Method for assembling and positioning large-size machine tool body

A positioning method and bed technology, applied in the direction of using mechanical devices, mechanical measuring devices, measuring devices, etc., to achieve the effects of high installation and positioning accuracy, reduced labor intensity, and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The method for assembling and locating the bed of a large machine tool in the present invention is divided into a method for assembling and locating the bed before leaving the factory and a method for assembling and locating the bed at the user's site.

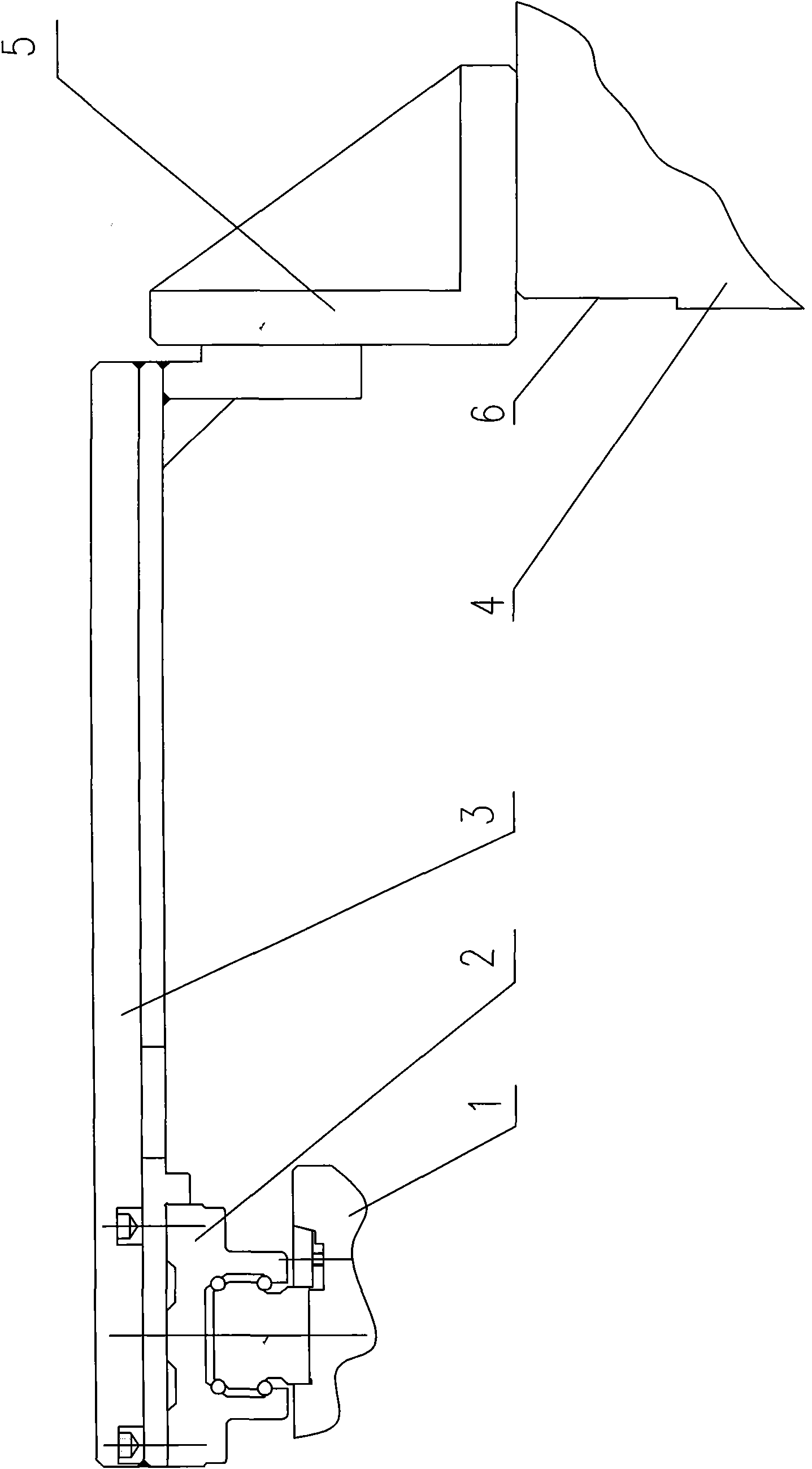

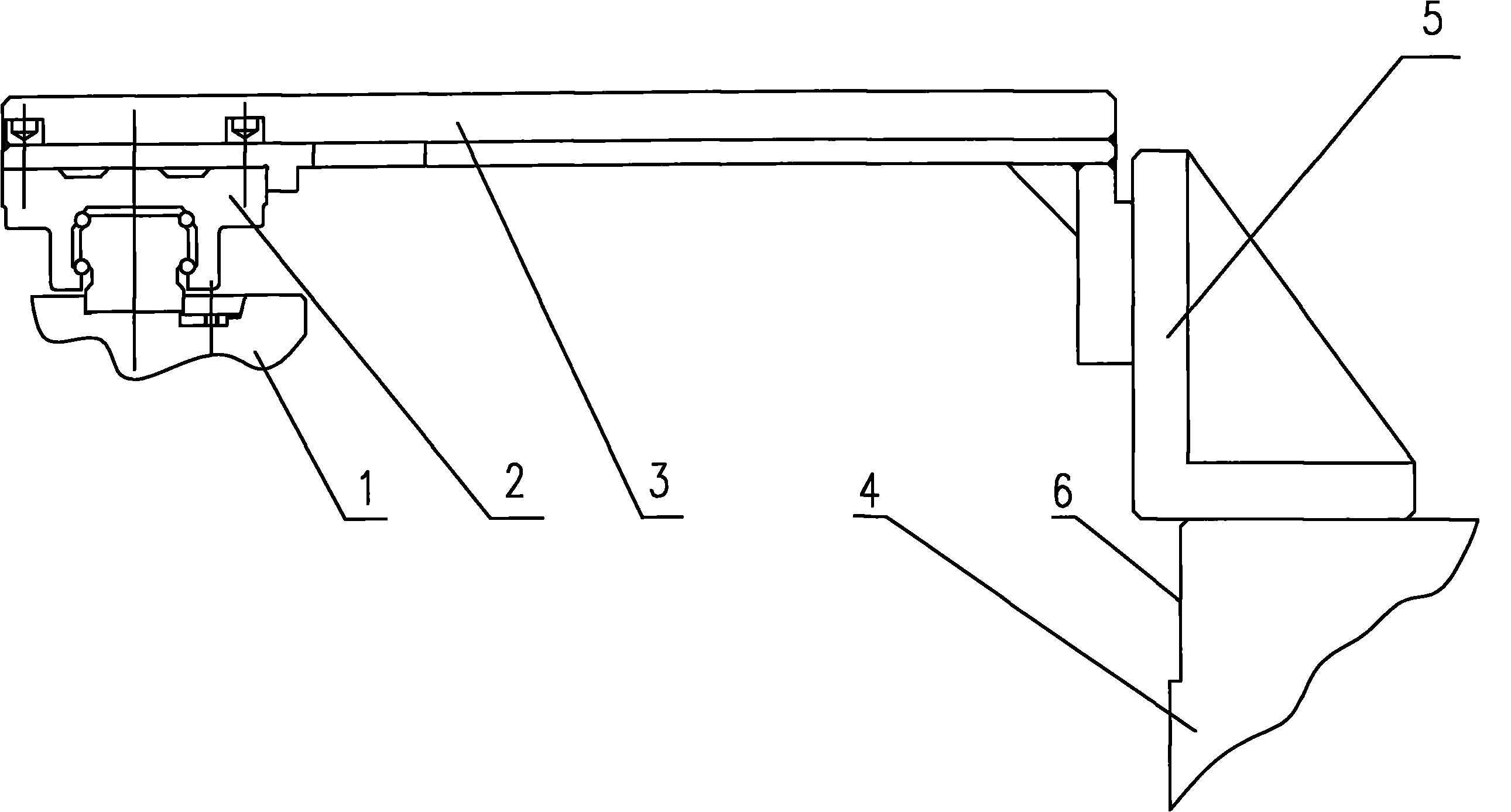

[0017] 1. The bed assembly and positioning method before leaving the factory: After the bed 1, the column and the beam are equipped with relevant connecting screw holes and fixed as one, use the line rail slider 2 on both sides of the bed 1 to position the detection rod 3, And measure the distance from the bed 1 on both sides to the detection reference plane 6 on the side of the workbench 4 by measuring the square 5, block gauge or depth gauge and record the data.

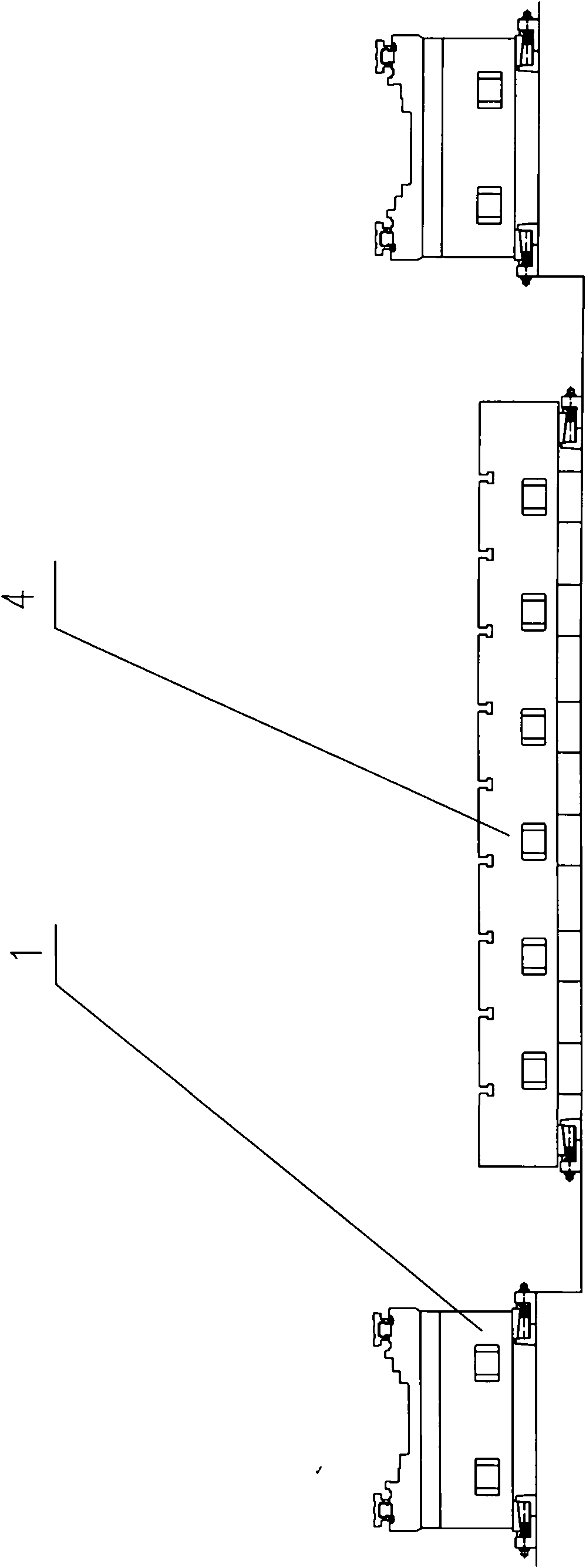

[0018] 2. At the user site, position the workbench 4 well, and roughly position the bed 1 on both sides of the workbench 4, such as figure 1 As shown, the detection rod 3 is also positioned by the line rail slider 2 on the bed 1 on both sides, and the distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com