Grinding wheel assembly for small-modulus gear grinding and assembling method

A small-modulus gear and grinding wheel technology is applied in the field of grinding wheel components and assembly for small-modulus gear grinding, and can solve the problem that it is difficult to meet the requirements of high-precision small-modulus gear grinding, the installation and positioning accuracy is difficult to guarantee, and the grinding head is inconvenient. Disassembly and other problems, to achieve good market application prospects and promotion value, compact structure, convenient disassembly and installation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

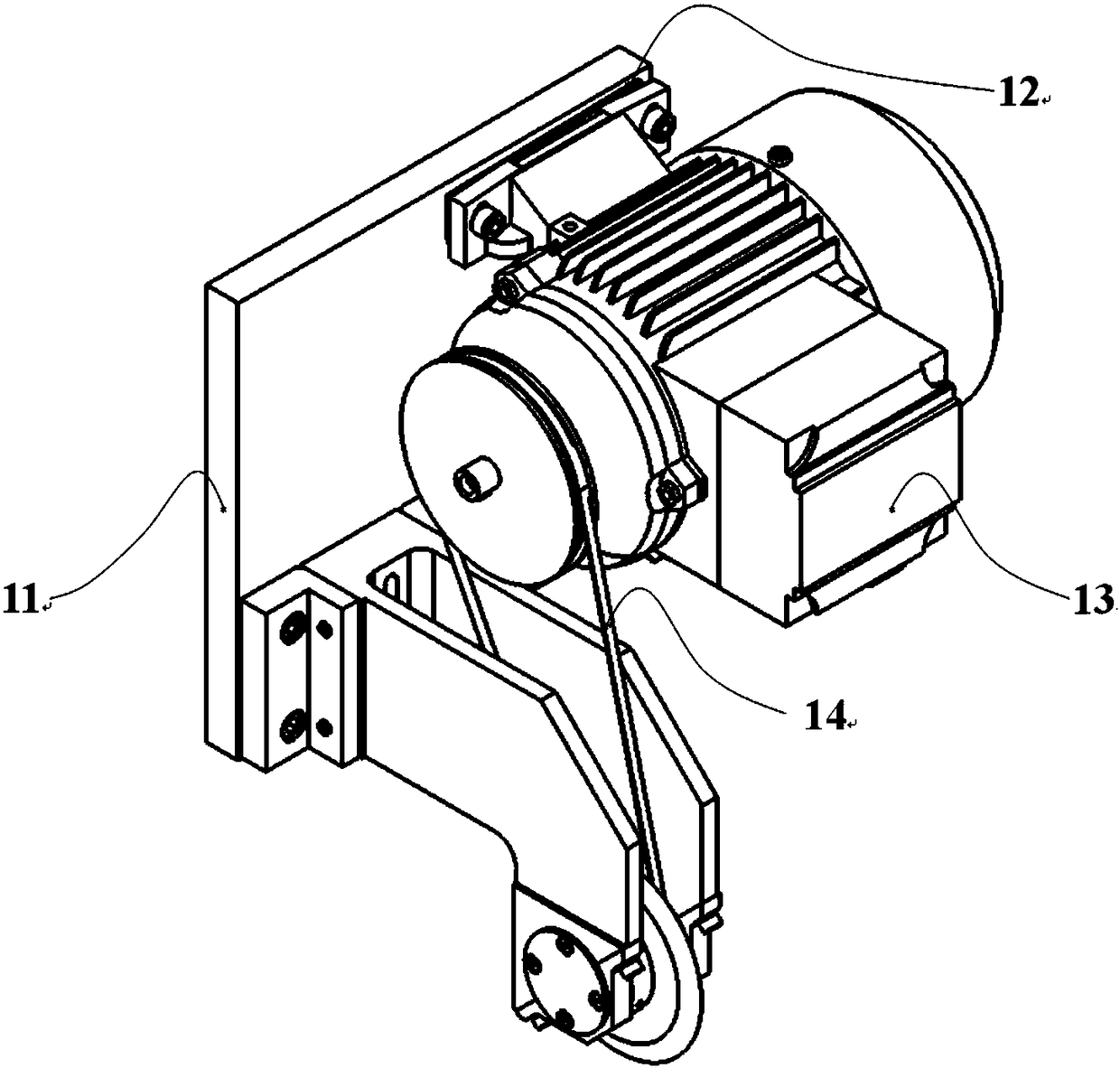

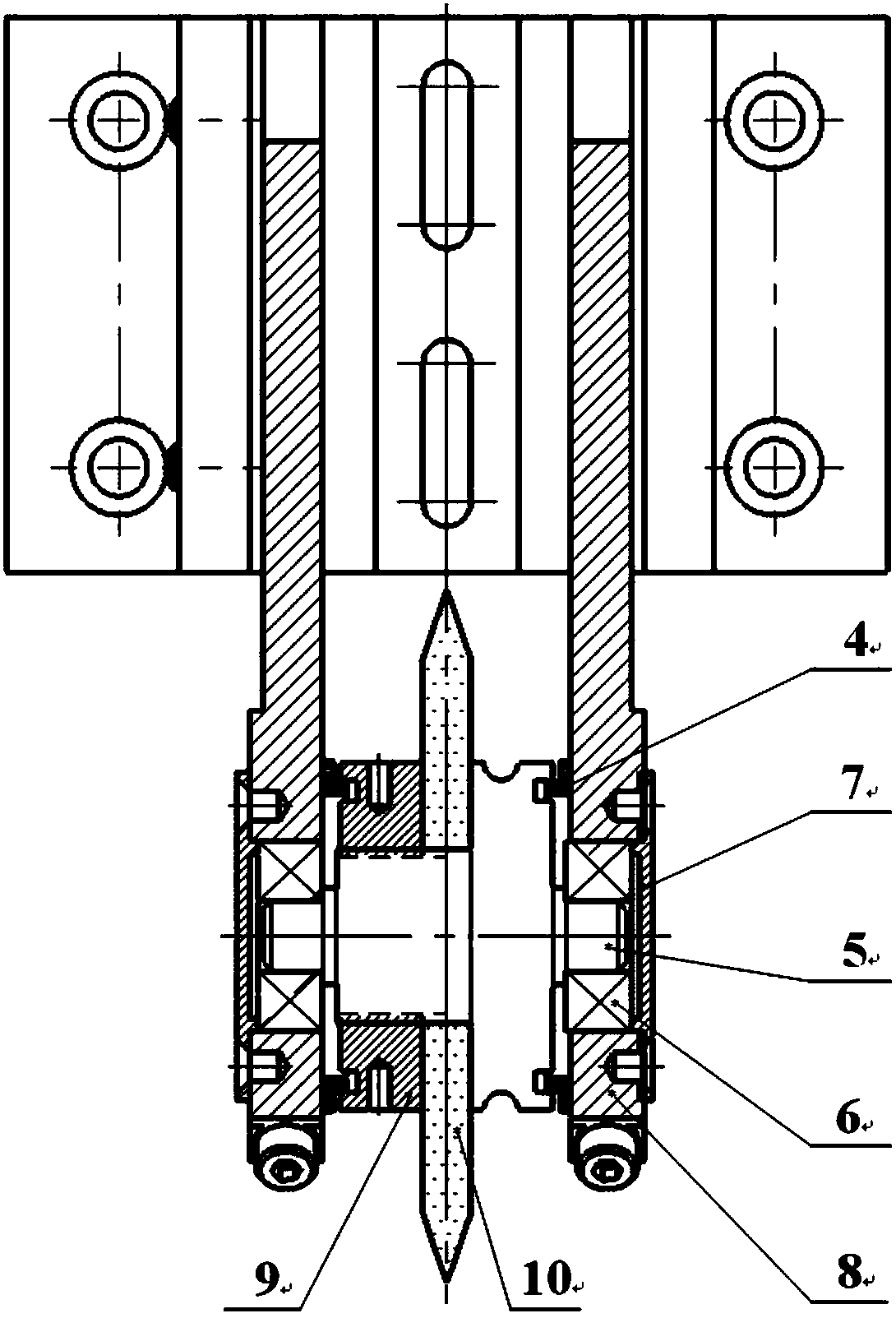

[0035] Through the principle of labyrinth sealing and V-shaped positioning structure, the integrated grinding wheel cantilever frame 2 and built-in pulley structure are adopted; the bearing 6 adopts V-shaped positioning mode, and the lock nut 9 adopts an integrated dynamic balance structure; A grinding wheel assembly and assembly method for small modulus gear grinding is proposed.

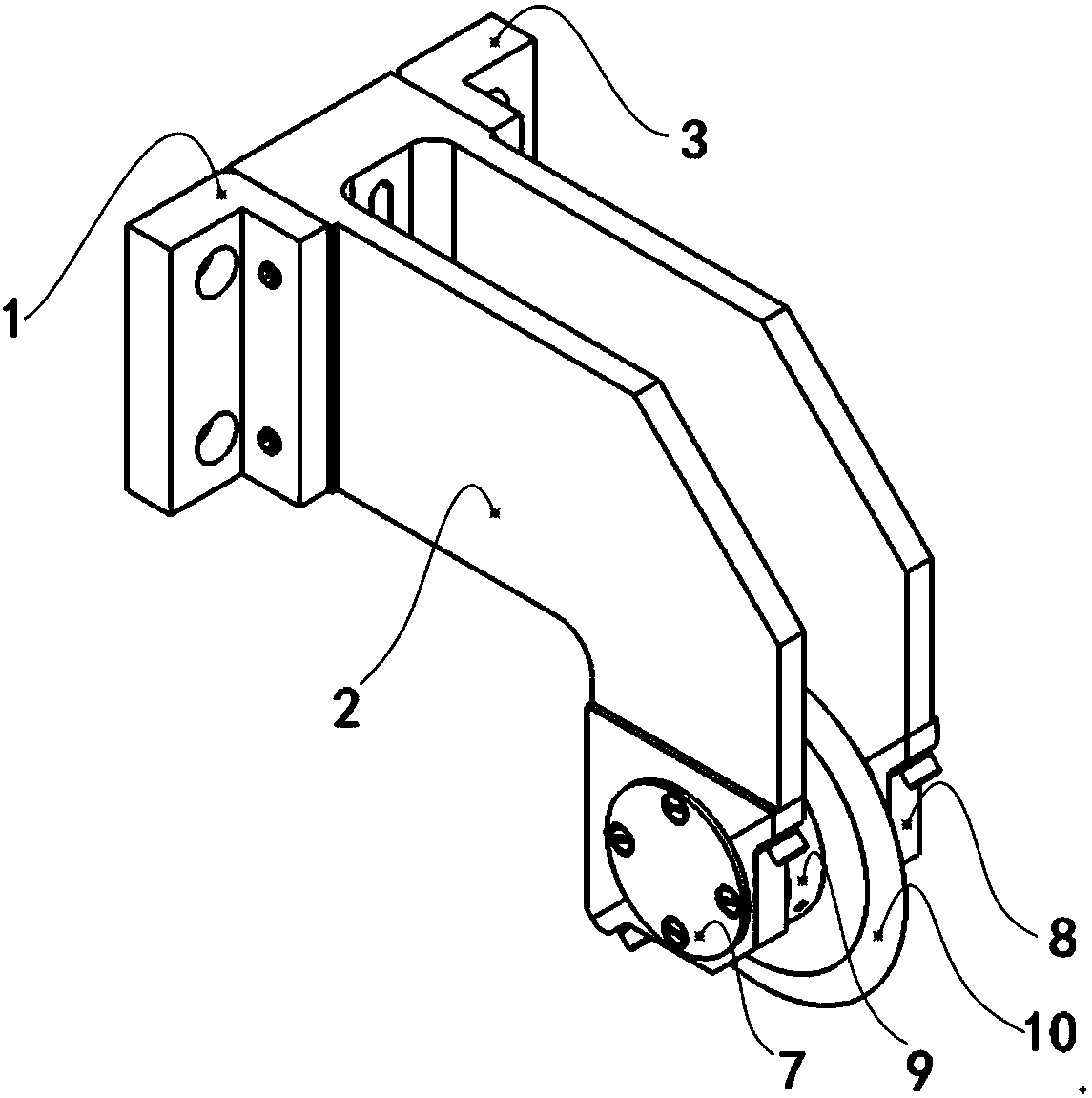

[0036] (1) The grinding wheel cantilever frame 2 adopts integral processing and has high-precision grinding surfaces B and C, and the base of the grinding wheel cantilever frame 2 is provided with two oblong holes 2-1 for position adjustment and installation of the grinding wheel cantilever frame; on the grinding wheel cantilever frame 2 One side uses the high-precision grinding surface D of the L-shaped positioning plate 3 as a reference, and is installed on the workbench through the countersunk hole B, and the other side is locked and fixed through the countersunk hole A in the L-shaped adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com