One-way sliding type vibration and noise reduction rubber bearing for rail transit bridge

A one-way sliding, rail transit technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problem of large-scale horizontal displacement without protective measures, and achieve the effect of reducing bridge deflection, reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

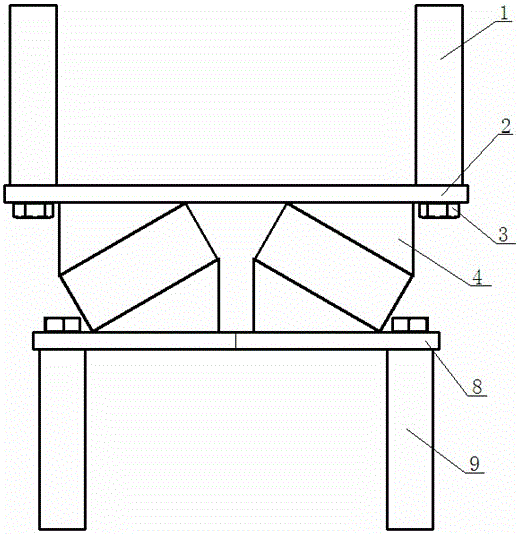

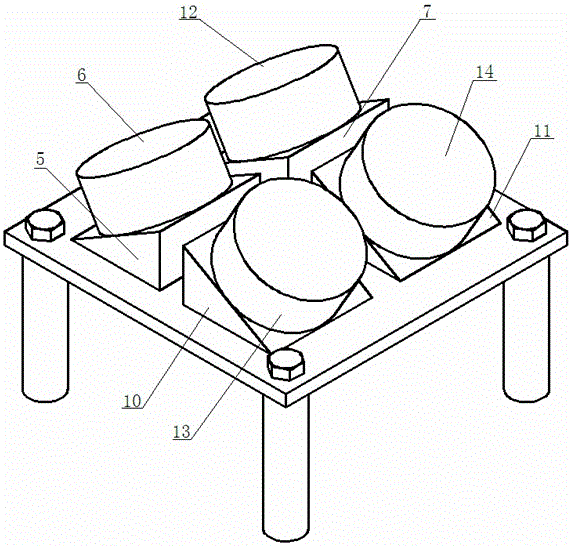

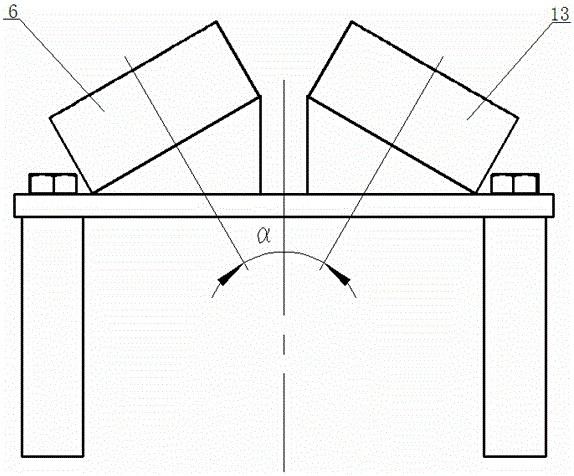

[0017] see figure 1 , figure 2 with Figure 4 , a one-way sliding type vibration-reducing and noise-reducing rubber bearing of a rail transit bridge, comprising an upper bearing plate 2 and a lower bearing plate 8; the upper bearing plate 2 is provided with four upper anchor rods 1, Four lower anchor rods 9 are arranged under the lower support plate 8 . The lower support plate 8 is provided with a lower wedge-shaped fixed block with the same structure 5. The lower wedge-shaped fixed block 7. The lower wedge-shaped fixed block 10 and the lower wedge-shaped fixed block 11, and the lower wedge-shaped fixed block 5 and the lower wedge-shaped fixed block 10 relatively arranged, the lower wedge-shaped fixed block 7 and the lower wedge-shaped fixed block 11 relatively arranged, the lower wedge-shaped fixed block 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com