Pulping equipment based on multi-vortex impact repulping

A multi-vortex and pulping technology, applied in the field of home realization, can solve the problems of low pulping efficiency and low slurry quality, and achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

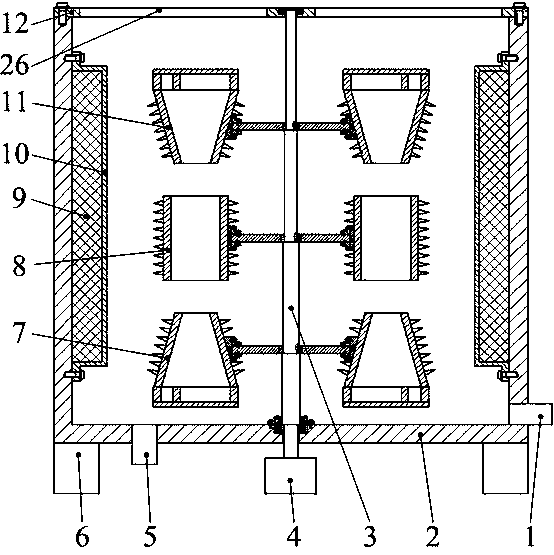

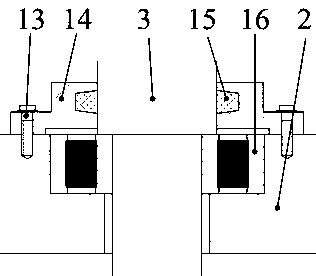

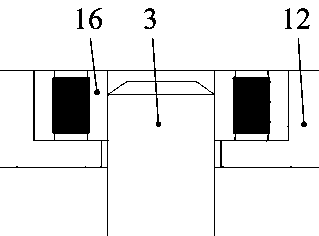

[0040] like figure 1 As shown in the figure, a pulping equipment based on multi-vortex impact pulping mainly includes a slurry generating device, a power driving device, an auxiliary vortex crushing device, a vibration and noise reduction device, a spinning-on pulping device, and a mutual-flushing pulping device. and unscrewing pulping device, the power drive device is installed under the slurry generating device, the auxiliary vortex crushing device and the vibration and noise reduction device are installed on the slurry generating device, the screwing-on pulping device, the mutual flushing pulping device and the unscrewing device are installed. The pulping devices are sequentially installed in the slurry generating device from bottom to top.

[0041] The present invention realizes the generation and output of the slurry through the slurry generating device, that is, the mixed liquid of scraps and water enters into the barrel 2 of the slurry generating device through the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com