Shaft-mounted brake disc

A brake disc and shaft mounting technology, applied in the direction of brake discs, brake types, brake components, etc., can solve problems affecting product use and driving safety, difficulty in process realization, and increased stress sources on the disc surface. Sand cleaning and shot blasting operations, improving structural strength and crack resistance, and easy operation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

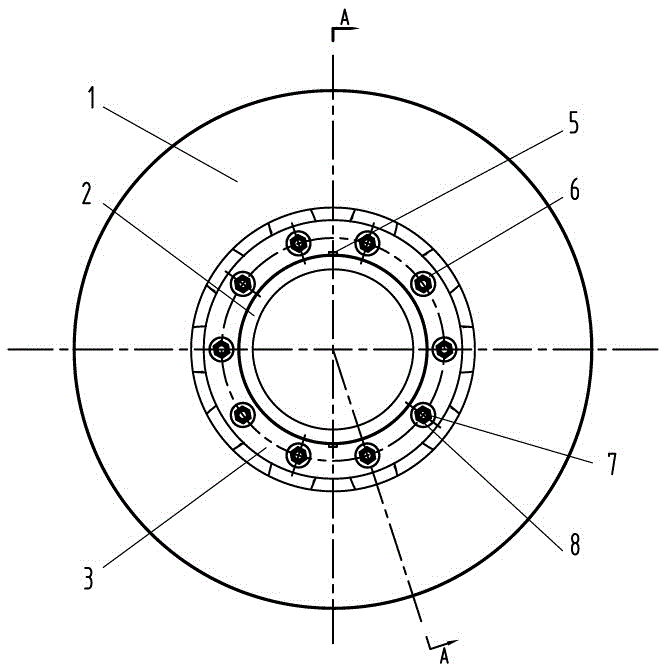

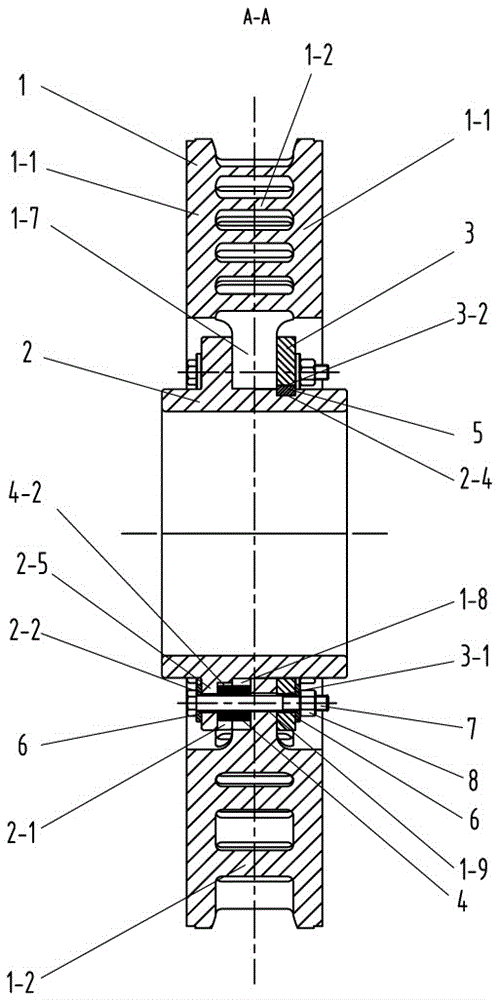

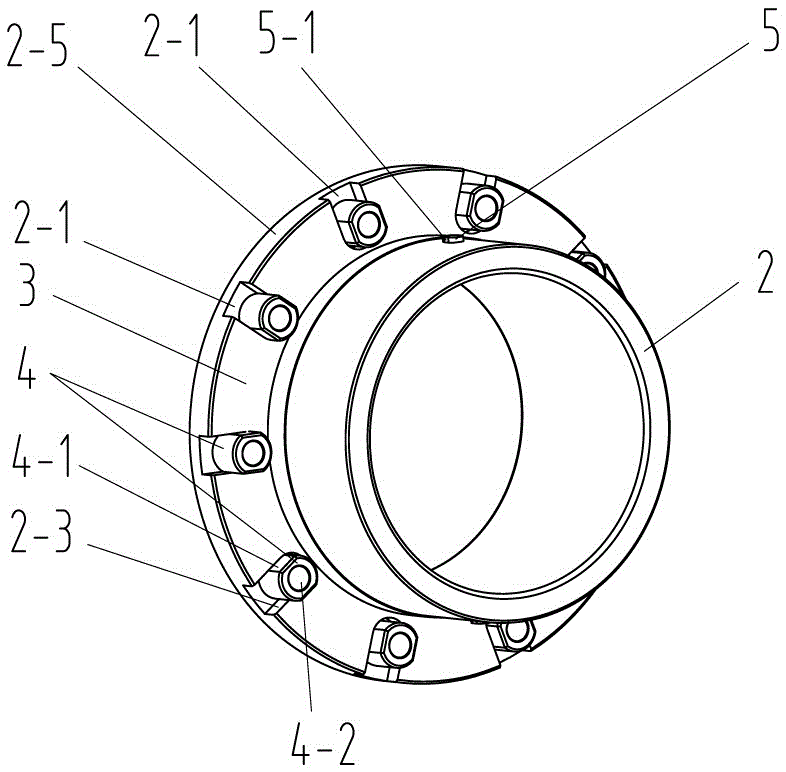

[0029] Such as figure 1 , 2, 3, and 4, the shaft-mounted brake disc of the present invention includes a disc body 1, a hub 2, a spacer ring 3, a slider 4, a positioning key 5, a gasket 6, a bolt 7 and a nut 8, and the disc body 1 includes two friction rings 1-1, a plurality of heat dissipation ribs 1-2 connected between the two friction rings 1-1, and several connecting claws 1 located on the inner ring of the friction ring 1-1 and arranged along the circumferential direction -7, the plurality of cooling ribs 1-2 are arranged in multiple circles from inside to outside along the radial direction of the friction ring 1-1, wherein the cross-sectional area of the cooling ribs 1-2 of the inner ring is smaller than that of the adjacent outer ring The cross-sectional area of the heat dissipation rib 1-2, the cross-sectional center of the single heat dissipation rib 1-2 of the inner ring is located on the radial symmetry line between the two heat dissipation ribs 1-2 of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com