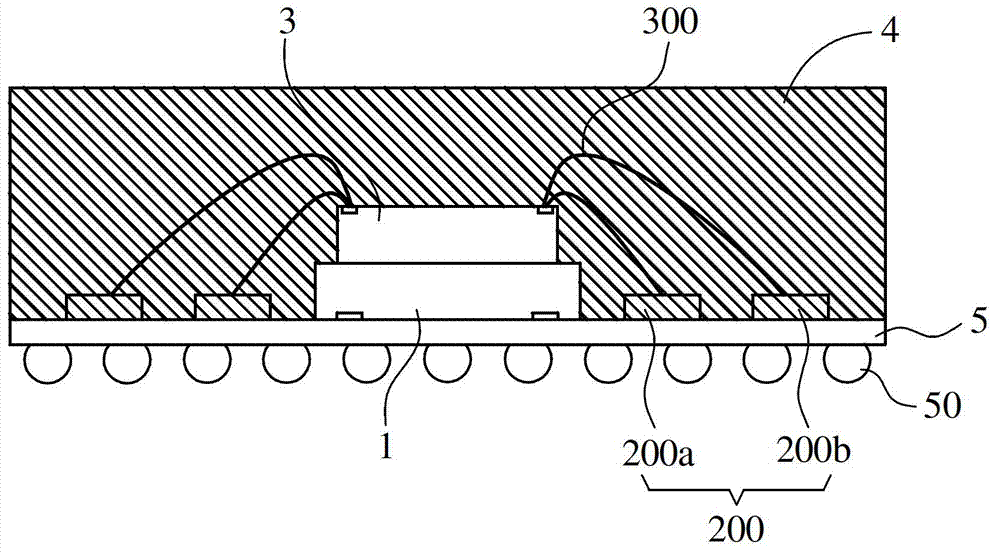

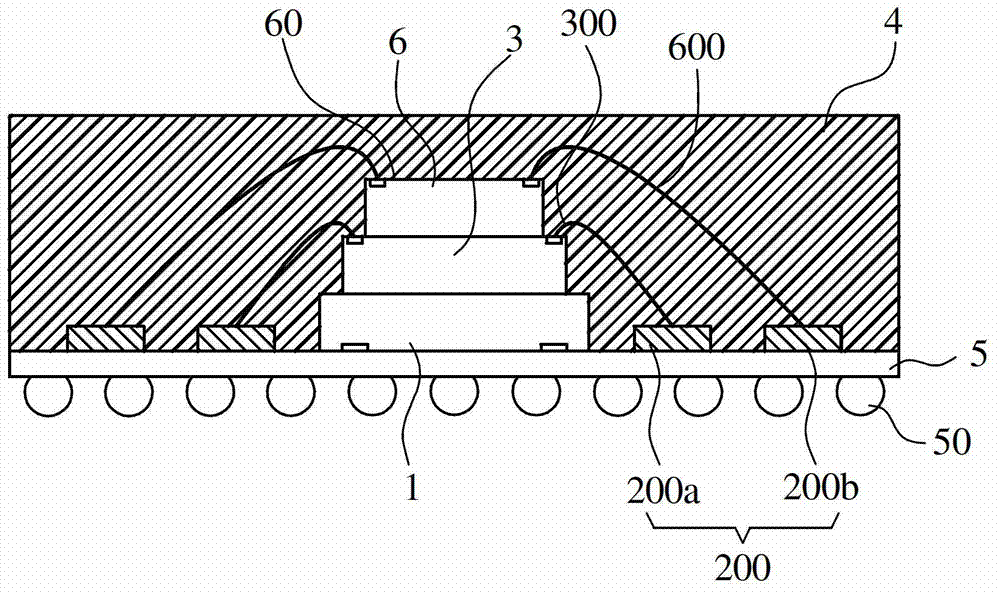

Wafer level semiconductor encapsulation structure with stacking chips and manufacturing method thereof

InactiveCN103199075ASmall sizeReduce structural stressSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageColloid

The invention provides a wafer level semiconductor encapsulation structure with stacking chips and a manufacturing method of the wafer level semiconductor encapsulation structure. The wafer level semiconductor encapsulation structure comprises a first chip, a plurality of wire frame terminals, a second chip and encapsulation colloid, wherein the first chip is provided with a downward active surface, the wire frame terminals surround the first chip, the second chip is stacked on the first chip in an insulation mode and provided with an upward active surface, the active surface of the second chip is electrically connected to the wire frame terminals through metal wires, the encapsulation colloid covers the first chip, the wire frame terminals and the second chip, and the active surface of the first chip and the bottom faces of the wire frame terminals are exposed. According to the wafer level semiconductor encapsulation structure with the stacking chips, chip stacking is achieved through connection of the wire frame terminals and the metal wires, the size of a product and structural stress can be effectively reduced.

Owner:ADVANCED SEMICON ENG INC

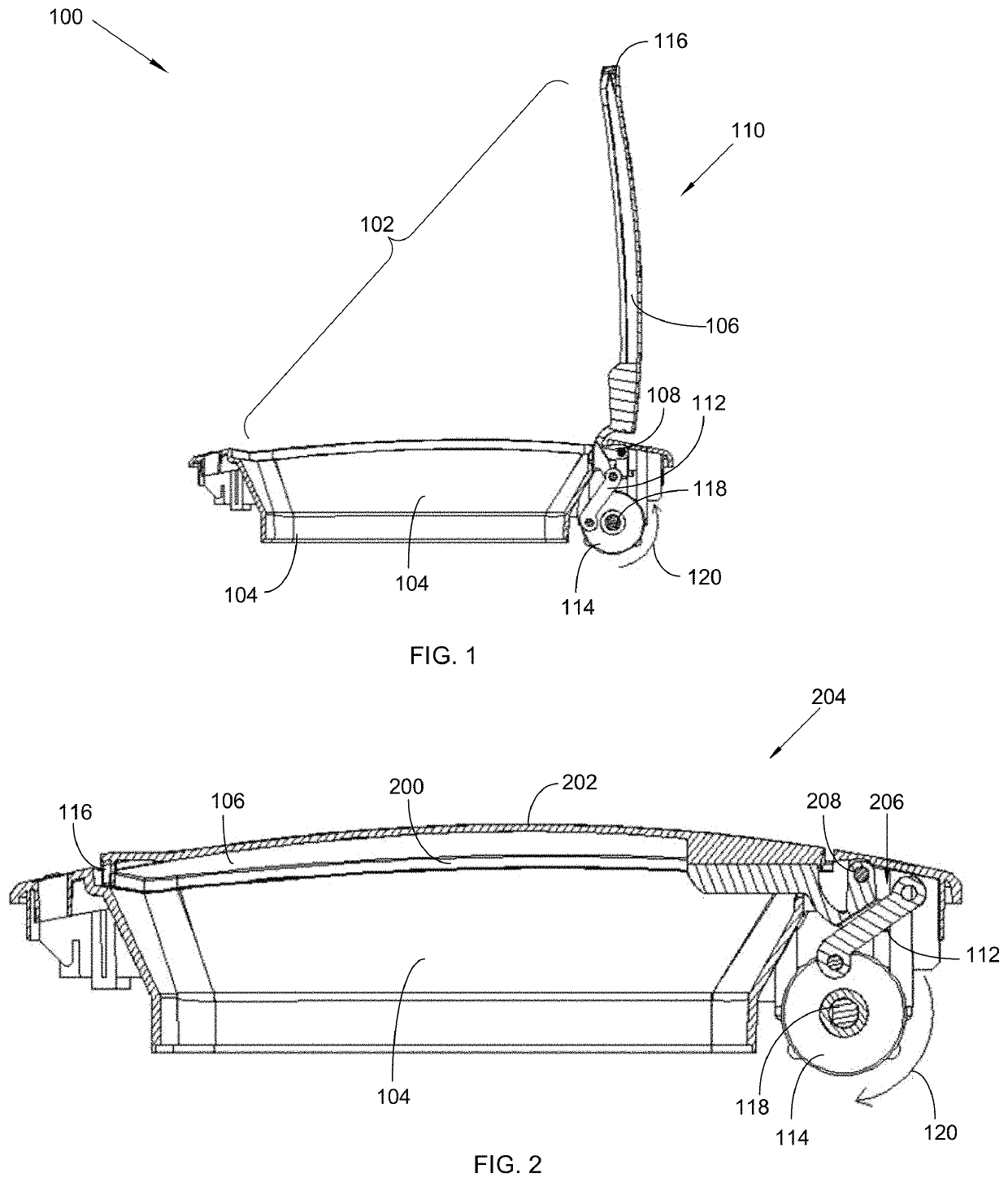

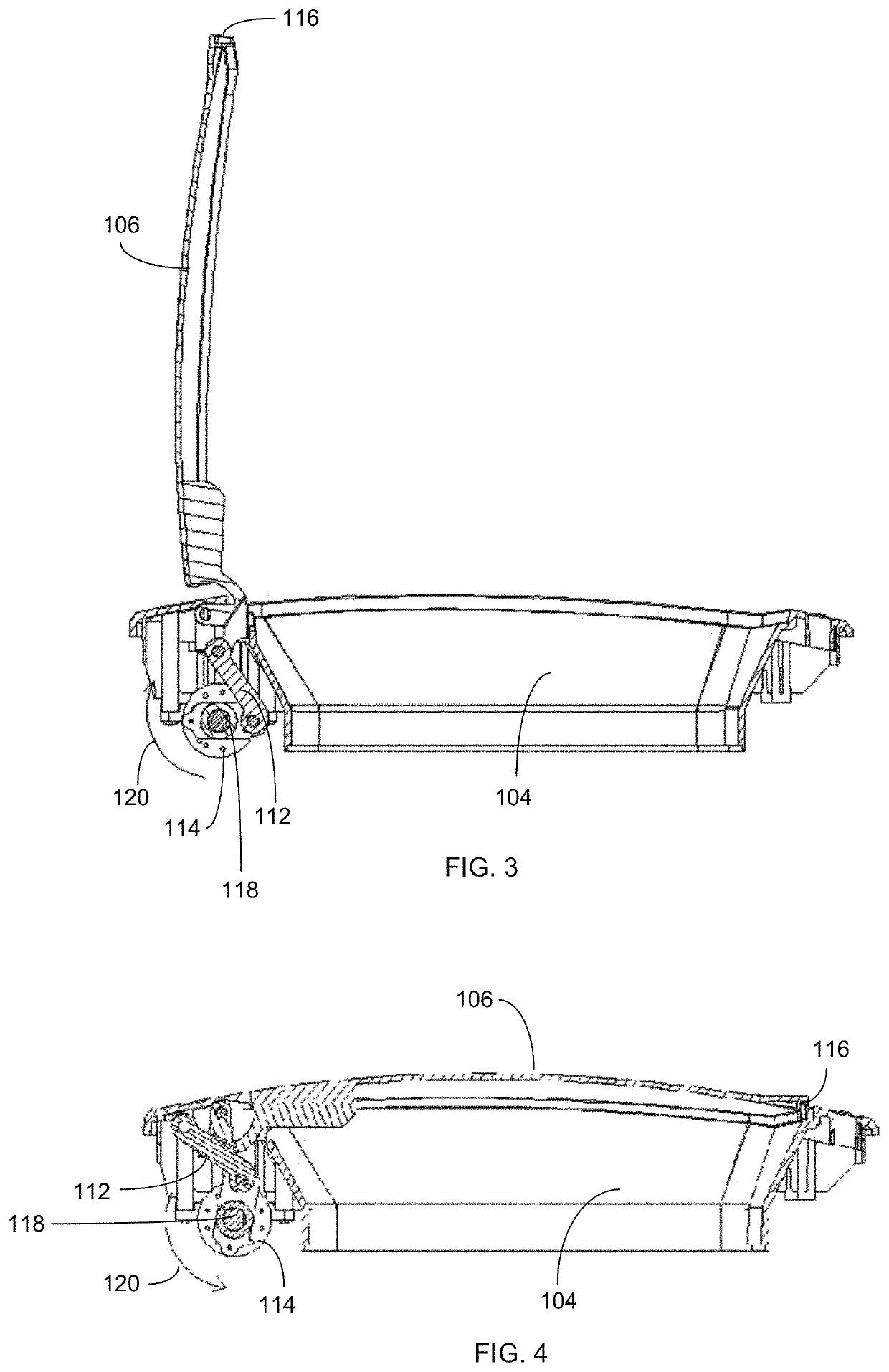

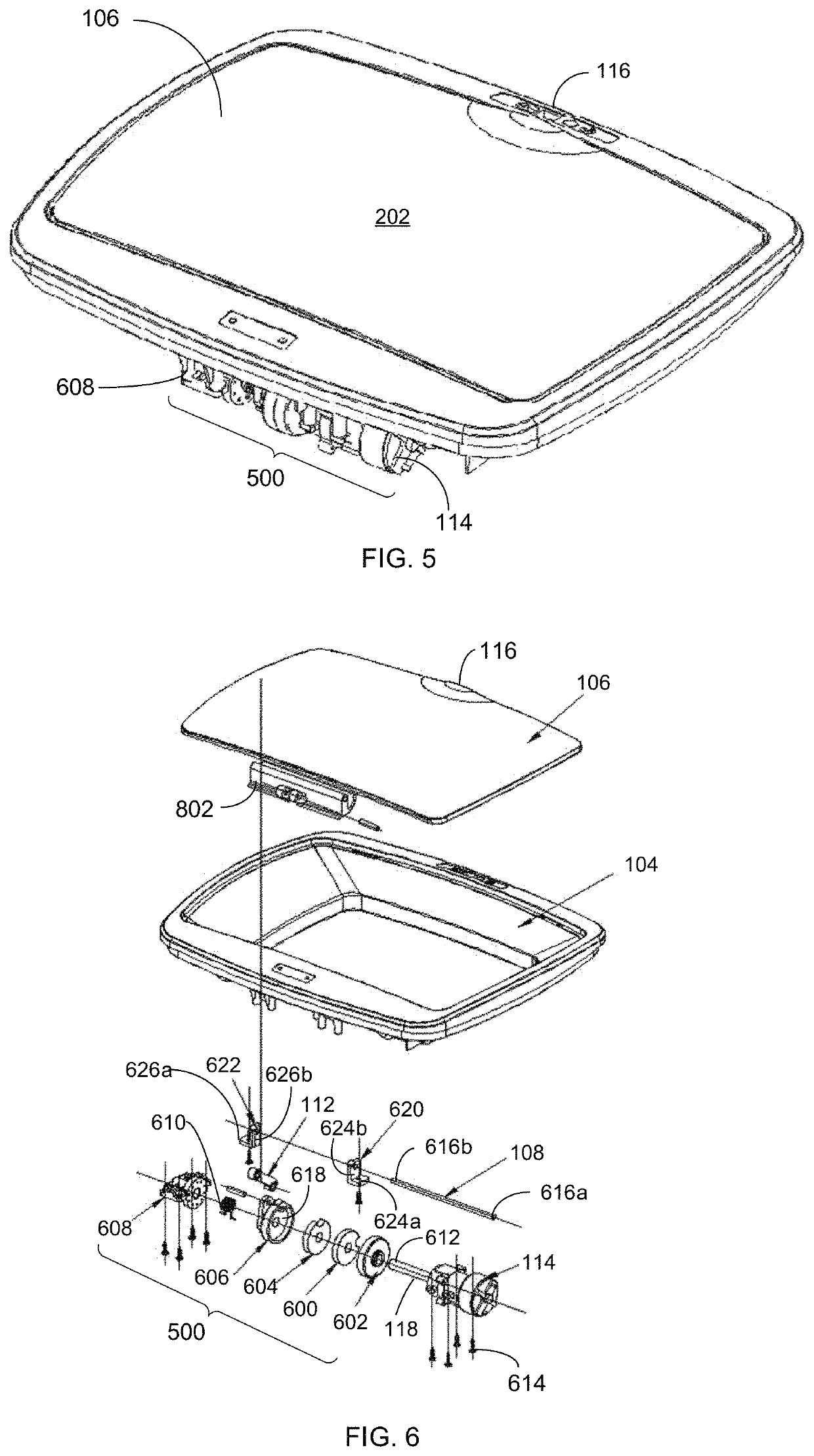

Magnetic drive intelligent trash bin lid assembly

ActiveUS10597228B1Extended service lifeMore practicalRefuse receptaclesElectric machineryDrive motor

A magnetic drive intelligent trash bin lid assembly automatically opens and closes a lid portion relative to a trash container. The lid portion comprises a shell that pivotally joins the container at a lid shaft. A sensor detects motion near the lid, and activates a drive motor in response. The drive motor powers an output shaft to rotate and engages a magnetic clutch. The magnetic clutch includes two magnets that are released from their respective seats to attract each other; and thereby axially displace the output shaft into engagement with a variable linkage. The magnetic clutch engages and disengages the drive motor and the variable linkage, allowing the variable linkage to articulate independently of the drive motor. This separation reduces excessive loads as the lid portion articulates between open and closed positions. A spring absorbs forces in the magnetic clutch, so as to reduce axial loads in the magnetic clutch.

Owner:HINAB INVESTMENT LLC

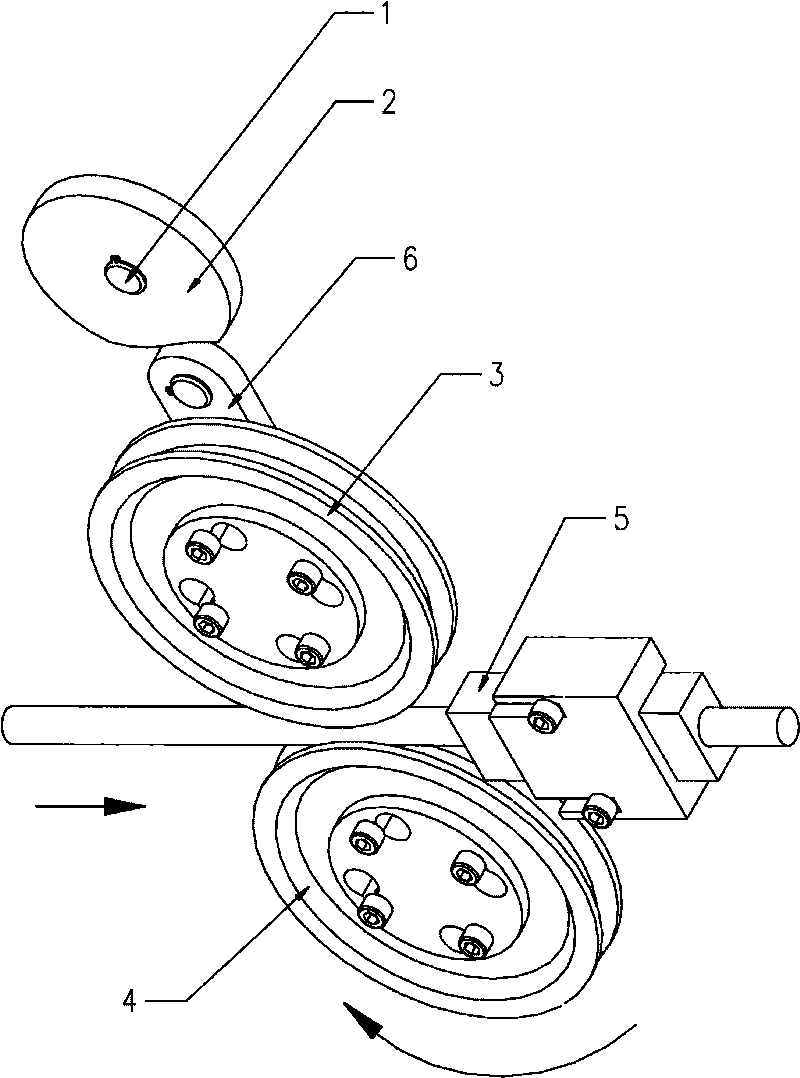

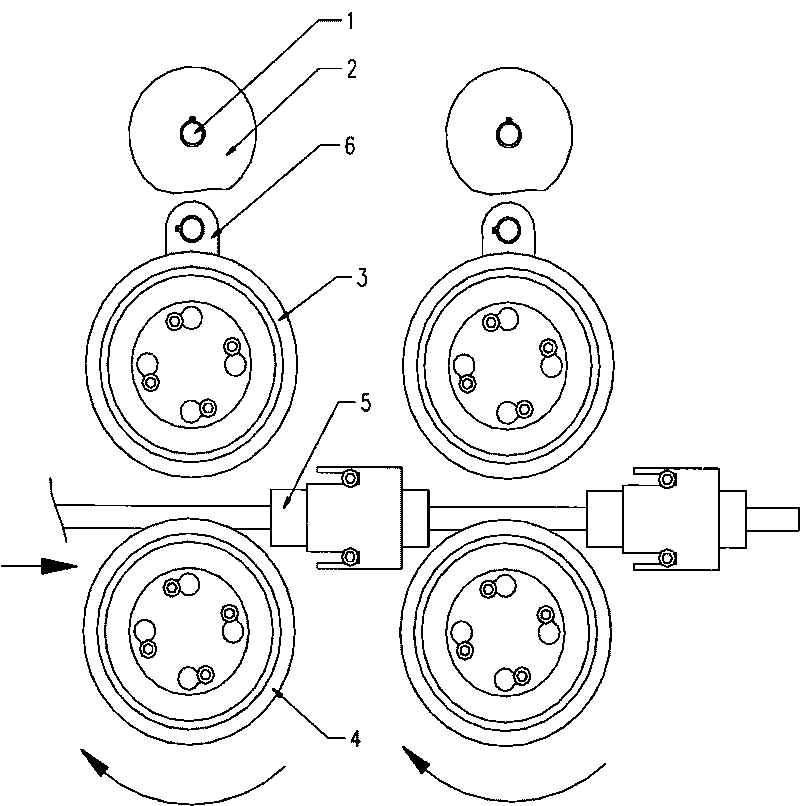

Spring machine wire feeding wheel and wire feeding mechanism

The invention discloses a spring machine wire feeding wheel and a wire feeding mechanism, which comprises a compression cam, an upper groove wheel, a lower groove wheel, a steel wire grip block and a slide block, wherein the compression cam is fixedly installed on a rotating shaft and driven by a servomotor, the upper groove wheel and the lower groove wheel are vertically arranged, the steel wire grip block is used for gripping steel wires, the slide block always close contacts the compression cam and is fixedly connected with the rotating shaft of the upper groove wheel, a curve arc slots matched with the maximum outside diameter of the steel wires is are arranged on the outer circumferences of the upper groove wheel and the lower groove wheel, and the each curve arc slot comprises a first curve arc segment, a second curve arc segment and a third curve arc segment, wherein the second curve arc segment is positioned between the first curve arc segment and the third curve arc segment, and the axial height of the second curve arc segment is lower, so a notch is formed.

Owner:俞家林

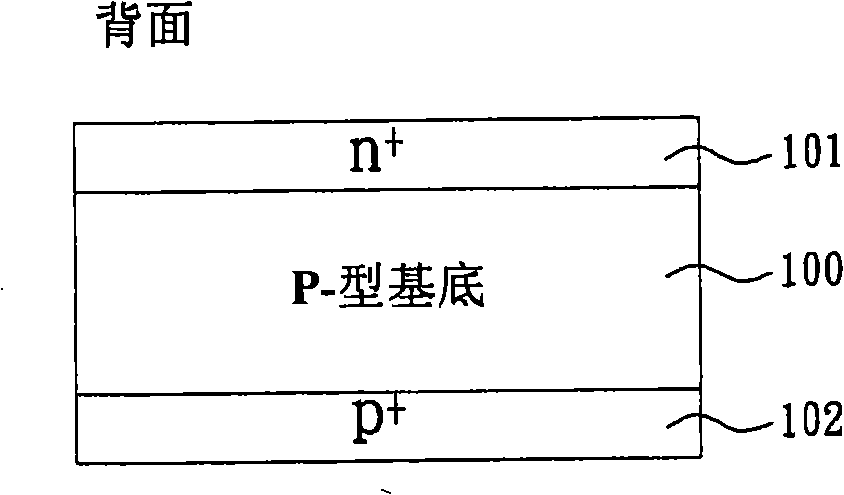

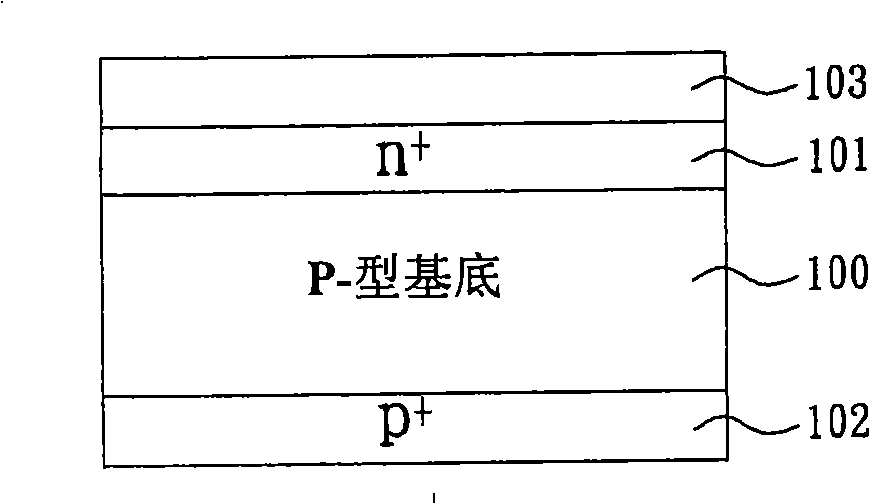

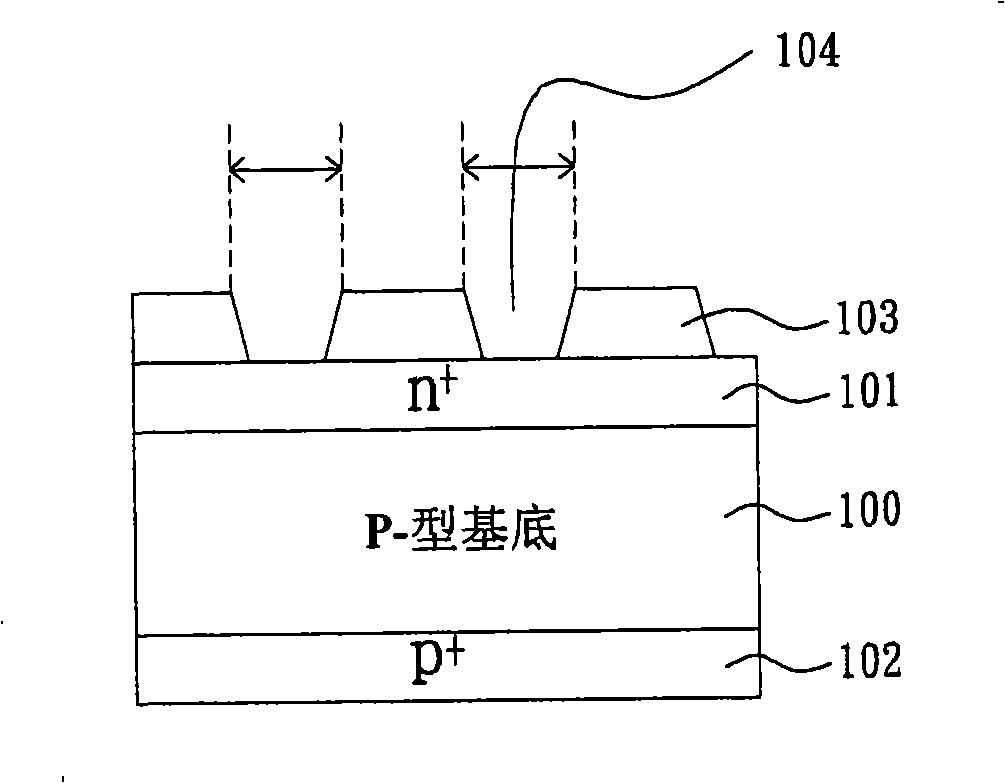

Solar battery

PendingCN101312219AImprove bending phenomenonReduce structural stressPhotovoltaic energy generationSemiconductor devicesOptoelectronicsSilicon oxide

Disclosed is a solar cell, which comprises a substrate, a buffer layer, recess patterns and a metal layer, wherein a p-n doped structure is arranged in the substrate, the buffer layer is formed on the substrate, the recess patterns are formed in the buffer layer, materials of the buffer layer comprise, but not limited to, silicon oxide (SiO2), silicon nitride (SiNX), a silicon oxynitride layer or the combination thereof, the optimal thickness of the buffer layer is 50-70 nanometers, the buffer layer is formed by sputtering, and the metal layer is formed on the buffer layer and is filled with the recess patterns.

Owner:GIGASTORAGE CORP

Wheel-mounted brake disc of high-speed train

The invention belongs to the technical field of train braking device, and particularly relates to a wheel-mounted braking disc of a high-speed train. The wheel-mounted braking disc of the high-speed train comprises an inner disc body and an outer disc body, and the inner disc body and the outer disc body are initially positioned through a positioning pin shaft and a wheel web; the sleeve hole of the inner disc body is provided with an inner splicing sleeve, the sleeve hole of the outer disc body is provided with an outer splicing sleeve, a pre-locking mechanism is arranged between the inner splicing sleeve and the outer splicing sleeve, and the inner disc body and the outer disc body are pre-locked through a pre-locking mechanism and the wheel web; the inner splicing sleeve and the outer splicing sleeve are correspondingly provided with bolt mounting holes, and the inner disc body and the outer disc body are final-locked through bolts and the wheel web. Compared with the traditional brake disc, the wheel-mounted braking disc of the high-speed train greatly reduces the risk of bolt breakage, and even if the bolt is broken, the splicing sleeve can still press the inner disc body andthe outer disc body on the wheel web, therefore, the reliability is higher.

Owner:南京中盛铁路车辆配件有限公司

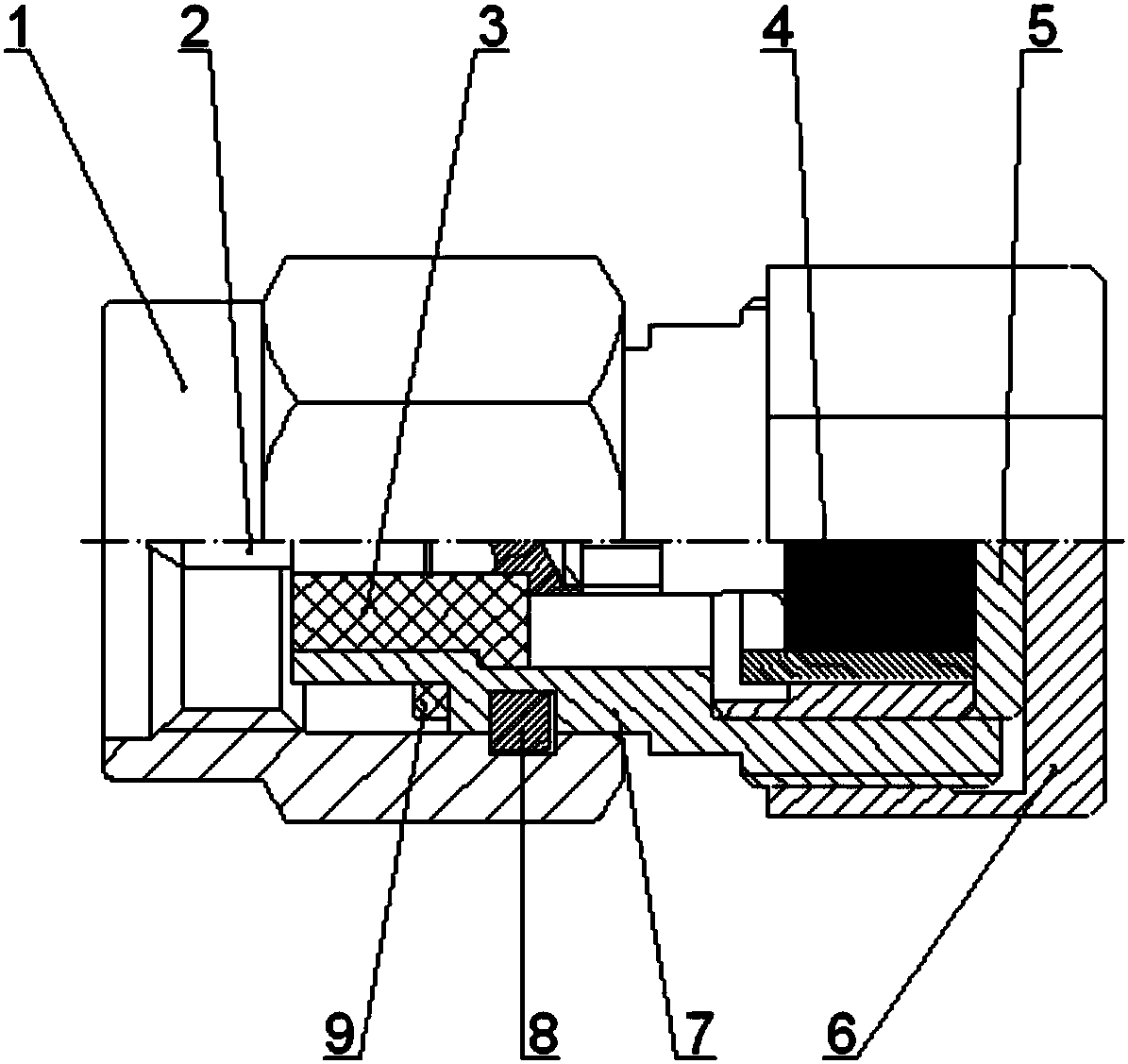

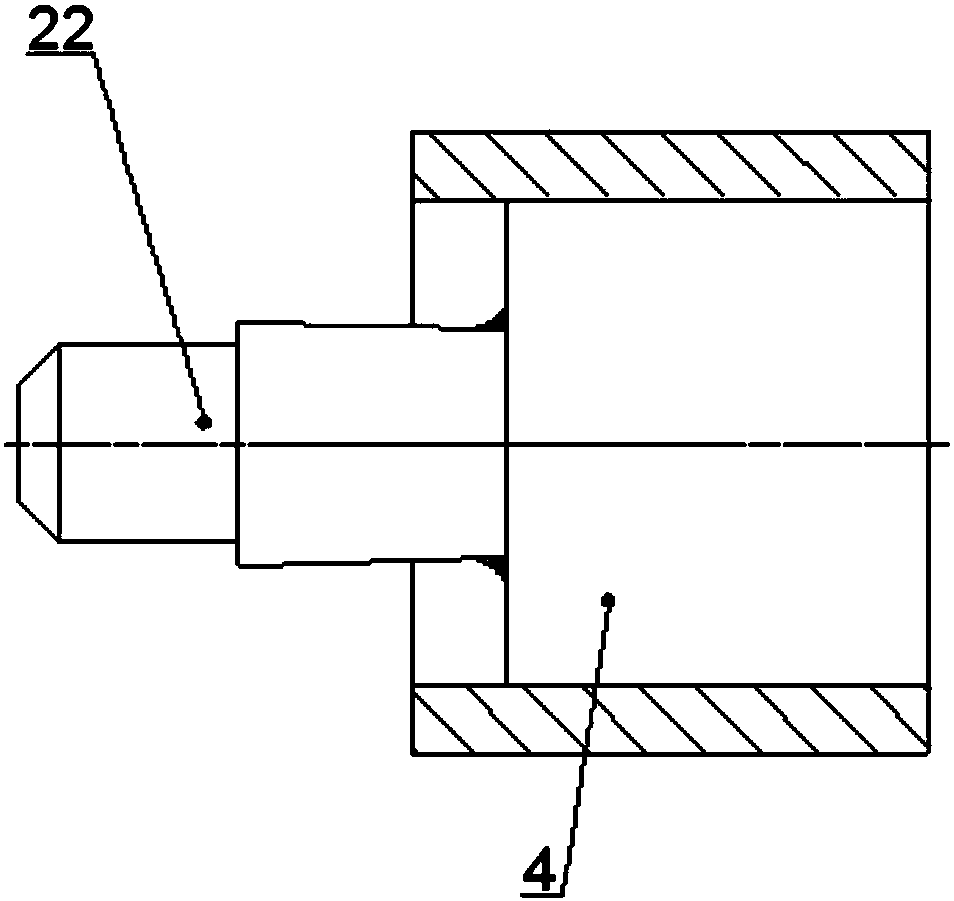

High-reliability coaxial load

InactiveCN108365314AReduce structural stressImprove assembly accuracyWaveguide type devicesElectrical conductorCoaxial transmission line

The invention discloses a high-reliability coaxial load, which comprises a joint, a pin conductor, an insulator, a microstrip resistor, a baffle, a cover plate, a shell, a clamp spring and a washer, wherein the shell is a hollow step shaft; a small-diameter end of the shell is connected with a microwave transmission device through the joint; the outer side of the small-diameter end of the shell issleeved with the washer for damping and buffering; a counter bore for mounting the clamp spring is arranged in the outer side of the shell; the outer side and the inner side of a large-diameter end of the shell are fixedly connected with the cover plate and the baffle separately; and the pin conductor is coaxially arranged in the shell in a penetrating manner and is connected with the insulator and the microstrip resistor separately. Through the cooperation of the joint, the pin conductor, the insulator, the microstrip resistor, the baffle, the cover plate, the shell, the clamp spring and thewasher, the reliability of a product is improved, the microwave property is optimized and the defects that traditional coaxial transmission line and microstrip resistor are easy to break and the transmission path is not continuous are compensated.

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP

Optical fiber isolator

The invention provides an optical fiber isolator. The optical fiber isolator comprises a glass encapsulating tube, a first tail-fiber capillary tube, a second tail-fiber capillary tube, a first lens, a second lens and a rotary optical component, wherein the rotary optical component, the first lens and the second lens are all mounted in the glass encapsulating tube, and the first lens and the second lens are located at the two sides of the rotary optical component and are fixed; the first tail-fiber capillary tube extends into a first open end of the glass encapsulating tube and is fixed, and the second tail-fiber capillary tube extends into a second open end of the glass encapsulating tube and is fixed. According to the optical fiber isolator, structurally, after the conventional collimator glass tube is omitted, an adhesive layer between the collimator glass tube and a capillary tube is omitted, the water vapor permeation resistance of the device is improved, the gas tightness is improved, and a structural stress resulting from different coefficients of thermal expansion and non-uniform thickness of media is reduced, so that the global stability and reliability of the device are improved.

Owner:SHANGHAI NEXTREND TECH

Composite ceramic material for LED energy-saving lamp base

InactiveCN103435334AImprove thermal conductivitySmall thermal expansionComposite ceramicWorking temperature

The invention relates to a composite ceramic material for an LED energy-saving lamp base. The composite ceramic material comprises 55.0-95.0% of alpha-alumina powder and 5.0-45.0% of aluminum nitride powder, wherein the grain size of the alpha-alumina powder is less than 0.010mm, and the grain size of the aluminum nitride powder is less than 0.005mm. The forming method can adopt injection moulding, compression moulding or hot press moulding. A nitriding atmosphere can be used for pressureless sintering or hot pressed sintering in the firing method. The firing temperatures of different firing methods are all not less than 1,500 DEG C. The composite ceramic material for the LED energy-saving lamp base provided by the invention is low in thermal conductivity, the working temperature of an LED energy-saving lamp is reduced, the illuminating efficiency and the service life of the LED energy-saving lamp are improved and prolonged, a novel high-temperature structure material is provided for the domestic field of LED energy-saving lamps, and the composite ceramic material for the LED energy-saving lamp base has wide application prospects.

Owner:唐山市科硕特种陶瓷制造有限公司 +1

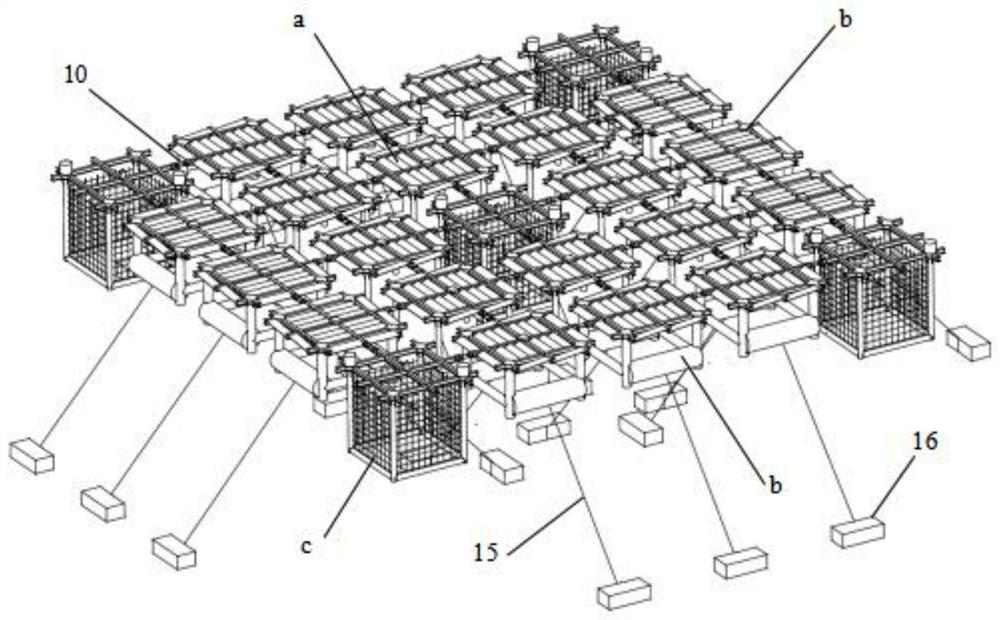

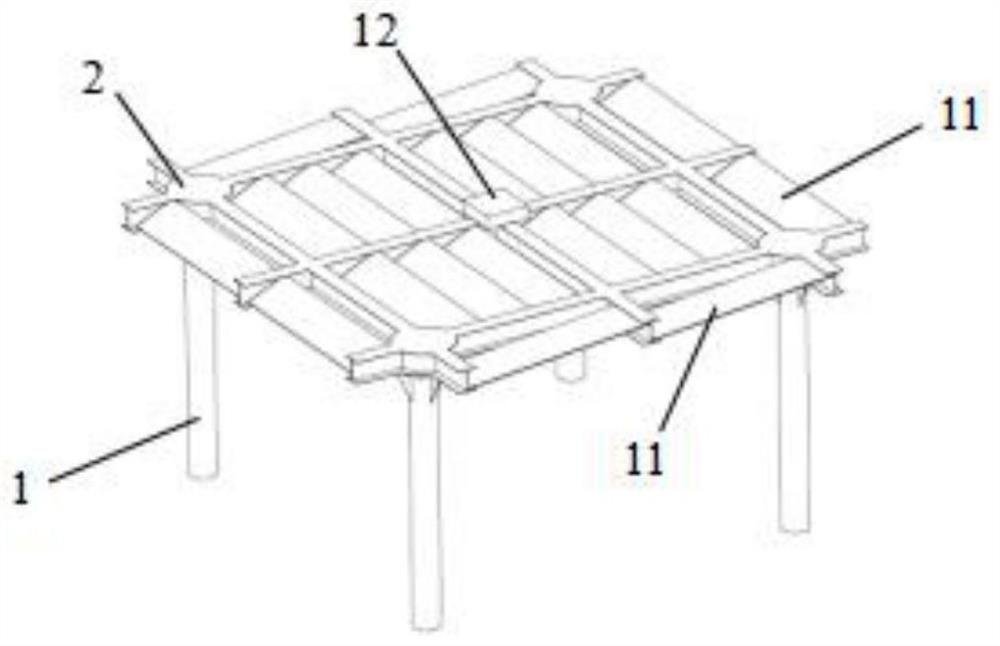

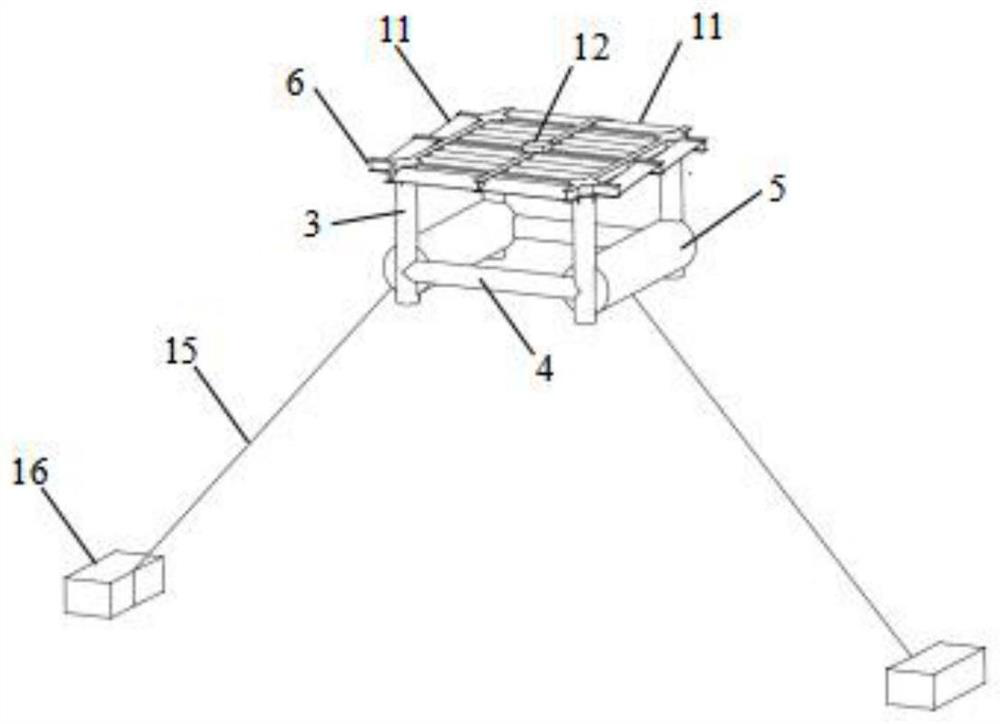

Flexible assembly type offshore photovoltaic power generation and aquaculture net cage comprehensive development platform

ActiveCN113349129AImprove flexibilityReduce structural stressClimate change adaptationAgricultural fishingMarine engineeringWind wave

The invention discloses a flexible assembly type offshore photovoltaic power generation and aquaculture net cage comprehensive development platform, and relates to the field of offshore photovoltaic power generation structure design and offshore net cage culture. The platform comprises photovoltaic units, mooring units and net cage units, and the mooring units are arranged on the outermost side of the whole structure array and surround the whole structure. The photovoltaic units are arranged in a ring defined by the mooring units, and the net cage units are distributed in the photovoltaic units or arranged on the ring defined by the mooring units. According to the platform, the photovoltaic units are of an array structure formed by splicing small units, the units are connected through double-hinge connectors, and the platform structure has high wind wave resistance, can achieve comprehensive development and utilization of offshore photovoltaic power generation and offshore net cage culture, has a certain wave dissipation capacity, and has the advantages of being easy and convenient to construct, convenient and fast to maintain and the like.

Owner:TIANJIN UNIV

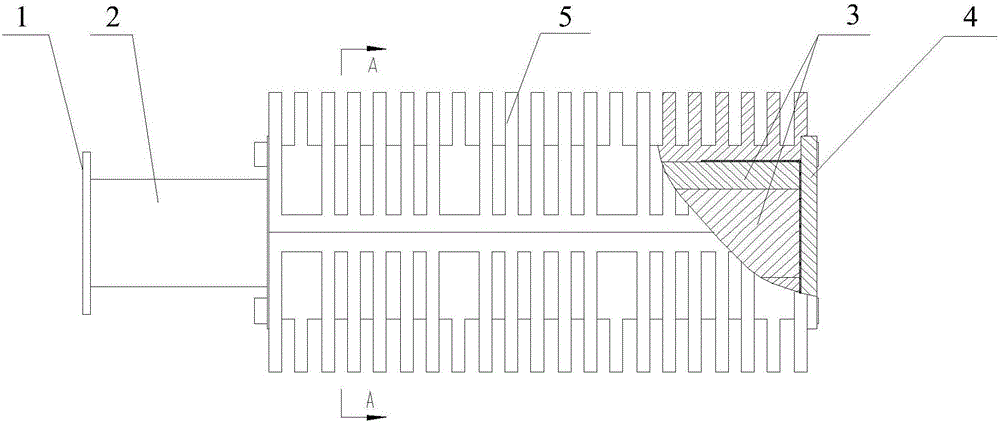

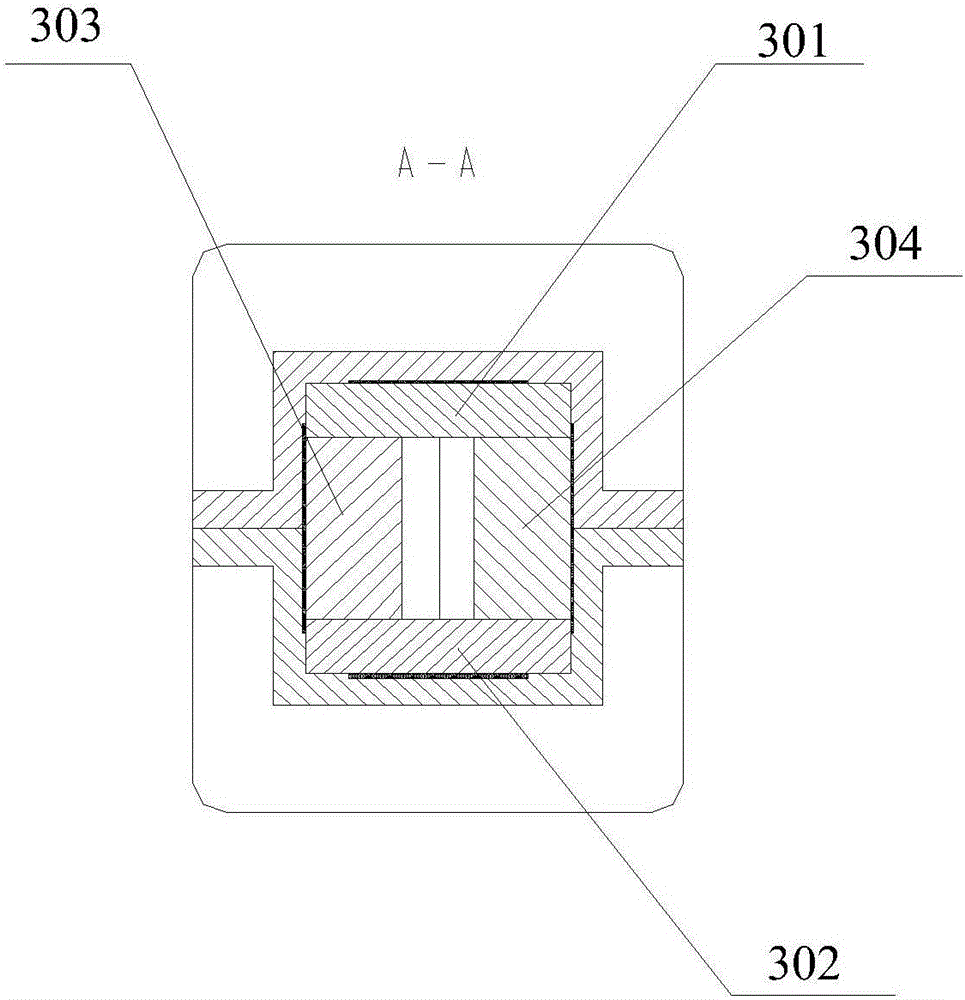

High-power waveguide load

ActiveCN106785282AReduce processing difficultyImprove processing efficiencyWaveguide type devicesEngineeringWaveguide

The invention discloses a high-power waveguide load comprising a connection flange, a transition cavity, an absorber, a rear cover plate, and a radiator. The transition cavity is connected with the connection flange and the radiator. The rear cover plate is connected with the end, away from the transition cavity, of the radiator. The absorber, which is arranged in the cavity of the radiator, includes a first rectangular ceramic absorbing sheet, a second rectangular ceramic absorbing sheet, a first tapered ceramic absorbing sheet, and a second tapered ceramic absorbing sheet. The sides of the first rectangular ceramic absorbing sheet, the second rectangular ceramic absorbing sheet, the first tapered ceramic absorbing sheet and the second tapered ceramic absorbing sheet are in closed connection, and the absorber obtained after connection is hollow inside. On the basis of satisfying the requirement for high power of the waveguide load, the machining difficulty of the absorber structure is reduced, and the machining efficiency and the precision of overall assembly are improved.

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP

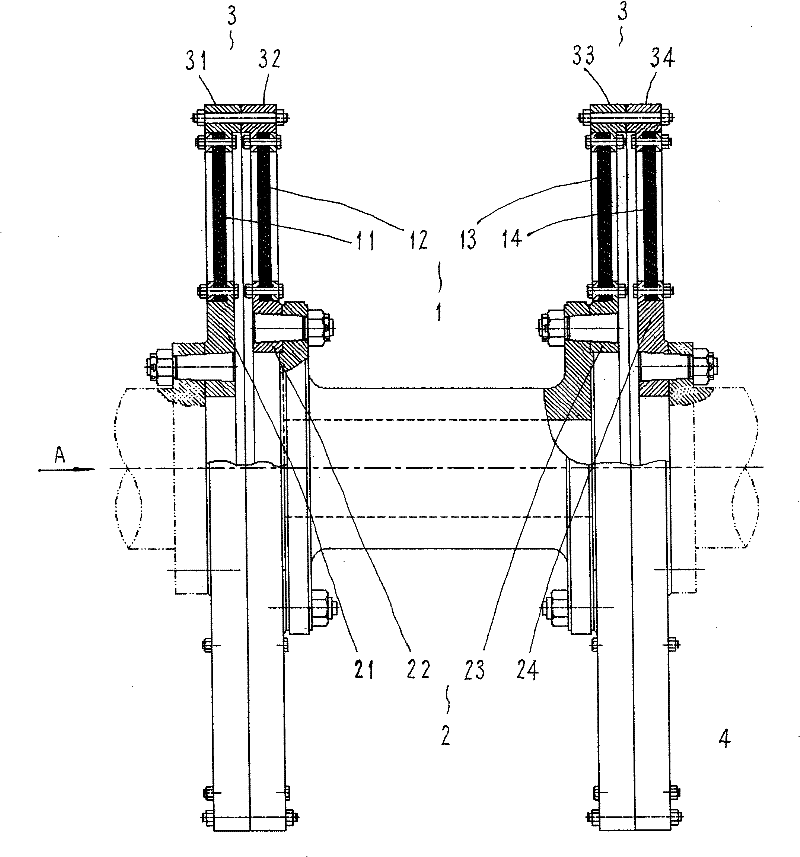

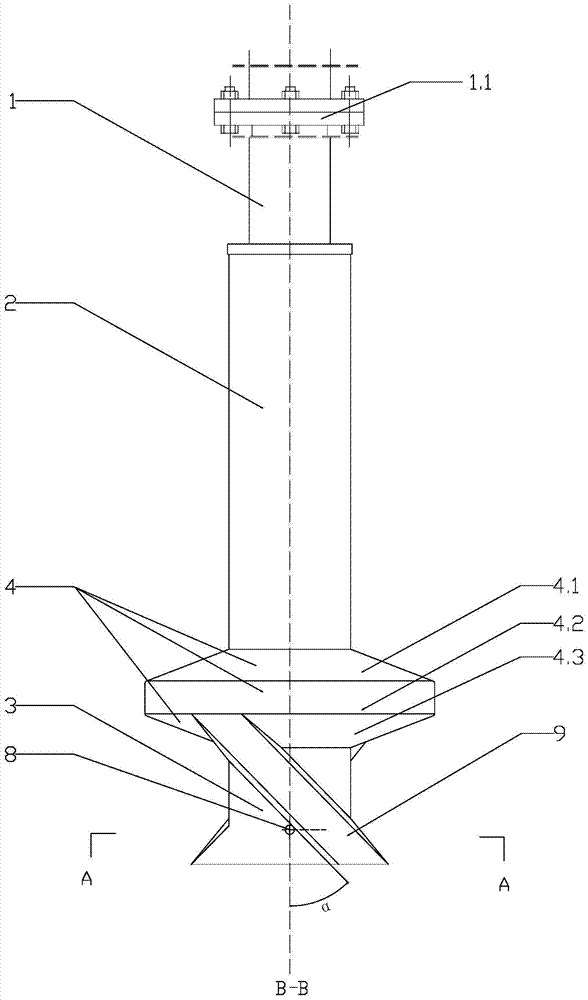

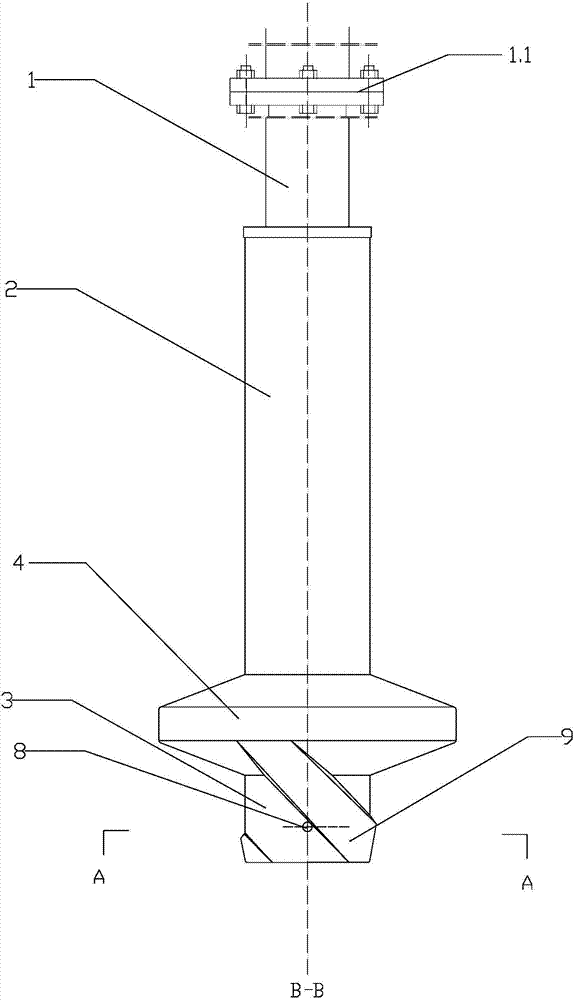

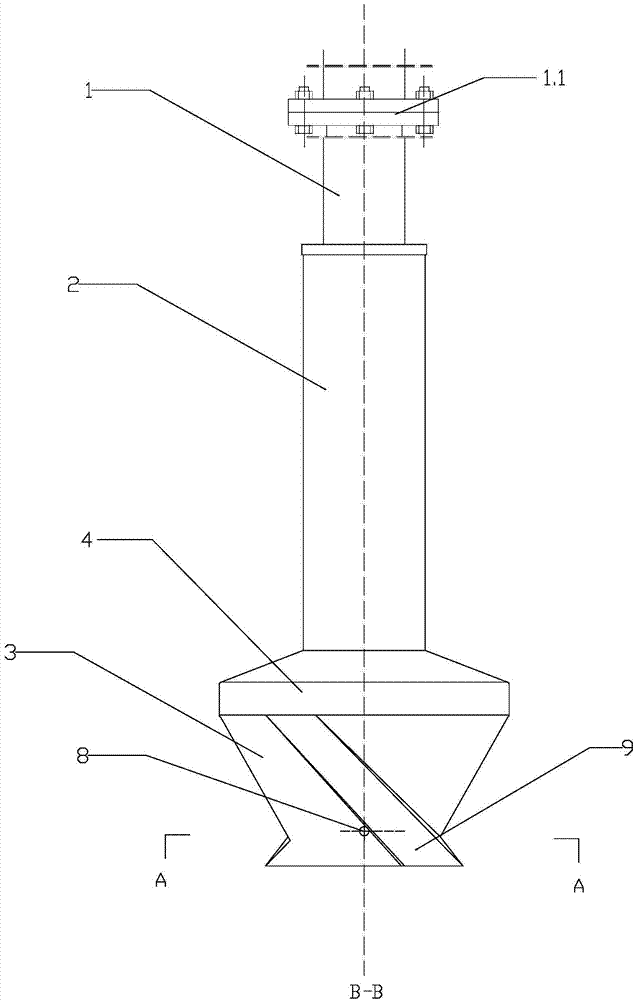

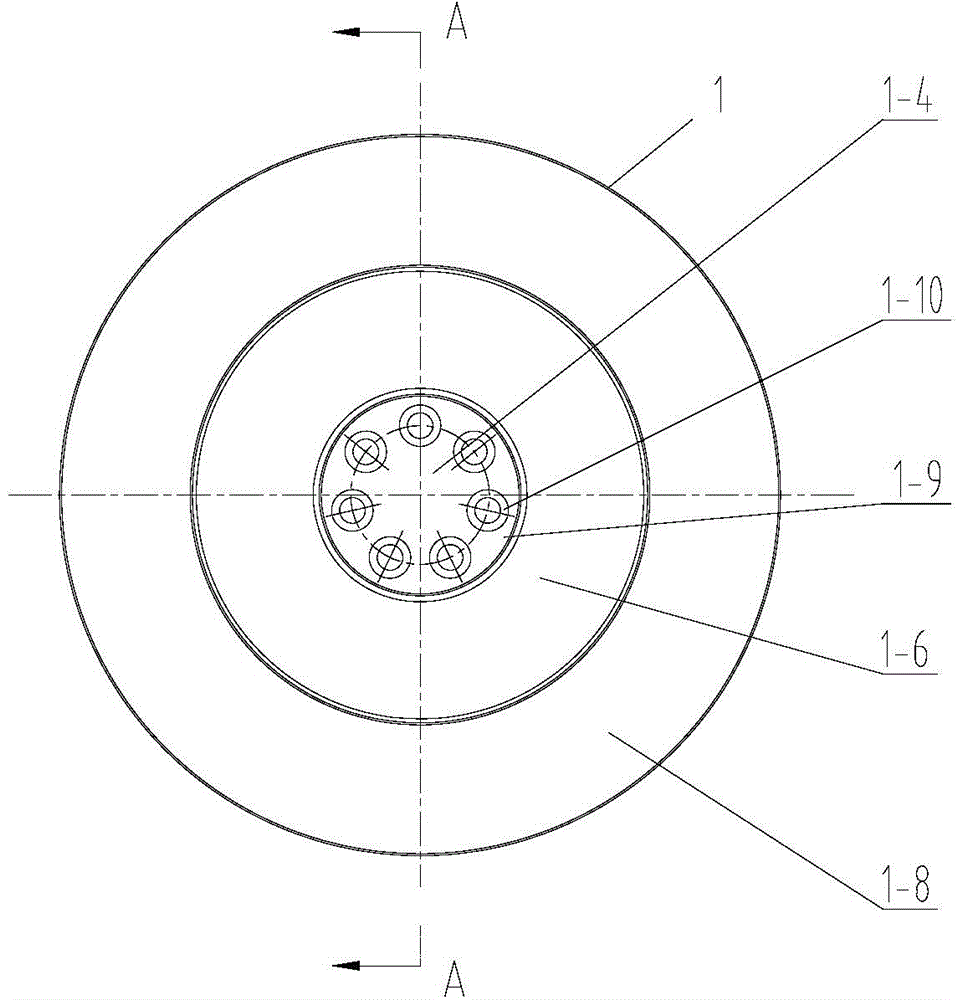

High-performance spray gun for molten iron injection pretreatment

The invention discloses a high-performance spray gun for molten iron injection pretreatment. The high-performance spray gun comprises a connection segment, a gun body segment and an injection segment, which are sequentially communicated, wherein a swirling diffuser is arranged between the gun body segment and the injection segment and comprises an upper cone, a cylinder and a lower reversed cone, which are sequentially communicated; 2-4 nozzles are uniformly formed between a main pipe of the spray gun and a seal head in the circumferential direction of the spray gun and positioned in the side wall of the injection segment; swirling pieces obliquely arranged on the outer wall from the top end of the lower reversed cone to the bottom end surface of the injection segment and positioned above the nozzles. By strengthening three key kinetic parameters of molten iron injection pretreatment, the spray gun significantly improves the kinetic conditions of molten iron injection pretreatment and achieves the comprehensive purposes of improving the sulfur removal efficiency of injection pretreatment and the utilization rate of desulfurizer reaction, shortening the injection time and increasing the production capacity of desulfurization equipment.

Owner:武汉钢铁有限公司

Micro heating disc and manufacturing method thereof

ActiveCN108271282AHigh speedAdapted release processTelevision system detailsImpedence networksElectrical resistance and conductanceWorking temperature

The invention relates to a micro heating disc and manufacturing method thereof. The micro heating disc comprises a substrate, an insulated support layer and a resistance heating layer which are stacked from bottom to top successively, the middle of the substrate is provided with a temperature isolated cavity, the insulated support layer in the upper portion of the temperature isolated cavity includes a temperature isolated suspension film, the substrate in the edge of the temperature isolated cavity is provided with a deformation isolated cavity communicated and integrated with the temperatureisolated cavity, a suspension film in the upper portion of the deformation isolated cavity is a deformation suspension film, and the deformation isolated suspension film is provided with through holes through which the air pressure of the temperature isolated cavity of the micro heating disk is balanced with that of the external environment. The structure of deformation isolated cavity is used, the through holes are formed in the deformation isolated suspension film to balance pressures at the two sides of the suspension film and eliminate pressure caused by temperature gradients in the through holes, deformation of the temperature isolated suspension film is inhibited from being conducted to the deformation isolated suspension film, the micro heating disc can bear a higher work temperature, the packaging technology is simple, integration of a single-chip system can be carried out, and a product can be more micro.

Owner:武汉微纳传感技术有限公司

Butterfly wing microgyroscope using polygonal vibration beam and preparation method thereof

ActiveCN109579811AEasy to processLittle impact on performanceSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesSilicon electrodeButterfly wing

The invention discloses a butterfly wing microgyroscope using a polygonal vibration beam and a preparation method thereof. The butterfly wing microgyroscope comprises a silicon electrode substrate, asilicon cover plate and a silicon sensitive structure with the vibration beam, and the vibration beam of the silicon sensitive structure is the polygonal vibration beam prepared by combining wet etching and dry etching using a SOI silicon wafer for preparing the silicon sensitive structure as a raw material, and the principal axis azimuth of the polygonal vibration beam is not equal to 90 degrees.The preparation method comprises the steps that the SOI wafer is used the raw material, and the butterfly wing microgyroscope is prepared by combining wet etching and dry etching. The flexible configuration of the principal axis azimuth of the microgyroscope can be achieved, and meanwhile the effect of reducing the machining technic error on the performance of the microgyroscope is reduced, and the butterfly wing microgyroscope has the advantages of high tolerance capability, simple machining technic, high machining quality, good machining robustness, good stability and wide range of application.

Owner:NAT UNIV OF DEFENSE TECH

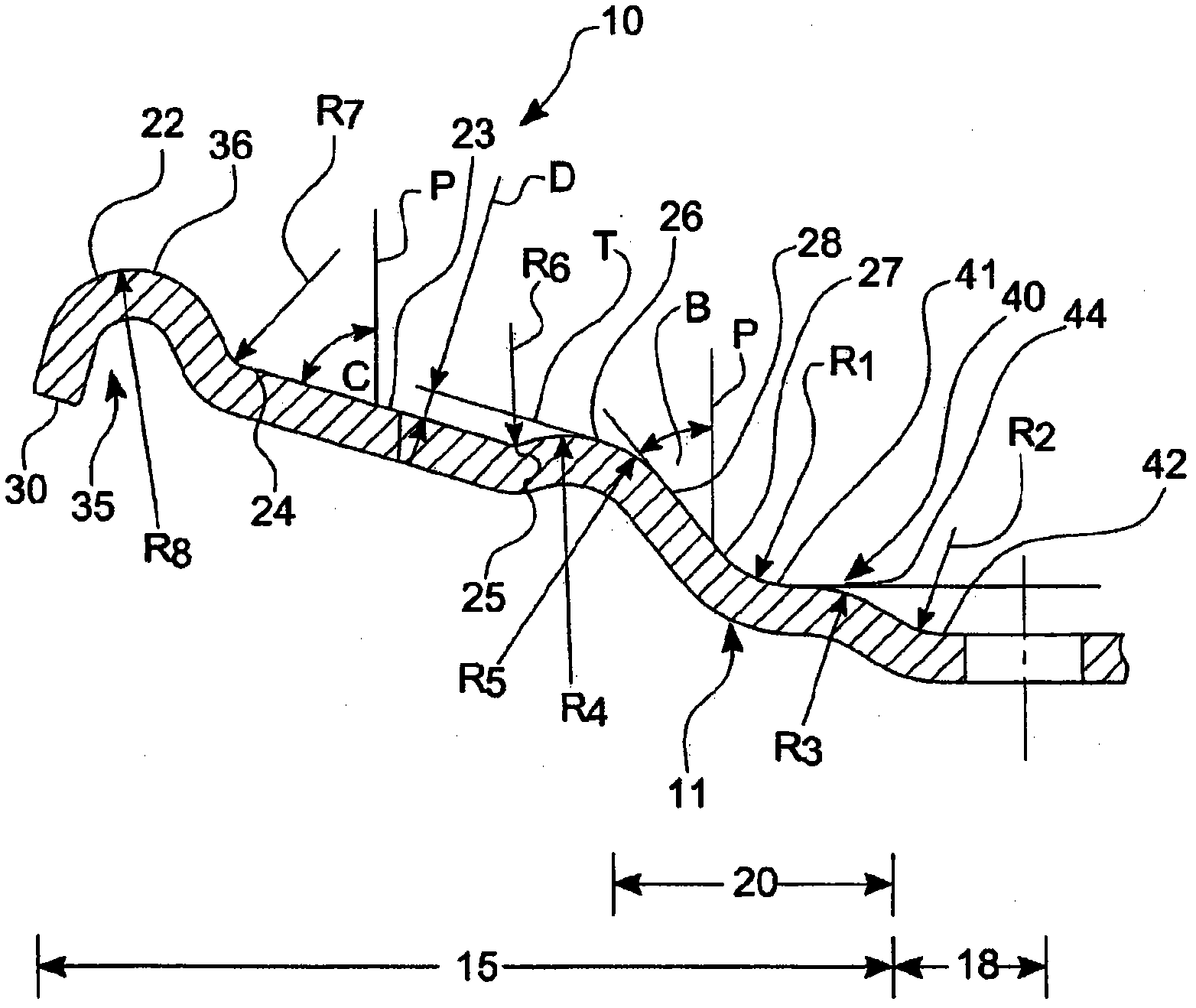

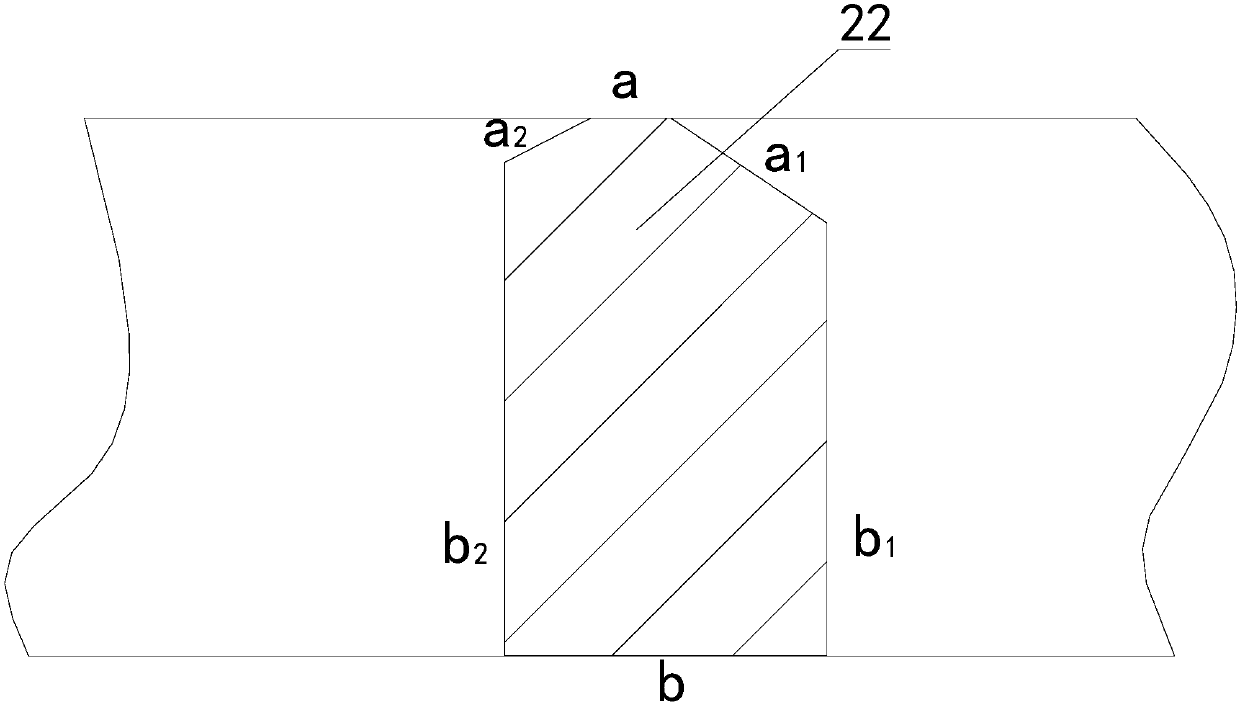

Wheel construction

A wheel construction (10) includes a wheel rim (11 ) which in use, at a tyre side (12) of the rim (11 ), receives a tyre (14), the rim (11) being circular and having axially inner and outer portions (16,15), and a mid-portion (18) between the axially inner and outer portions (16,15), the mid-portion (18) including a circumferential well where the radius of the wheel rim (11 ) is a minimum, and each axially inner and outer portion (16,15) providing a flange (22), a connecting surface (23) adjoining the flange (22) and extending axially towards the mid portion (18), the flange (22) and a part of the connecting surface (23) providing a seat for a bead of the tyre (14), and there being a side part (19,20) between the connecting surface (23) and the mid portion (18) and wherein for at least one of the inner and outer portions (16, 15), the connecting surface (23); is frusto-conical having an axial end (24) of greatest radius and an axial end (25) of least radius, the connecting surface (23), at its axial end (24) of greatest radius, adjoining the flange (22), and the side part (20, 19) of the at least one of the axially inner and outer portions (16, 15) including a generally frusto-conical region (28) and a curved region (40), the frusto-conical region (28) at its end of greatest radius (26) adjoining the connecting surface (23), and the curved region (40) including first (41 ), second (42) and third (43) axially spaced circumferentially extending concave surfaces, when viewed from the tyre side (12) of the rim (11 ), the curved region (40) adjoining an end (29) of least radius of the frusto-conical region (28) and the mid-portion (18).

Owner:GKN OFFHIGHWAY LTD

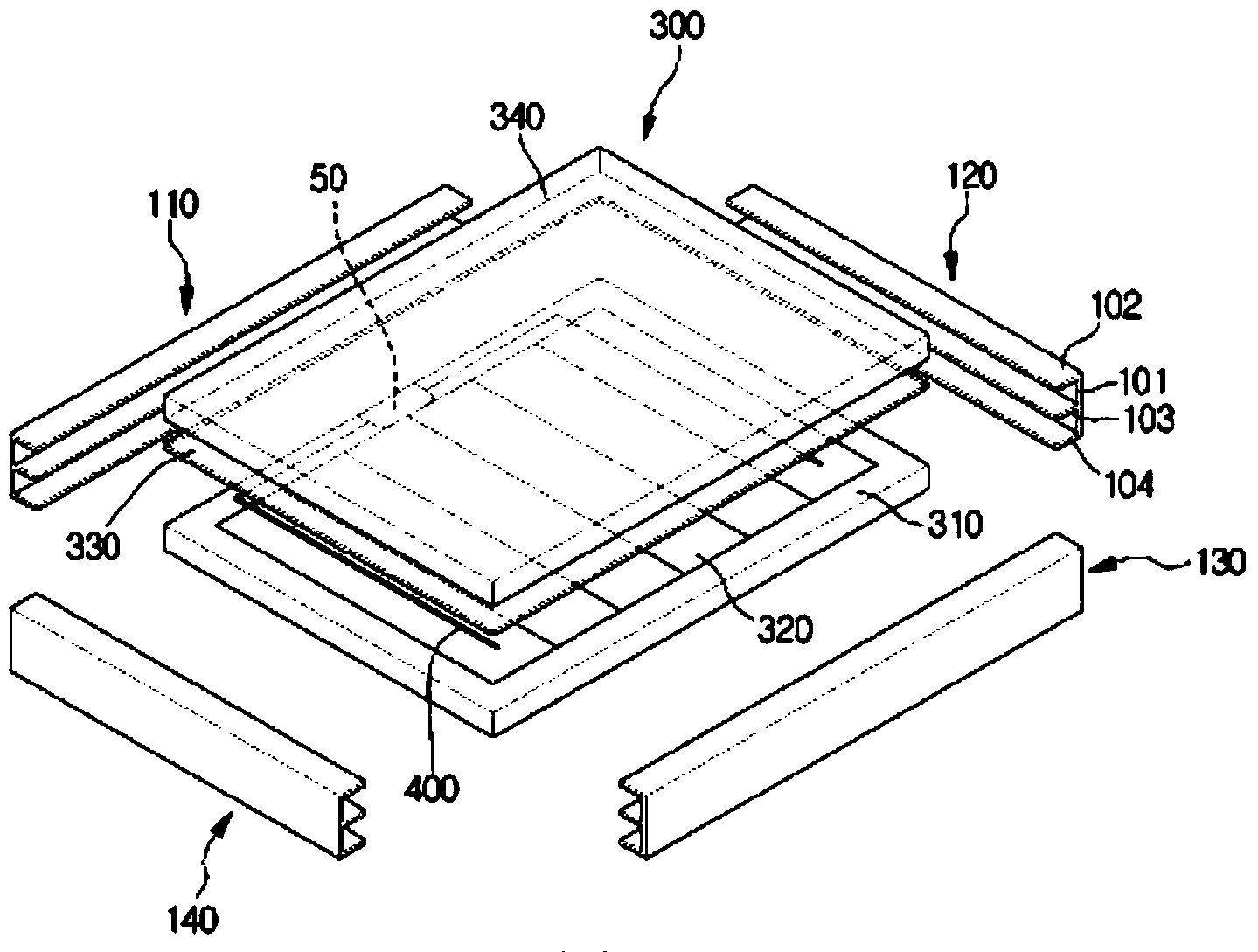

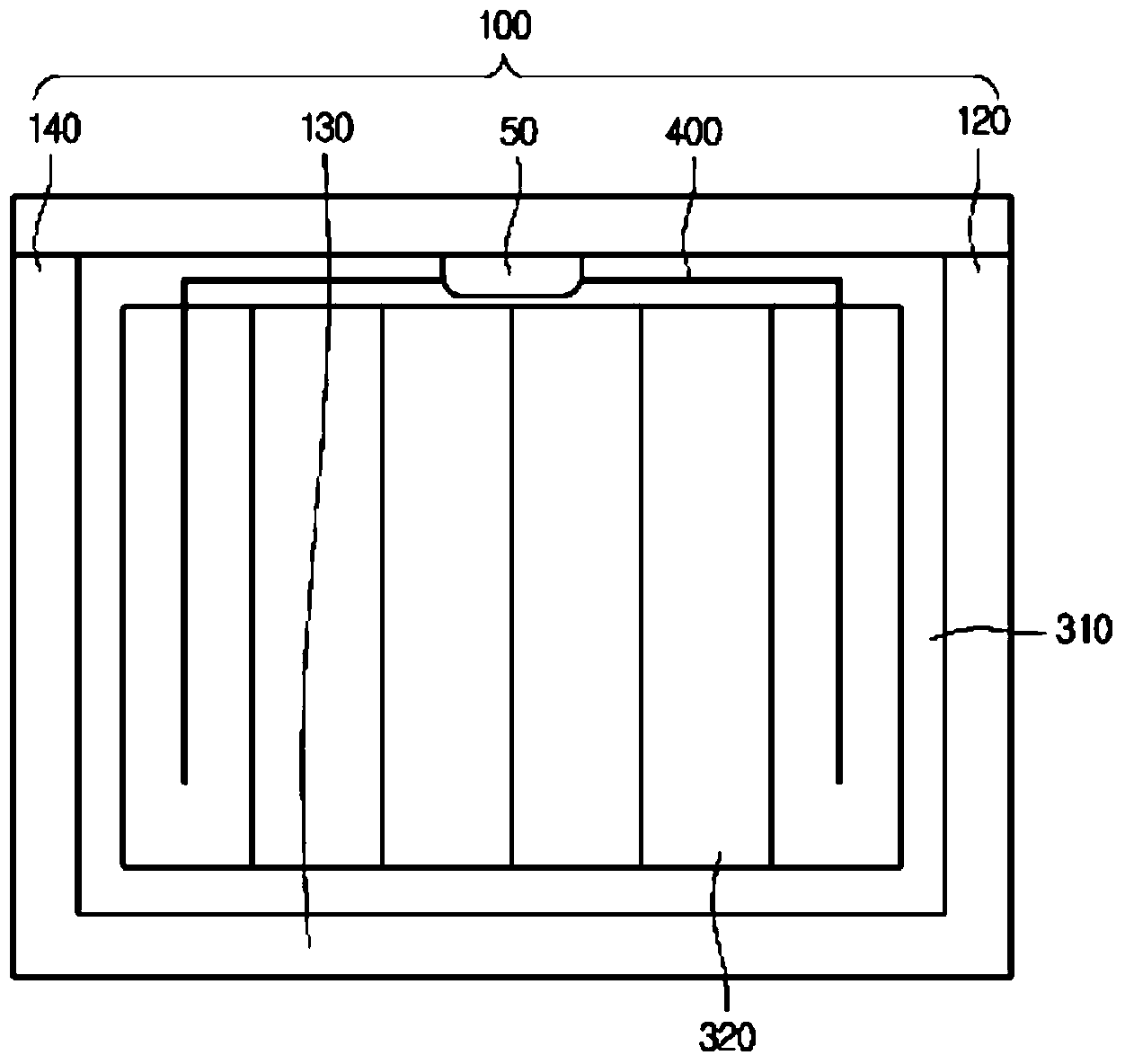

Solar cell module and method of fabricating the same

InactiveCN104067511AImprove reliabilityLow failure ratePhotovoltaic supportsPhotovoltaic energy generationElectricitySolar cell

A solar cell module according to the embodiment includes a support substrate having a single hole at a peripheral region of the support substrate; solar cells at an upper portion of the support substrate; a bus bar electrically connected to the solar cells; and a junction box connected to the bus bar, wherein the junction box includes an insertion part partially inserted in the single hole.

Owner:LG INNOTEK CO LTD

Collector heat dissipation structure for radiant cooling type space traveling-wave tube

ActiveCN110970278ASimple structureStrong mechanical resistanceTransit-tube collectorsMechanical resistanceEngineering

The invention discloses a collector heat dissipation structure for a radiant cooling type space traveling-wave tube. A collector comprises a collector electrode, an insulating porcelain plate and a collector outer cylinder; the collector electrode is a cylinder; a plurality of insulating porcelain plates are uniformly fixed on the outer cylindrical surface; and the collector outer cylinder surrounds the cylindrical surface of the collector electrode, the inner wall of the collector outer cylinder is provided with fixing grooves in one-to-one correspondence with the insulating porcelain plates,the heat dissipation structure comprises a plurality of O-shaped rings and a heat radiator surrounding the collector outer cylinder, the outer circumference of the collector outer cylinder is uniformly and fixedly provided with the plurality of O-shaped rings, and the outer edge of each O-shaped ring is fixed on the inner wall of the heat radiator. The structure is simple, the mechanical resistance is high, the reliability is good, the process realizability is good, and the working requirement of the long-life space traveling-wave tube can be met.

Owner:NANJING SANLE GROUP

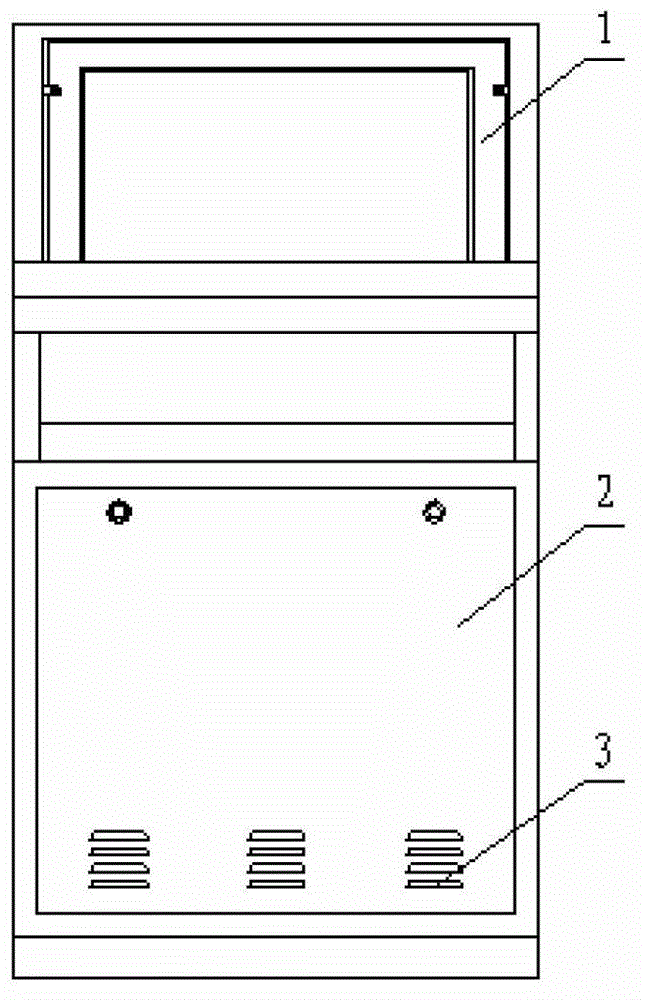

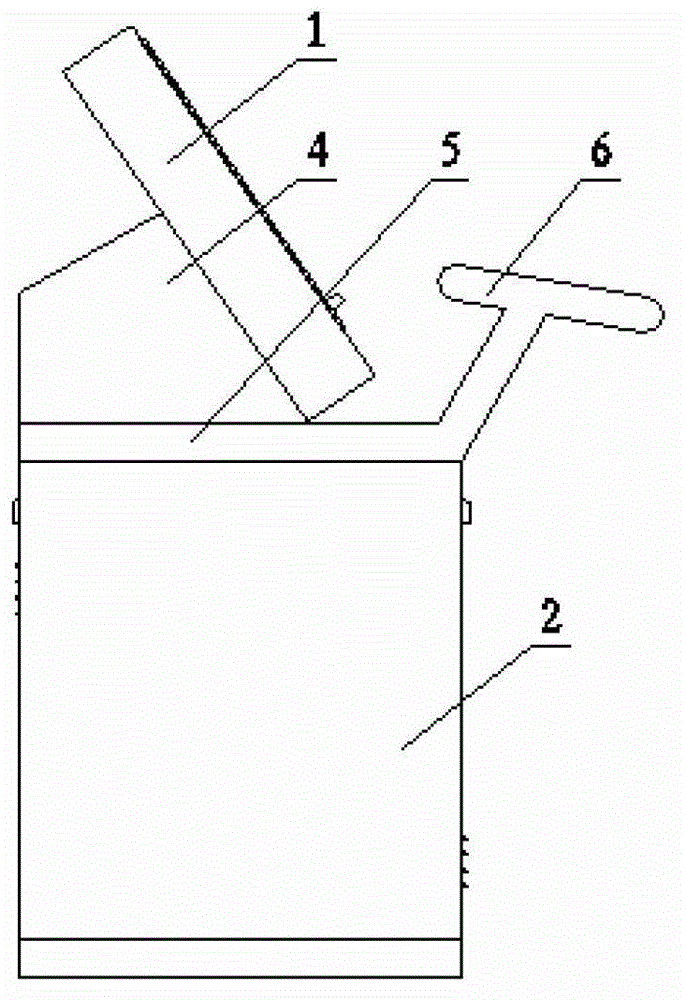

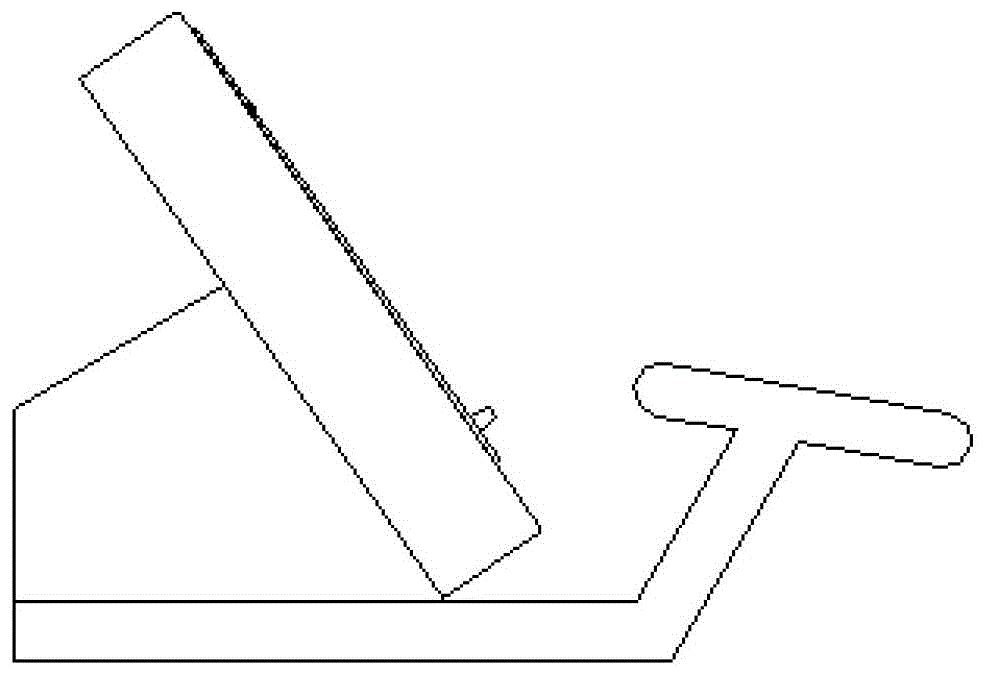

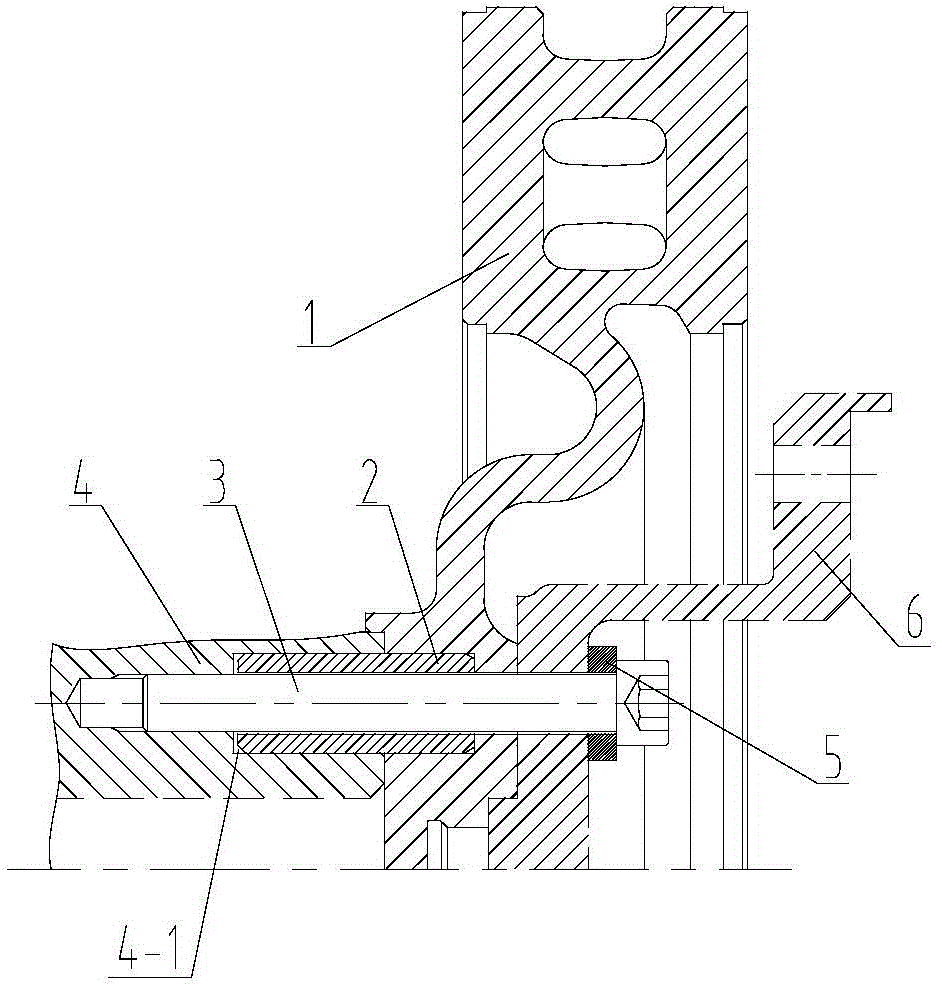

Ship cab console

InactiveCN102975842AAvoid joint muscle fatigueEasy to operatePropulsion power plantsPropulsive elementsMarine engineeringCrowds

The invention relates to a ship cab console. The ship cab console comprises a box body which is formed by mutually mounting an upper plate, a bottom plate, a front panel, a back panel, a left side plate and a right side plate, wherein a tray is arranged above the box body; a display screen mounting box is arranged on the tray; and an operation panel is arranged on the tray positioned in front of the display screen mounting box. The ship cab console is simple and reliable in structure, relation among a user, a machine and an environment is fully considered, due to the adoption of a double-percentile size design, the demands of operators can be met to the maximum extent, the labor strength of the operators during daily driving work is reduced, the error operation rate is reduced, meanwhile, the box body is high in mechanical strength, good in expandability and high in electromagnetic compatibility, the safety of driving is improved to the maximal degree, and the safety of the navigation of a ship is effectively ensured.

Owner:TIANJIN NAVIGATION INSTR RES INST

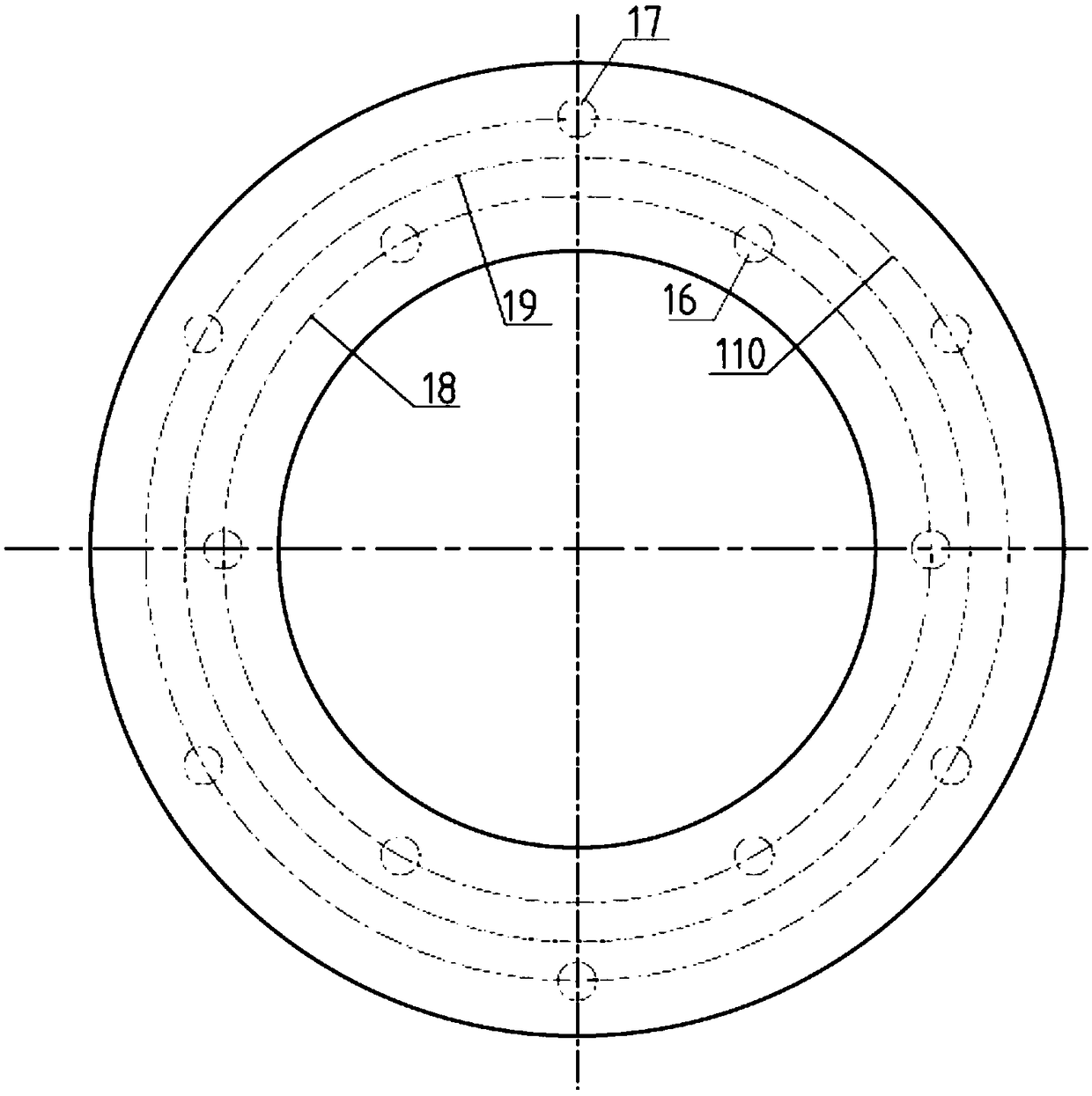

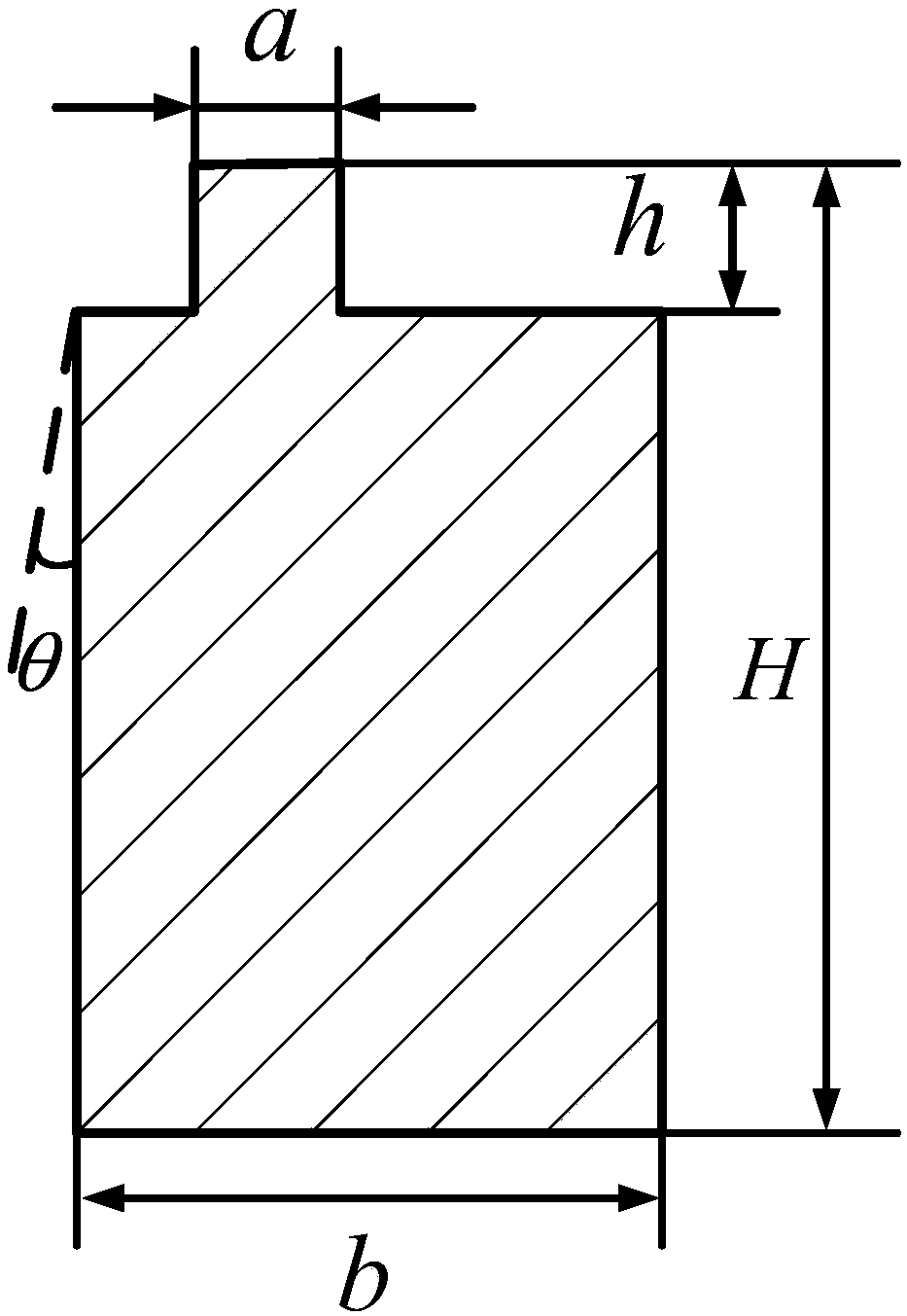

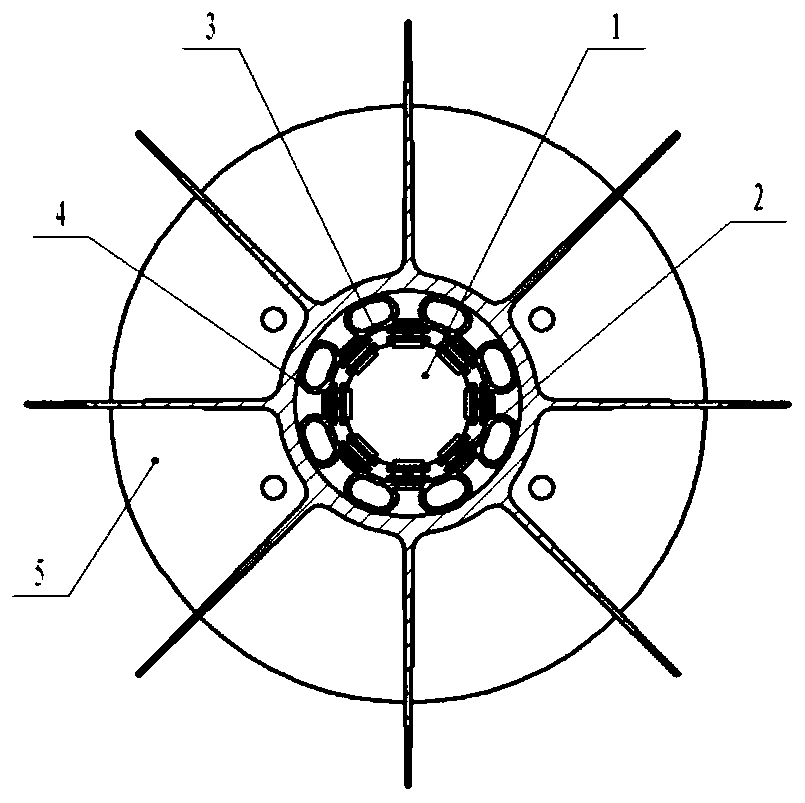

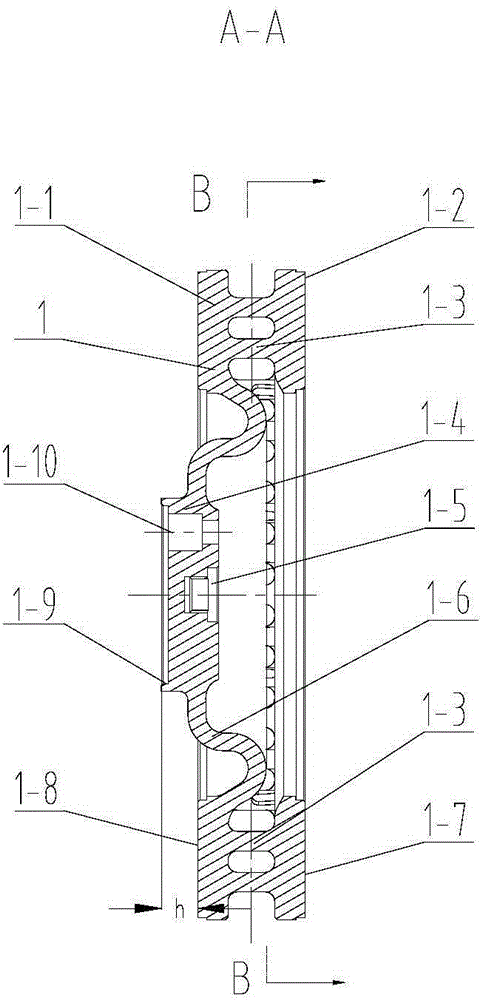

Connecting structure of wheel mounted type brake disc for rail transit vehicle

The invention relates to a connecting structure of a wheel mounted type brake disc for a rail transit vehicle. The connecting structure comprises a wheel connecting part, a disc body and connecting screws. The disc body comprises an inner friction ring, an outer friction ring and a disc bowl which are integrated. The distance between the inner end face of the disc bowl and the inner friction surface of the inner friction ring is h. The disc bowl is connected with the inner friction ring through an arc-shaped center plate. Radiating ribs are arranged between the inner friction ring and the outer friction ring in the circumferential direction. The inner end face of the disc bowl is provided with an inner positioning hole matched with the wheel connecting part. The end of the wheel connecting part is arranged in the inner positioning hole of the disc bowl. The disc bowl is provided with at least three step holes, and the wheel connecting part is provided with step mounting holes corresponding to the step holes. Elastic cylindrical pins are arranged in the step holes of the disc bowl and the step mounting holes of the wheel connecting part. The connecting screws penetrate through the disc bowl and the elastic cylindrical pins and are connected with the wheel connecting part. The connecting structure is simple, higher in assembling and positioning precision and convenient to dismount, structural stress in the braking process can be reduced, and the reliability of the connecting structure is improved.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

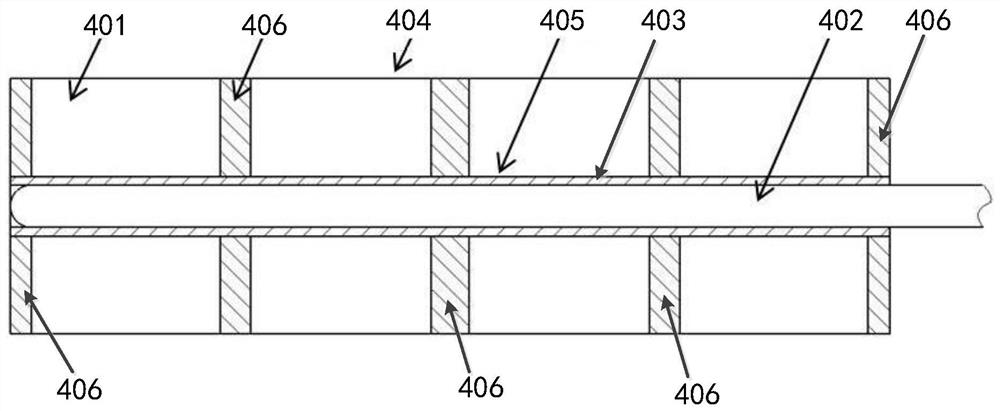

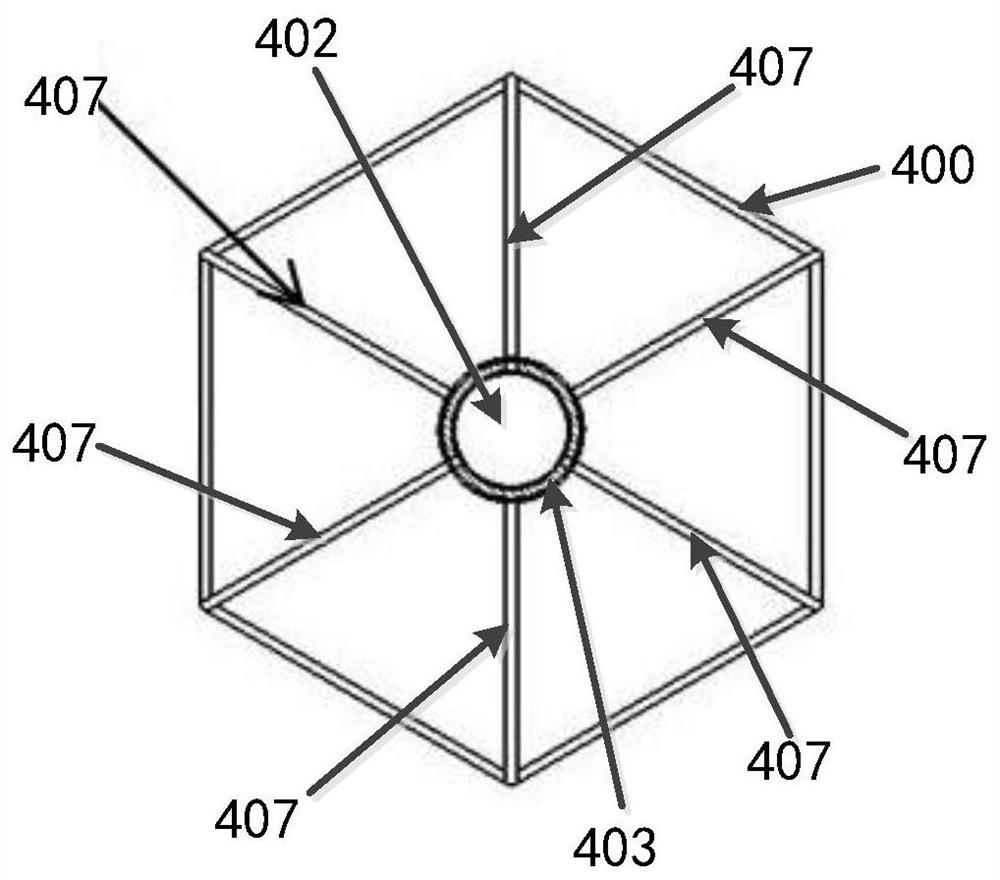

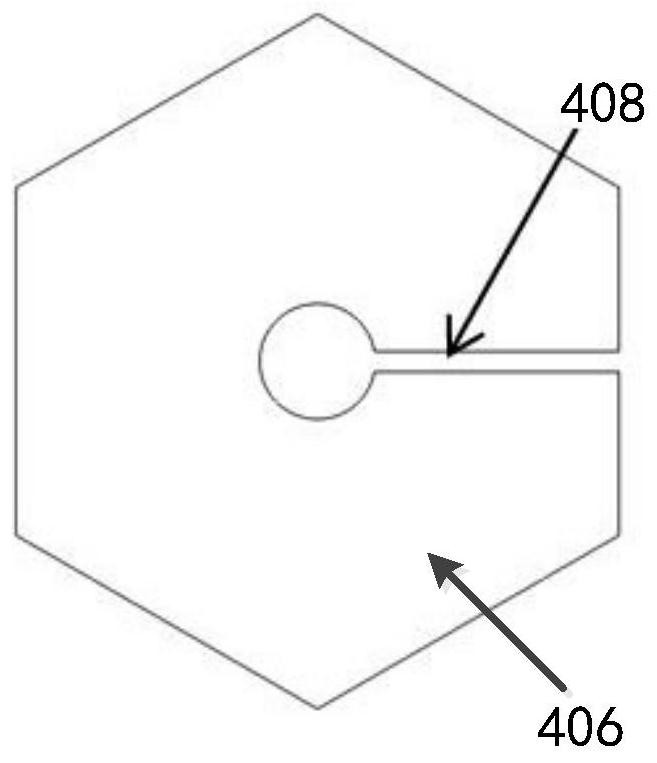

Efficient heat-conducting heat pipe reactor fuel element

ActiveCN113130097AImprove power densityImprove thermal conductivityFuel elementsNuclear energy generationEngineeringMechanical engineering

The invention relates to an efficient heat-conducting heat pipe reactor fuel element. The fuel element comprises a nuclear fuel, a cladding pipe, a heat pipe and a heat conduction ring. The cladding pipe comprises an inner wall and an outer wall which are arranged in a sleeved manner, the heat pipe is arranged in an inner hole of the inner wall, and the heat conduction ring sleeves the heat pipe and is located between the heat pipe and the inner wall. A plurality of axial heat conduction plates and a plurality of radial heat conduction plates are arranged between the inner wall and the outer wall of the cladding pipe, the cladding pipe is divided into a plurality of fuel areas used for being filled with the nuclear fuel by the axial guide plates and the radial guide plates, and stress release grooves are formed in the axial guide plates. According to the efficient heat-conducting heat pipe reactor fuel element, the nuclear fuel is arranged in the cladding pipe, and nuclear heat generated by operation is transferred to the heat pipe through the wall of the cladding pipe; the axial and radial heat conduction plates are arranged in the cladding pipe and are used for assisting efficient heat conduction; the heat pipe is arranged in the center of the fuel element and is used for guiding heat of a reactor core out of the reactor; and the heat conduction ring is arranged between the heat pipe and the cladding pipe, and contact heat transfer between the heat pipe and the cladding pipe is achieved.

Owner:安徽中科超核科技有限公司

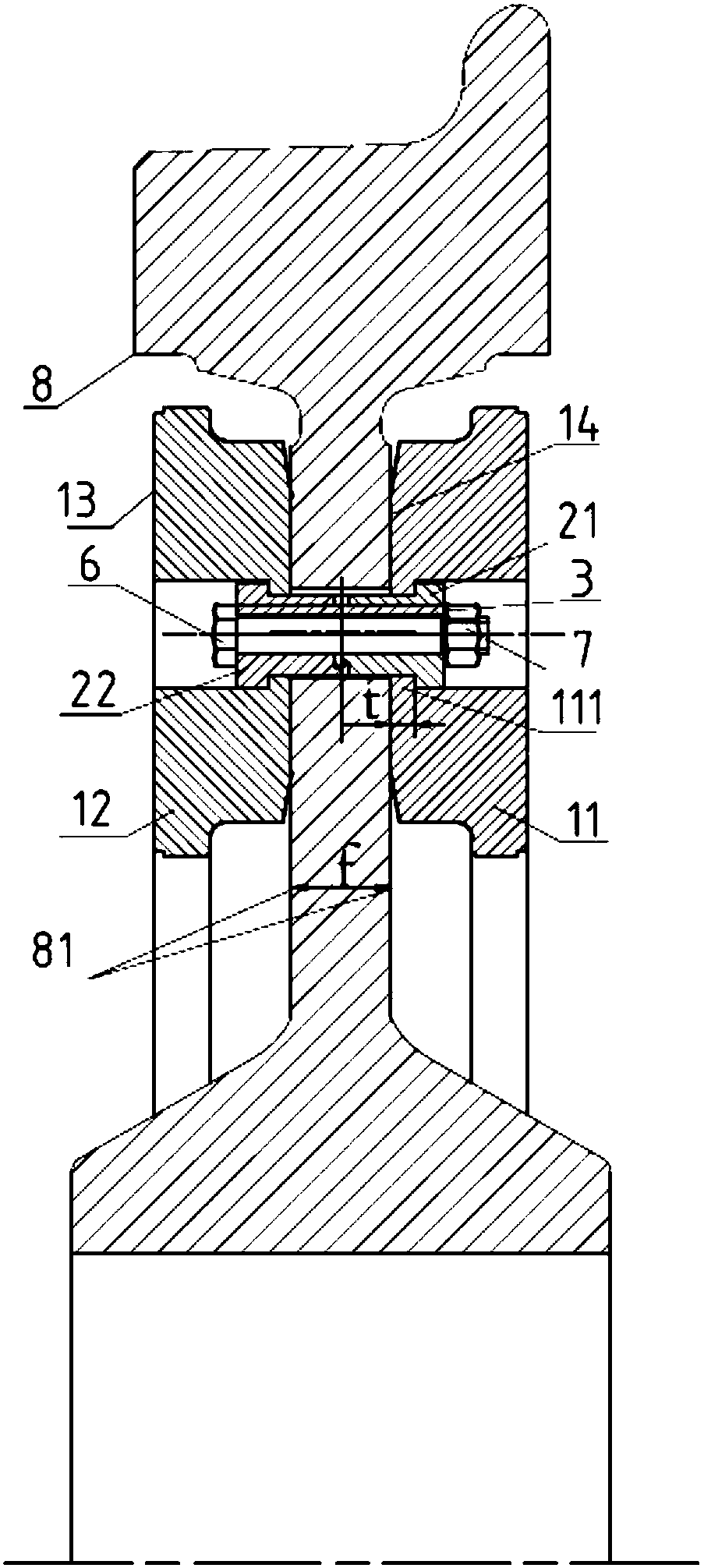

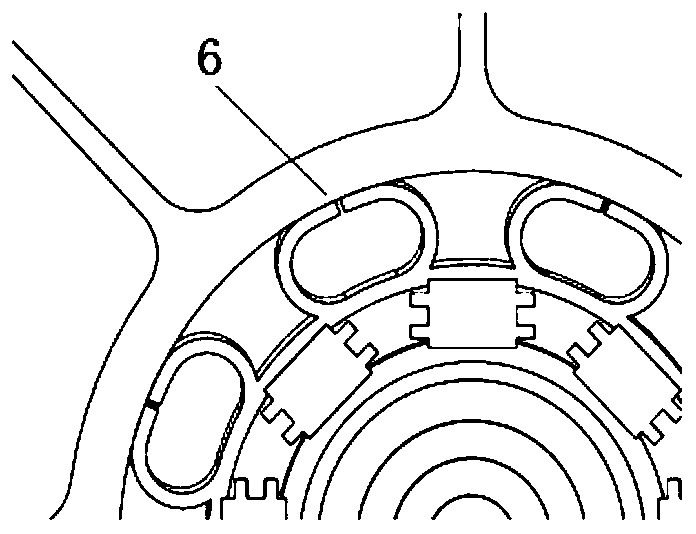

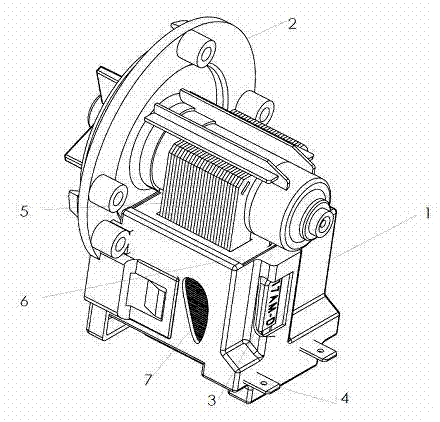

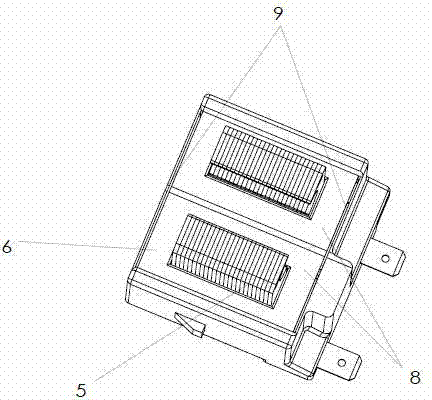

Semi-plastic sealed permanent magnet synchronous motor

ActiveCN103516090BPrevent oxidationAvoid corrosionWindings insulation shape/form/constructionMagnetic circuit stationary partsPermanent magnet synchronous motorStator coil

The invention relates to a semi-plastic-package permanent-magnet synchronous motor including a stator assembly (1), a rotor assembly (2), a heat protector (3) and a lead-out wire inserting sheet (4). The stator assembly is composed of a stator iron core (5), a coil frame (6) and a stator coil winding (7). The stator coil winding (7) is coiled on the coil frame (6). The stator coil winding (7) is connected with the heat protector (3). The heat protector (3) is connected with the lead-out wire inserting sheet (4). Connection positions of the heat protector (3), the stator coil winding (7), the heat protector (3) and the lead-out wire inserting sheet (4) are completely plastic-packaged in resin material on the coil frame (6). At least one part of a rest part of the coil frame (6) has an exposed surface and is not plastic-packaged by the resin material. Therefore, the semi-plastic-package permanent-magnet synchronous motor can be prevented from oxidation and corrosion and can have a good heat dissipation effect.

Owner:CHANGZHOU LEILI MOTOR SCI & TECH

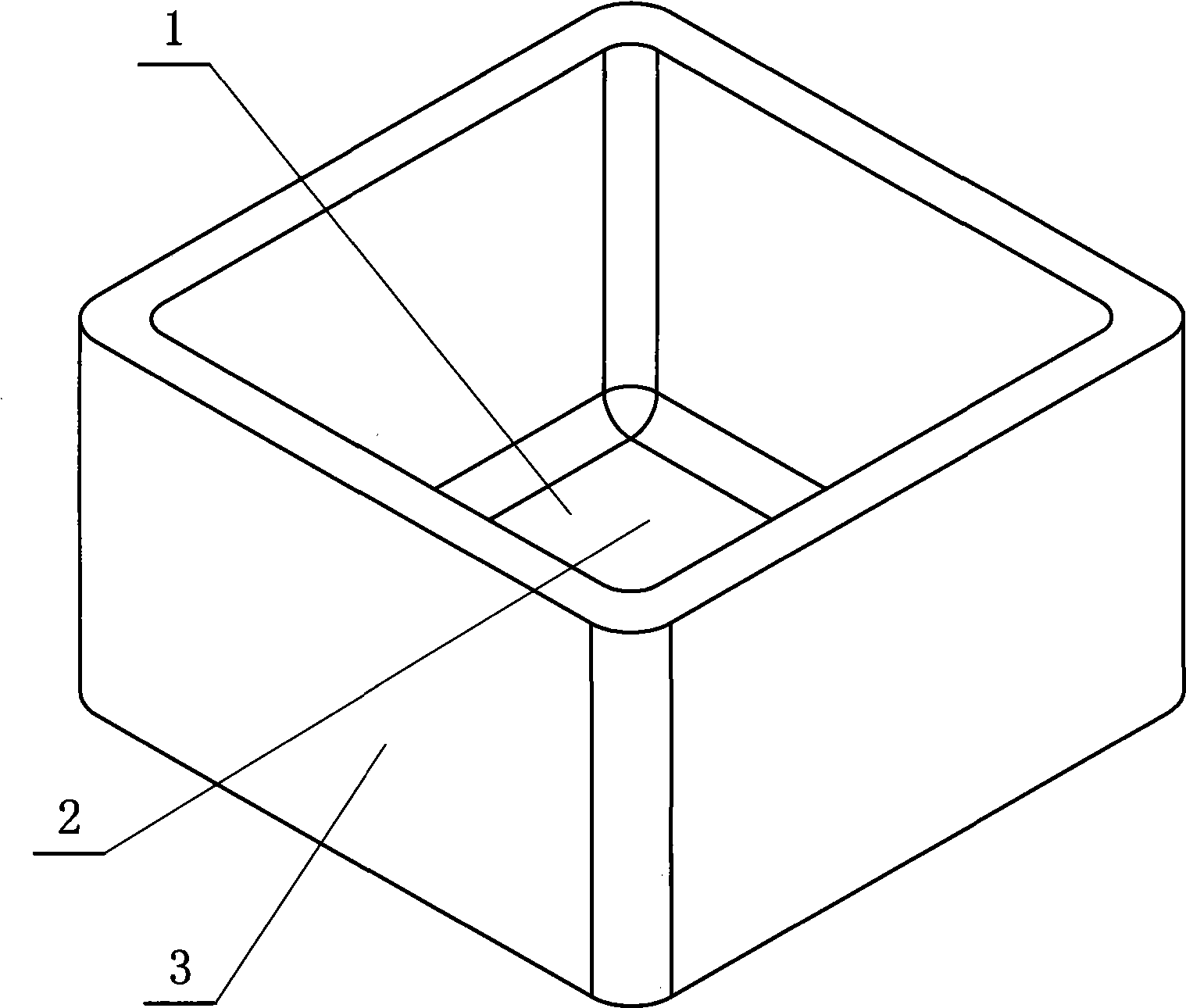

Baking sagger for lithium battery material

InactiveCN101487665AReduce structural stressExtended service lifeCharge manipulationFurnace typesEngineeringLithium battery

The invention discloses a lithium battery material furnacing seggar which can effectively solve the problem in the prior art that a seggar has large structural force which easily causes crackles. The lithium battery material furnacing seggar comprises a bottom surface and lateral walls, the lateral walls and the bottom surface form a concave cavity for furnacing, the lateral walls feature circular arc transition, so do the lateral walls and the bottom surface. The invention has the advantages that: the product is easily formed, thus reducing the structural force and forming force of the seggar, crackles are not easily caused, thus lengthening service life of the seggar, reducing production cost and obviously improving product quality.

Owner:冯维银

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com