Patents

Literature

121results about How to "Improve installation positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

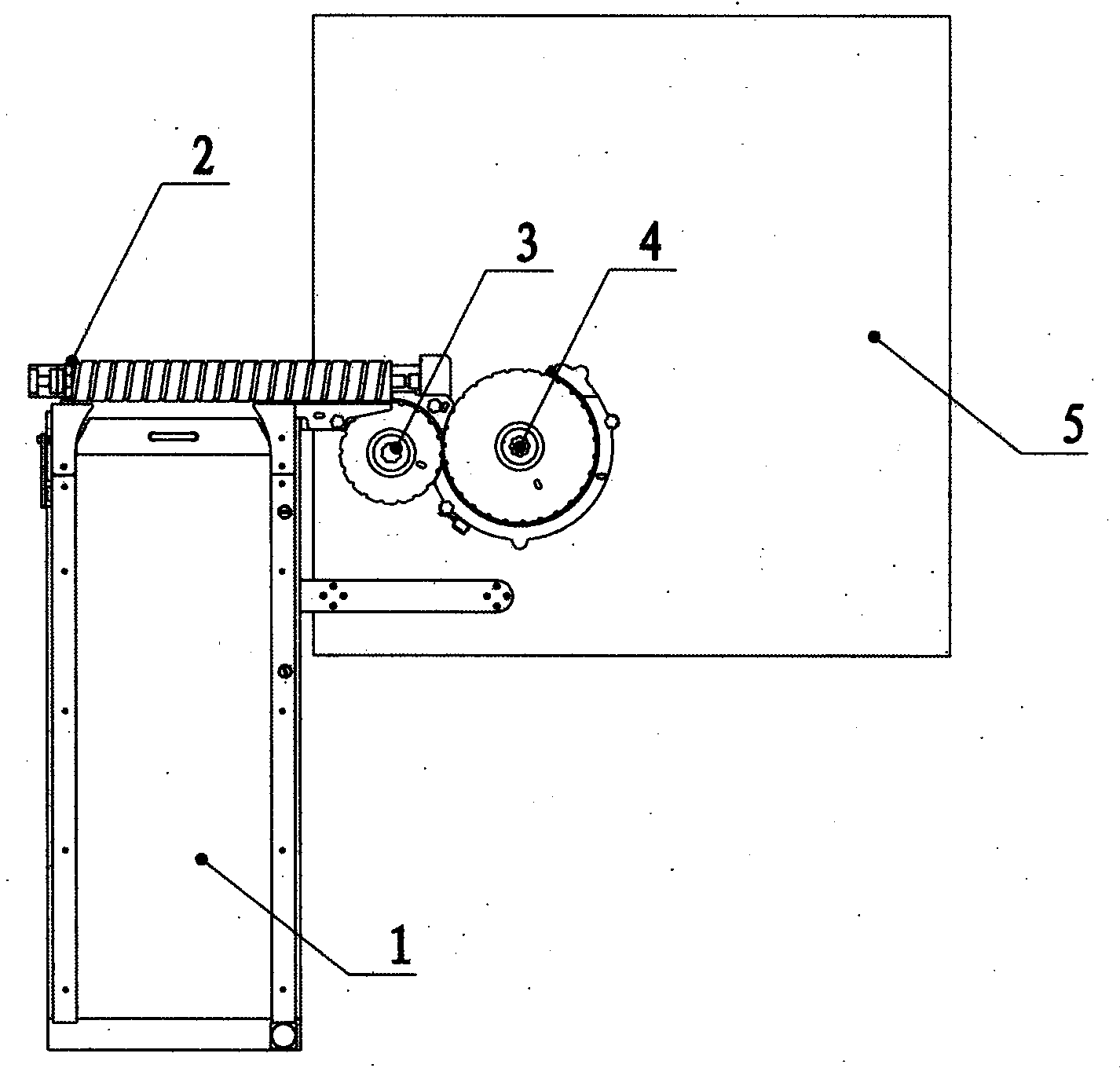

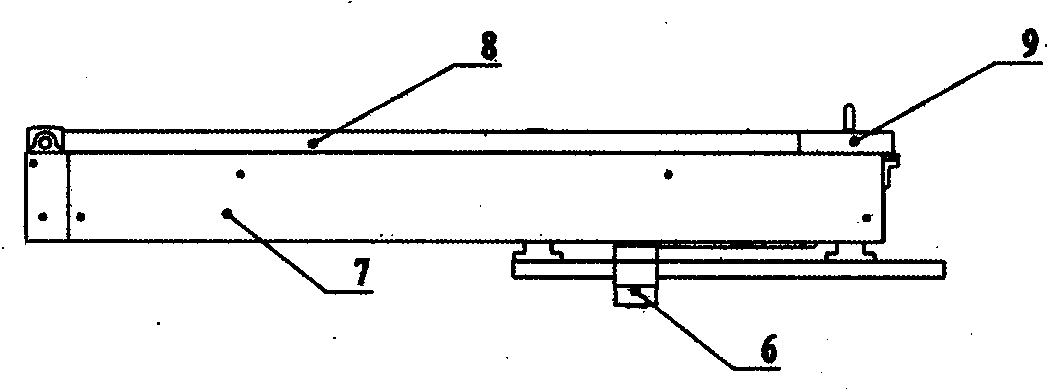

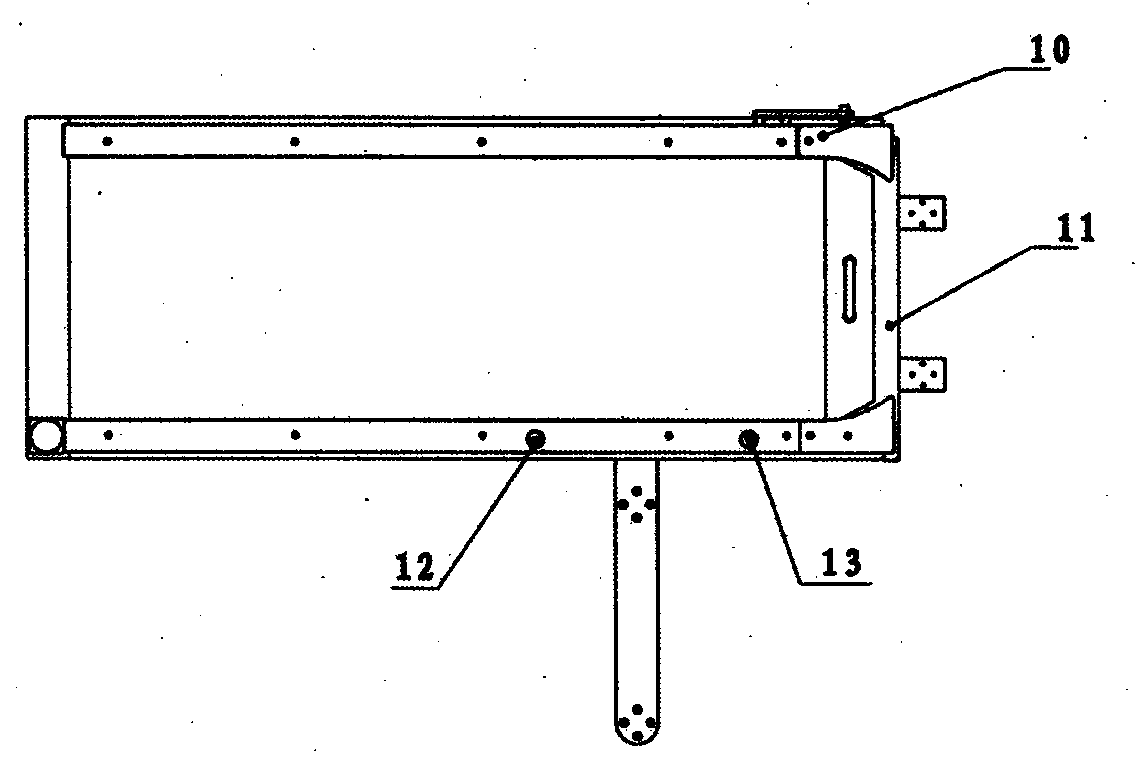

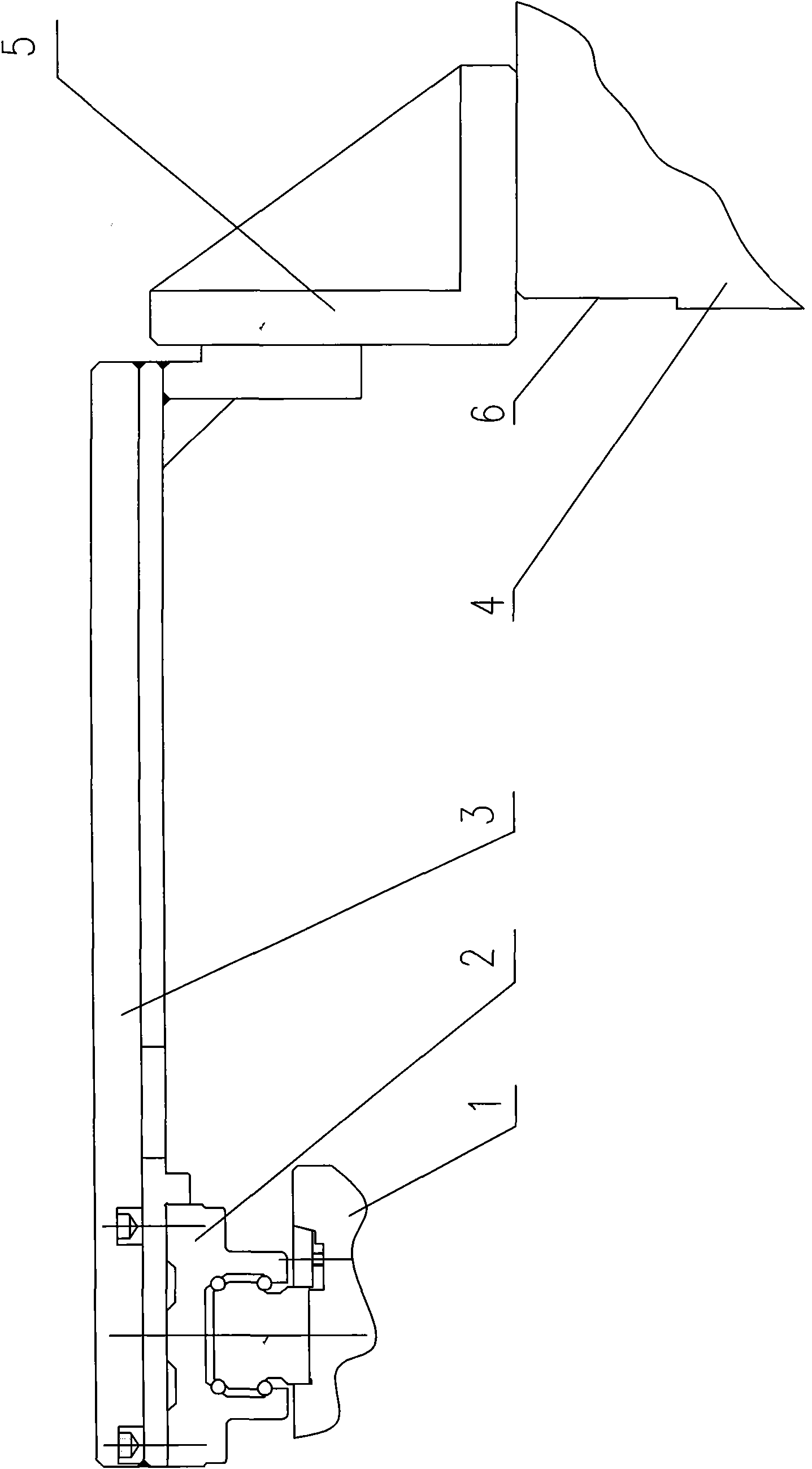

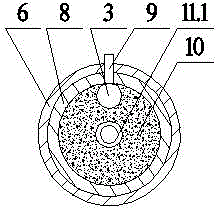

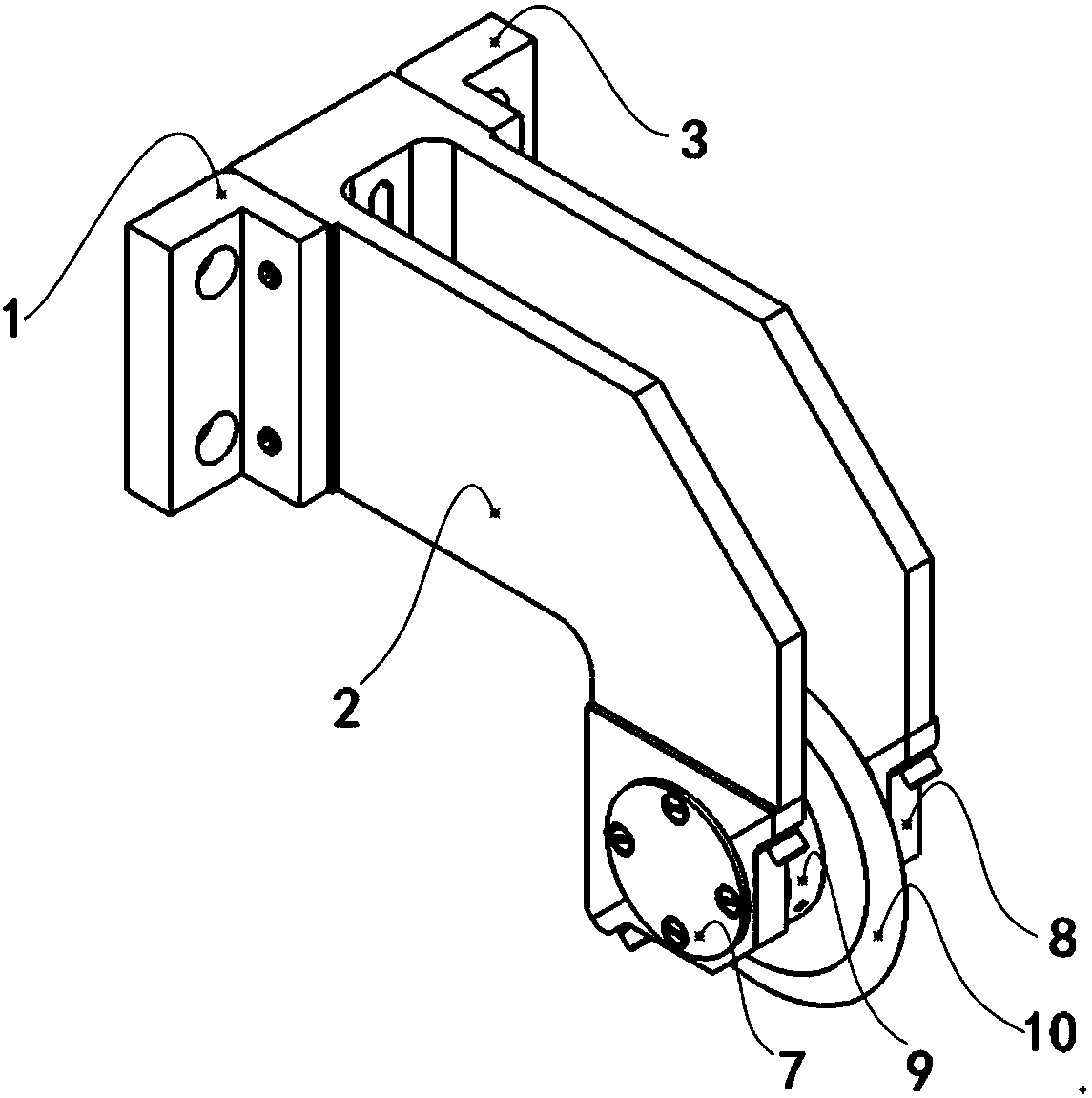

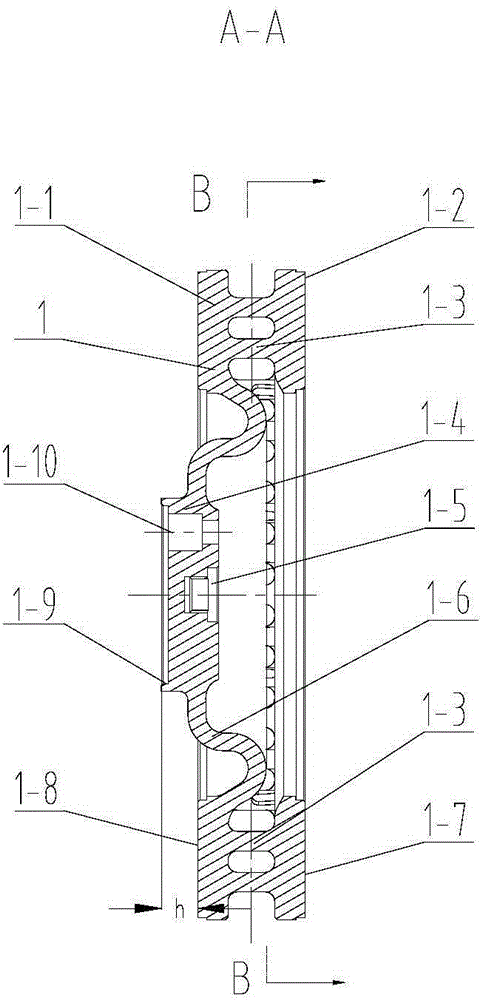

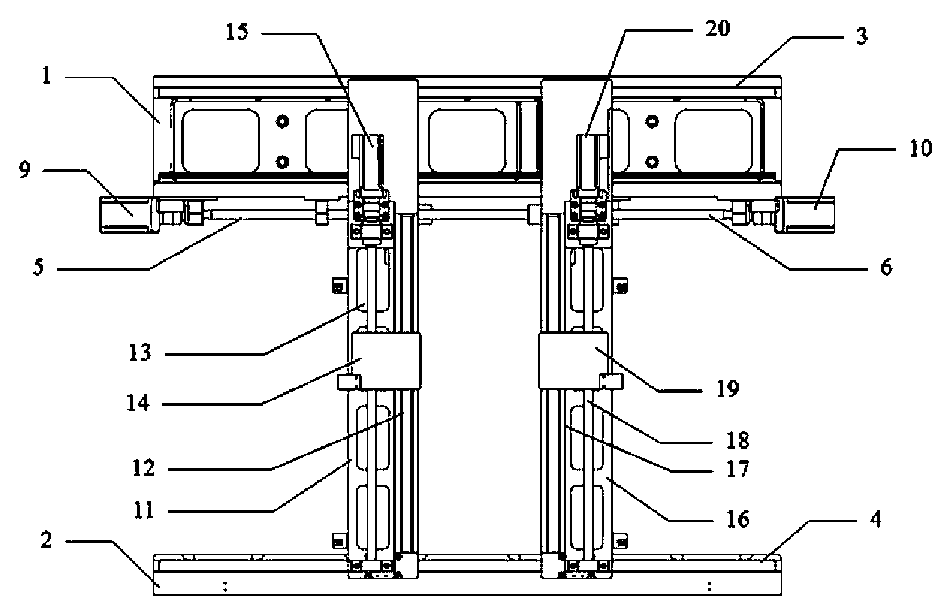

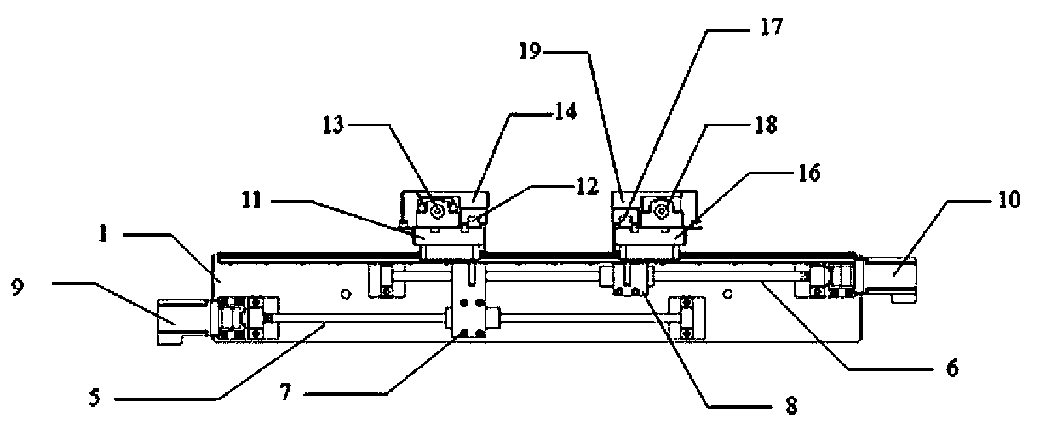

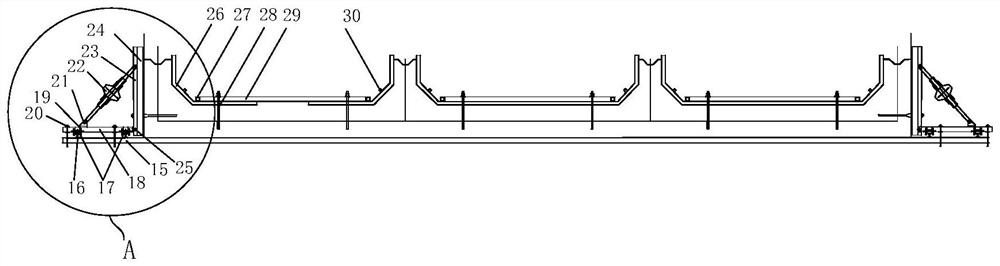

Ampoule bottle feeding device used for light examining machine

InactiveCN103508168AImprove installation positioning accuracyEasy to replaceOptically investigating flaws/contaminationMechanical conveyorsScrew systemEngineering

The invention provides an ampoule bottle feeding device for a light examining machine. The ampoule bottle feeding device is characterized by comprising a feeding conveyor belt system, a screw system, a screw matching star wheel system and a head detection star wheel system. The feeding conveying system and the screw matching star wheel system are arranged on one side of the screw system. The screw matching star wheel system comprises a first star wheel, the head detection star wheel system comprises a second star wheel, and the first star wheel is meshed with the second star wheel. Due to the adoption of the ampoule bottle feeding device, ampoule bottles which are manually well collected and loaded to a tray can be stably and quickly conveyed to a main shaft system of the light examining machine one by one to be automatically examined.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

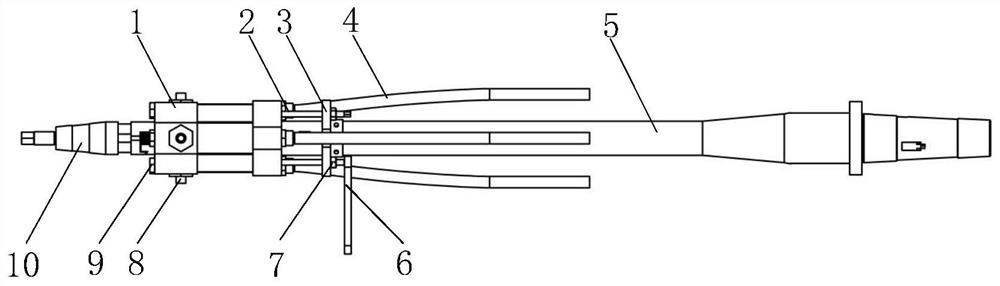

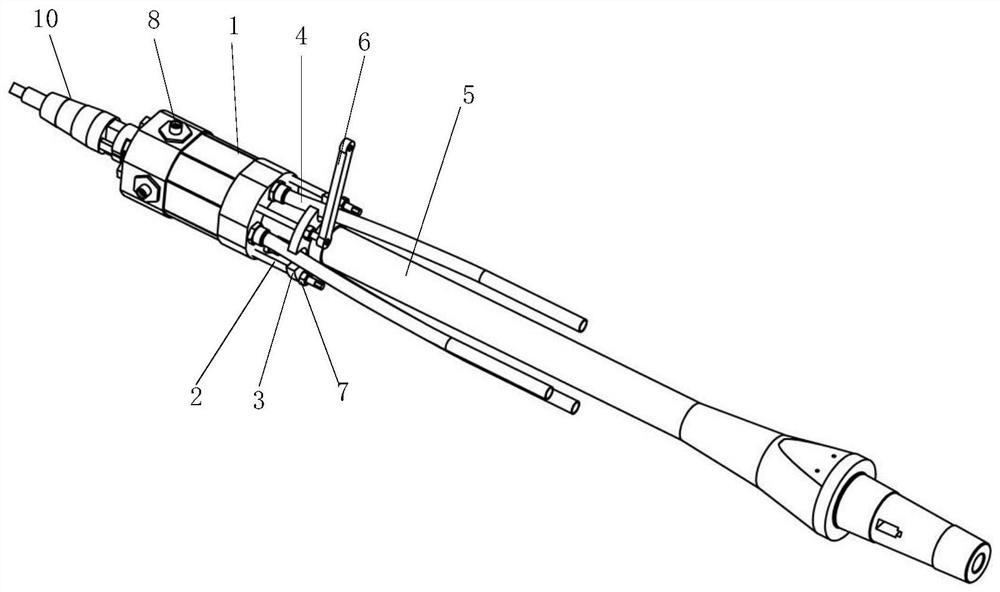

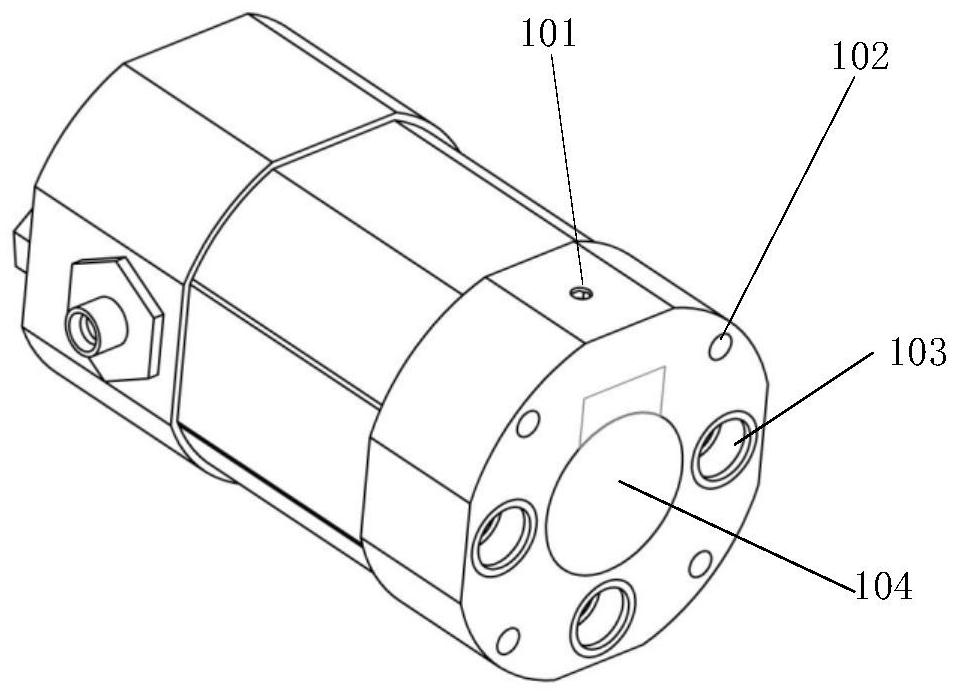

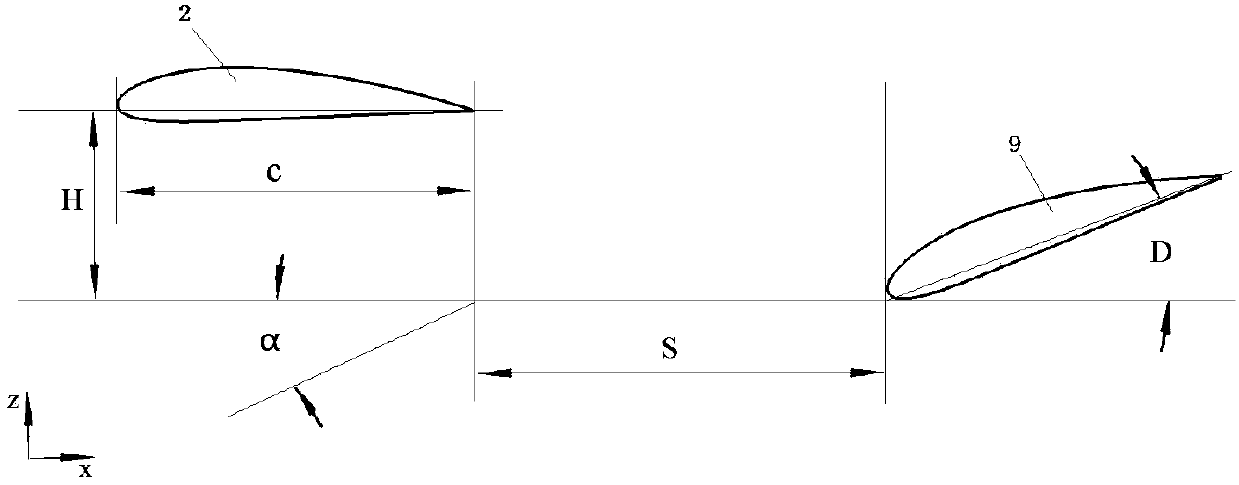

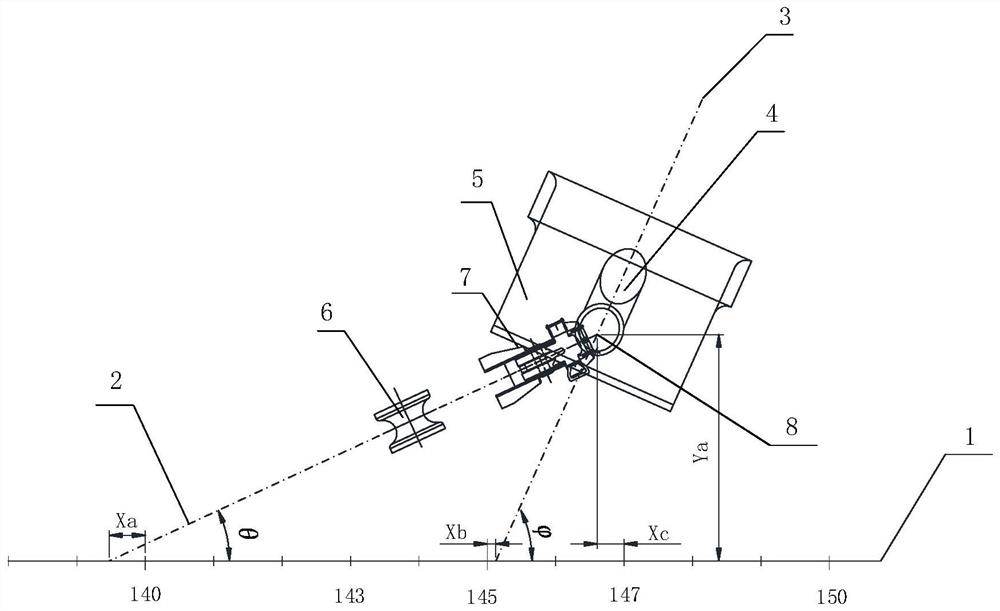

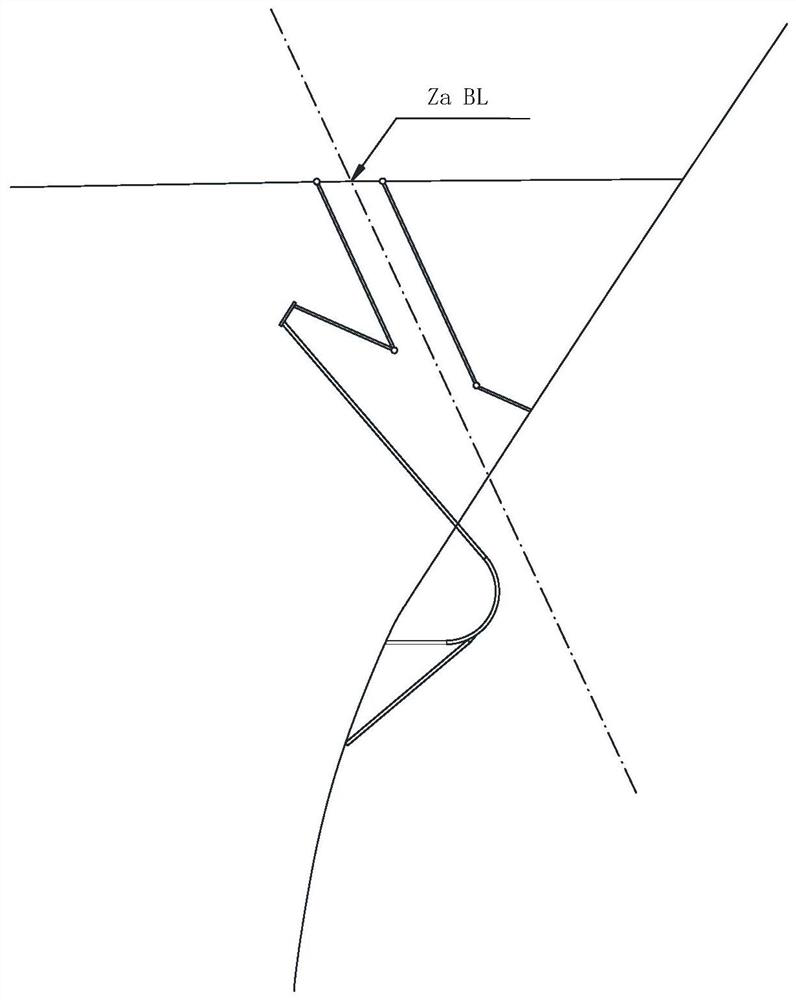

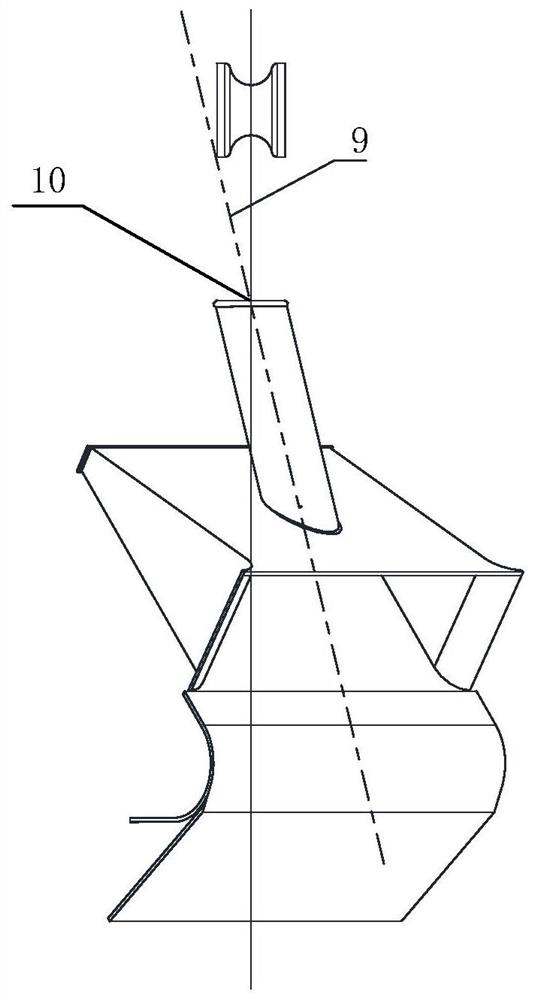

Rod type balance-based orbit control jet flow interference test device and installing and positioning method thereof

ActiveCN112763177AReduce installation and positioning workloadImprove installation positioning accuracyAerodynamic testingJet flowEngineering

The invention discloses a rod type balance-based orbit control jet flow interference test device and an installing and positioning method thereof. A rod type balance for measuring aerodynamic force is installed on the central axis of a model of the orbit control jet flow interference test device, and the rod type balance is fixedly connected with the model and fixed to a middle support of a hypersonic wind tunnel through a tail supporting rod; jet flow plenum chambers which are annularly distributed in the circumferential direction of the rod type balance are installed in the inner cavity of the model, and annular gaps are reserved between the jet flow plenum chambers and the rod type balance and between the jet flow plenum chambers and the inner wall of the model; the jet flow plenum chamber is fixed on a fixed chassis of the tail support rod through an adjusting screw rod, and the jet flow plenum chamber moves forwards or backwards along the central axis by adjusting the adjusting screw rod; and a ventilation pipeline of the jet plenum chamber is externally connected with a high-pressure air source. According to the installing and positioning method, the problem that the positions of the calibration center and the pressure center of the balance are inconsistent in the hypersonic wind tunnel orbit control jet interference test is solved by adopting the rod type balance; and the installation and positioning workload of the spray pipe is reduced, the positioning precision is improved, and the test efficiency is improved.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

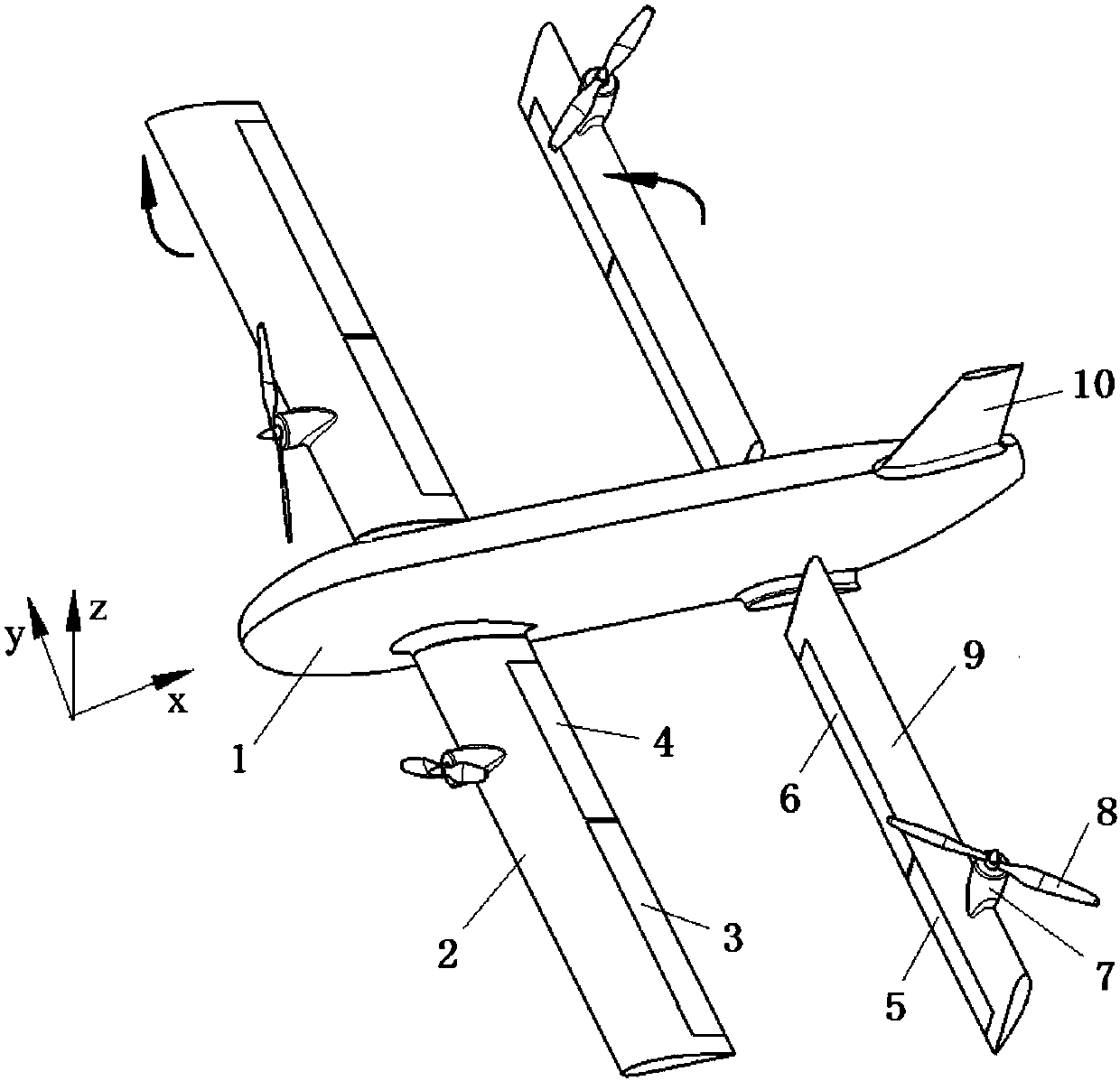

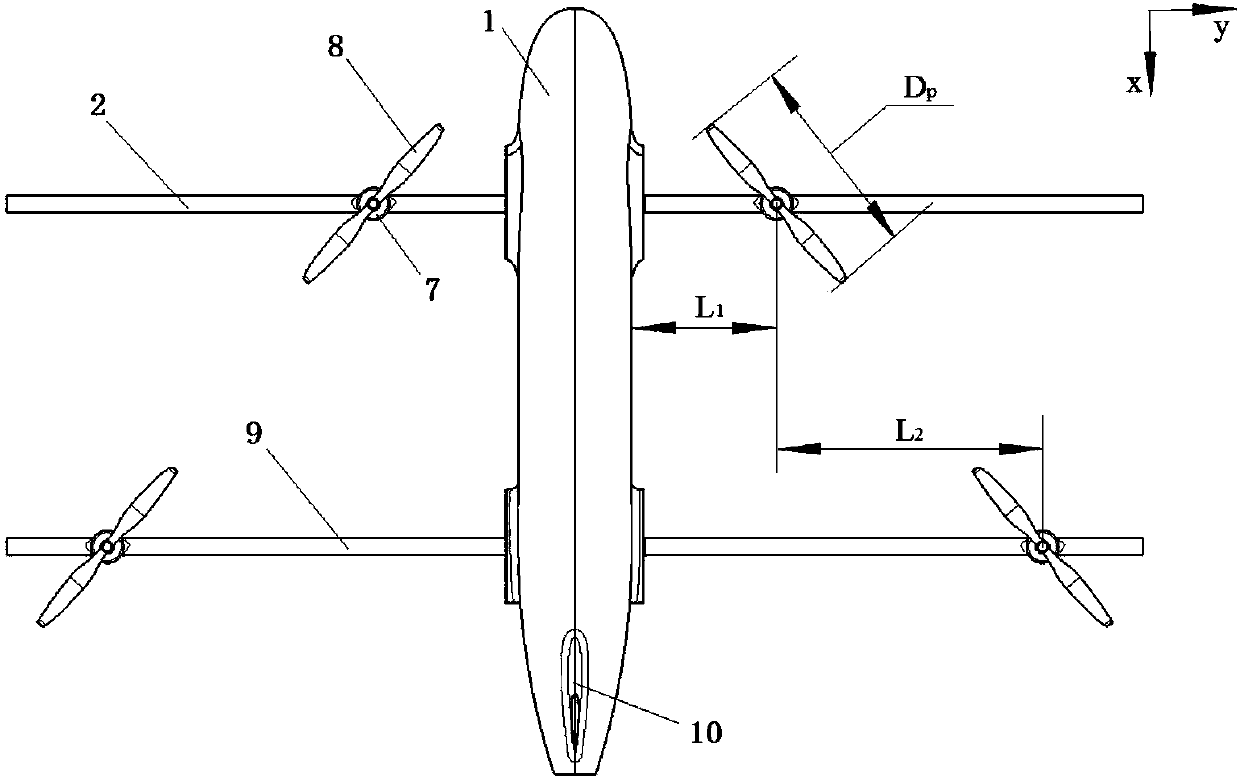

Trapezoid layout tandem tilt wing aircraft and tilting mechanism thereof

ActiveCN107600403AImprove aerodynamic efficiencyImprove installation positioning accuracyWing adjustmentsVertical landing/take-off aircraftsAttitude controlElectric power system

The invention discloses a trapezoid layout tandem tilt wing aircraft and a tilting mechanism thereof. Tandem wing layout, trapezoidal power system arrangement, multiple control surfaces and electric power system differential combination control are adopted, so the aircraft integrates vertical takeoff and landing functions and high-speed hover performance advantages, and also has the long-enduranceand long-range characteristics of a fixed wing aircraft and the hovering and vertical takeoff and landing characteristics of a helicopter. The vertical takeoff and landing and the air fixed wing modecruising are completed through the tilting wing layout, so the requirements for a taking off and landing place are reduced, and the cruising efficiency is improved; the trapezoid dynamic system layout can improve the efficiency of propellers; the roots of wings and a fuselage are fused, and the tilting sections of the wings and the fuselage section fused wing roots are connected and rotate relative to each other, so the mounting and positioning precision of the wings is improved; and the multi-control surface layout of the wings makes the control surfaces on the wings generate the rudder effect by using rotor wake during the vertical takeoff and landing, and attitude control participating in the vertical take-off and landing state reduces the control surfaces of a vertical fin, so the structural efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

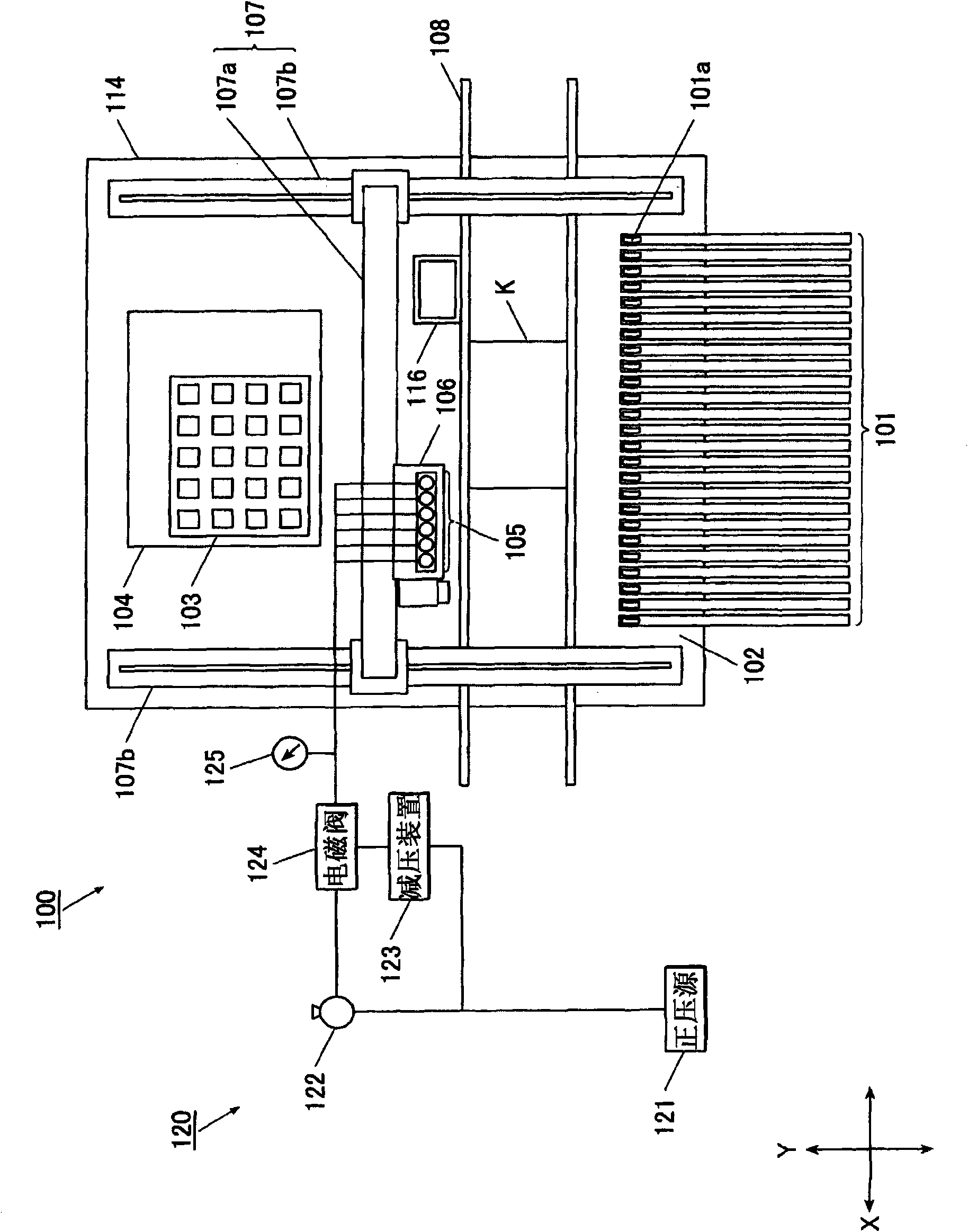

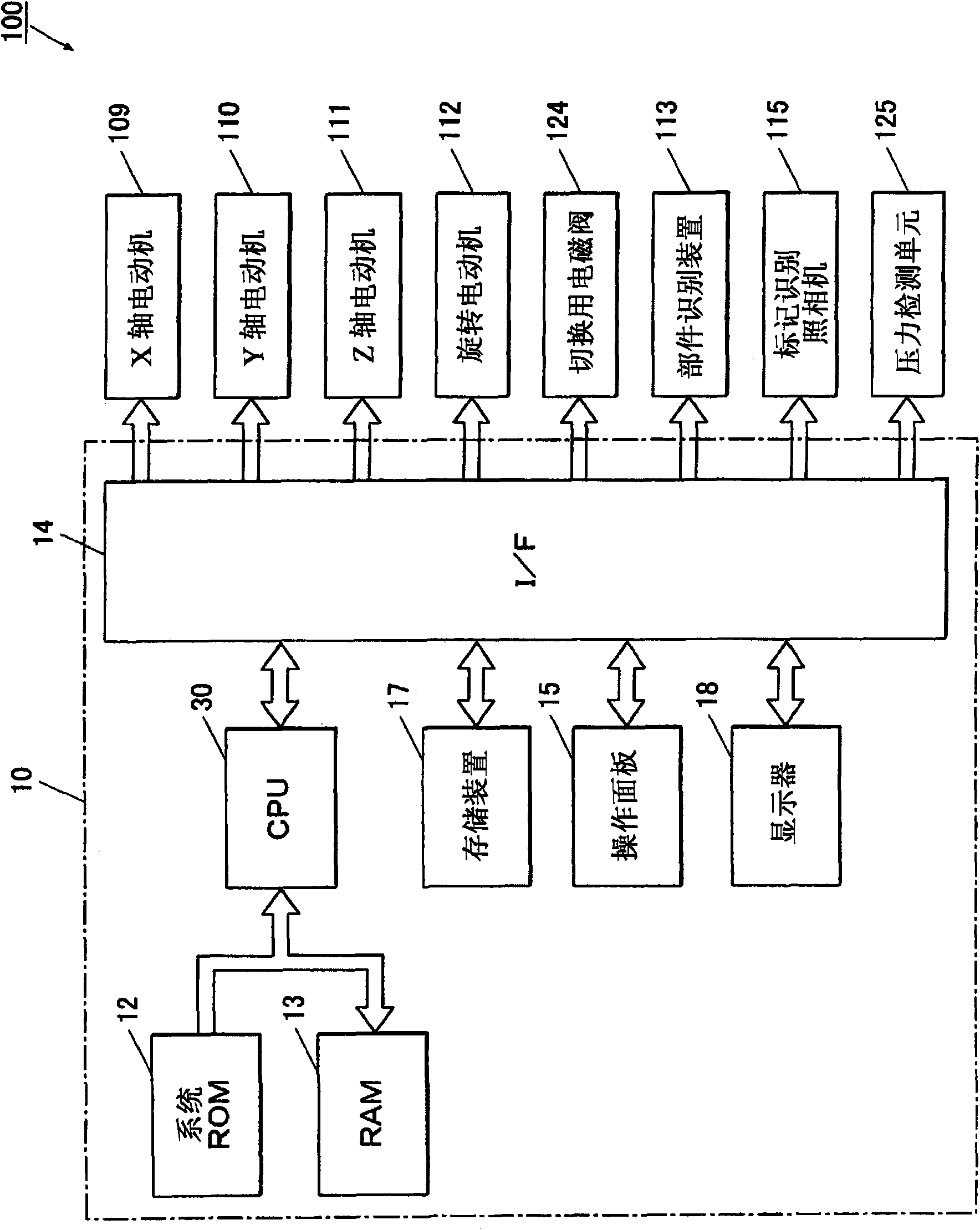

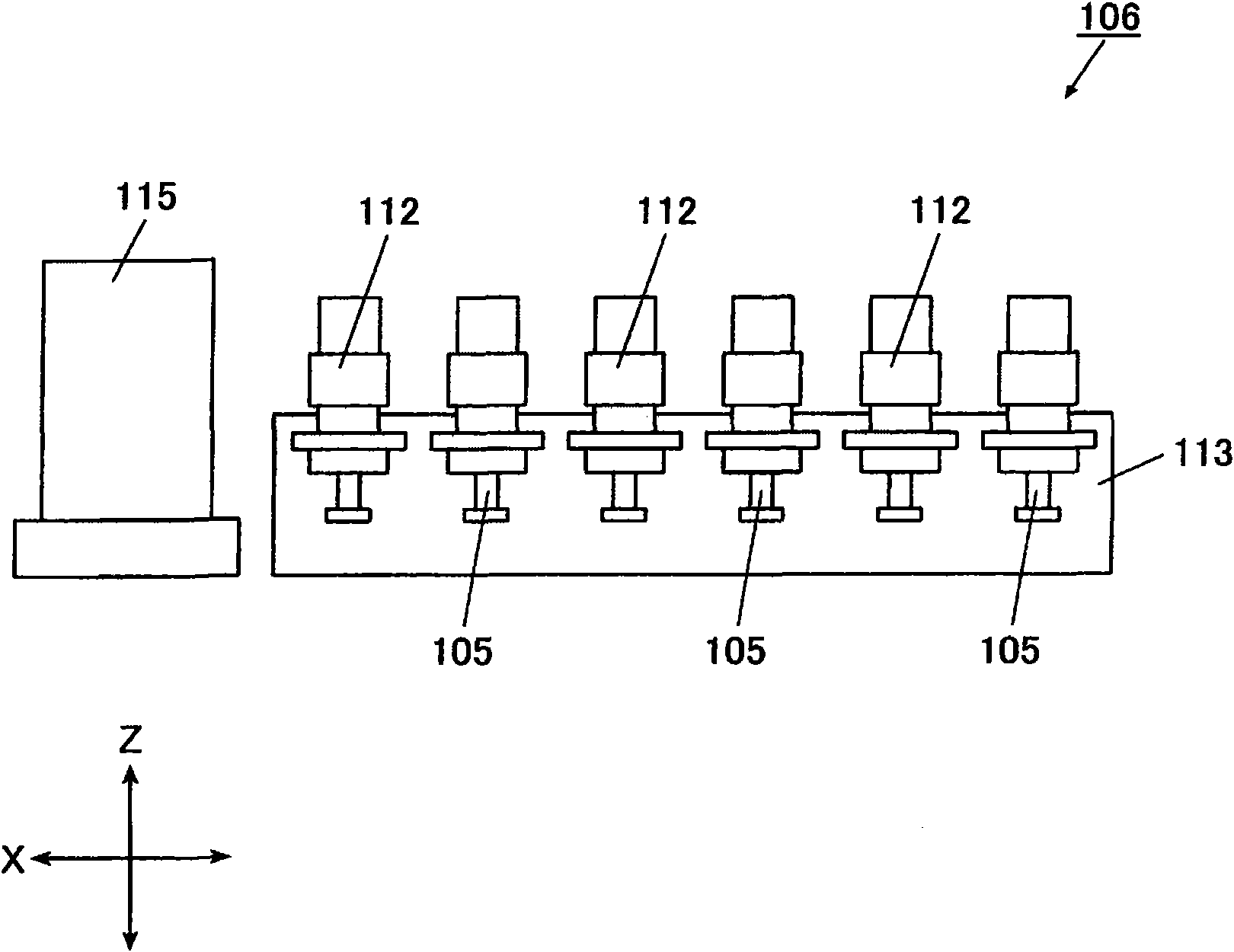

Component mounting method and apparatus

InactiveCN1860837AHigh precisionHigh-precision component mountingElectrical componentsEngineeringGlass sheet

Owner:PANASONIC CORP

Electronic compound mounting device

The invention relates to an electronic compound mounting device for preventing absorption error and leading-back of electronic compounds. The electronic compound mounting device (100) is provided with: a pressure detection unit (125) detecting the inner pressure of an adsorption nozzle (105); and an acquisition control unit (30) of absorption required time, wherein the absorption action of the absorption nozzle is carried out through a negative pressure supply unit (122) in a compound supply part (102) relative to each electronic compound when mounting action control is not carried out, and the pressure detection unit measures and stores the absorption required time till the detection pressure becomes the target absorption pressure, and the absorption nozzle is raised after the absorption of each electronic compound is continuous through the negative supply unit according to the absorption required time obtained by the acquisition control unit of absorption required time when the action control unit is installed on the electronic compound.

Owner:JUKI CORP

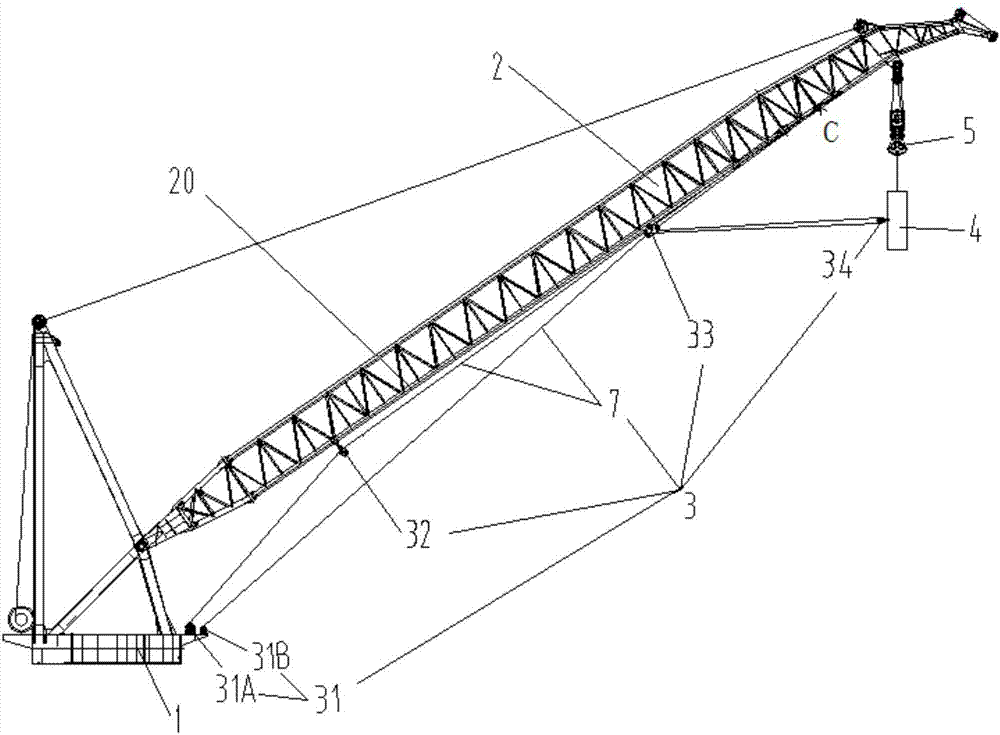

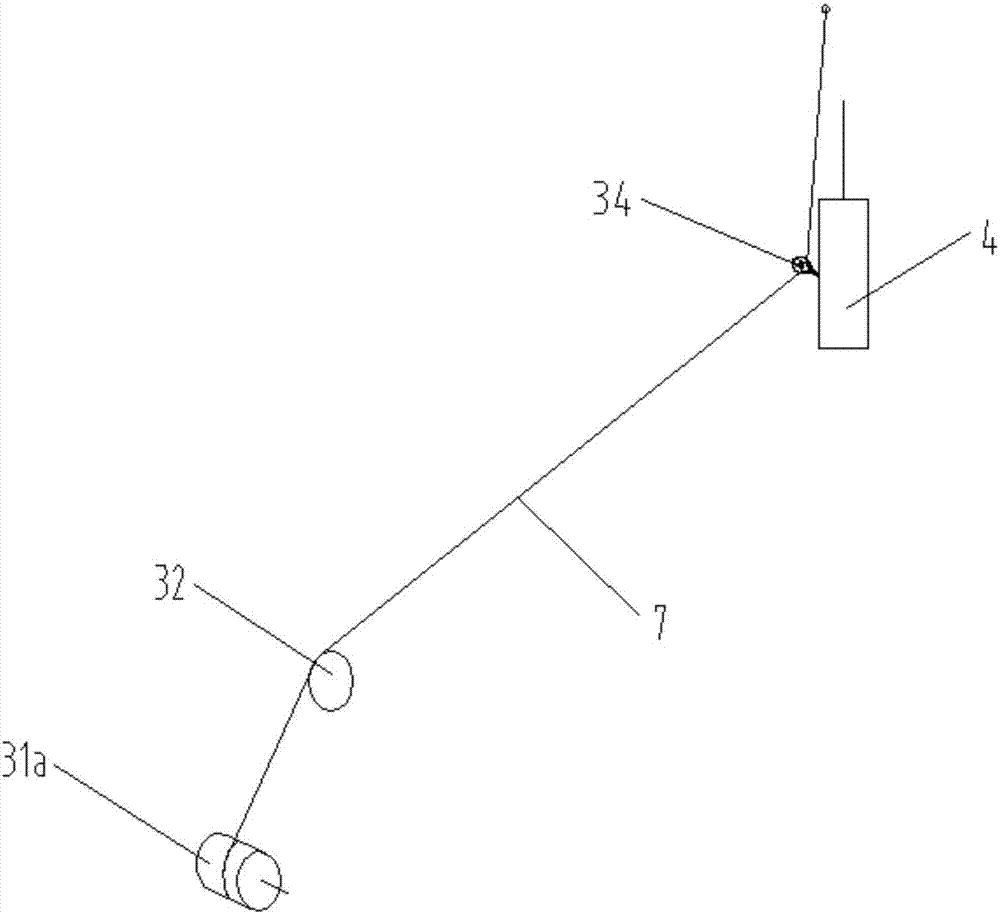

Floating crane cargo stabilizing device

The invention discloses a floating crane cargo stabilizing device which comprises a rotating platform, a cantilever crane supported on the rotating platform, and a cargo stabilizing mechanism arranged on the rotating platform and the cantilever crane. The cargo stabilizing mechanism comprises cargo stabilizing guide winches, a cargo stabilizing guide pulley, a cargo stabilizing pulley yoke, a cargo stabilizing guide cargo pulley and cargo stabilizing steel wire ropes, the cargo stabilizing guide winches are arranged on the rotating platform, the cargo stabilizing guide pulley is arranged in the position, close to the bottom, of a cantilever crane lower chord, a lifting hook is arranged on the lower side of the upper part of the cantilever crane, a sling load is tied in the lifting hook, the cargo stabilizing pulley yoke is arranged on the cantilever crane lower chord and located between the cargo stabilizing guide pulley and a fixing frame which is arranged in the position, close to the lifting hook, of the lower side of the upper part of the cantilever crane, the cargo stabilizing guide cargo pulley is arranged on the sling load, the cargo stabilizing steel wire ropes are arranged among the cargo stabilizing guide winches, the cargo stabilizing guide pulley, the cargo stabilizing pulley yoke and the cargo stabilizing guide cargo pulley optionally in a penetrating winding mode. According to the floating crane cargo stabilizing device provided by the invention, when sling loads of different sizes are lifted to different lift heights, cargo stabilizing can be achieved by converting different rope winding modes.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

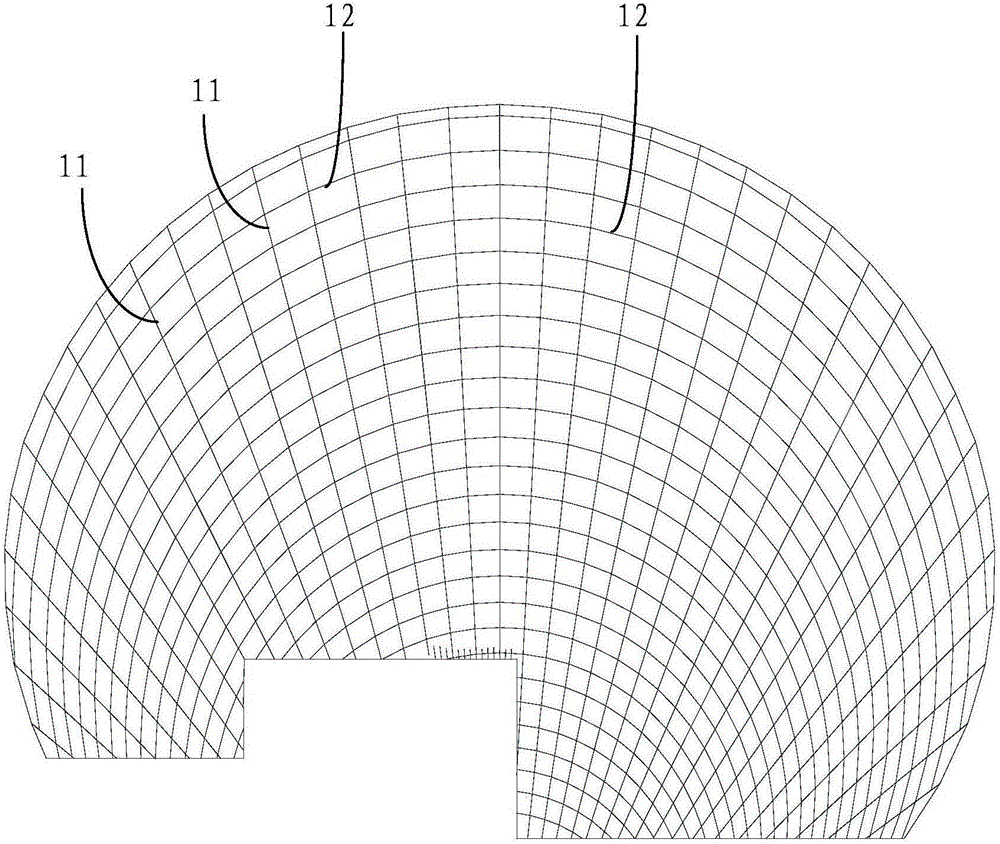

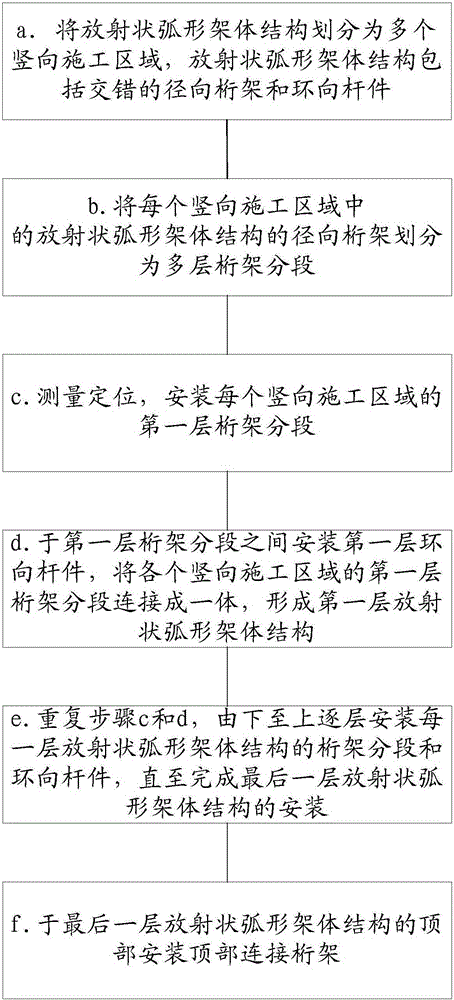

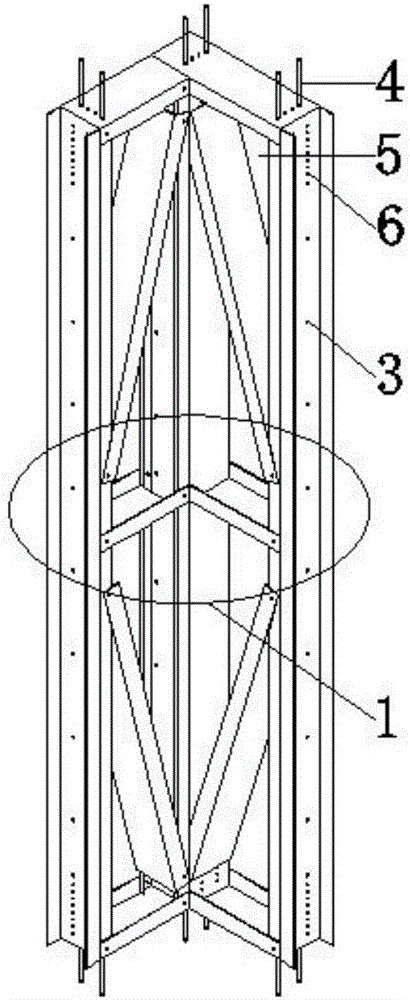

Construction method for large radial arc-shaped frame body structure

InactiveCN105178607AHigh positioning accuracyReduce construction difficultyArched structuresVaulted structuresStress systemBuilding construction

The invention discloses a construction method for a large radial arc-shaped frame body structure. The construction method comprises the steps that a, the frame body structure is divided into multiple vertical construction areas; b, vertical trusses in each vertical construction area are divided into multi-span truss sections; c, measurement and positioning are performed, and a first layer of truss sections in each vertical construction area are assembled; d, a first layer of annular rod member is arranged among each first layer of truss sections, so that the first layers of truss sections in all vertical construction areas are connected into a whole to form a first layer of radial arc-shaped frame body structure; e, the step c and the step d are repeated, so that the truss sections and annular rod member of each layer of radial arc-shaped frame body structure are assembled layer by layer until the last layer of radial arc-shaped frame body structure is assembled; and f, a top connection truss is arranged. According to the construction method disclosed by the invention, area-separated and annular section-separated construction is adopted by the frame body structure, so that the construction difficulty is reduced; and the truss sections in each vertical construction area are synchronously constructed layer by layer, and closure is performed after hoisting and assembling at each layer are finished, so that an integrally stable stress system is formed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

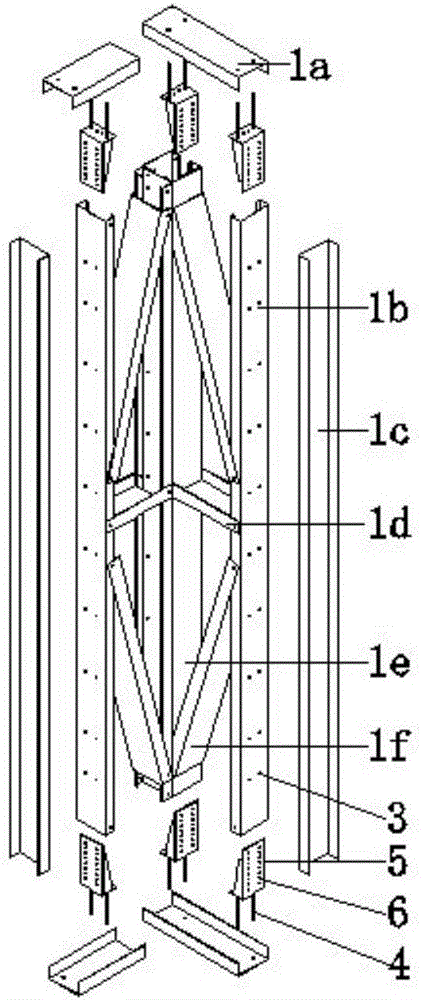

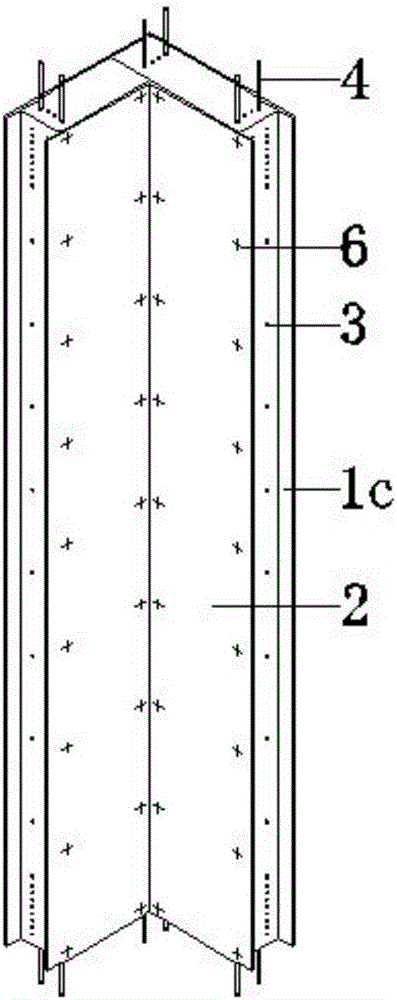

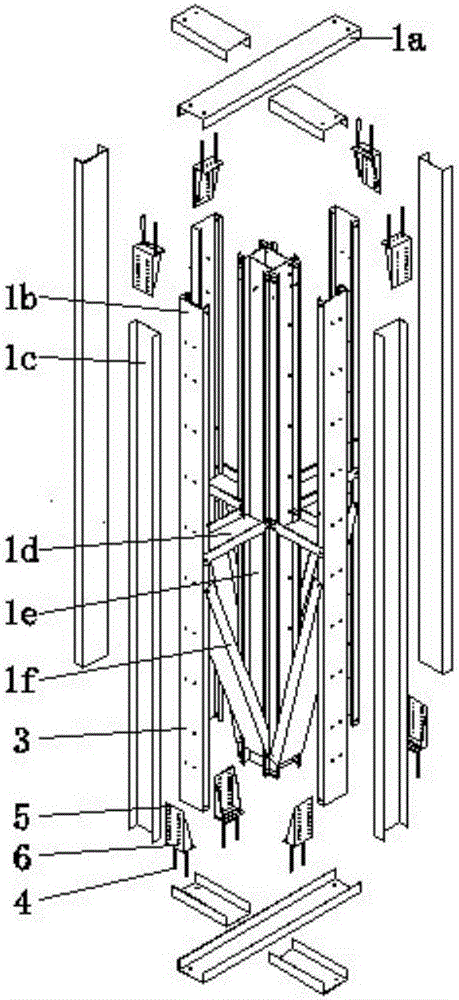

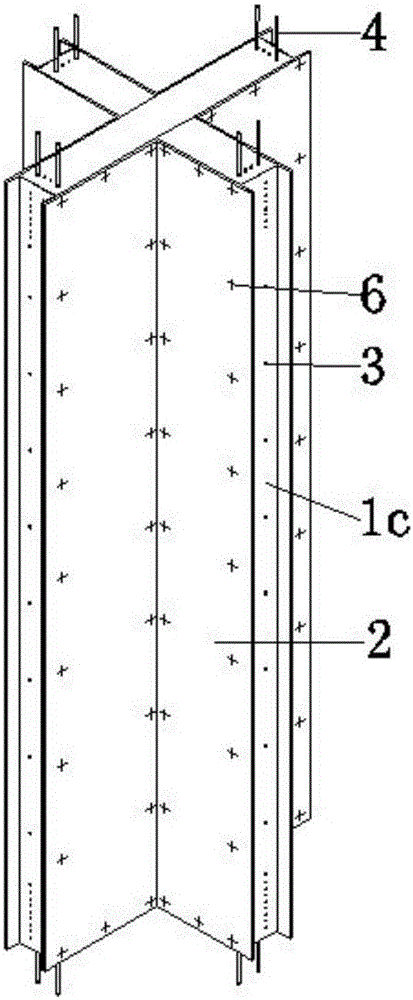

Modular assembly type L-shaped cold-formed thin-walled steel combined wall and connecting mode thereof

The invention discloses a modular assembly type L-shaped cold-formed thin-walled steel combined wall and a connecting mode of the modular assembly type L-shaped cold-formed thin-walled steel combined wall. The modular assembly type L-shaped cold-formed thin-walled steel combined wall is characterized in that the middle part of an L-shaped cold-formed thin-walled steel framework is filled with a heat preservation layer; a wall panel and the L-shaped cold-formed thin-walled steel framework are connected through self-tapping screws; the modular assembly type L-shaped cold-formed thin-walled steel combined wall is formed by the L-shaped cold-formed thin-walled steel framework, the heat preservation layer and the wall panel. Horizontal-direction connection between an L-shaped cold-formed thin-walled steel combined wall module and a common wall module is realized through a horizontal connecting mode between wall modules; vertical-direction connection between two adjacent L-shaped cold-formed thin-walled steel combined wall modules which are adjacent in the vertical direction is realized through a vertical connecting mode between the wall modules. The modular assembly type L-shaped cold-formed thin-walled steel combined wall disclosed by the invention integrates structural bearing and heat preservation, and has the advantages of high integration and assembly degrees, applicability in industrial production and the like, and the problems of weak connection between a longitudinal wall and a horizontal wall, high difficulty and difficulty in handling installation seams, and the like can be solved. The connecting mode of the modular assembly type L-shaped cold-formed thin-walled steel combined wall is simple in structure and is quick and efficient, and a large amount of labor cost can be reduced.

Owner:BEIJING UNIV OF TECH

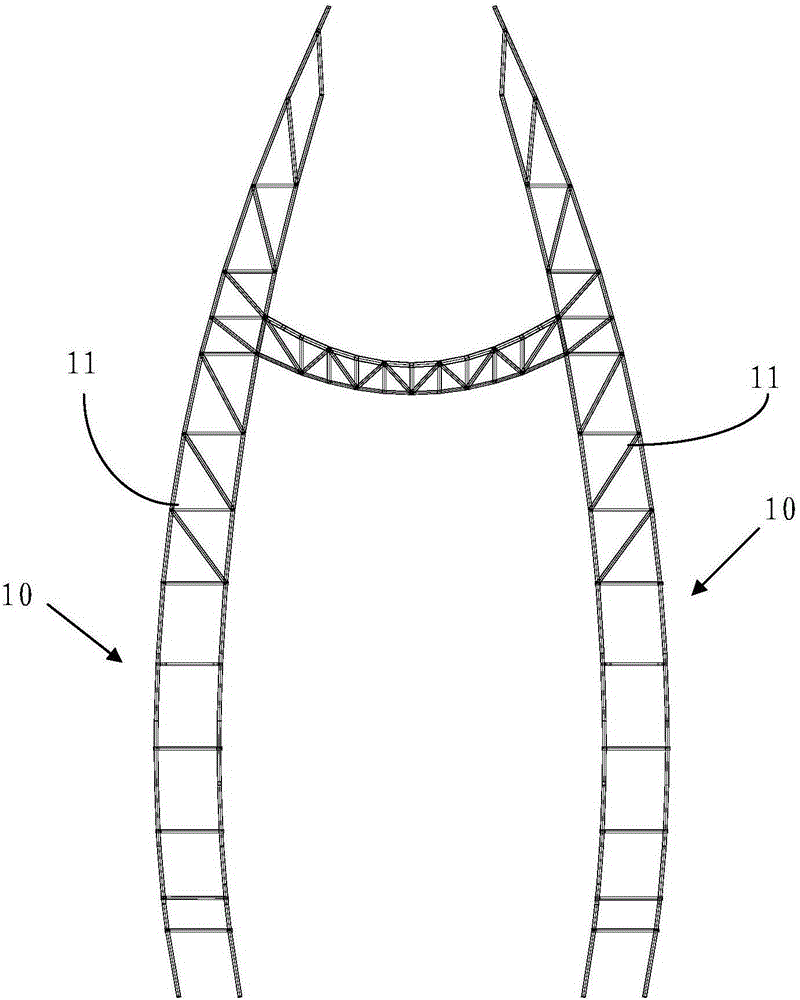

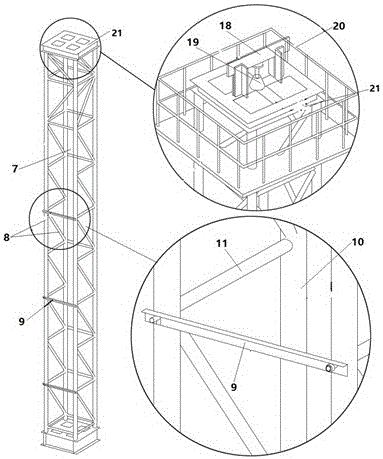

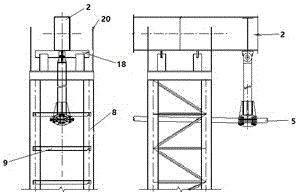

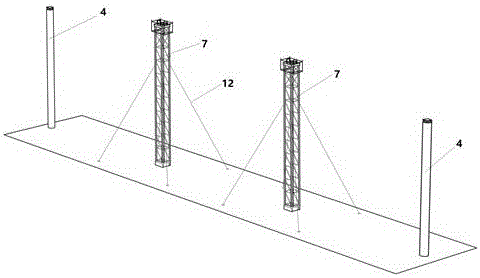

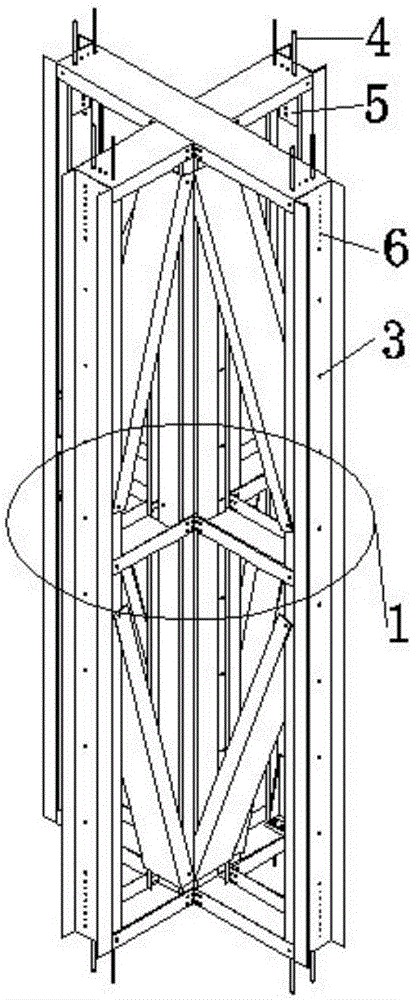

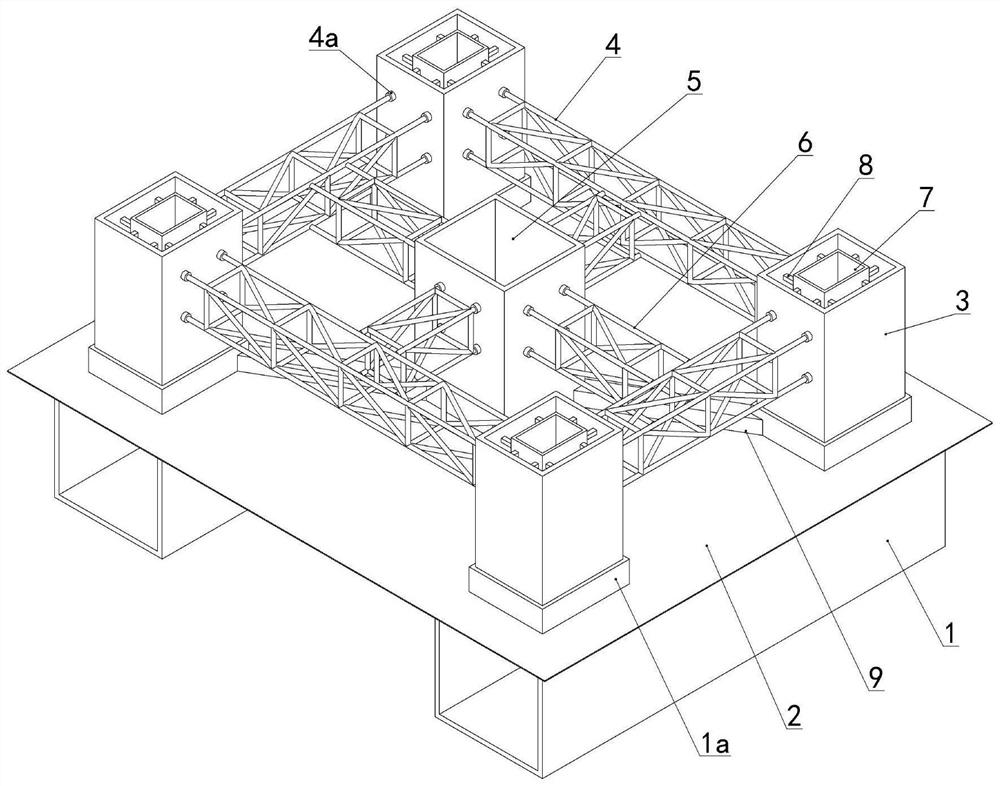

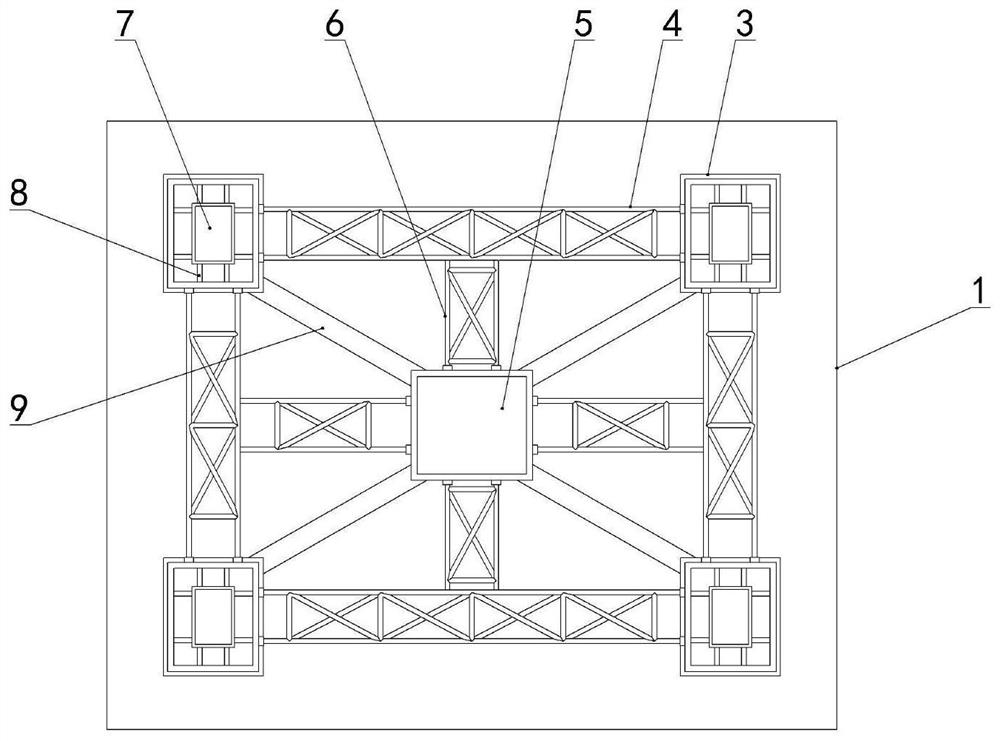

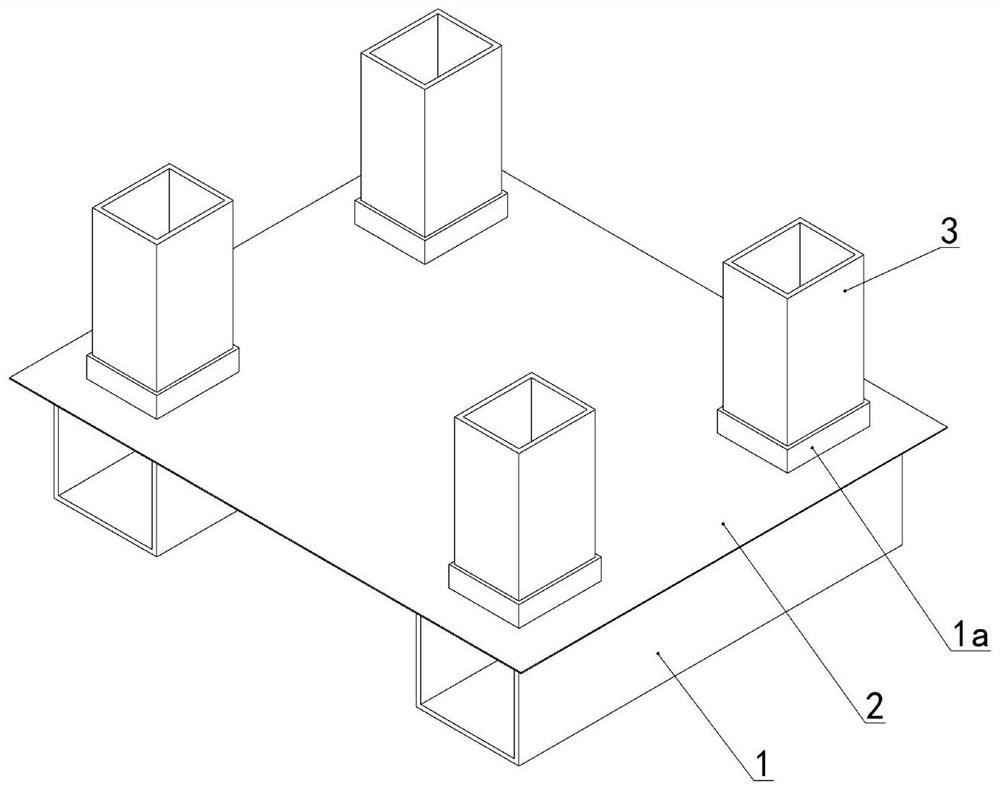

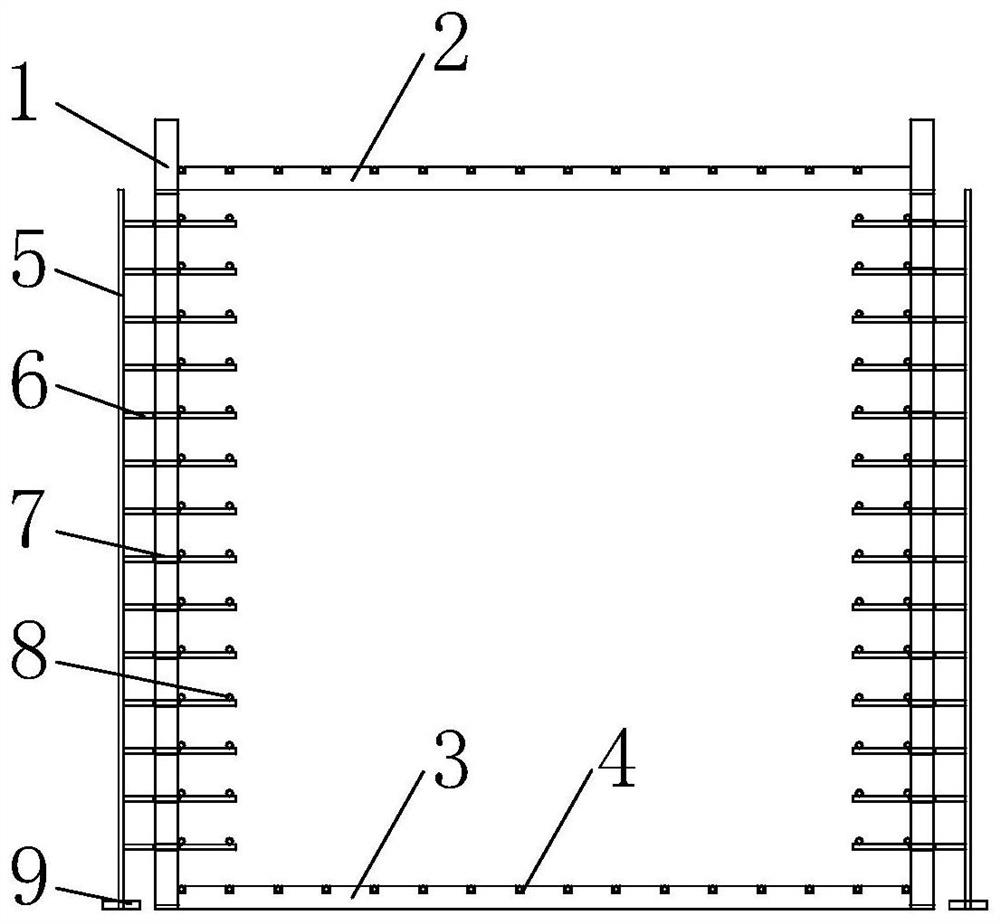

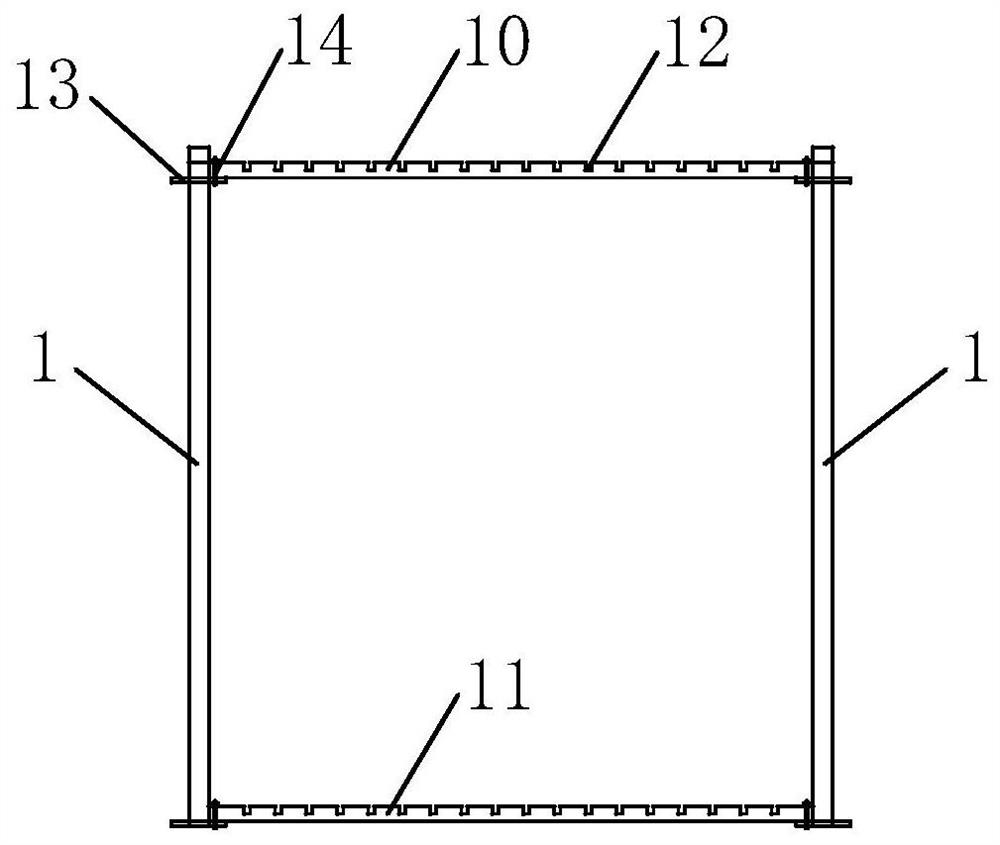

Supporting structure for mounting of roof beam string segments

InactiveCN106677543AImprove installation efficiencyImprove installation positioning accuracyBuilding material handlingHandrail

The invention provides a supporting structure for mounting of a roof beam string. The supporting structure comprises a supporting single-piece structure, transverse movable tie bars and a supporting upper end operation platform. A lattice type supporting structure is composed of the supporting single-piece structure and the transverse movable tie bars. The supporting single-piece structure comprises stand bars and web members. One ends of the transverse movable tie bars are hinged to the supporting single-piece structure, and the other ends of the transverse movable tie bars are detachably connected with the supporting single-piece structure through nuts. The supporting upper end operation platform comprises an elevation adjustment template, a jack and operation platform enclosing handrails. By adoption of the supporting structure, mounting of beam string segments and stay ropes can be achieved at the same time, the problem that the stay ropes are difficult to mount after the roof beam string segments are mounted is solved, the mounting efficiency of the roof beam string is improved, the mounting and positioning precision of the roof beam string is increased, and the error rate is decreased.

Owner:JIANGSU HUNING STEEL MECHANISM

Method for assembling and positioning large-size machine tool body

InactiveCN102183187ALower requirementReduce labor intensityMechanical measuring arrangementsUltimate tensile strengthLarge size

The invention discloses a method for assembling and positioning a large-size machine tool body. A method for assembling and positioning the machine tool body before delivery and a method for assembling and positioning on a user site are involved. The method for assembling and positioning the machine tool body before delivery comprises the following steps of: forming relevant connecting screw holes among the machine tool body, a stand column and a cross beam and fixing the machine tool body, the stand column and the cross beam into a whole; positioning a detecting rod by using a linear rail sliding block on the machine tool body on both sides, measuring distances from the machine body on both sides to a detecting reference surface on the side of a working table through a detecting tool, and recording data; on the user site, positioning the working table, roughly positioning the machine tool body on both sides of the working table, positioning the detecting rod by using the linear rail sliding block on the machine tool body on both sides; and measuring the distances from the machine body on both sides to the detecting reference surface on the side of the working table through the detecting tool, and regulating to make the distances consistent with the recorded data before delivery. The method is high in installation and positioning precision, the requirement on the detecting tool is low, the labor intensity of operators is reduced greatly, and the installation speed is increased.

Owner:GUILIN MACHINE TOOL

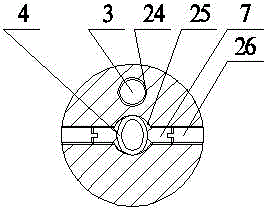

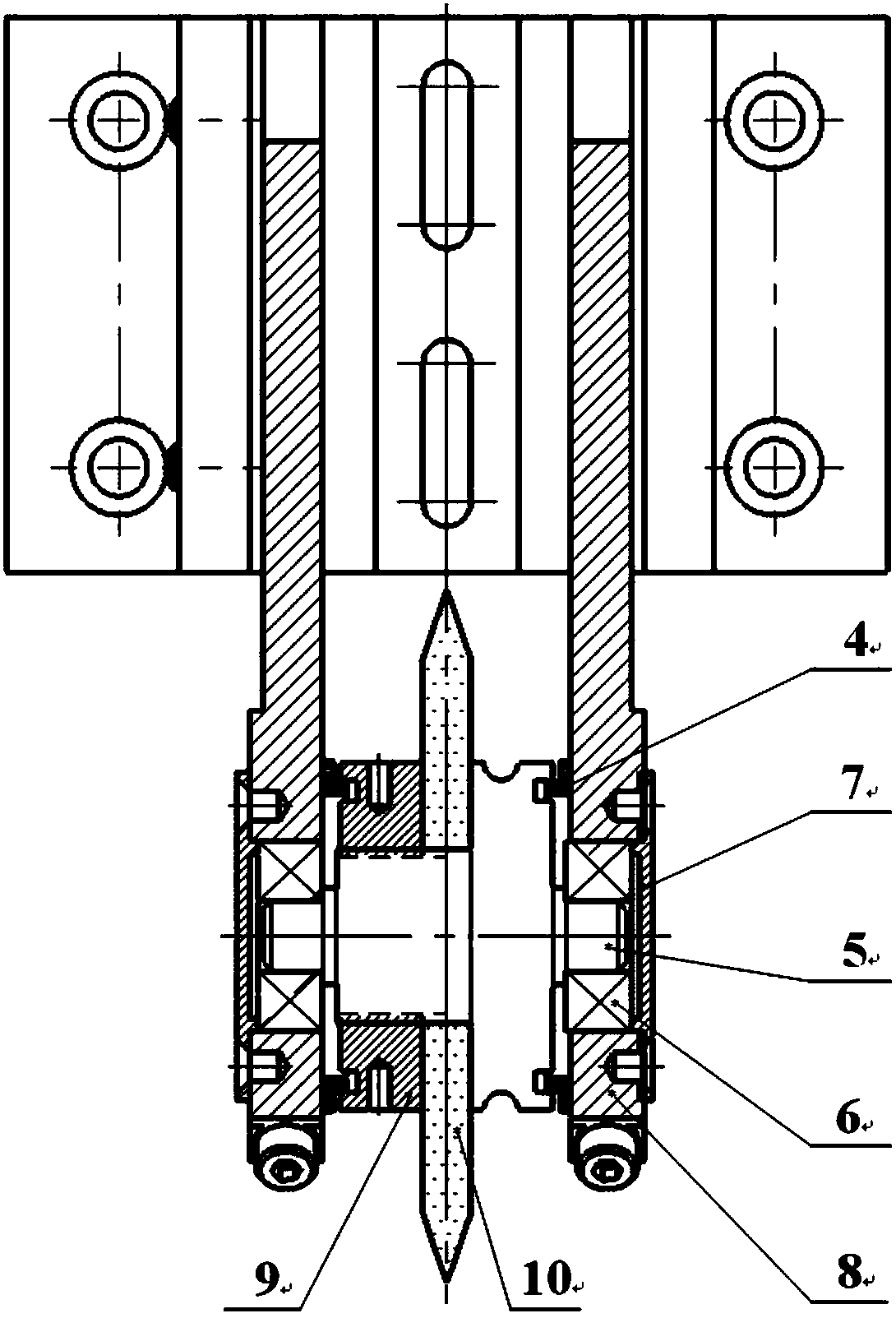

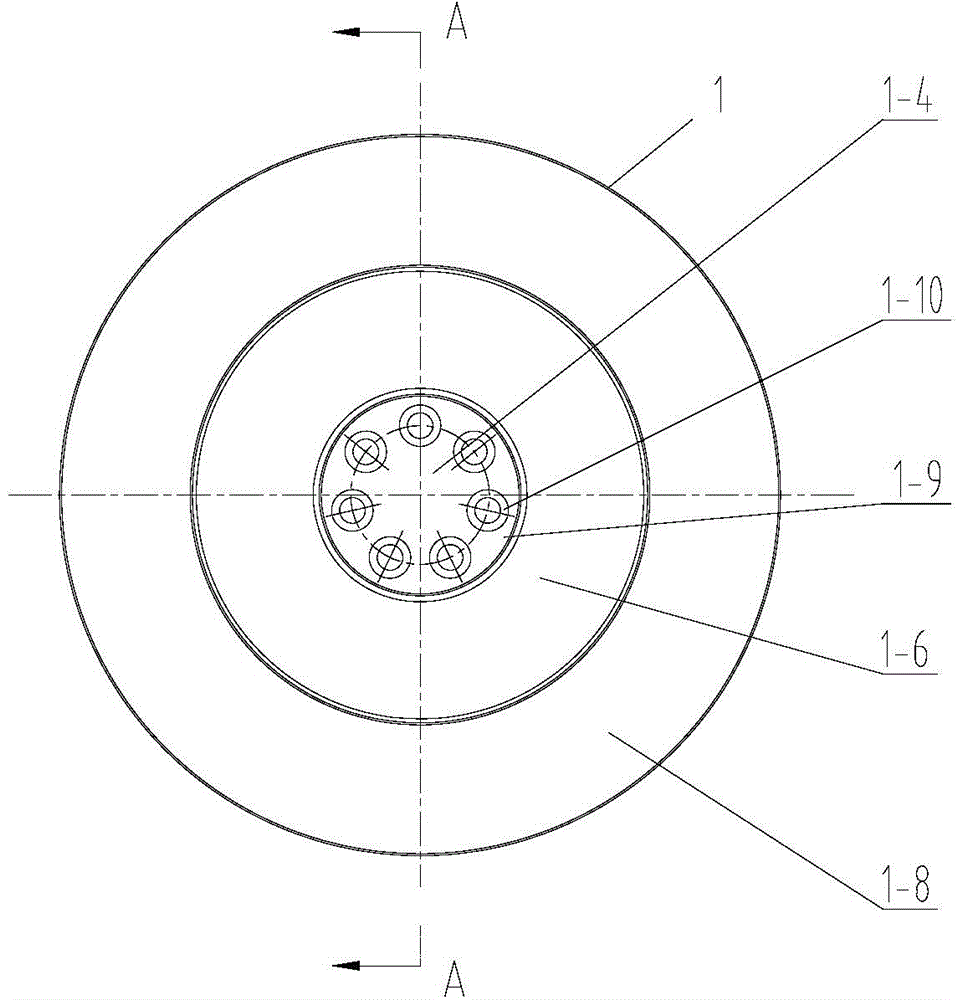

Zero-position memory pump injection-type inclusion strain gauge

InactiveCN104964667ARealize uniform pasteAvoid enteringMeasurement devicesSealing/packingStrain gaugeMechanical engineering

The invention provides a zero-position memory pump injection-type inclusion strain gauge with greatly raised installation and positioning precision. The inclusion strain gauge comprises an installation section and an installation rod used for pushing the installation section. The installation section comprises a measuring line, a hole opening end cover, an inclusion base pipe and a hole bottom end cover. The hole opening end cover, the inclusion base pipe and the hole bottom end cover are connected in order. The hole opening end cover and the hole bottom end cover are equipped with a plugging ring, a glue inlet hole, a glue guiding hole and an annular glue guiding groove arranged in an outer surface, and the glue inlet hole, the glue guiding hole and annular glue guiding groove are communicated in order. The glue guiding groove covers glue expanded bag. The glue inlet hole of the hole opening end cover is communicated with the glue inlet hole of the hole bottom end cover. A pressure regulating hole and a glue outlet hole are arranged in the hole bottom end cover. A pressure regulating member used for control connection and disconnection of the glue outlet and the glue guiding hole is arranged in the pressure regulating hole. The glue outlet hole is located in the outer surface of the hole bottom end cover and is located at the left side of the glue expanded bag of the hole bottom end cover. The reliability and availability of strain measuring data are raised and the installation survival rate is raised.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

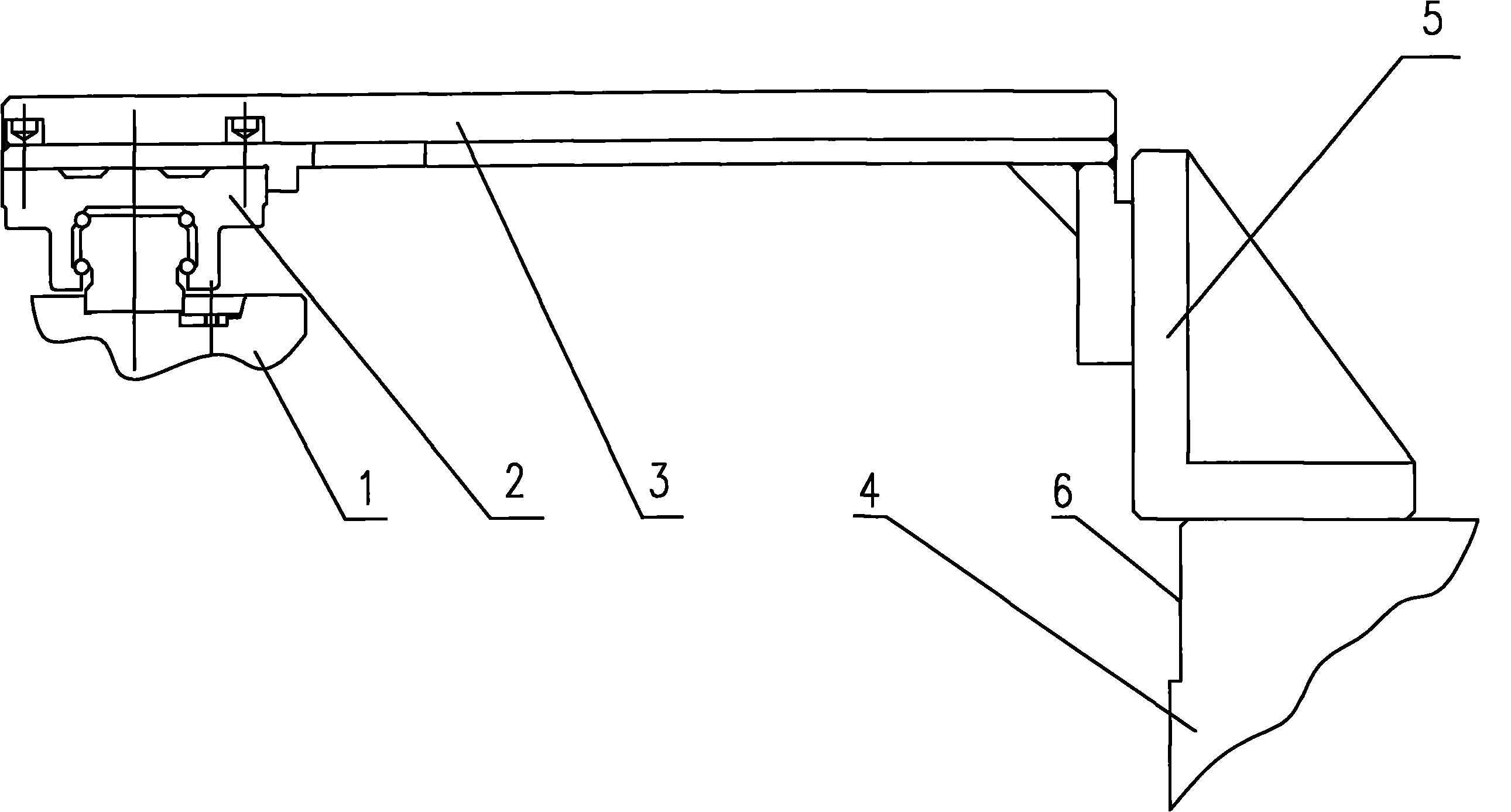

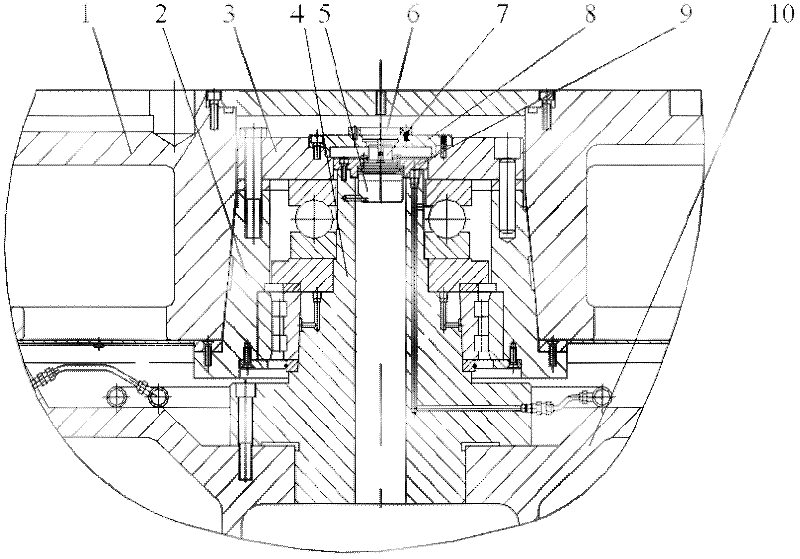

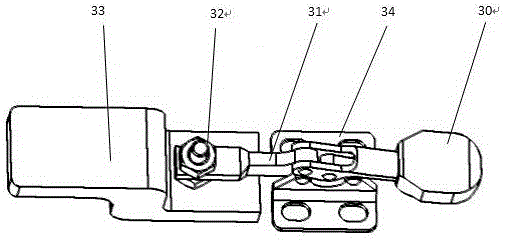

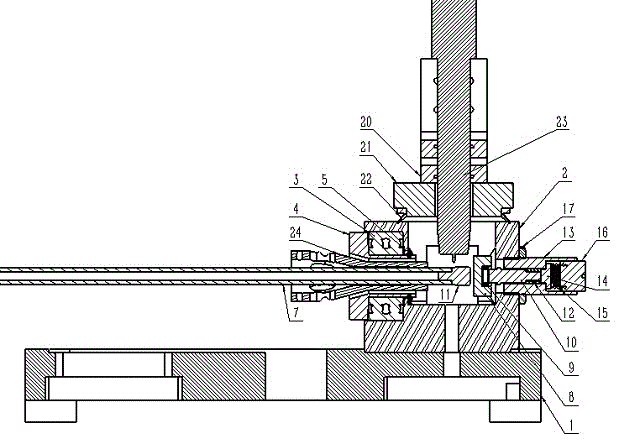

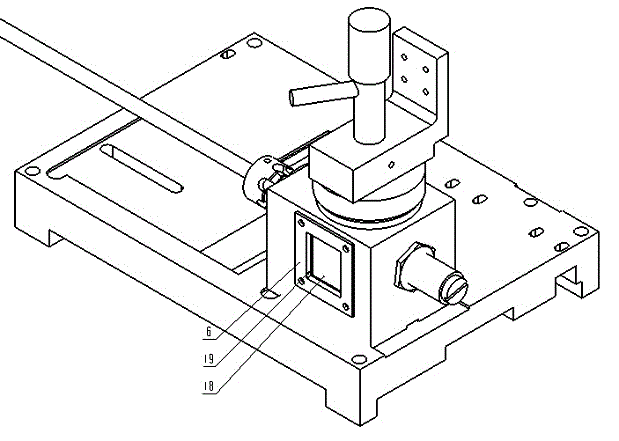

Speed feedback mechanism for vertical lathe worktable

ActiveCN102407462AImprove installation positioning accuracyEasy to processThread cutting auxillary apparatusMeasurement/indication equipmentsNumerical controlElectrical control

The invention discloses a speed feedback mechanism for a vertical lathe worktable. A worktable (1) is arranged on a fixedly-arranged main shaft (4) and is driven by a rotary driving mechanism; a rotary coder (5) is arranged on the main shaft (4); and a signal circuit of the rotary coder (5) is connected with an electrical control system of the vertical lathe. By adopting the technical scheme, the mounting and positioning precision of a speed measuring mechanism of the speed feedback mechanism is high, and thus the speed feedback mechanism is convenient for producing and manufacturing; and after the numerical control knife rest vertical lathe is provided with the set of coder mechanism, the function of threading can be achieved.

Owner:WUHU HENGSHENG HEAVY MACHINE TOOL

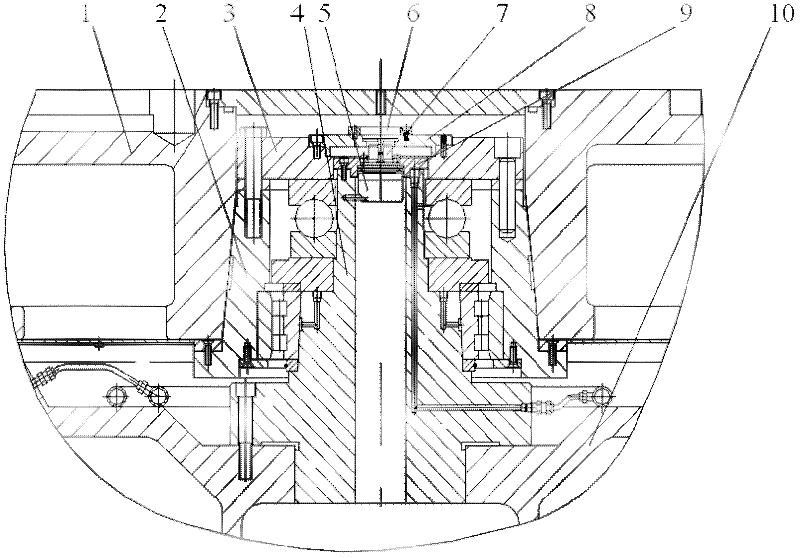

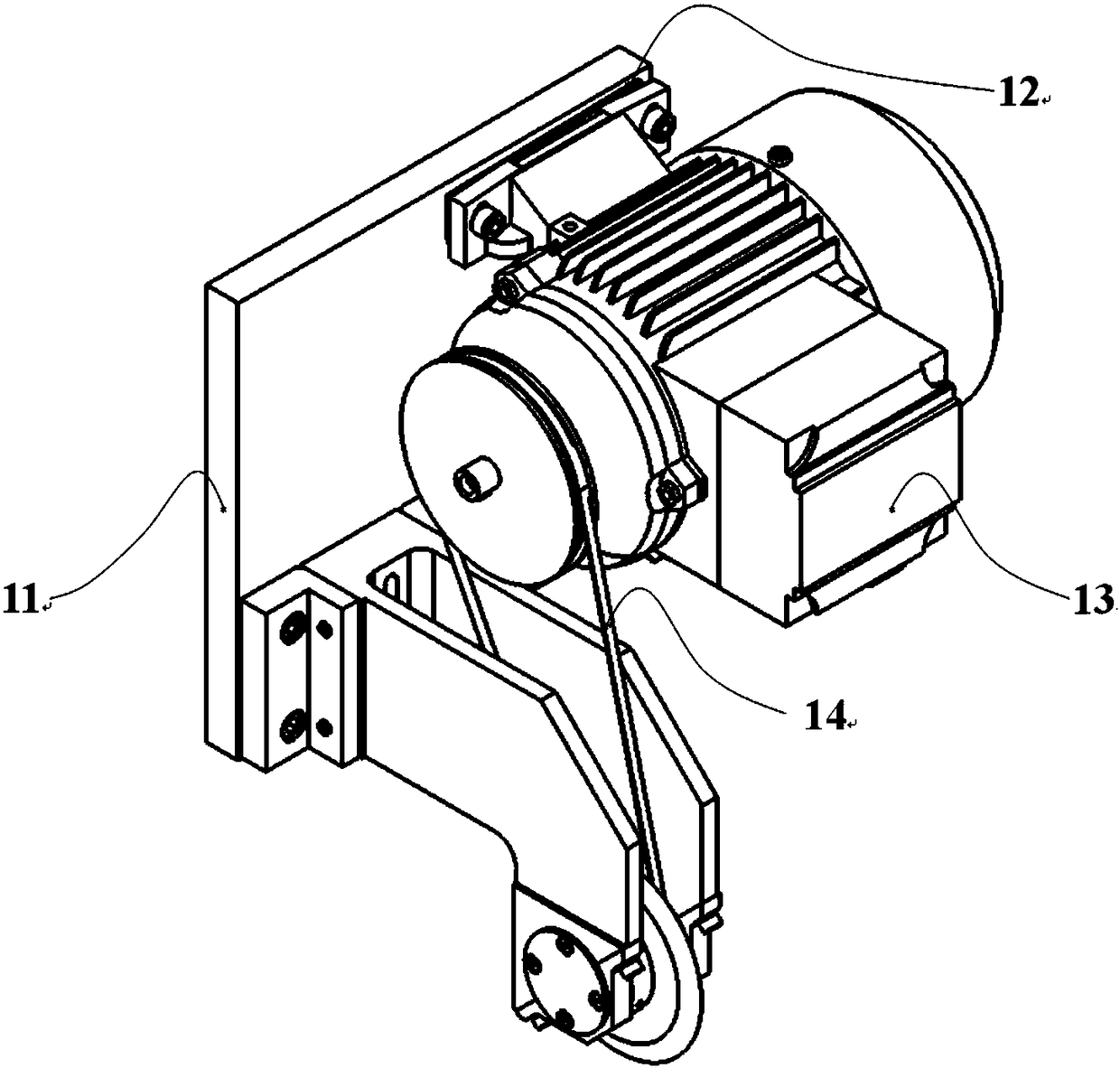

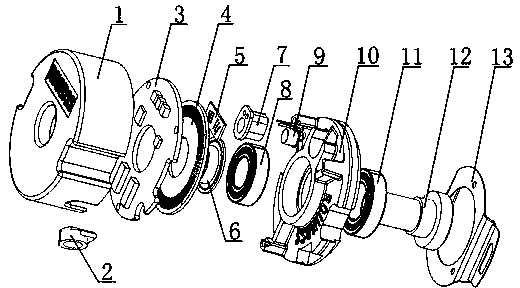

Grinding wheel assembly for small-modulus gear grinding and assembling method

ActiveCN108500399AAchieve vibration and noise reductionSatisfy the grinding processAssembly machinesGear teeth manufacturing toolsGear grindingDynamic balance

The invention belongs to the technical field of precision machining, and provides a grinding wheel assembly for small-modulus gear grinding and an assembling method to solve the grinding problem of small-modulus gears. The integrated structure of a grinding wheel cantilever frame and a built-in belt pulley is adopted, so that high installation and positioning precision and the compact structure are achieved; a bearing adopts a V-shaped positioning mode, so that disassembling and installation positioning are convenient; a plurality of evenly distributed threaded holes are formed in a locking nut in an integrated mode and used for adjusting the dynamic balance of a rotating part in the grinding wheel assembly, so that vibration reduction and noise reduction of the grinding wheel assembly areachieved, and the service life of a system is prolonged; and a U-shaped groove is formed in the shaft shoulder of a grinding wheel main shaft for transmission of an O-shaped belt, and the dustproof effect is achieved through the labyrinth sealing principle. The grinding wheel assembly has the advantages of being compact in structure, convenient to disassemble, high in positioning precision, convenient to operate and the like, grinding of small-modulus outer gears and inner gear rings is achieved, and good market application prospects and popularization value are realized.

Owner:DALIAN UNIV OF TECH

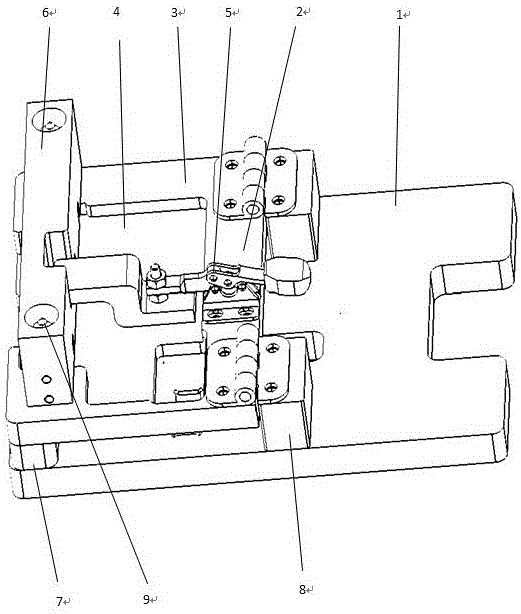

Welding fixture capable of being turned over

ActiveCN105855782AGood effectImprove installation positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesMetal sheetEngineering

The invention discloses a welding fixture capable of being turned over. The welding fixture comprises a bottom plate, a turnover mechanism is installed on the bottom plate and provided with a movable face plate, and a product to be welded is put on the movable face plate; a quick chuck is assembled on the movable face plate, one end of the bottom plate is provided with fixing cushion blocks with the same height, the other end of the bottom plate is provided with height limiting blocks capable of being hinged to the movable face plate, and the quick chuck compresses a metal sheet and a PCB through a pressing plate; when obverse-side welding operation is completed, the welding fixture is turned over 180 degrees to weld electronic components arranged on the reverse side of the product. After the welding fixture is used, the labor intensity of workers is relieved, the welding quality is stable, and the welding efficiency is greatly improved.

Owner:上海福宇龙汽车科技有限公司

Modularized assembling-type cross-shaped cold-bending thin-wall profile steel combined wall and connection method thereof

InactiveCN105908855AImprove carrying capacityImprove torsion resistanceWallsHeat proofingThermal insulationKeel

The invention provides a modularized assembling-type cross-shaped cold-bending thin-wall profile steel combined wall and a connection method thereof. A cross-shaped cold bending thin-wall steel framework is filled with a thermal insulation layer. A wall face board and a cross-shaped cold bending thin-wall steel keel are connected together through tapping screws. The cross-shaped cold bending thin-wall steel framework, the thermal insulation layer and the wall face board form the modularized assembling-type cross-shaped cold-bending thin-wall profile steel combined wall. The cross-shaped cold-bending thin-wall profile steel combined wall and a common wall module are in horizontal connection realized through an inter-wall-module horizontal connection method. An upper cross-shaped cold-bending thin-wall profile steel combined wall and a lower cross-shaped cold-bending thin-wall profile steel combined wall are in vertical connection realized through an inter-wall-module vertical connection method. The modularized assembling-type cross-shaped cold-bending thin-wall profile steel combined wall integrates functions of structural load bearing and thermal insulation and has advantages of being high in integration and assembly degree and being suitable for industrial production and the like. Problems that field assembly and connection of joints of walls whose four faces are perpendicular to each other is poor in strength, high in difficulty and the mounting joints are difficult to process.

Owner:BEIJING UNIV OF TECH

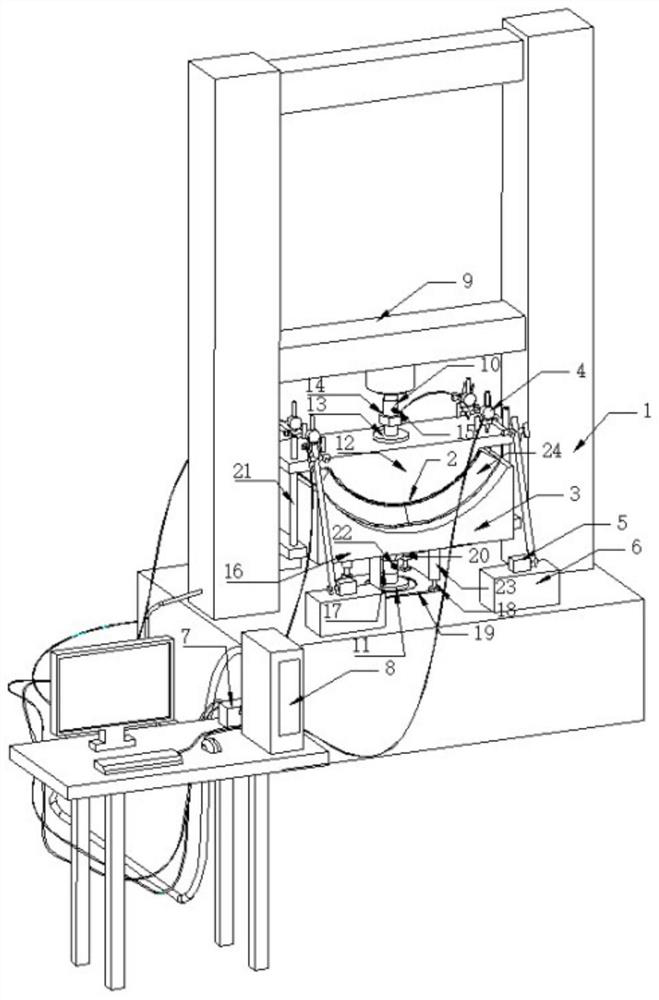

Static load test system suitable for barrel missile adapter and test method of static load test system

PendingCN113092233APrecise control of vertical positionHigh force measurement accuracyMaterial strength using tensile/compressive forcesSimulationData acquisition

The invention provides a static load test system suitable for a barrel missile adapter, the static load test system comprises a material universal mechanical testing machine, a simulated missile body tool, a simulated barrel tool, an electronic dial indicator, a magnetometer stand, an equal-height block, a data acquisition instrument and a test computer, the simulated missile body tool and the simulated barrel tool are respectively connected with the material universal mechanical testing machine; the equal-height blocks are placed on a material universal mechanical testing machine; the magnetic gauge stand is connected with the equal-height block; the electronic dial indicator is connected with the magnetic gauge stand; the data acquisition instrument is connected with the electronic dial indicator through a transmission line; and the test computer is respectively connected with the data acquisition instrument and the material universal mechanical testing machine through transmission lines. Through the arrangement of the static load test system, high force value measurement precision can be realized, the applied load can be accurately controlled, the vertical direction position of the simulated projectile body tool can be accurately controlled, and the test repeatability and the operation convenience are high.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

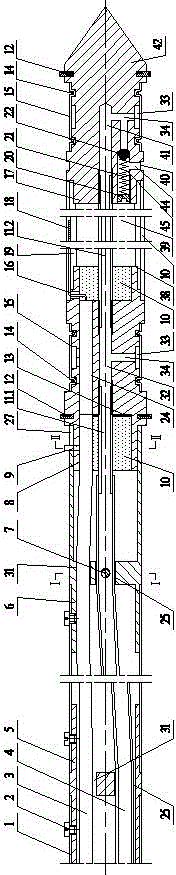

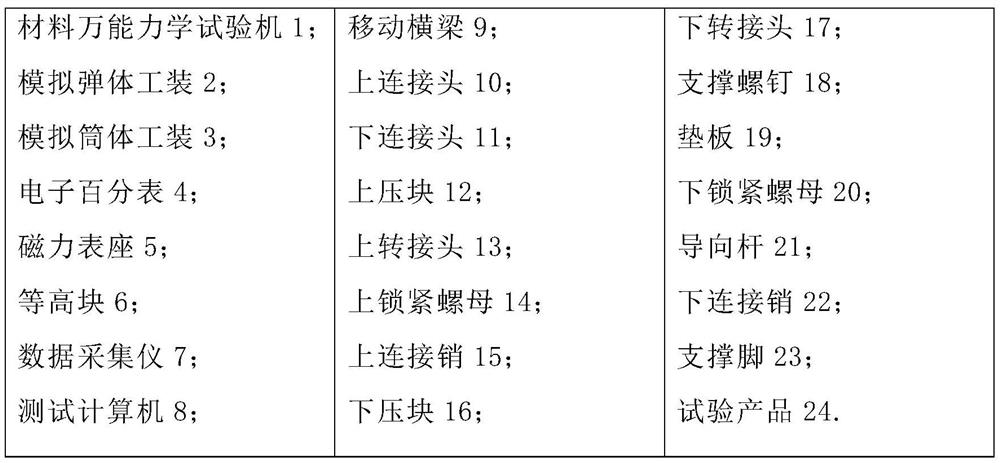

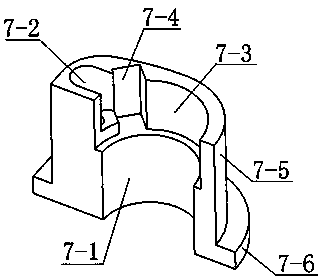

Ultra-thin encoder of permanent magnet servo high-speed motor

The invention relates to an encoder, also named speed and displacement sensor, in particular to an ultra-thin encoder of a permanent magnet servo high-speed motor. The ultra-thin encoder comprises a shell, a rubber-formed wire protecting bushing, a circuit board provided with electric elements, a movable raster, a fixed raster, a movable raster base, a first bearing, a light emitting diode, a main support, a second bearing, a hollow shaft and a blade spring. The ultra-thin encoder of the permanent magnet servo high-speed motor is characterized in that the ultra-thin encoder further comprises a light emitting diode sleeve, the light emitting diode is sleeved with the light emitting diode sleeve, and the light emitting diode sleeve is arranged on the main support. Due to the fact that the light emitting diode of the encoder is installed in an embedded mode, space is saved, production positioning accuracy is improved, and the problem that in the prior art, a light emitting diode is fixed by means of a circuit board, and fixation is unstable and unreliable is solved. The ultra-thin encoder of the permanent magnet servo high-speed motor is compact, small in occupied space, simple, reasonable, and convenient and fast to assembly and adjust. Compared with existing encoders, the ultra-thin encoder of the permanent magnet servo high-speed motor is lighter, thinner and lower in cost. The installation space is small, and requirements of the modern industry for smaller size and more powerful function are met.

Owner:CHANGCHUN RONGDE OPTICS

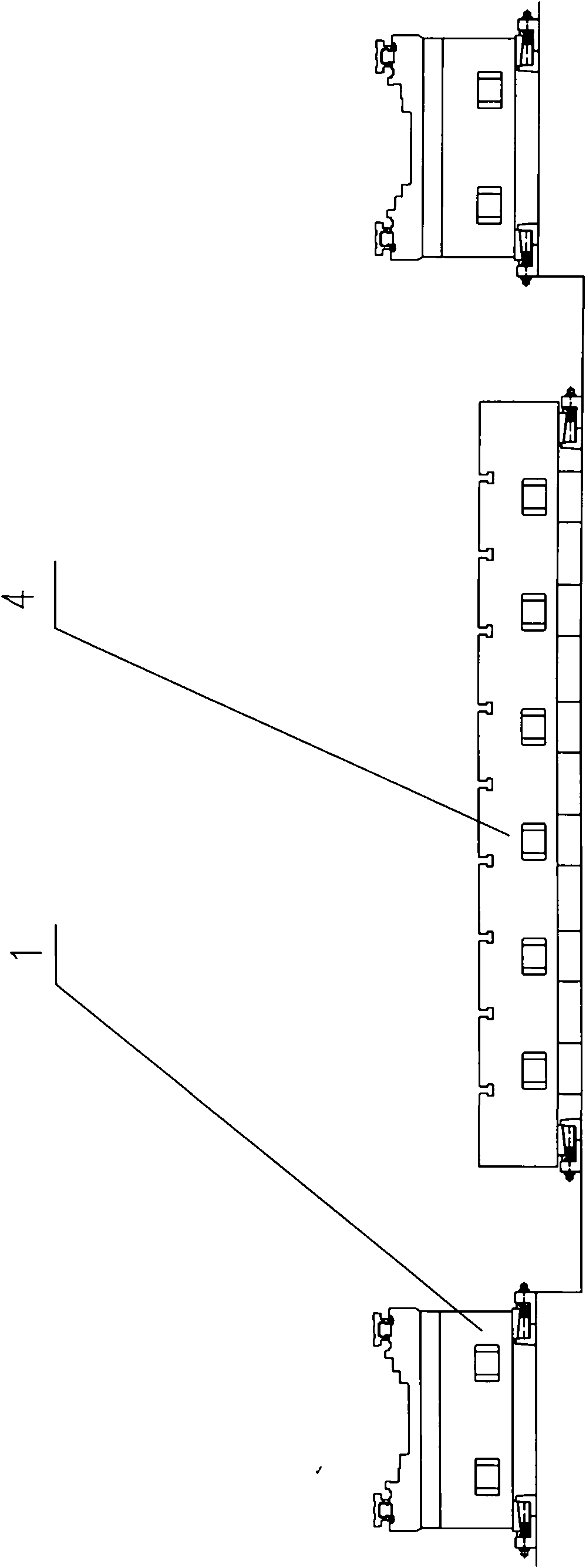

Multi-interface beam tower matching precision control method and device

ActiveCN113322816AImprove installation positioning accuracyEasy to useWelding/cutting auxillary devicesBridge structural detailsButt jointStress relief

The invention relates to a multi-interface beam tower matching precision control method and device. Two steel main beams are located below a top plate, each steel main beam is provided with two tower beam combination ports, the ports are connected with tower columns in a welded mode; outer flower stands are arranged between the tower columns in a spot welding mode, and a core cylinder is arranged in the center of the tower columns; the four side faces of the core cylinder are in butt joint on the outer flower stands through spot welding of an inner flower stand; shear cylinders are arranged in the inner cavities of the tower columns; the shear cylinders are in spot welding connection with the inner walls of the tower columns through a plurality of cross arms. Components such as the shear cylinders, the core cylinders, the inner flower stand and the outer flower stands are arranged inside and outside the tower columns to form a composite frame-cylinder structure in which the inner frame cylinders and outer frame cylinders of the tower columns are matched with each other; the rigid fixing structures of inner shear walls and outer shear walls resist torsion caused by shear force caused by welding stress on the side walls of the tower columns and a shear force hysteresis effect, and the stability of the shapes of the tower columns is kept in the full penetration welding process; stress relief operation is completed through ultrasonic aging; and the mounting position precision of the tower columns on the steel beams is effectively improved.

Owner:CHINA RAILWAY JIUJIANG BRIDGE ENG +1

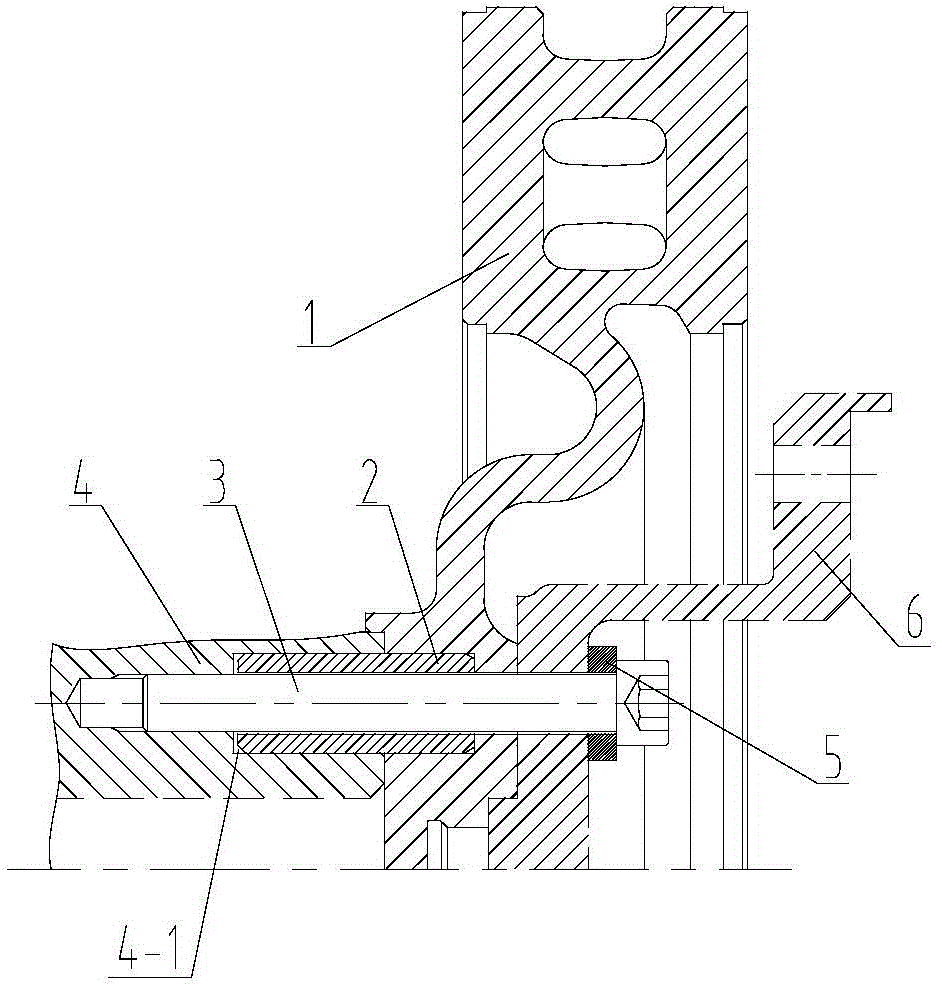

Connecting structure of wheel mounted type brake disc for rail transit vehicle

The invention relates to a connecting structure of a wheel mounted type brake disc for a rail transit vehicle. The connecting structure comprises a wheel connecting part, a disc body and connecting screws. The disc body comprises an inner friction ring, an outer friction ring and a disc bowl which are integrated. The distance between the inner end face of the disc bowl and the inner friction surface of the inner friction ring is h. The disc bowl is connected with the inner friction ring through an arc-shaped center plate. Radiating ribs are arranged between the inner friction ring and the outer friction ring in the circumferential direction. The inner end face of the disc bowl is provided with an inner positioning hole matched with the wheel connecting part. The end of the wheel connecting part is arranged in the inner positioning hole of the disc bowl. The disc bowl is provided with at least three step holes, and the wheel connecting part is provided with step mounting holes corresponding to the step holes. Elastic cylindrical pins are arranged in the step holes of the disc bowl and the step mounting holes of the wheel connecting part. The connecting screws penetrate through the disc bowl and the elastic cylindrical pins and are connected with the wheel connecting part. The connecting structure is simple, higher in assembling and positioning precision and convenient to dismount, structural stress in the braking process can be reduced, and the reliability of the connecting structure is improved.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

Design and adjustment method of inclined guide chain type anchor system

ActiveCN111806651AHigh positioning accuracyShorten the installation cycleGeometric CADVessel designingControl engineeringIndustrial engineering

The invention discloses a design and adjustment method of an inclined guide chain type anchor system. The design and adjustment method comprises a series of processes of digital model establishment, anchor system part designing and positioning, position verification and adjustment, dynamic calculation and analysis, knife switch chain stopper adjustment and the like. According to the inclined guidechain type anchor system design and knife switch chain stopper adjustment method, digital modeling, space positioning and dynamic calculation are applied so that the design positioning and adjustmentmodes of an anchor system part model are visual. The method has advantages that a new technology is comprehensively applied, the design method and the success rate of the current inclined guide chaintype anchor system are improved, the knife switch chain stopper positioning adjustment method can be given in a design stage, the adjustment work of installation and positioning of the real ship anchor system is greatly reduced, and a later workload and working time are saved.

Owner:JIANGSU UNIV OF SCI & TECH

Integrated radioactive source welding chamber

InactiveCN104646804ASubstantiveImprove air tightnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRadioactive source

The invention relates to an integrated radioactive source welding chamber which comprises a mounting bottom plate, a welding small chamber, view window components, a clamping guide component, a welding gun mounting and sealing component and a heat radiating double-spring top plate component, wherein the welding small chamber is fixedly connected with the mounting bottom plate; the heat radiating double-spring top plate component is mounted at the right end of the welding small chamber; the welding gun mounting and sealing component is mounted at the top of the welding small chamber; the clamping guide component is mounted at the left end of the welding small chamber; the view window components are arranged at the front and back ends of the welding small chamber. The welding small chamber of the integrated radioactive source welding chamber is integrally formed; the processing size precision, position precision and mounting position precision are greatly improved; the gas tightness of the welding chamber is enhanced; the welding small chamber is convenient to dismount and the inner wall of the welding small chamber is convenient to clean. The integrated radioactive source welding chamber disclosed by the invention is simple and practical in structure, convenient to operate, high in rotating precision during working, and stable, safe and reliable.

Owner:SHANGHAI UNIV

Liquid ejecting head unit, liquid ejecting apparatus, and method of producing liquid ejecting apparatus

ActiveUS20120147093A1High positional accuracyHigh positioning accuracyInking apparatusWriting implementsAdhesiveEngineering

A liquid ejecting head unit includes a liquid ejecting head having a nozzle forming surface provided with nozzle rows consisting of several rows of nozzles for ejecting liquid; and a head fixing member to which the liquid ejecting head is fixed with an intermediate member therebetween. The liquid ejecting head has an intermediate-member fixing portion to which the intermediate member is fixed. The intermediate member has a head-fixing-member bonding surface to be securely bonded to an intermediate-member bonding surface of the head fixing member with adhesive. The head-fixing-member bonding surface has a chamfered portion along at least a portion of an outer edge thereof, the chamfered portion being provided such that the distance from the intermediate-member bonding surface gradually increases from the inner side toward the outer side of the head-fixing-member bonding surface.

Owner:SEIKO EPSON CORP

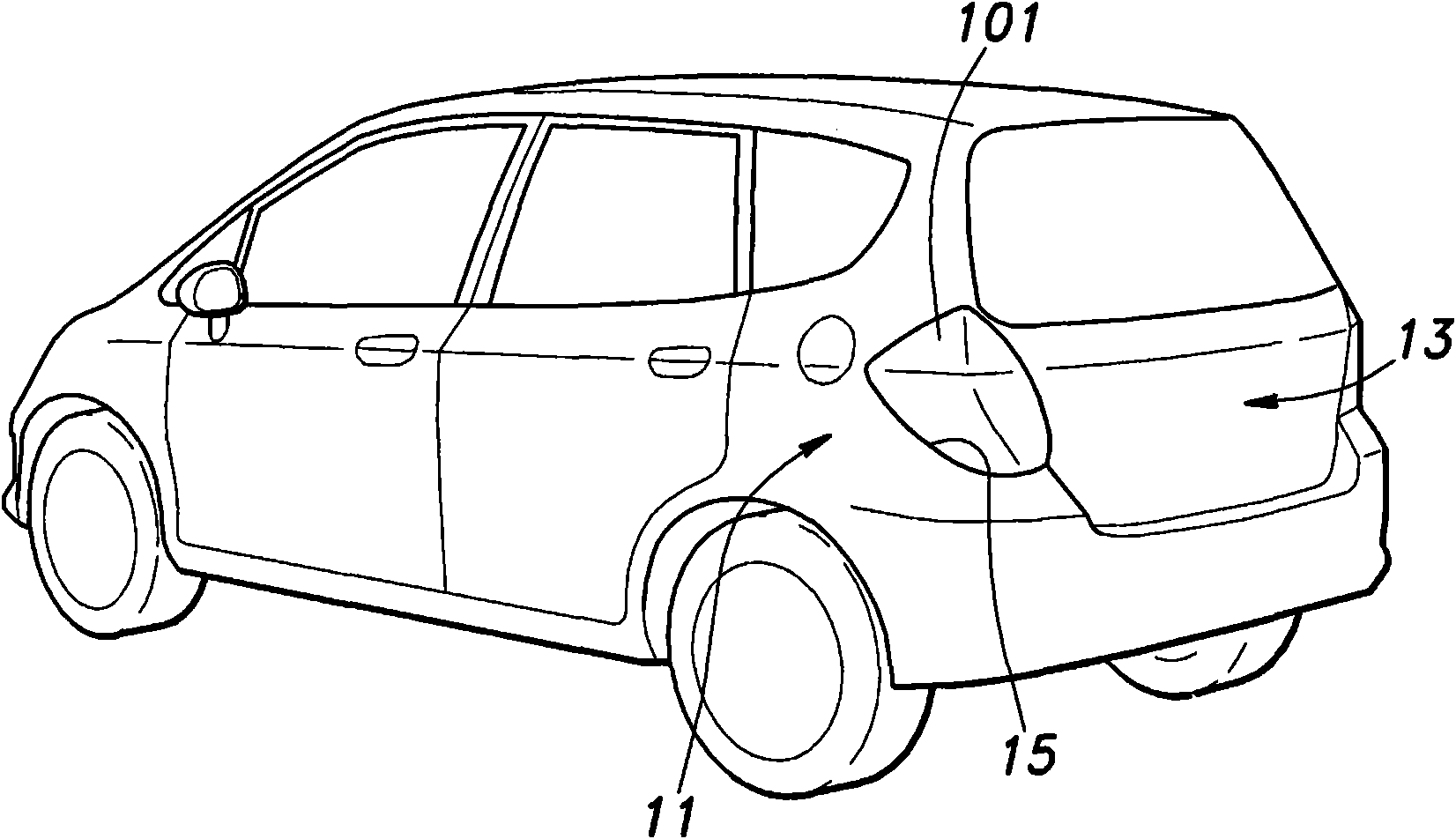

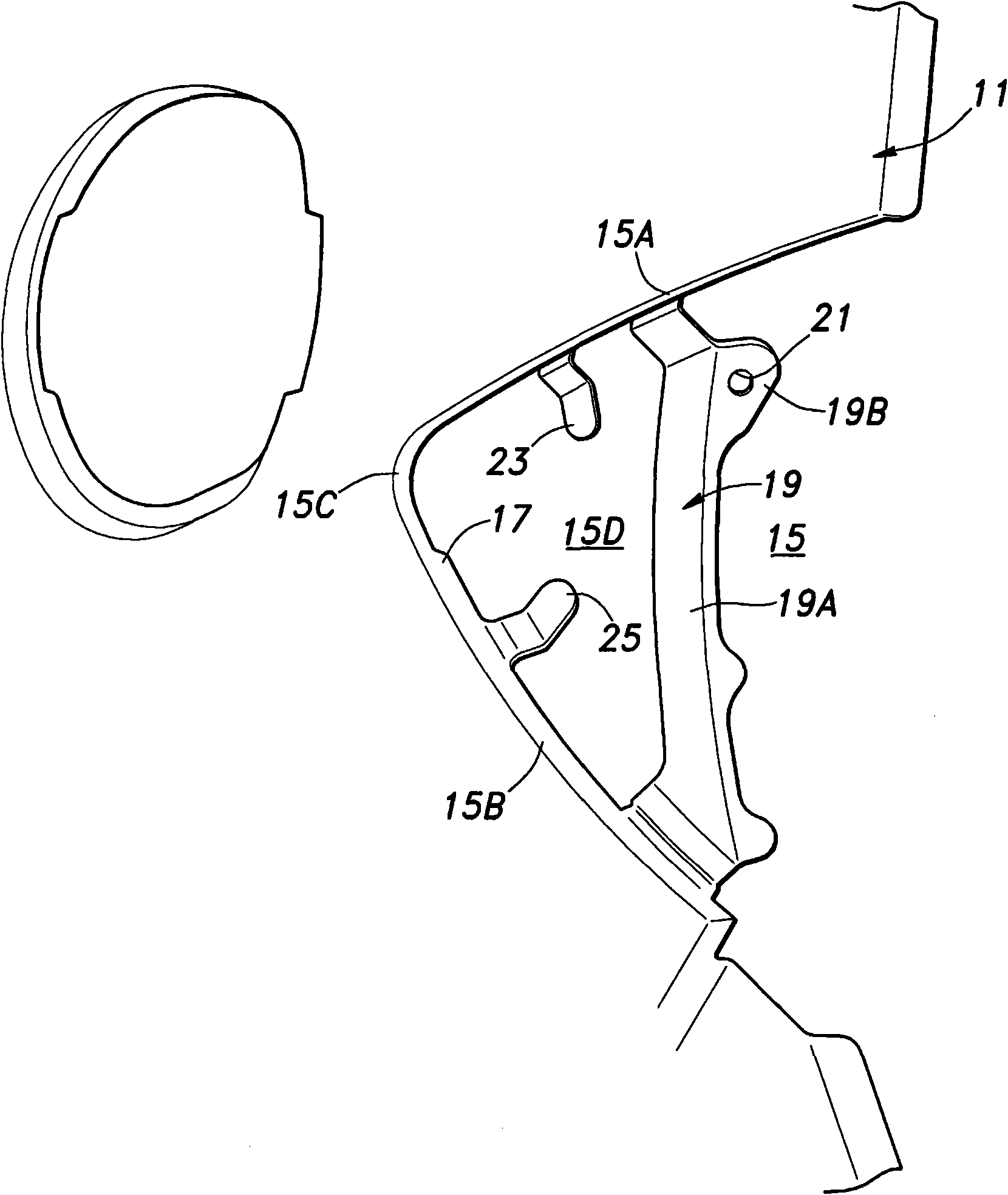

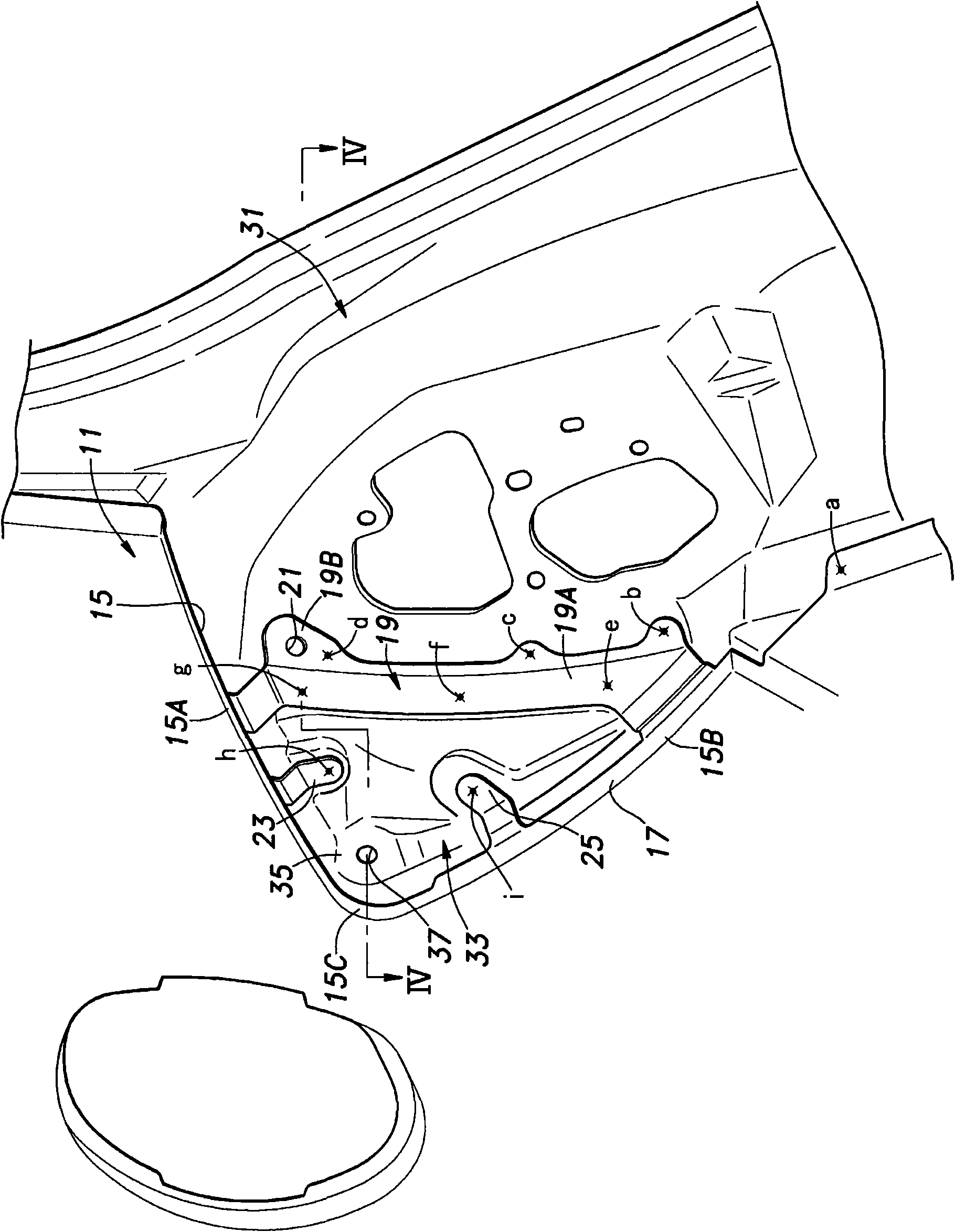

Rear panel structure of automobile

ActiveCN101626942AImprove installation positioning accuracyWith weldingSuperstructure subunitsOptical signallingEngineeringChassis

Degree of freedom in tail light design is enhanced while highly ensuring that the surface of the lens member of the tail light is designed to be continuous to the rear profile of the chassis. A tail light fixing opening (15) is formed in the rear panel outer (11), a coupling piece (19) having an L-shaped transverse section for coupling the upper edge (15A) and the lower edge (15B) of the tail light fixing opening (15) is formed integrally with the rear panel outer (11), and the fixing reference hole (21) of the tail light is formed in the rear panel outer (11).

Owner:HONDA MOTOR CO LTD

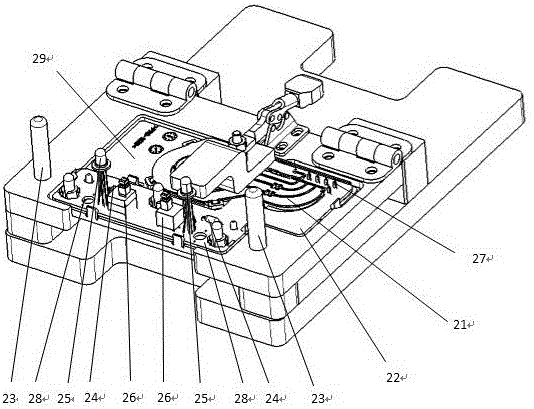

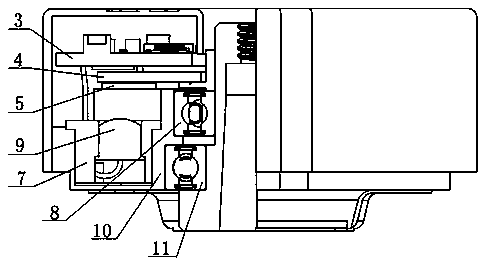

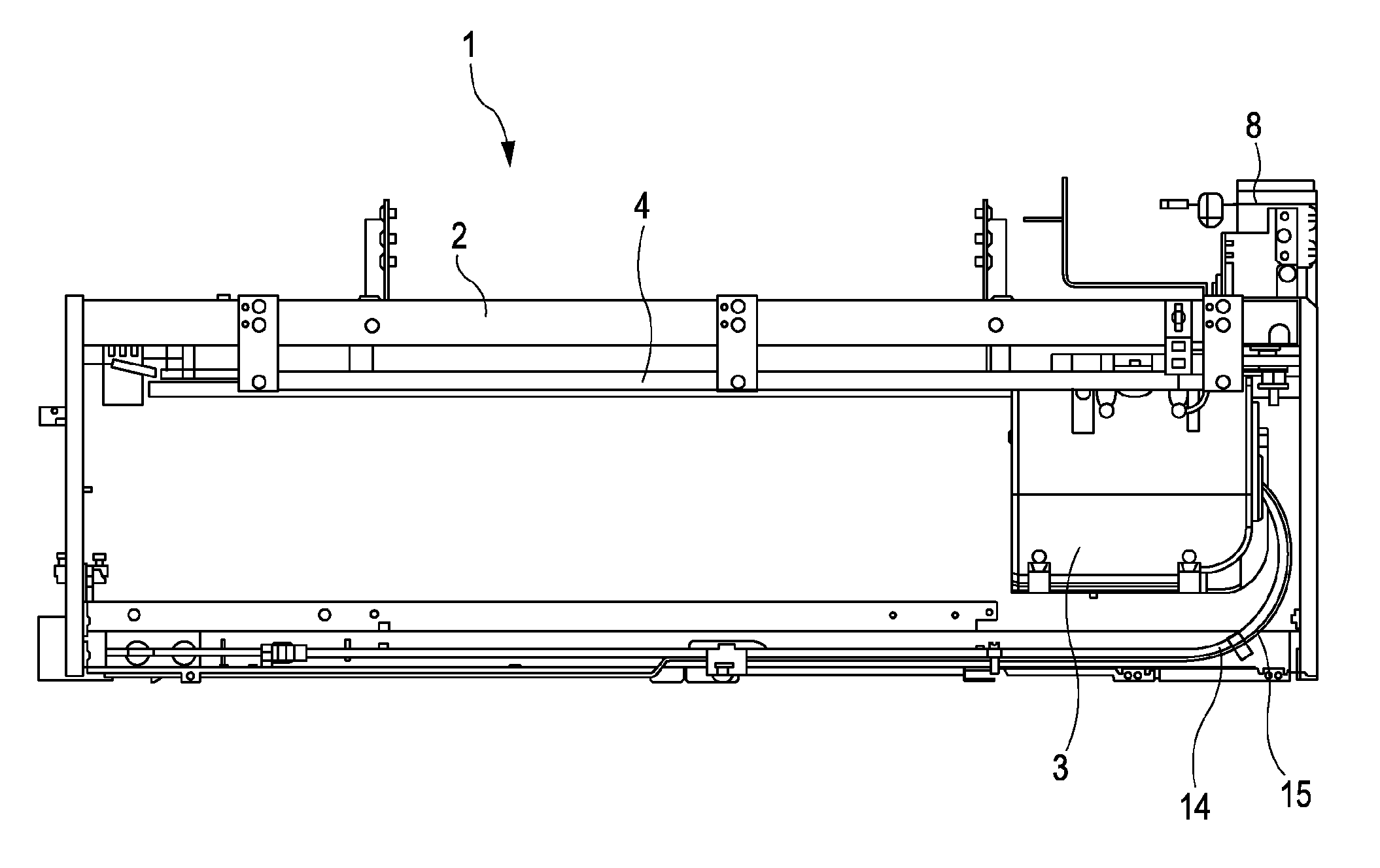

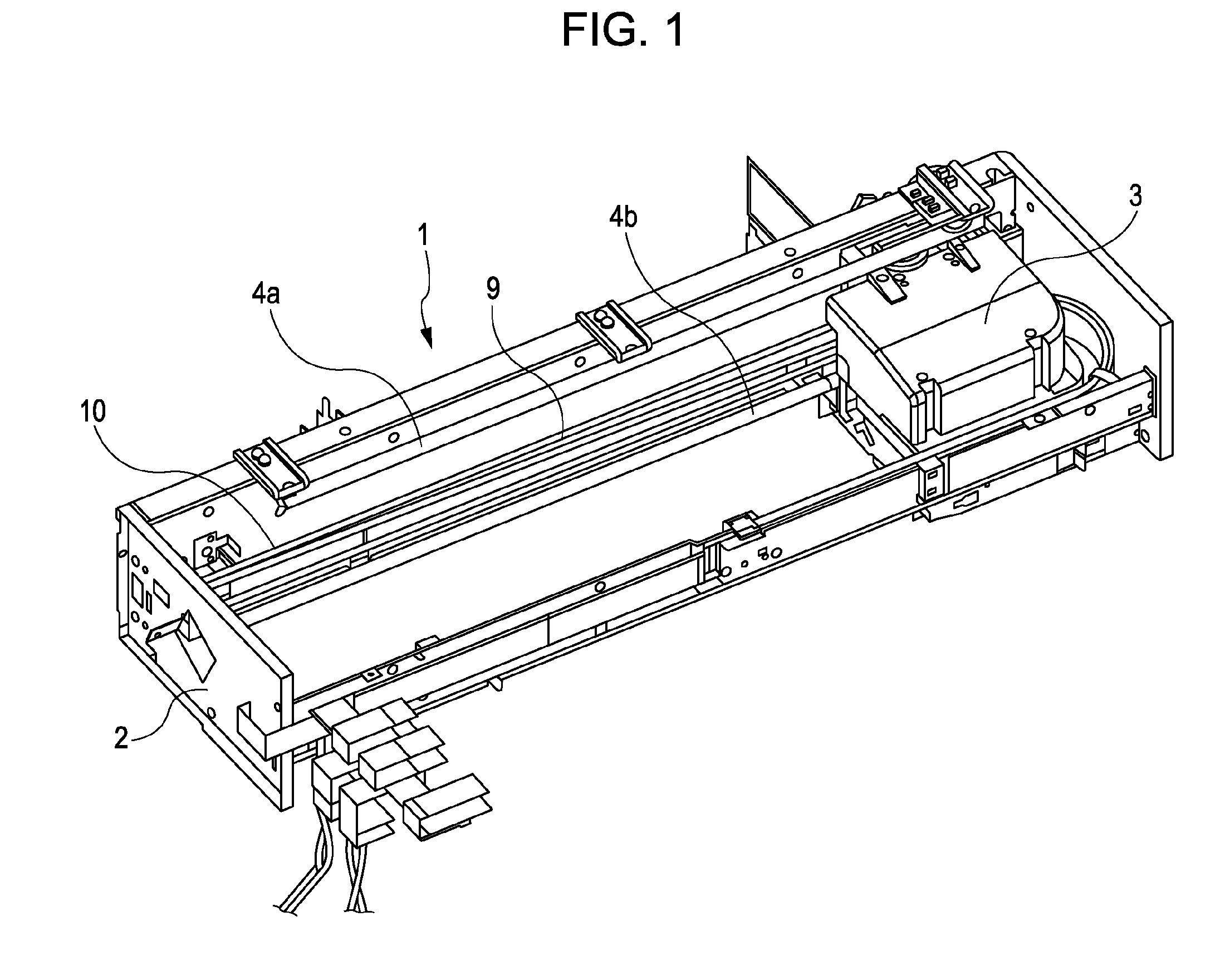

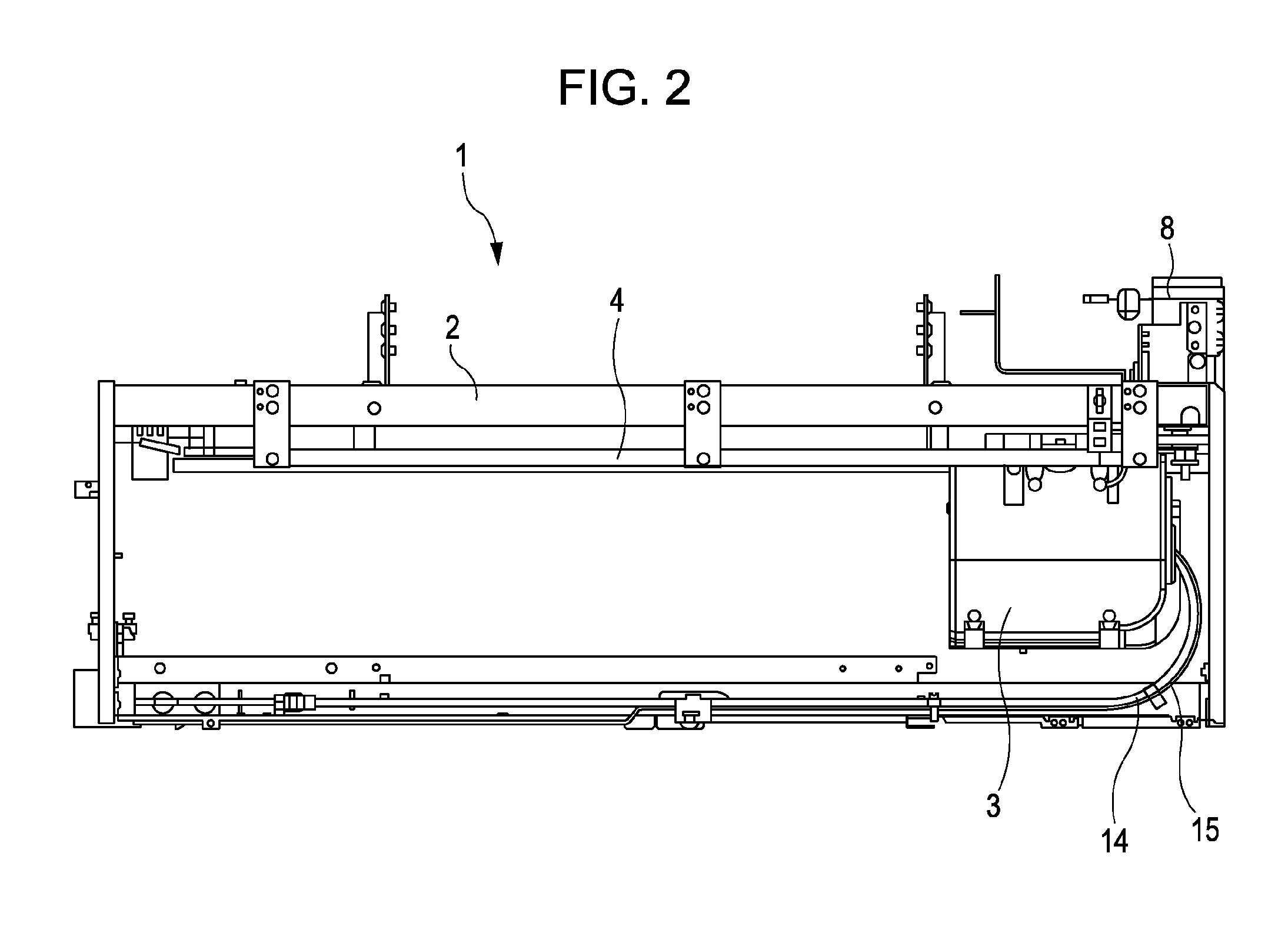

A flying probe test device

ActiveCN107255783BMeet the performance requirements of high-speed motionReasonable structurePrinted circuit testingEngineeringTest platform

Owner:BEIJING SEMICON EQUIP INST THE 45TH RES INST OF CETC

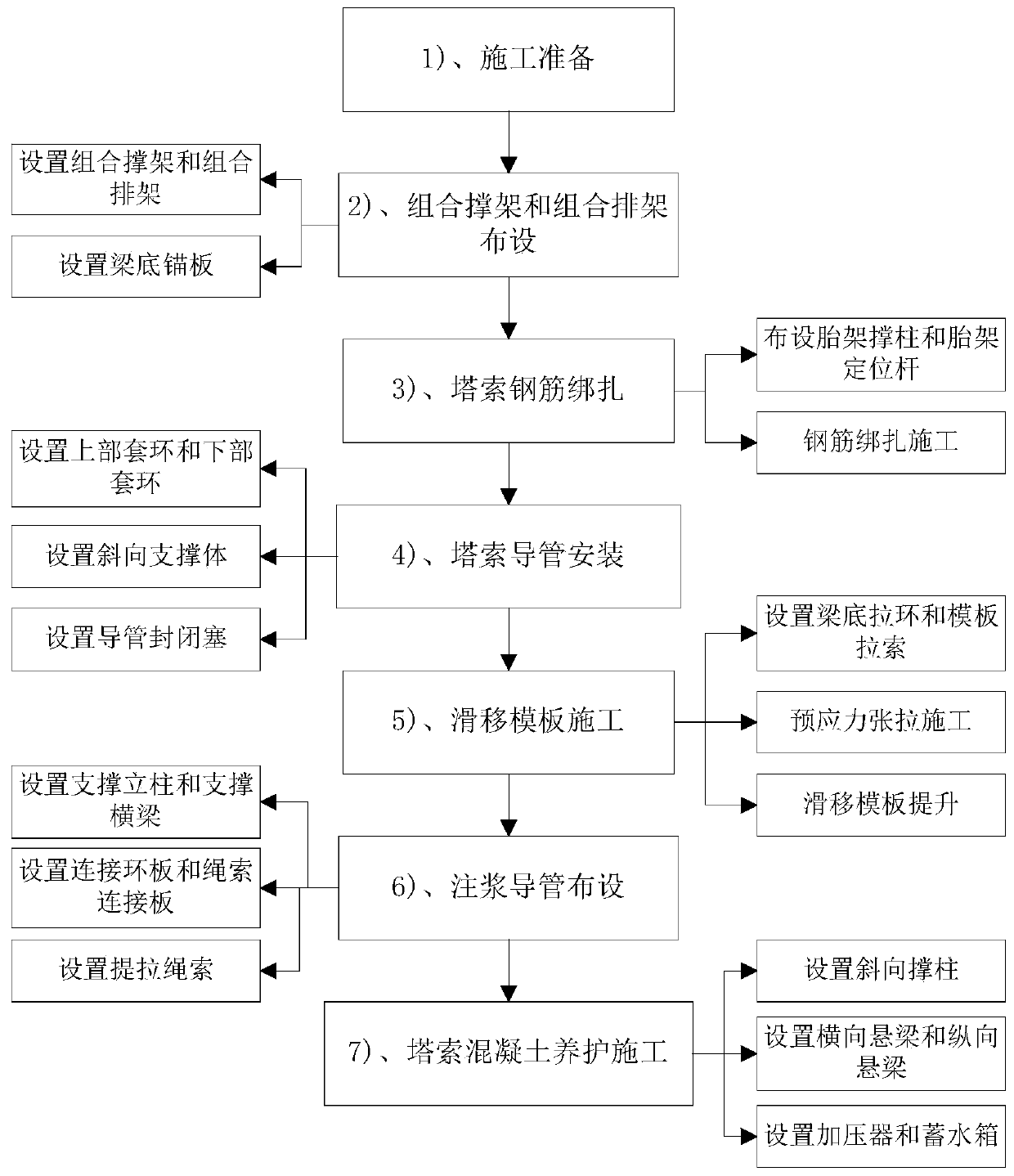

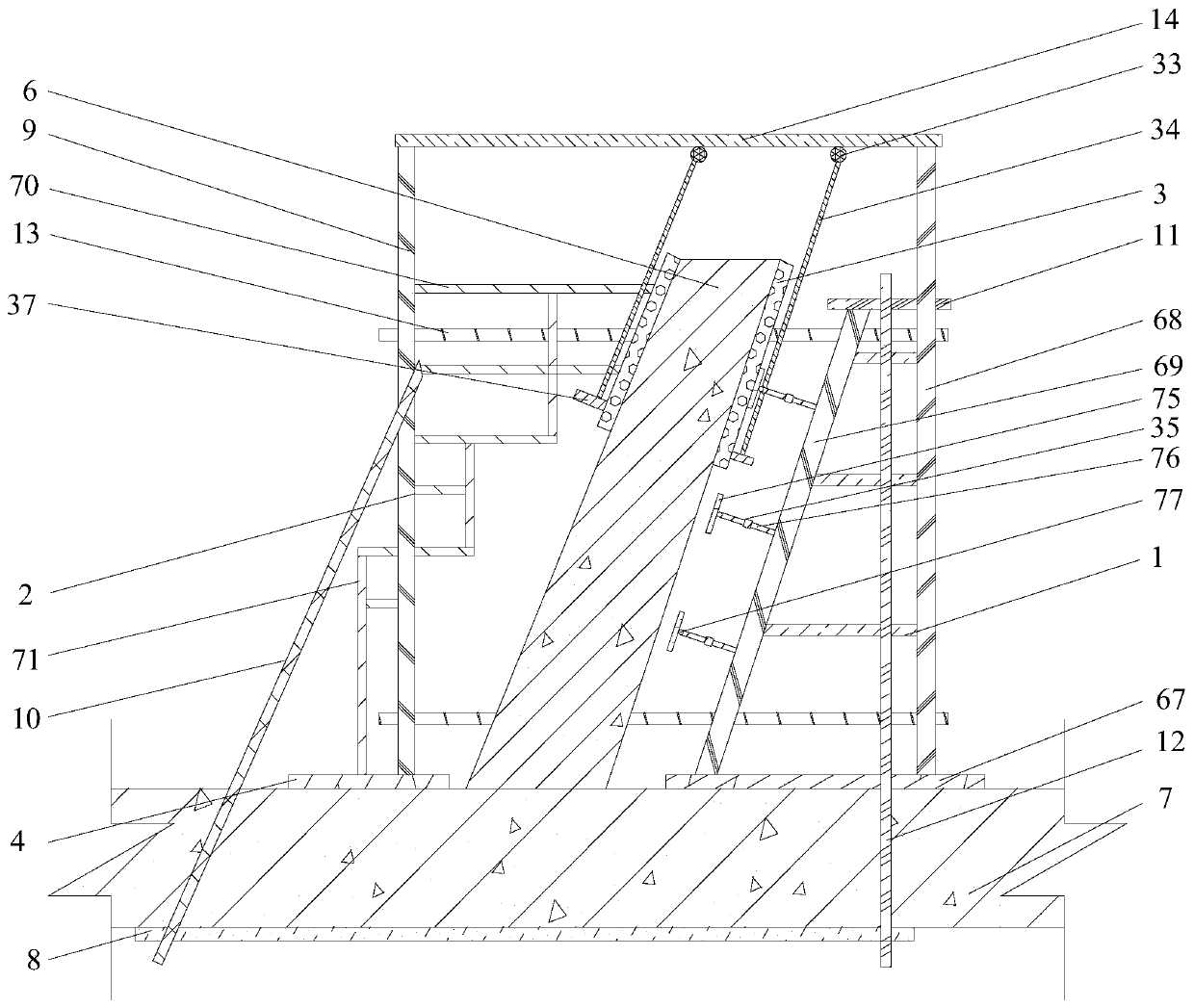

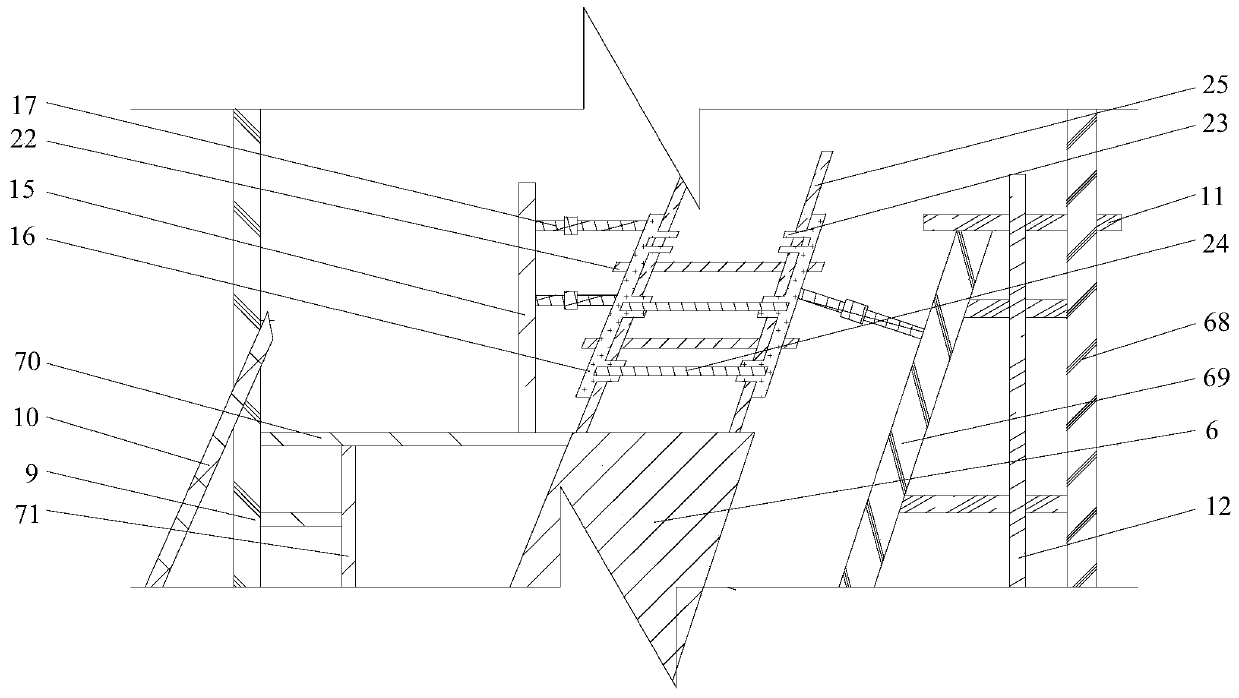

Construction method of inclined cable tower construction structure system

The invention relates to a construction method of an inclined cable tower construction structure system, which comprises the following steps of: 1) construction preparation; 2) arrangement of a combined support frame and a combined grid frame; 3) binding of cable tower steel bars; 4) installation of a tower cable guide pipe; 5) construction of a sliding moulding plate; 6) arrangement of a groutingguide pipe; and 7) concrete maintenance construction of the cable tower. The construction method of the inclined cable tower construction structure system has the advantages that arrangement efficiency of the combined support frame and the combined grid frame can be improved, integrity of the structure can be enhanced, and supporting quality of the sliding moulding plate can be effectively improved; positioning of the cable tower steel bars is accurate, connection is convenient, binding construction quality of longitudinal steel bars and transverse stirrups can be effectively improved, and on-site construction difficulty is reduced; and on-site arrangement of the concrete grouting guide pipe is convenient, an inclination angle of the grouting guide pipe can be dynamically adjusted according to an inclination condition of the cable tower, on-site positioning difficulty is reduced, and concrete pouring quality is improved.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

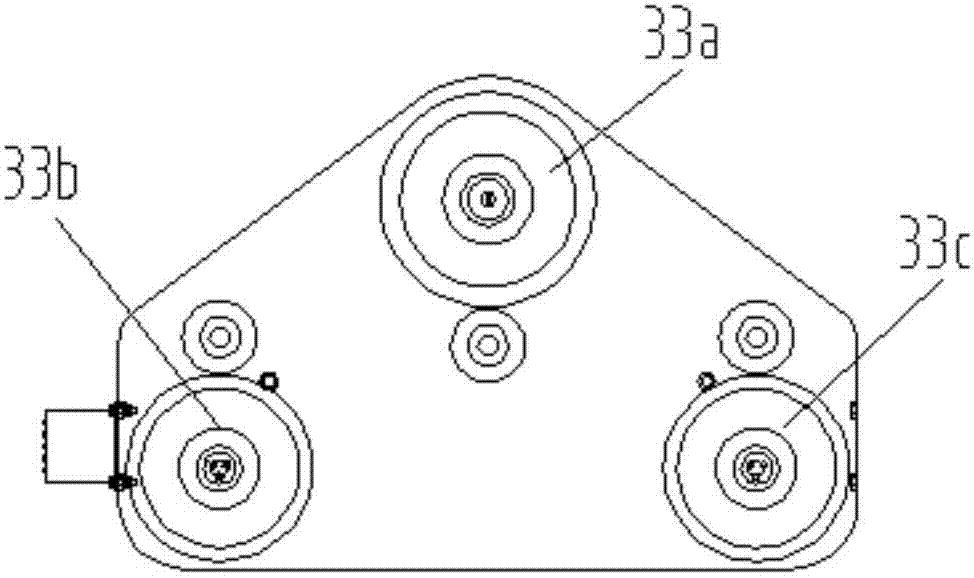

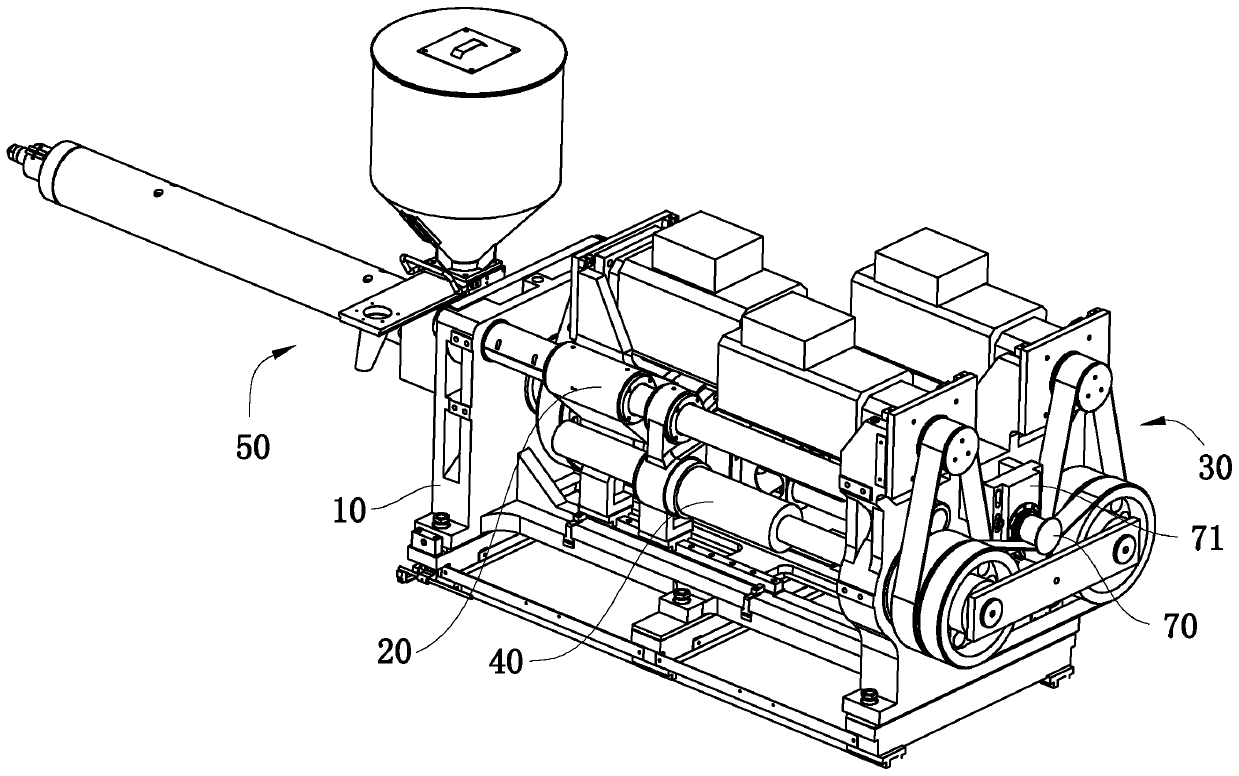

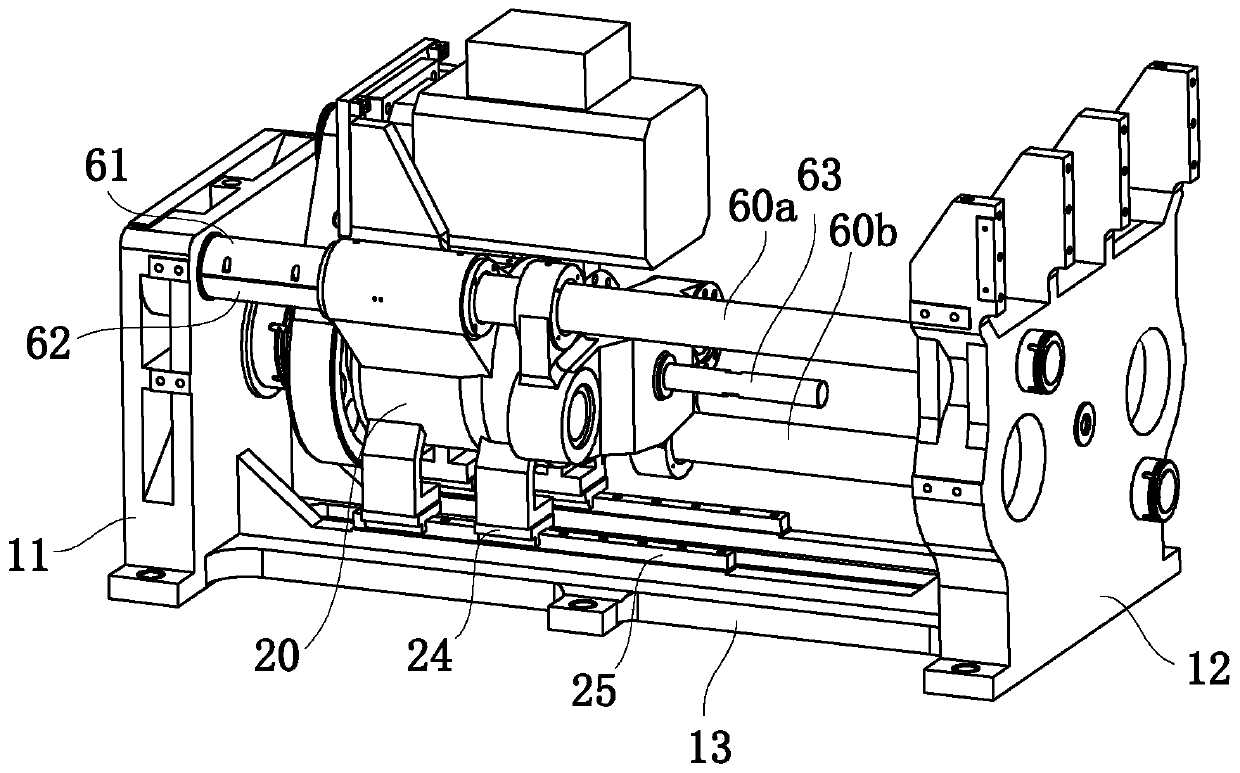

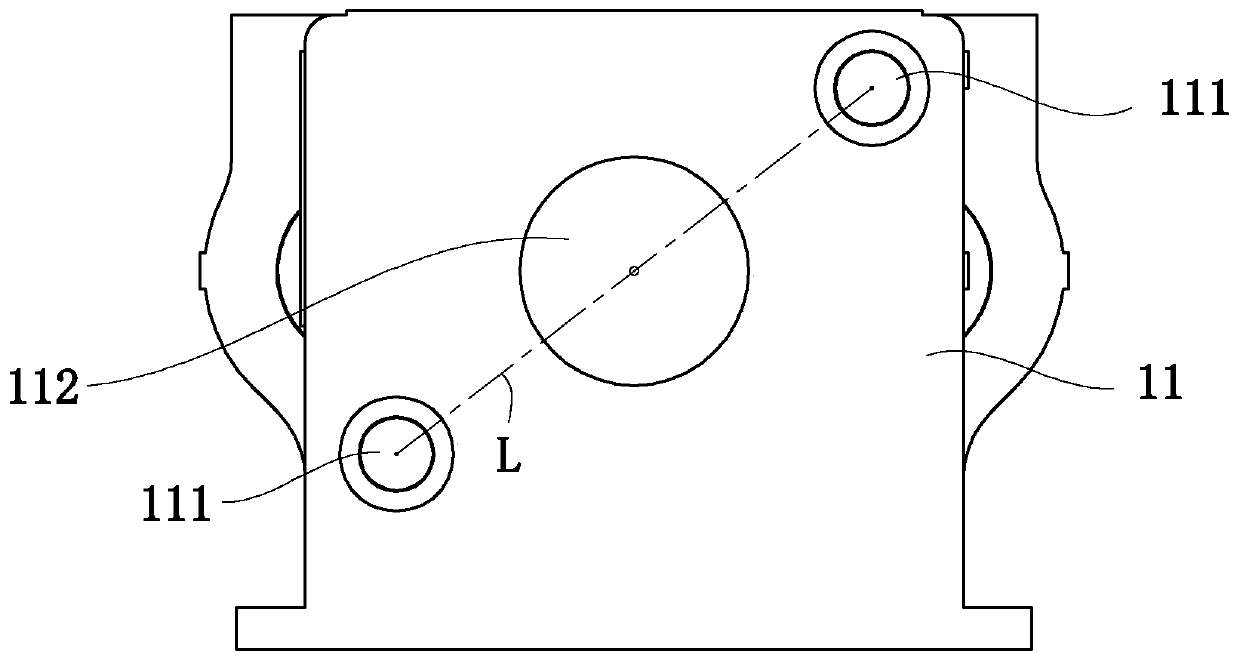

Injection molding machine and electric injection device thereof

The invention discloses an injection molding machine and an electric injection device thereof. The injection molding machine comprises a base, a pull rod set and a driving mechanism, wherein lead screw assemblies are driven by second belt wheels so as to force an injection seat to displace in the axial direction of the pull rod set; and a second synchronous belt is arranged on two adjacent secondhubs in a meshed mode. According to the injection molding machine and the electric injection device thereof, the injection speed is improved by adopting a double-motor double-screw driving mode, and the synchronism of double lead screws is improved by meshing the second synchronous belt with the two second belt wheels, so that the stability in the displacement process of the injection seat is improved, better injection quality can be achieved at higher injection speed, and meanwhile extrusion abrasion between the lead screws and the injection seat is reduced, and the service life of the deviceis prolonged.

Owner:宁波海雄塑料机械有限公司

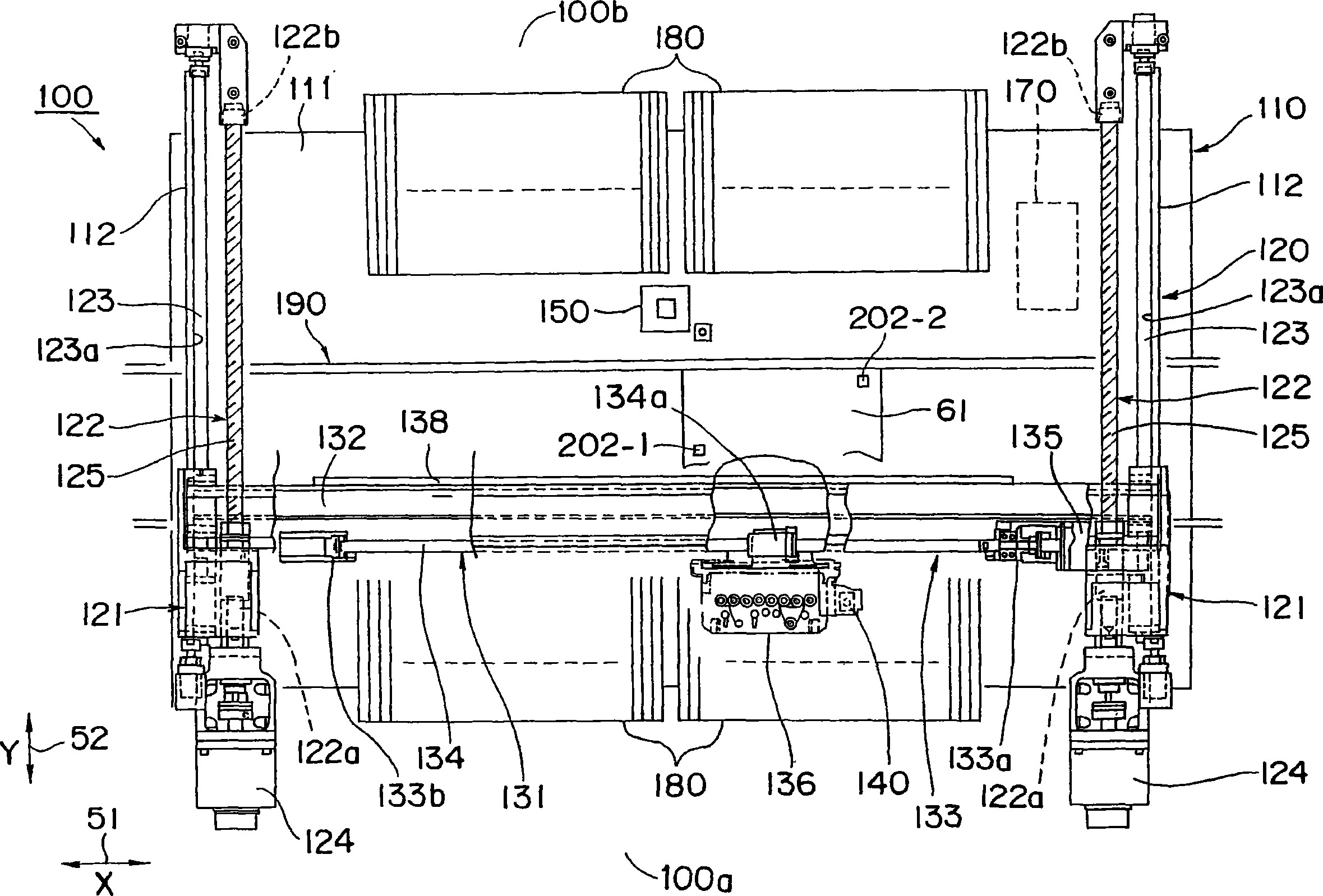

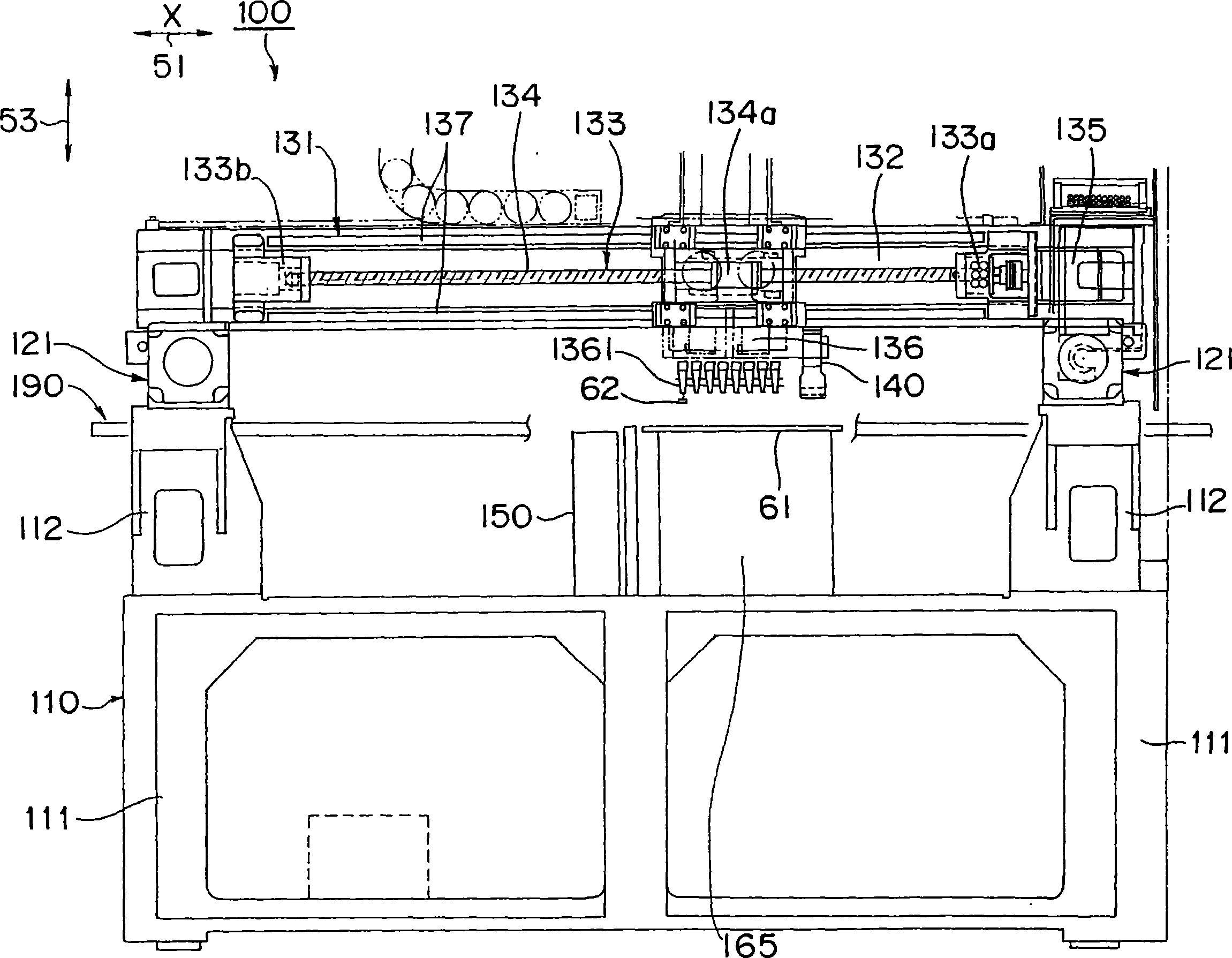

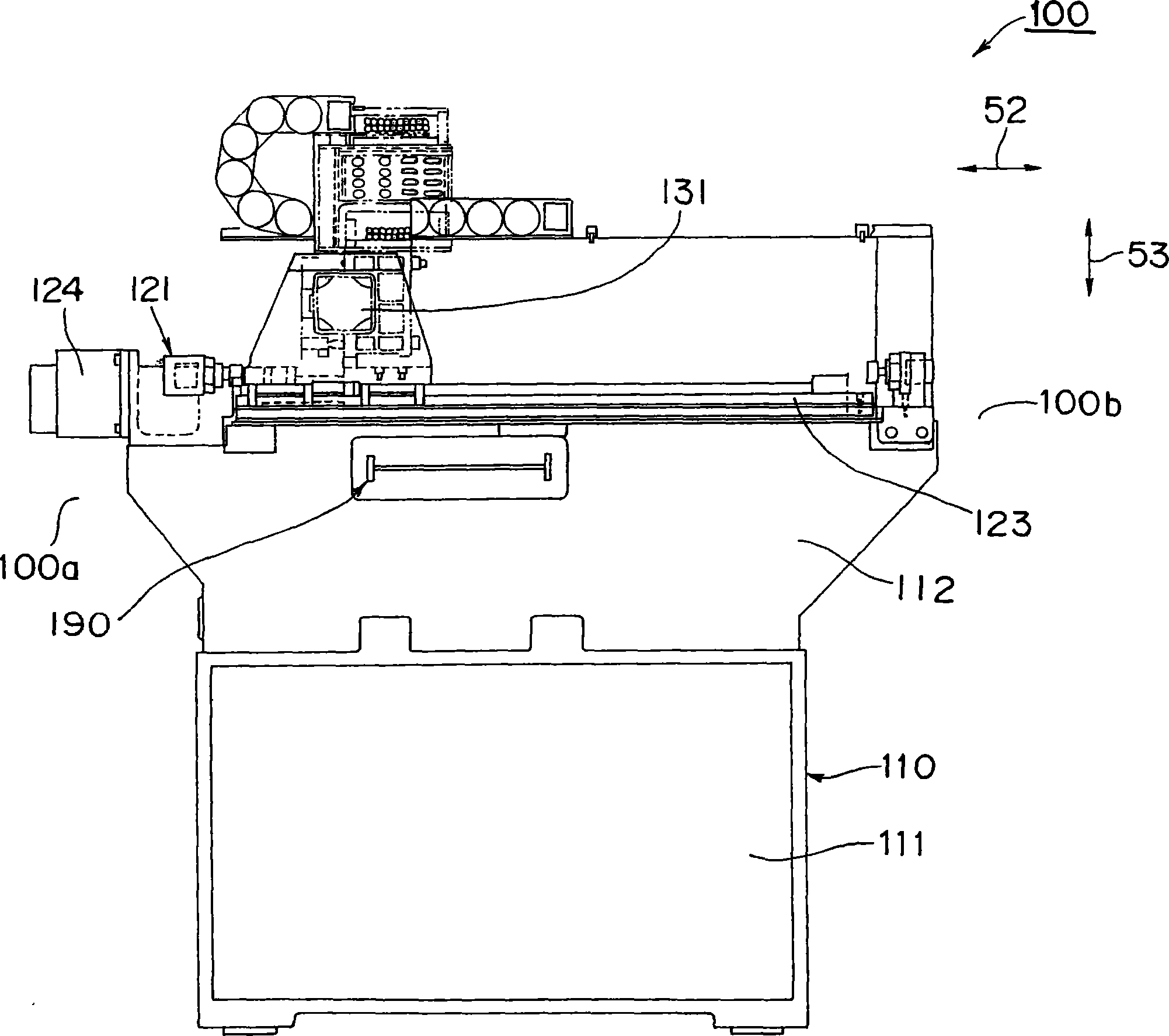

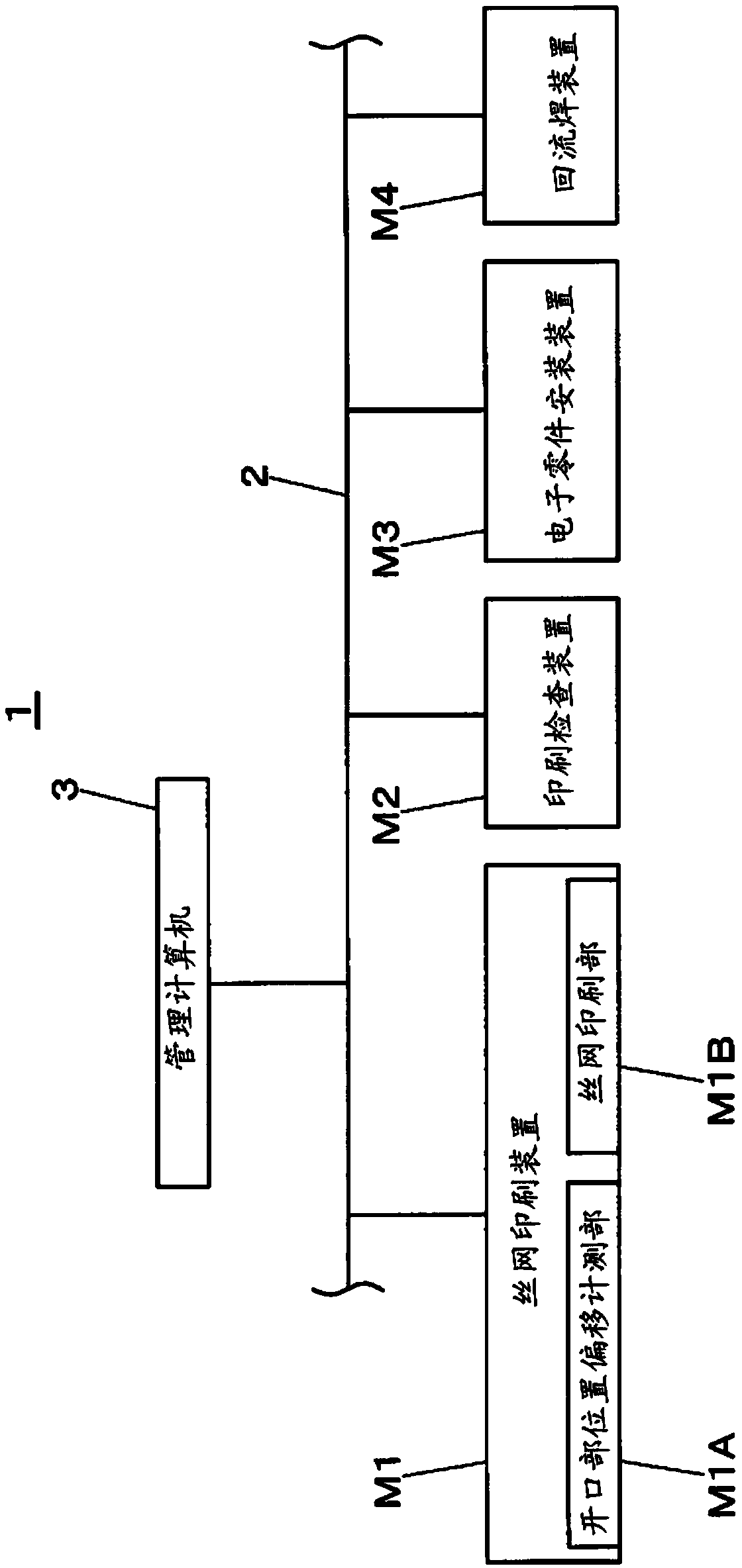

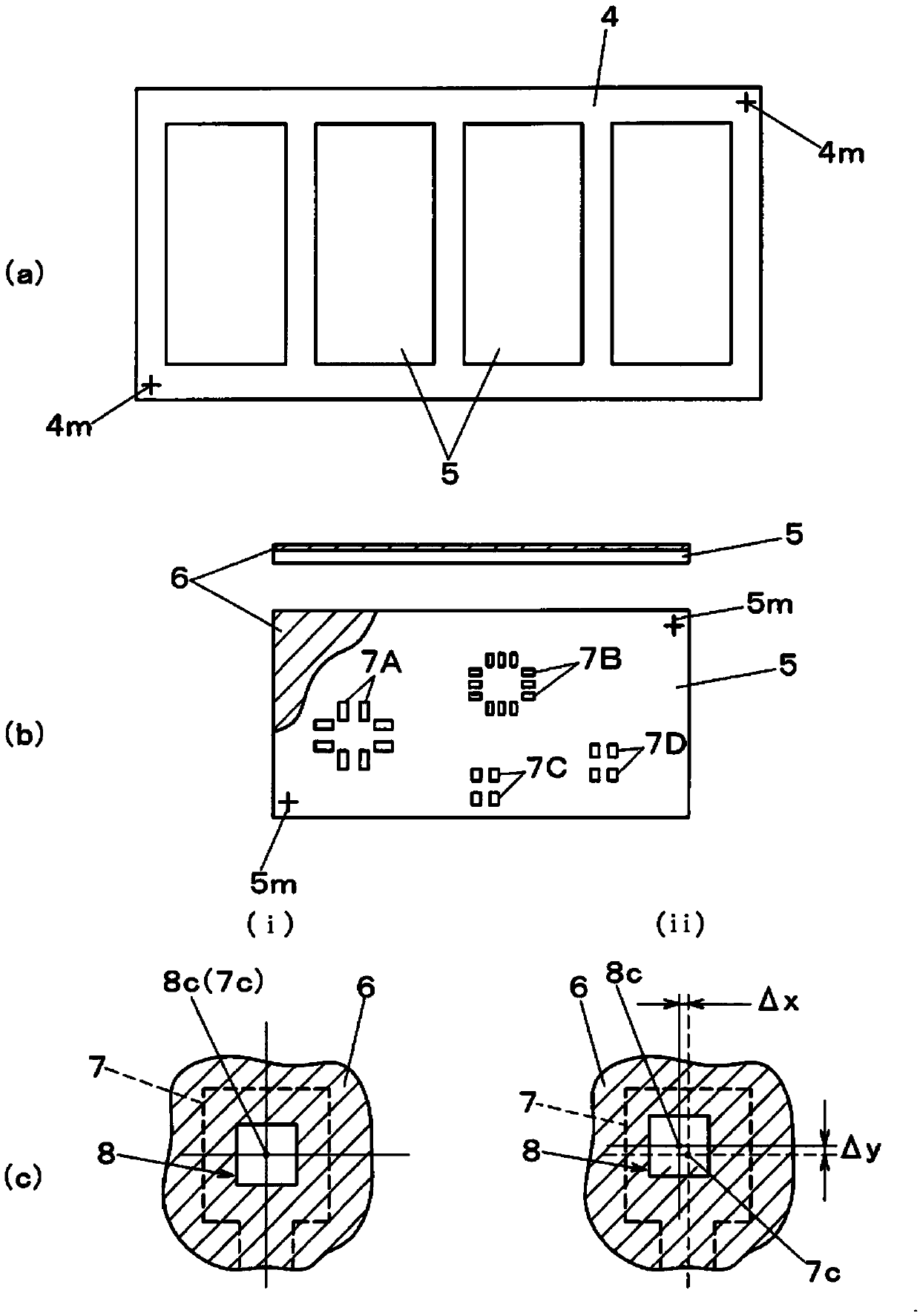

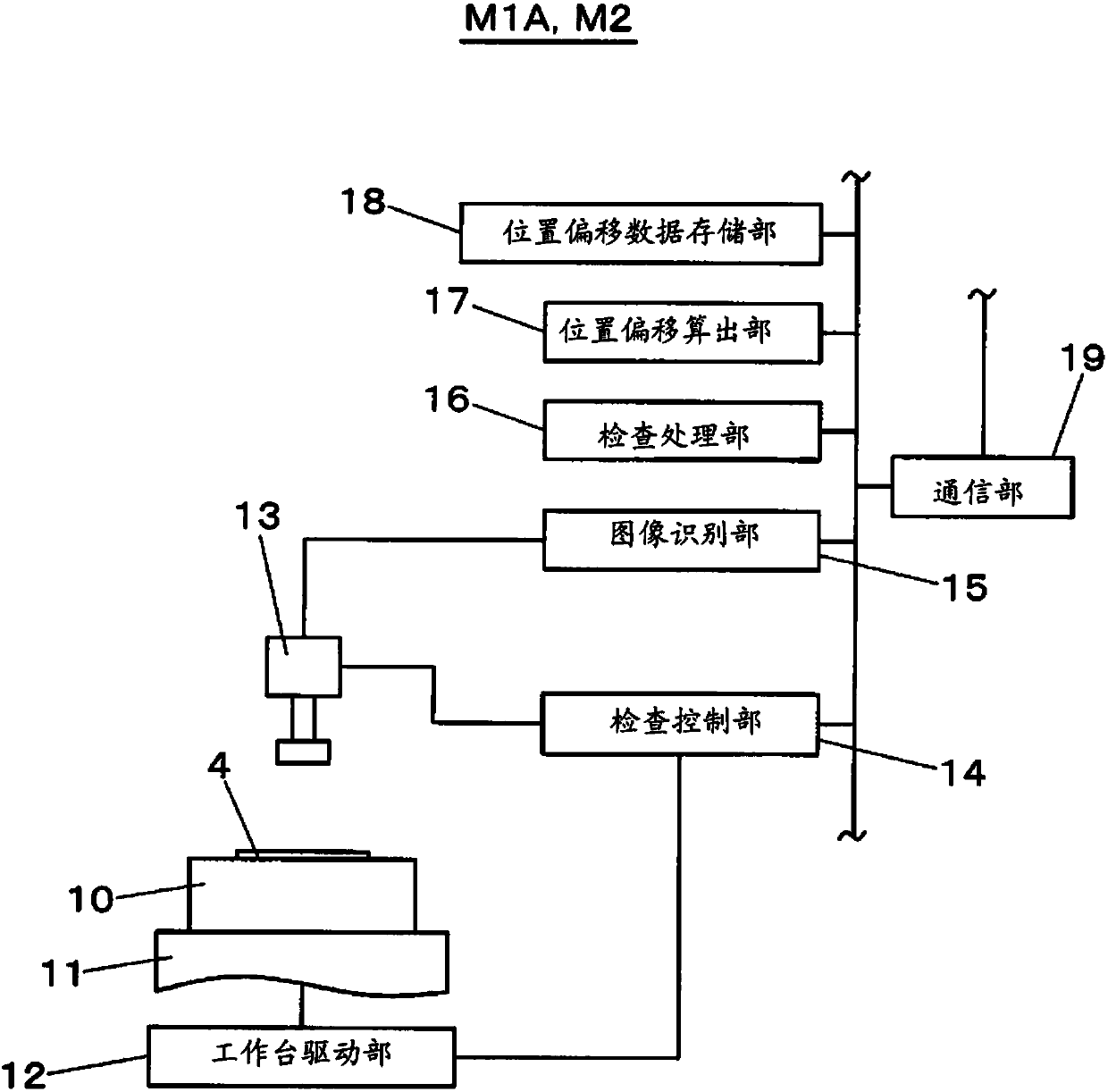

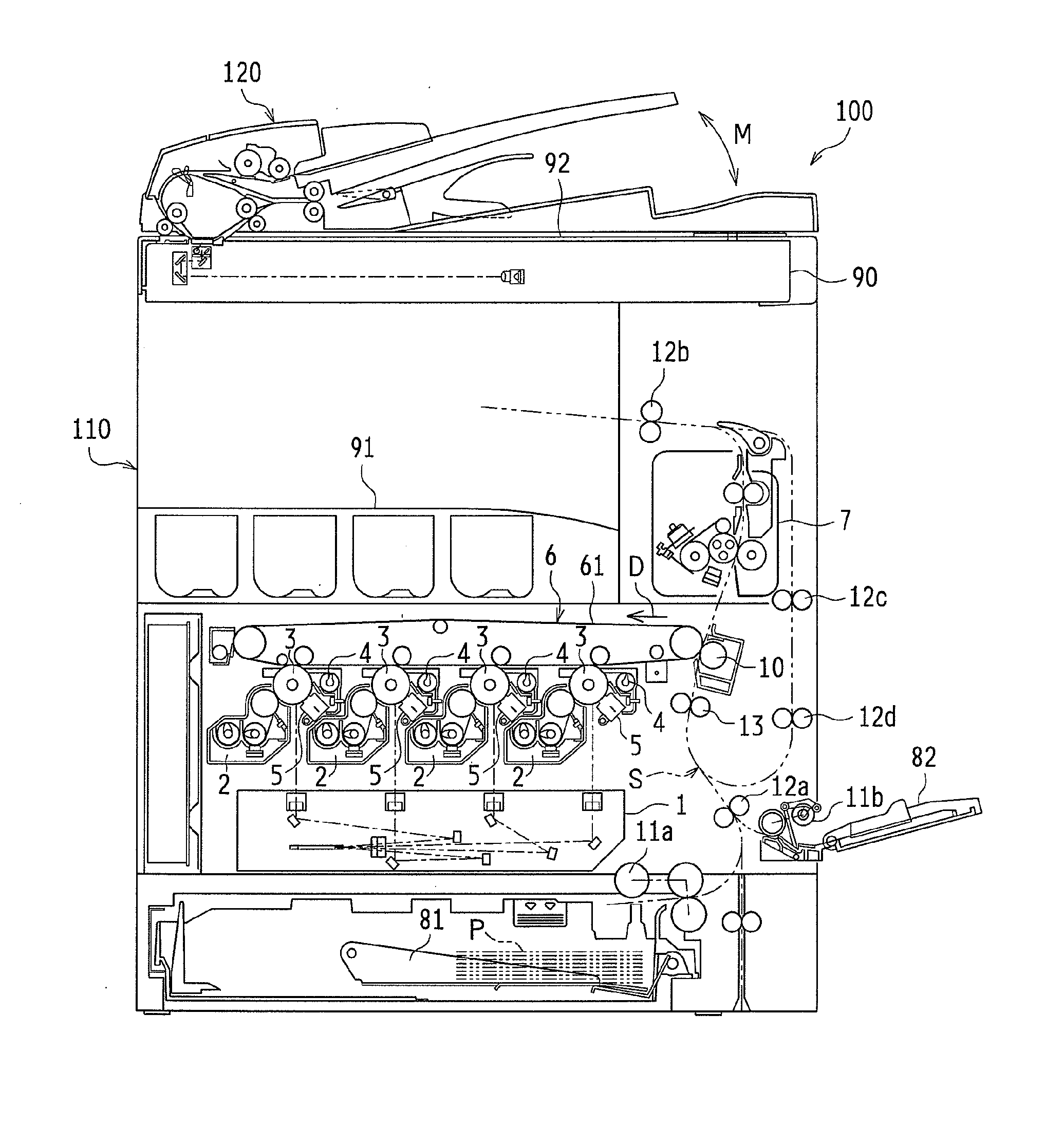

Electronic component mounting system, electronic component mounting apparatus and electronic component mounting method

ActiveCN103635076AImprove installation positioning accuracyPrinted circuit assemblingElectrical componentsTectorial membraneEngineering

The invention provides an electronic component mounting system, an electronic component mounting apparatus and an electronic component mounting method, wherein except the part to be formed as the opening part of an electrode, the other part of a substrate is covered with a protective film. With the above substrate as a target, the printing is ensured to be good in position accuracy. Before the solder printing process, an opening part (8) is optically identified. Meanwhile, the opening position offset between the standard position of the electrode (7) and the actual position of the opening part (8) is stored. Furthermore, with the position of the opening part (8) as a target position, the solder (S) is printed. After that, the printed solder (S) is optically identified. Meanwhile, the solder position offset between the position of the solder (S) and the position of the opening part (8) is stored. During the installation control process, a component mounting mechanism controls a mounting head to transfer electronic components to a single substrate (5). Meanwhile, based on the above opening position offset and the solder position offset, the component mounting mechanism is controlled in such as a way that electronic components (9) are landed in an installation position between the centre-of-gravity position (8*) of the opening part (8) and the centre-of-gravity position (S*) of the printed solder.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Porous cast-in-place box culvert bottom plate and construction method

ActiveCN112647436AHigh speedHigh precisionGround-workFoundation engineeringArchitectural engineeringRebar

The invention discloses a porous cast-in-place box culvert bottom plate and a construction method, and belongs to the technical field of concrete pouring. The method comprises the steps that 1, a reinforcement cage is bound, specifically, reinforcing steel bars are supported in an auxiliary mode through a reinforcement cage binding jig frame, the reinforcing steel bars are bound to form the reinforcement cage, and then the reinforcement cage binding jig frame is removed; 2, an outer side truss supporting rail moving side formwork is installed; 3, a hanging type anti-floating easily-disassembled inner side corner formwork is installed; 4, concrete pouring is conducted, specifically, the positions of the formworks on the two sides are adjusted, and then concrete pouring is conducted; and 5, form removal is conducted, specifically, after the strength of the poured concrete reaches the standard, the hanging type anti-floating easily-disassembled inner side corner form is removed. By reducing the binding difficulty of the box culvert reinforcement cage, the mounting and positioning precision of the porous box culvert bottom plate template is improved, and the construction quality and the construction efficiency of the porous cast-in-place box culvert bottom plate are effectively improved.

Owner:中峥建设集团有限公司

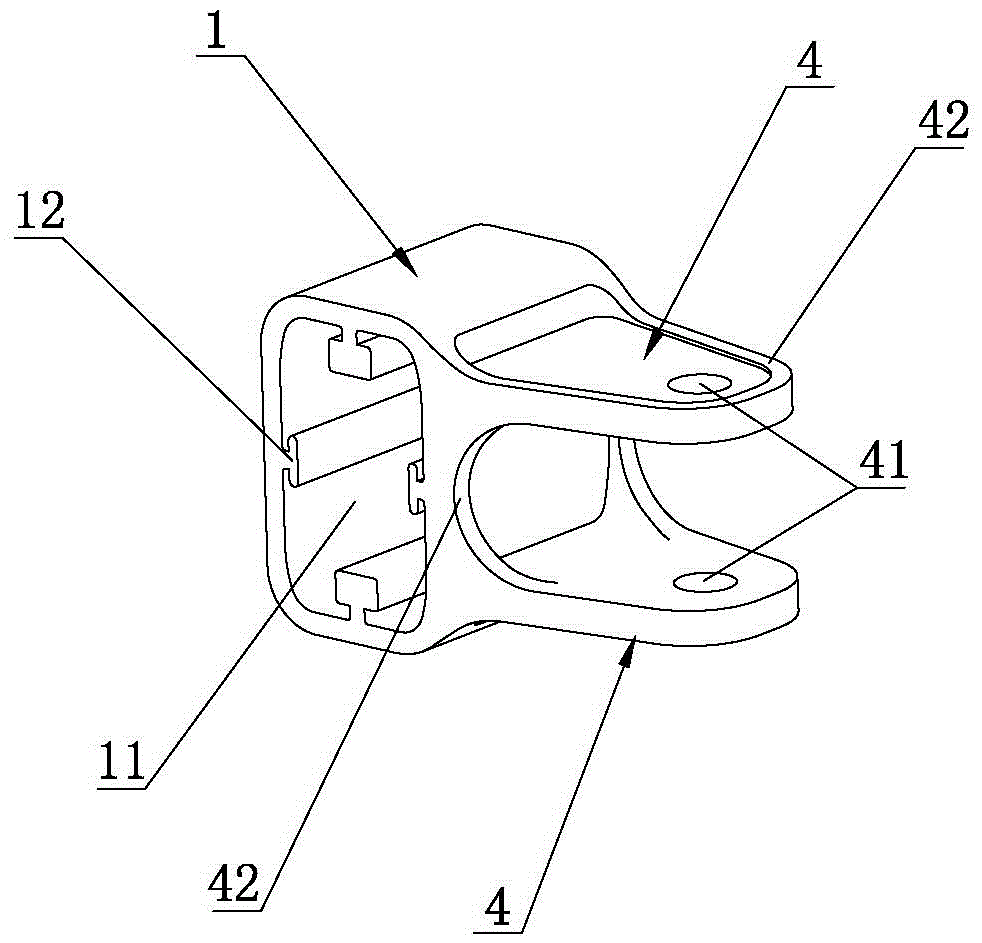

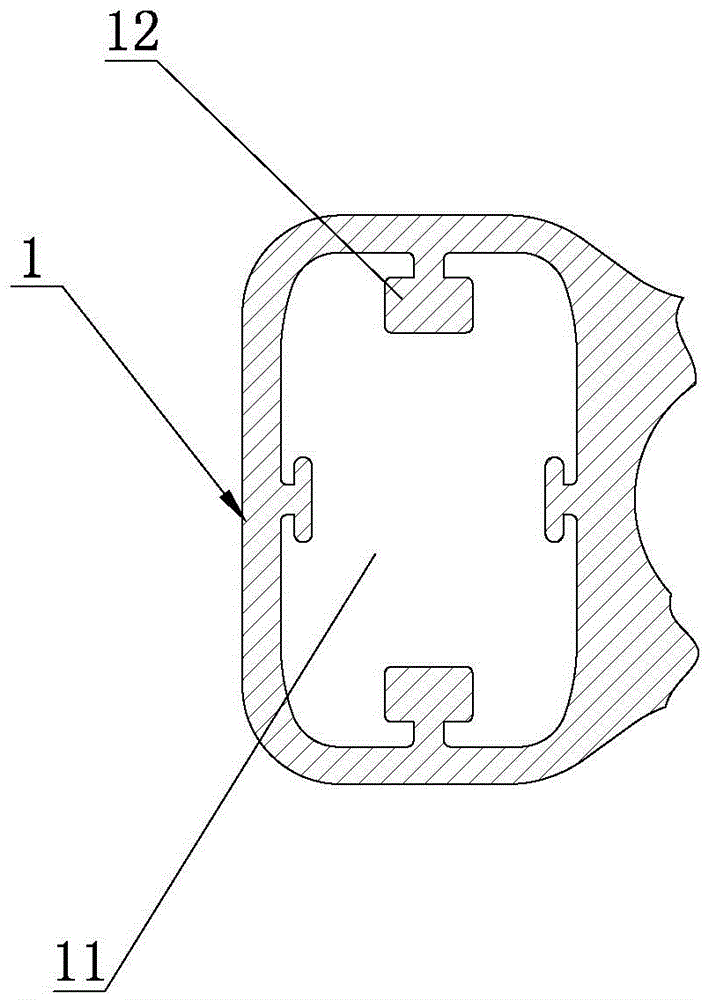

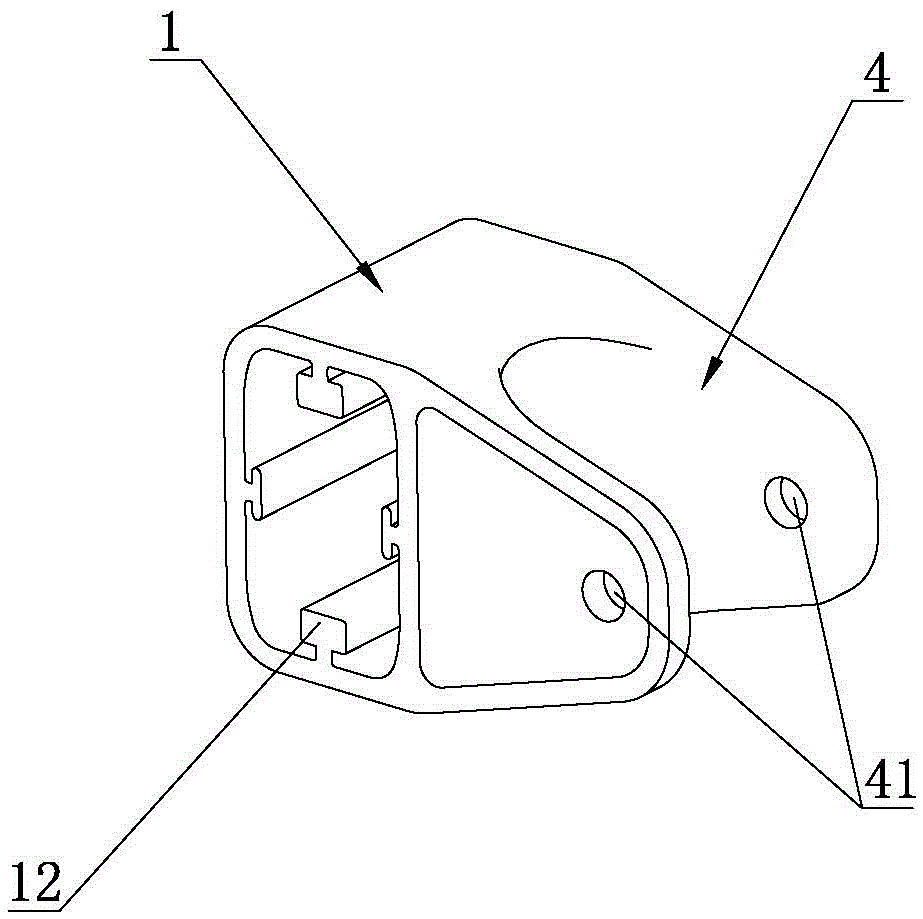

Automobile suspension rack supporting base structure

InactiveCN106042806ASimple and compactImprove installation positioning accuracyPivoted suspension armsAutomotive engineeringUltimate tensile strength

The invention relates to the automobile technology field and particularly relates to an automobile suspension rack supporting base structure. The automobile suspension support seat structure comprises an axle sleeve main body; the axle sleeve main body is internally provided with a sleeve hole going through the self axis; the axle sleeve main body is fixed on a section bar beam of the vehicle body through the sleeve hole; the axle sleeve main body is provided with installation ear sheets for installing a swinging member; the installation ear sheet is provided with an axle hole; and the swinging member is rotatably connected to the installation ear sheets through the axle hole. The automobile suspension supporting base is compact in structure, high in installation positioning accuracy, easy in manufacture and assembling and applicable to the supporting base positioning of various suspension racks, and can reduce the vehicle body weight through optimizing a topological structure and a size of a connection member. The automobile suspension rack supporting base structure can conveniently and reliably install the vehicle suspension rack system on the vehicle body structure, and can guarantee enough strength and rigidity of the suspension rack and thus guarantees the safety of the automobile. The automobile suspension system adopting the automobile suspension supporting base structure is light in weight, good in sensitivity, simple in structure and saving in space.

Owner:INST OF DONGGUAN SUN YAT SEN UNIV +1

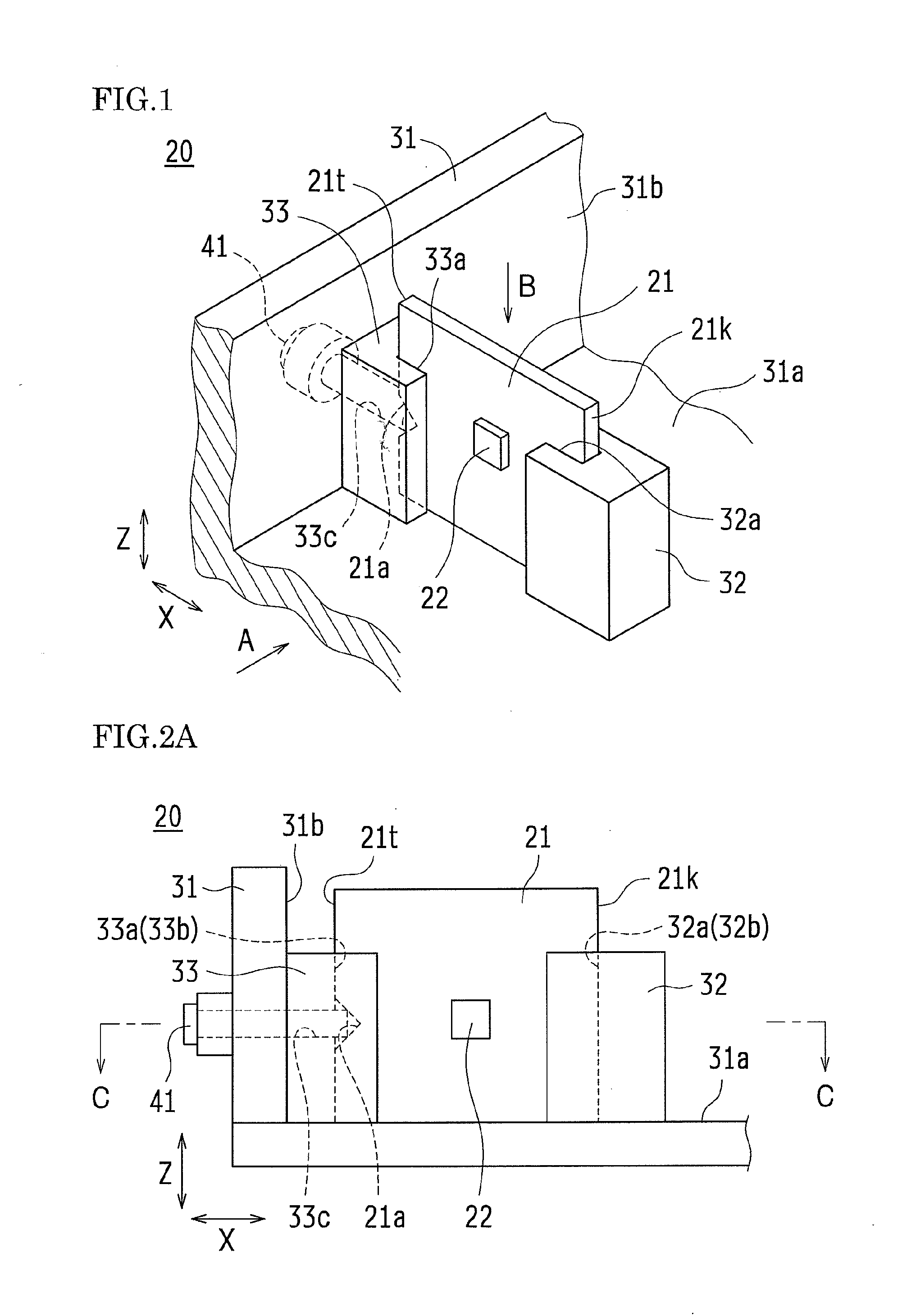

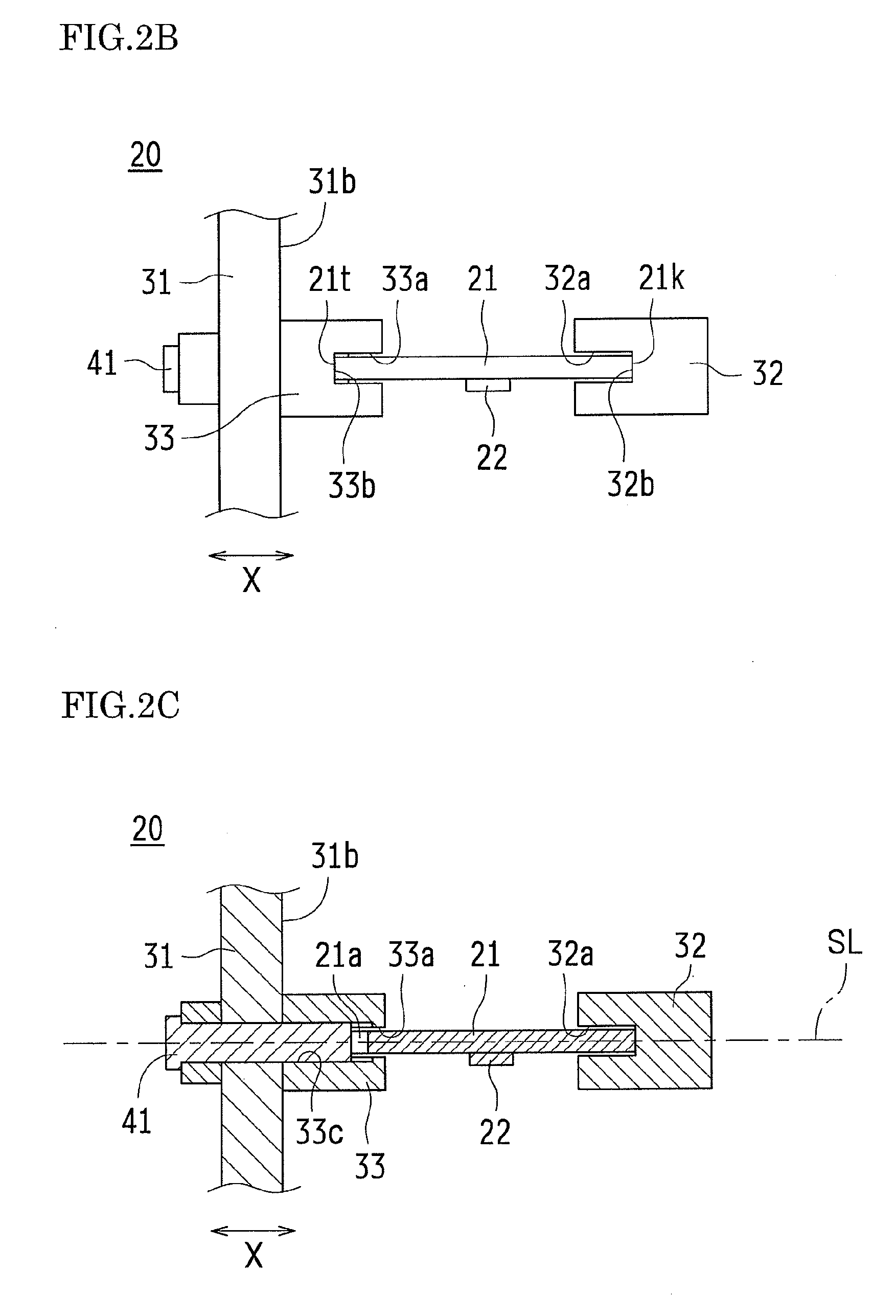

Substrate fastening structure, optical scanning device, and image forming apparatus

InactiveUS20120224238A1Excellent accuracyStable operationCircuit arrangements on support structuresElectrographic process apparatusEngineeringPerpendicular direction

A substrate fastening structure is provided with a substrate on which an optical detection sensor is mounted, and a casing to which the substrate is secured internally. The casing is provided with a reference portion having a reference groove formed in a perpendicular direction with respect to a first surface configured on an inner side of the casing, and an opposing portion having an opposing groove that opposes the reference groove. The opposing portion is provided with a pass-through hole that is located on an extension of a straight line on which the reference groove and the opposing groove oppose each other, and that passes through the opposing portion. The substrate is inserted extending across the reference groove and the opposing groove, and has an opposing end face that opposes the opposing portion, and has a cut-out portion formed in the opposing end face, and a fastening member that is inserted into the pass-through hole presses the cut-out portion.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com