Semi-plastic sealed permanent magnet synchronous motor

A permanent magnet synchronous motor and component technology, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of increasing failure rate, application limitation, unsatisfactory sealing effect, etc., to reduce and vibration noise, The effect of reducing structural stress and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

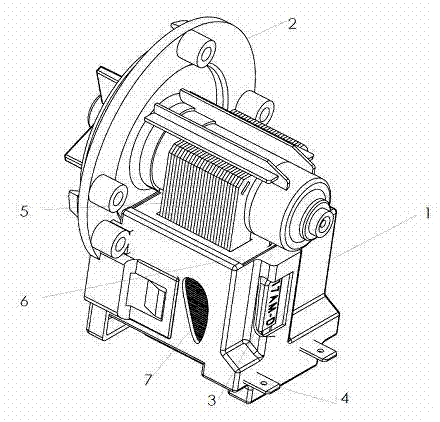

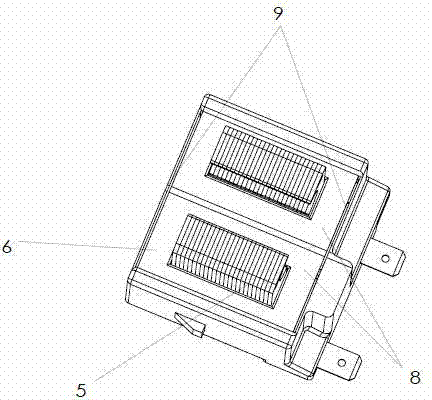

[0024] figure 1 It shows the overall structure of a semi-plastic-encapsulated permanent magnet synchronous motor of the present invention applied in a washing machine. Such as figure 1 As shown, it includes a stator assembly 1, a rotor assembly 2, a thermal protector 3, and an outlet wire insert 4. The stator assembly 1 is composed of a stator core 5, a coil frame 6 and a stator coil winding 7. The rotor assembly 2 includes The permanent magnet rotor located inside the pump body ( figure 1 not shown), the magnetic field generated after the stator coil winding 7 is energized drives the permanent magnet rotor to rotate, thereby driving the impeller coaxially arranged with the permanent magnet rotor to rotate, thereby realizing functions such as water supply or drainage. The stator assembly 1 is fixedly installed on the pump body of the rotor assembly 2 through the coil frame 6, the stator coil winding 7 is wound on the coil frame 6, the stator coil winding 7 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com