Connecting structure of wheel mounted type brake disc for rail transit vehicle

A technology for rail transit vehicles and connecting structures, which is applied in the field of brake discs for rail transit vehicles, can solve the problems of inaccurate positioning structure, large braking torque, and low reliability of train operation, and achieves high installation and positioning accuracy, maintenance and repair. Convenience, Enhanced Reliability Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

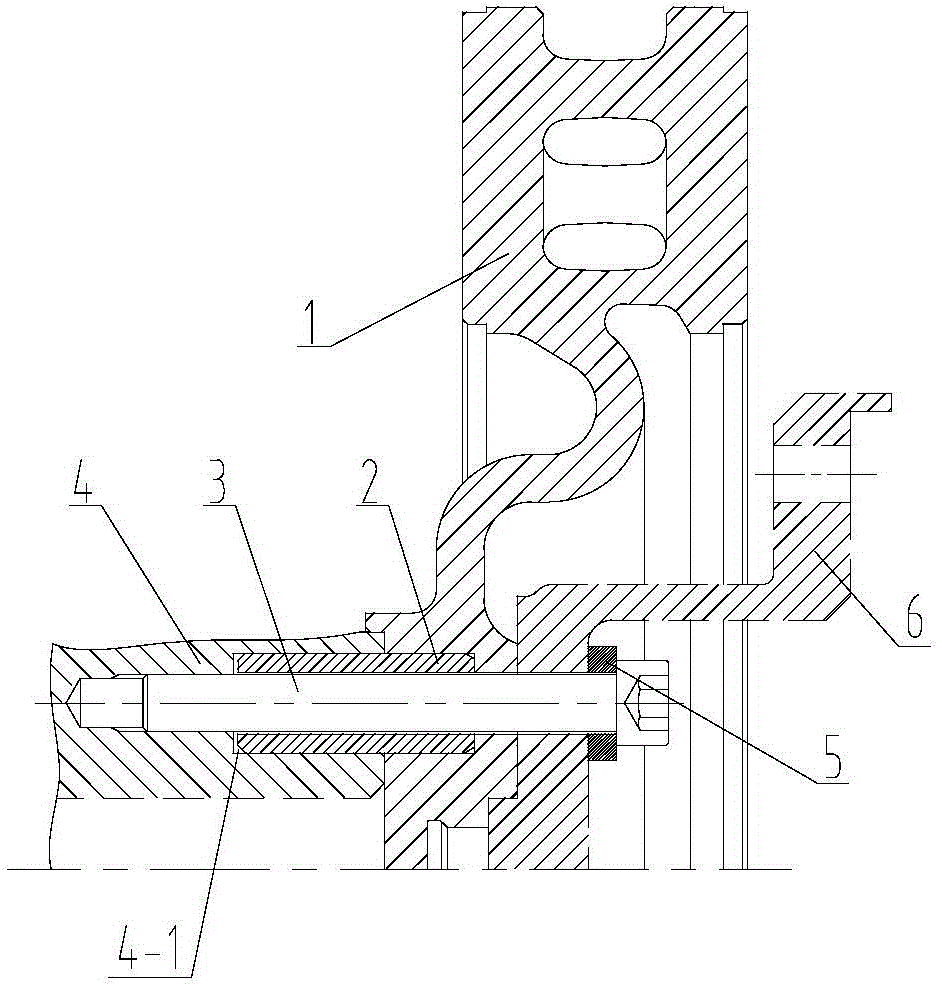

[0022] See Figure 1~4 As shown, the connection structure of the wheel-mounted brake disc for a rail transit vehicle of the present invention includes a wheel connector 4 , a disc body 1 and a connecting screw 3 for connecting the wheel connector 4 and the disc body 1 .

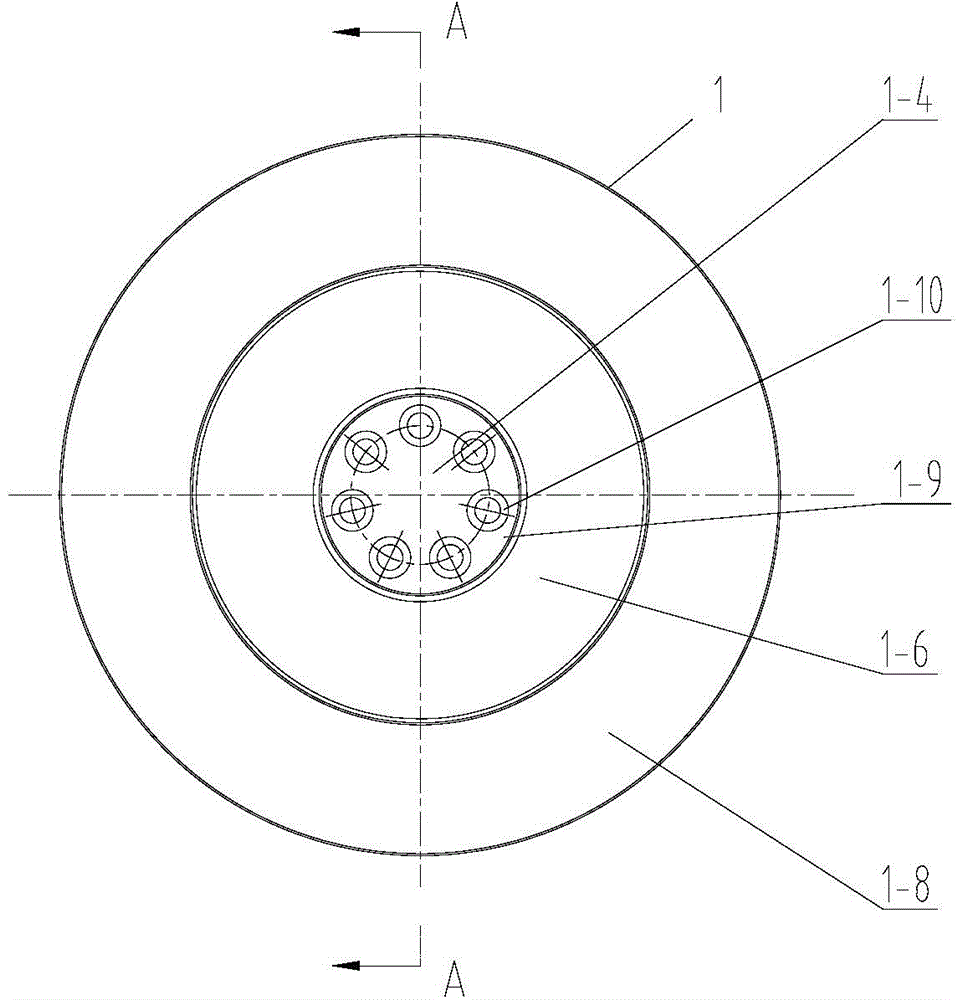

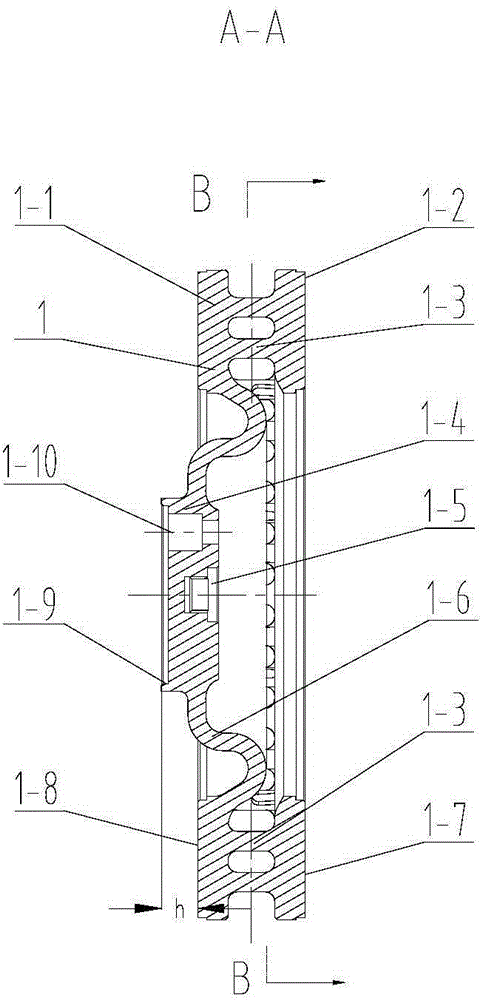

[0023] See Figure 1~4 As shown, the disc body 1 of the present invention includes an integrated inner friction ring 1-1, an outer friction ring 1-2 and a dish bowl 1-4, an inner friction ring 1-1, an outer friction ring 1-2 and a dish bowl 1-4. 4 have the same axis, the inside of the inner friction ring 1-1 is provided with an inner friction surface 1-8, and the outer side of the outer friction ring 1-2 is provided with an outer friction surface 1-7, and the inner and outer friction surfaces and the brake pads In contrast, there is a distance h between the inner end surface of the dish bowl 1-4 and the inner friction surface 1-8 of the inner friction ring 1-1. 1-4 is connected with the inner friction ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com