Welding fixture capable of being turned over

A PCB board and metal sheet technology, applied in the field of reversible welding fixtures, can solve the problems of difficult quality assurance, increased labor intensity, poor reliability, etc., and achieve stable welding quality, high installation and positioning accuracy, and consistent welding feet Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

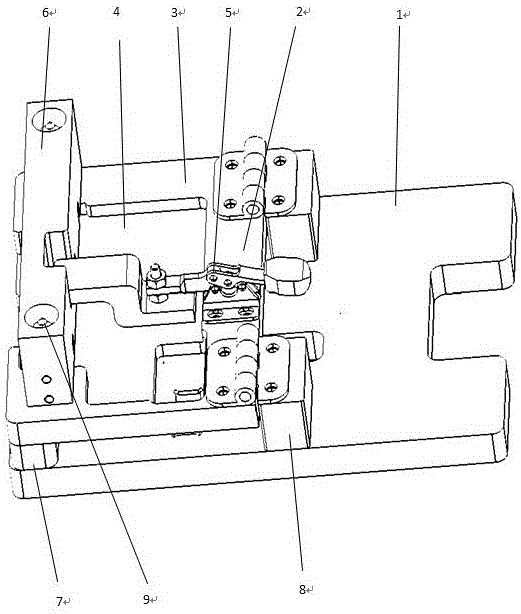

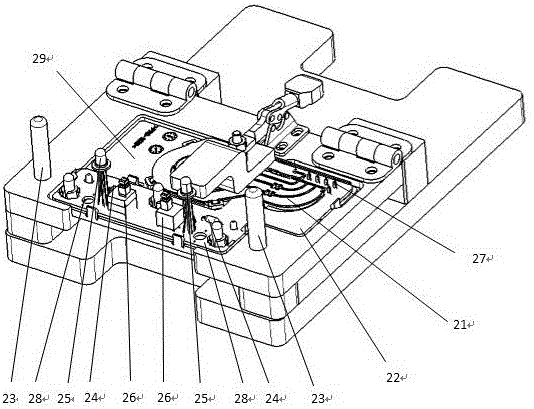

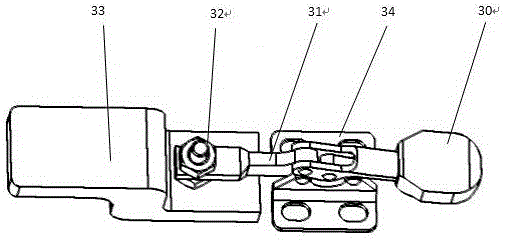

[0012] The invention provides a reversible welding jig, comprising a bottom plate 1, one end of the bottom plate 1 is provided with two fixed pads 7 of equal height, and the other end is provided with two height-limiting blocks 8 which are hinged with the movable panel through hinges, An overturn mechanism 2 is installed on the bottom plate 1, and the overturn mechanism 2 is composed of a movable panel 3, a quick chuck 5, a bead 6, a height limit block 8, and a hinge. The movable panel 3 can be rotated 180 degrees by the overturn mechanism Flip over, quick chuck 5 and positioning column 23 are installed on movable panel 3, positioning hole 9 matching with positioning column 23 is set on bead 6 and a groove for receiving the front end of quick chuck pressing plate is arranged, and described movable panel is set to receive to be welded The cavity 4 of the product can place a bearing plate, on which there are metal sheets and PCB boards, and LED lights, self-locking switches, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com