Electronic component mounting system, electronic component mounting apparatus and electronic component mounting method

A technology for electronic parts and installation systems, which is applied in the direction of assembling printed circuits, electrical components, and electrical components with electrical components, which can solve the problems of difficulty in ensuring printing position accuracy, increase in manufacturing costs, and difficulty in obtaining position correction effects, and achieve good installation. Position accuracy, the effect of securing the installation position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

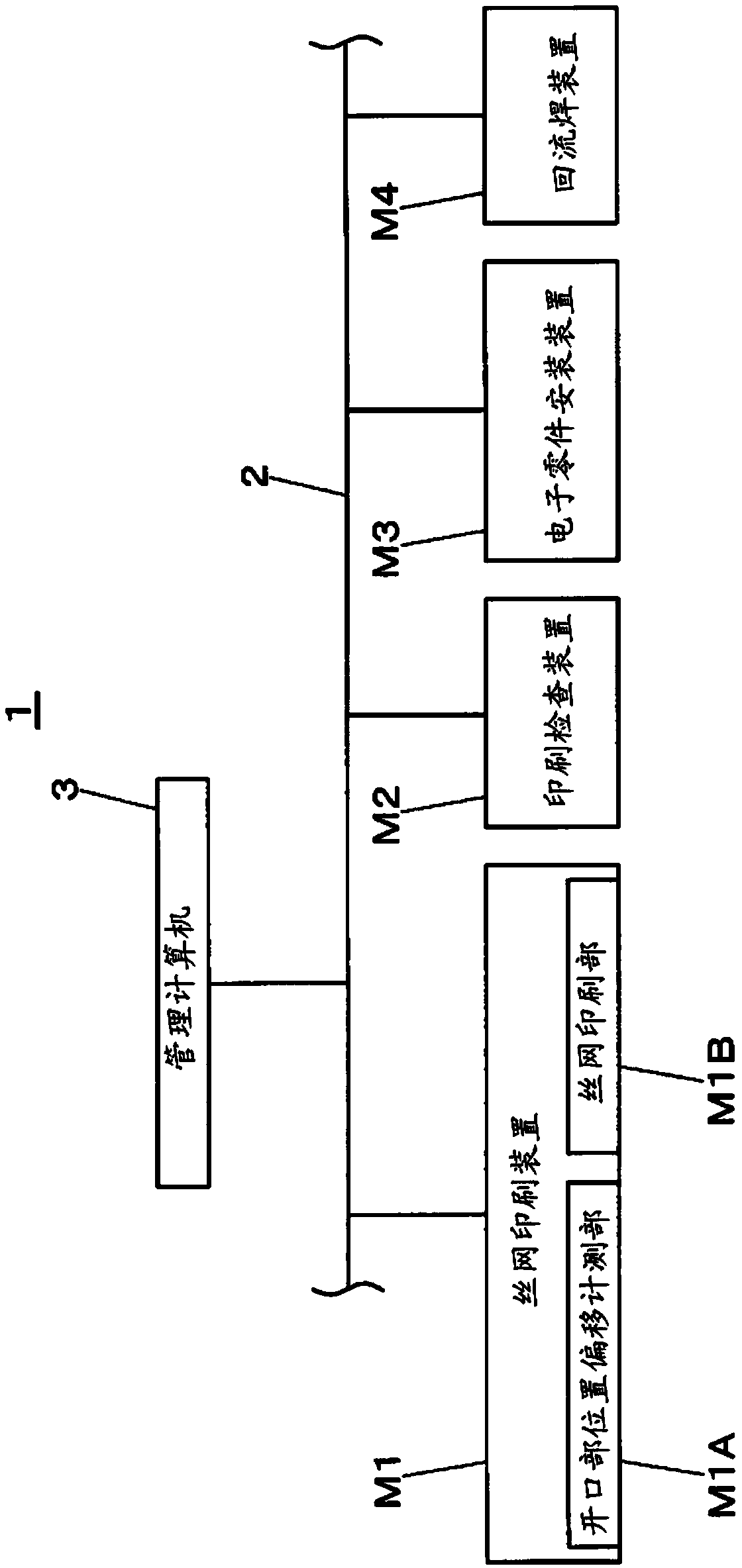

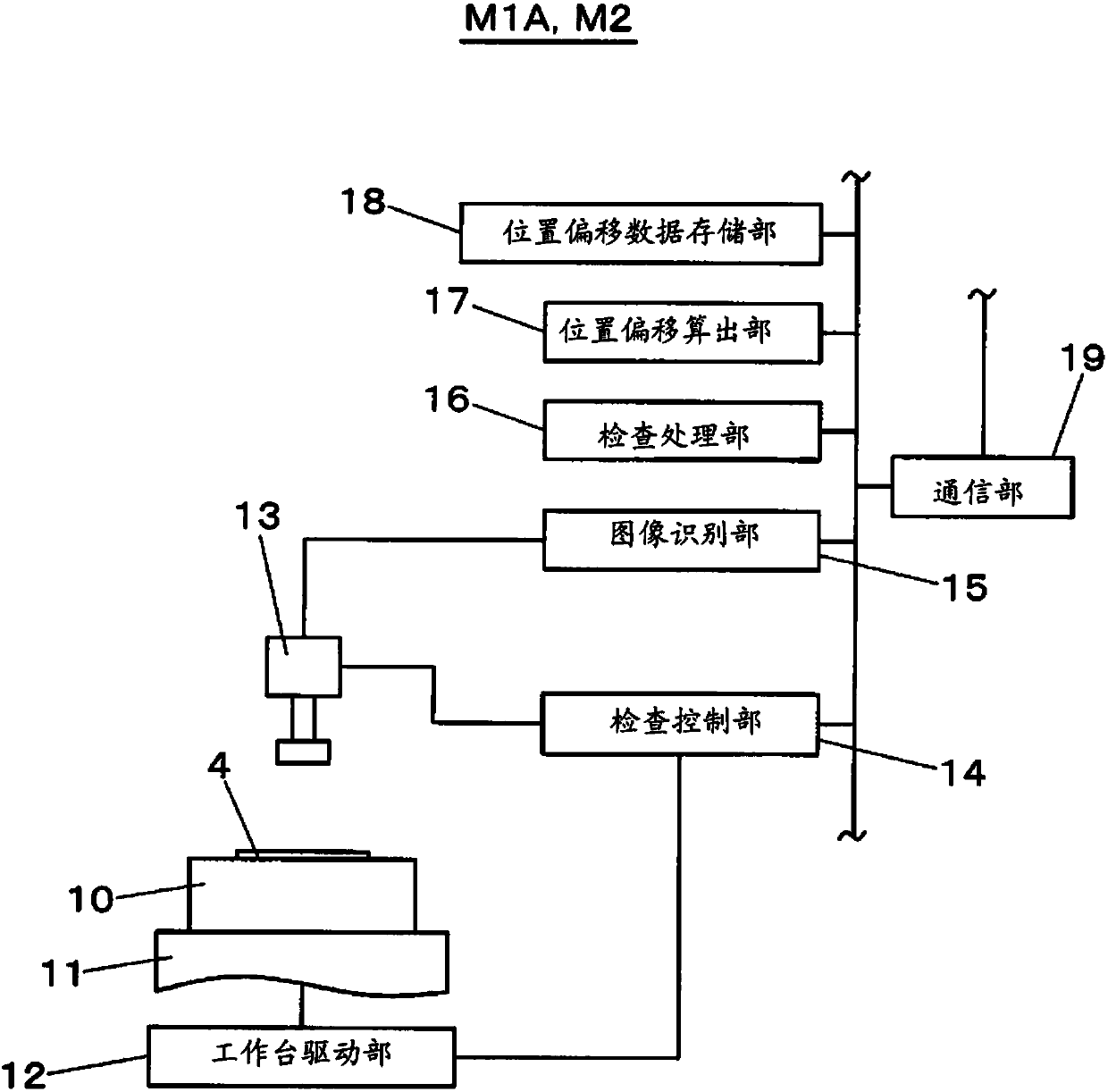

[0031] Hereinafter, embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 The configuration of the electronic component mounting system 1 having a function of manufacturing a mounted substrate by mounting electronic components on the substrate by soldering will be described. exist figure 1 Among them, the electronic component installation system 1 adopts the configuration that the electronic component installation line is connected through the communication network 2, and is controlled by the management computer 3. The electronic component installation line connects the screen printing device M1, the printing inspection device M2, the electronic The component mounting device M3, the reflow soldering device M4 and other devices are connected together.

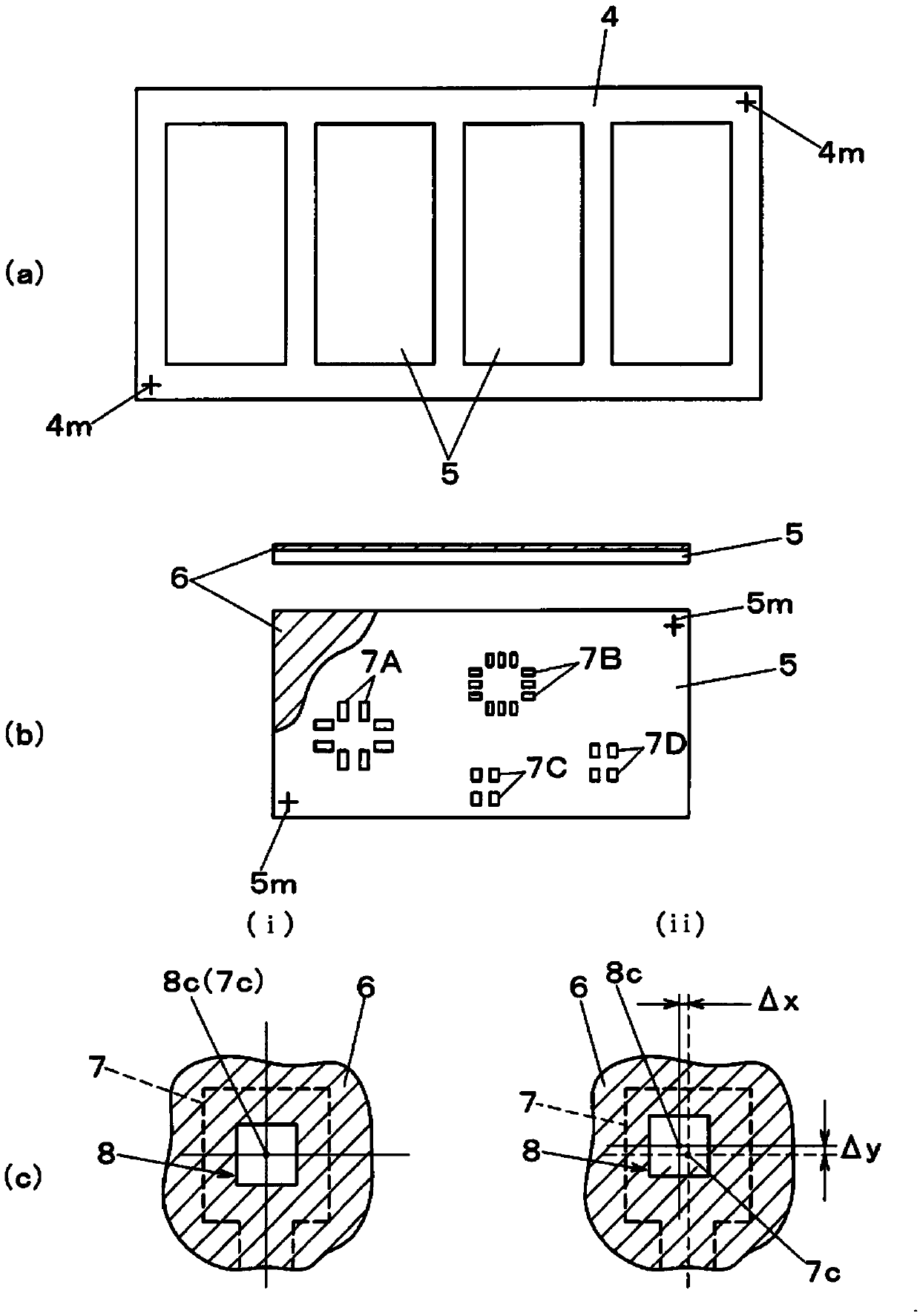

[0032]The screen printing apparatus M1 screen-prints cream solder (cream solder) for bonding electronic components on a substrate to be processed. The printing inspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com