Micro heating disc and manufacturing method thereof

A manufacturing method and micro-thermal technology, applied in the field of microelectronic systems, can solve the problems of limiting the integration of single-chip systems, increasing the difficulty of chip bonding, limiting product miniaturization, etc., to simplify the through hole etching process, small temperature gradient, The effect of stress relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

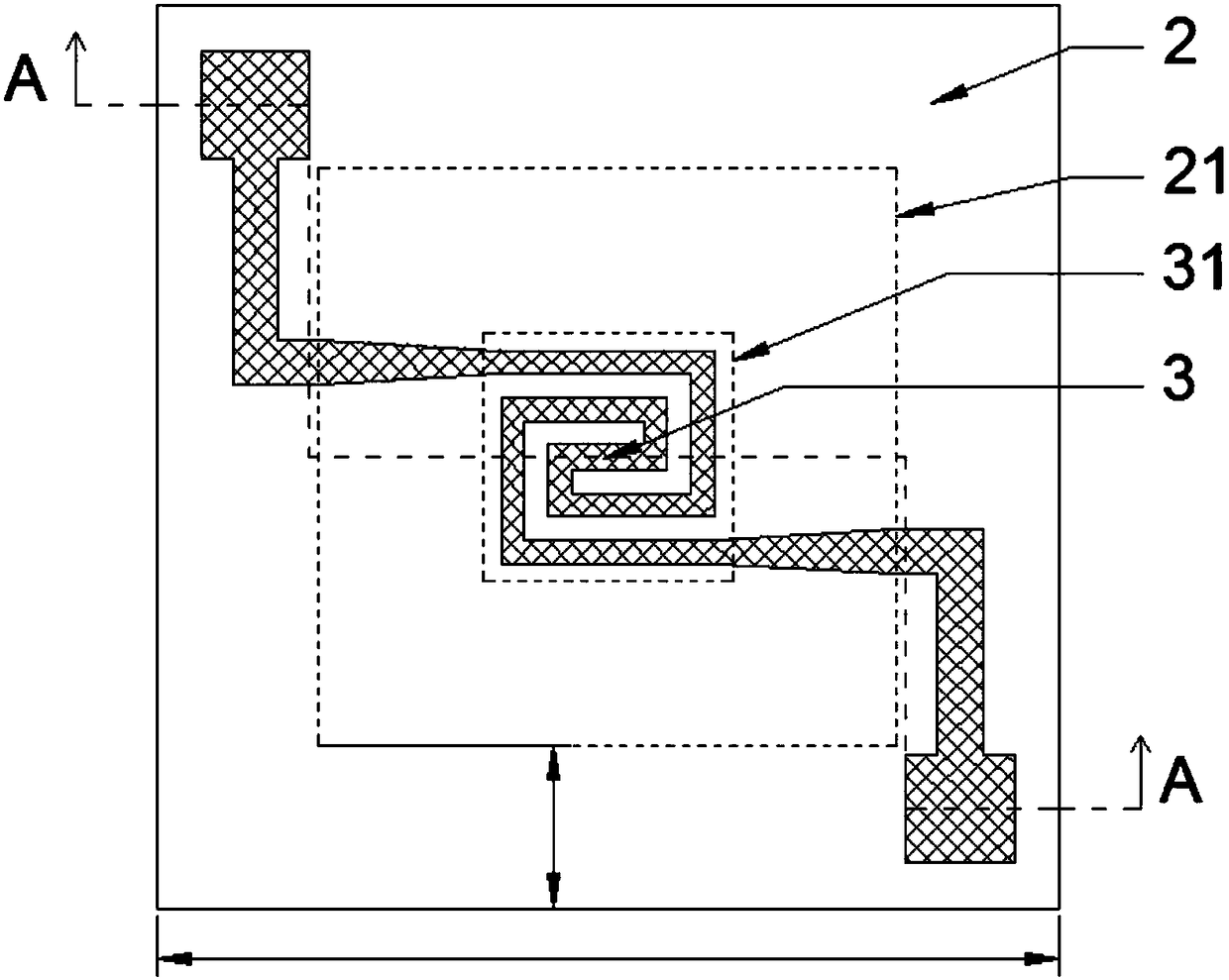

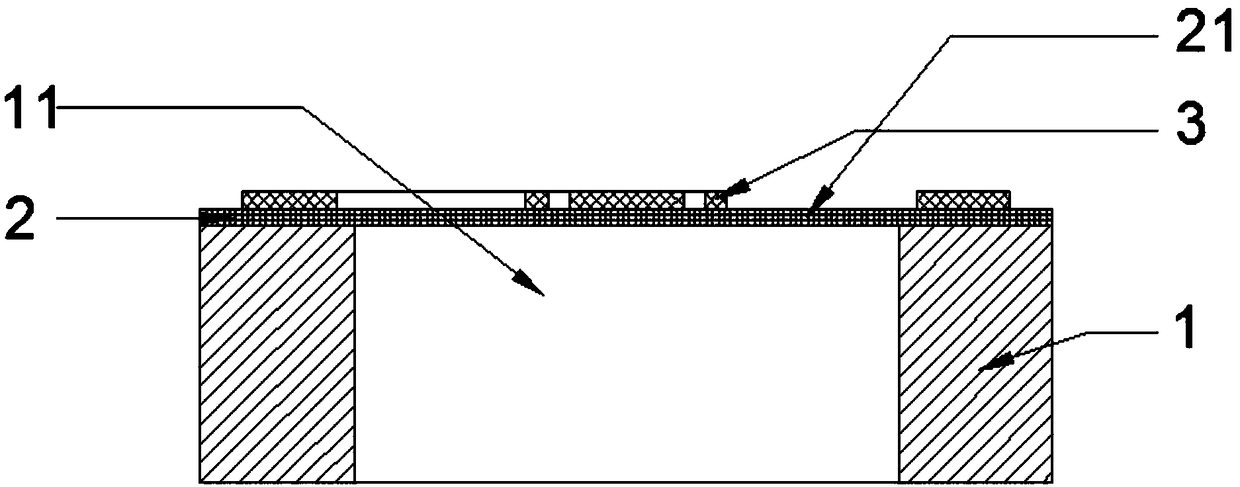

[0043] A micro hot plate, such as image 3 and Figure 4As shown, it includes: a substrate 1, an insulating support layer 2 and a resistance heating layer 3 stacked sequentially from bottom to top, a temperature isolation cavity 11 is arranged in the middle of the substrate 1, and the insulation support layer on the upper part of the temperature isolation cavity 11 is The temperature isolation suspension film 21, the resistance heating layer 3 is located on the insulating support layer 2, the heating area 31 of the resistance heating layer 3 is located in the middle part of the temperature isolation suspension film 21, and the substrate at the edge of the temperature isolation cavity 11 is provided with a The isolation cavity 11 is connected to the integrated deformation isolation cavity 12, and the insulating support layer on the upper part of the deformation isolation cavity 12 is a deformation isolation suspension film 22, and the deformation isolation suspension film 22 is...

Embodiment 2

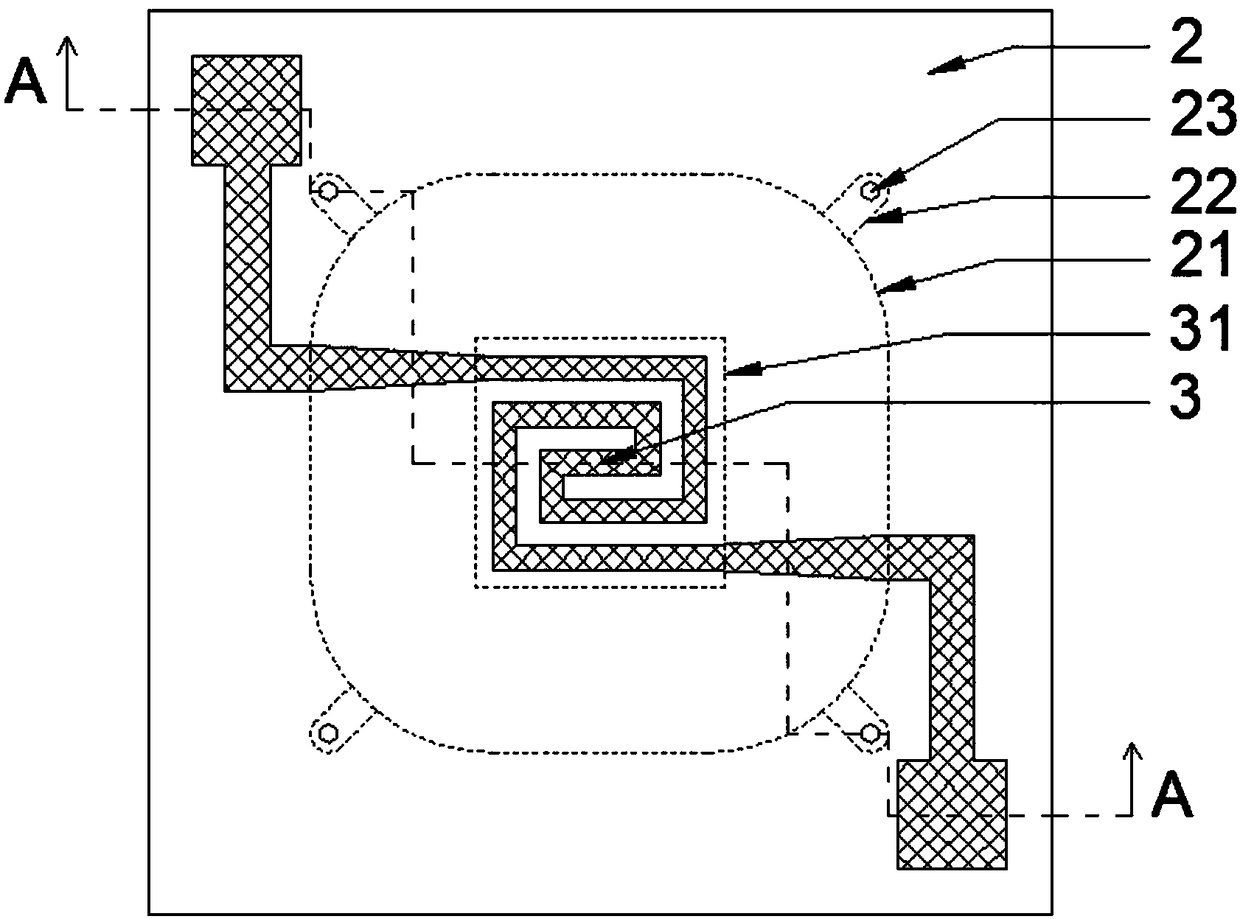

[0059] A micro hot plate, such as Figure 5 and Image 6 As shown, it includes: a substrate 1, an insulating support layer 2, and a resistance heating layer 3. The insulating support layer 2 is arranged on the substrate 1, the resistance heating layer 3 is arranged on the insulating support layer 2, and the substrate 1 is provided with temperature isolation. Cavity 11, the insulating support layer 2 on the top of the temperature isolation cavity 11 is a temperature isolation suspension film 21, a deformation isolation cavity 12 is arranged on the edge of the temperature isolation cavity 11, and the insulation support layer 2 on the top of the deformation isolation cavity 12 In order to deform the isolation suspension membrane 22, two semi-annular through holes 23 are arranged on the deformation isolation suspension membrane 22.

[0060] Wherein, the material of the substrate 1 is single crystal silicon, the material of the insulating support layer 2 is silicon nitride, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com