Multi-interface beam tower matching precision control method and device

A precision control, multi-interface technology, applied in auxiliary devices, bridges, welding equipment, etc., can solve problems such as reducing bearing capacity, cracking, and large stress on the cylinder wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

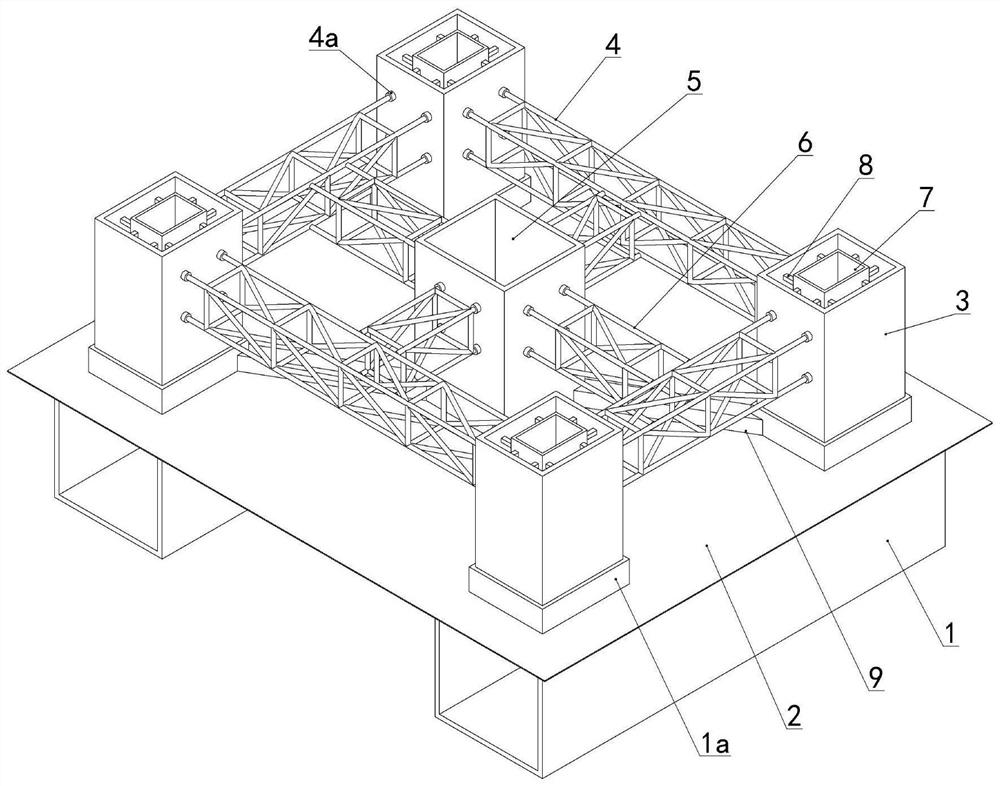

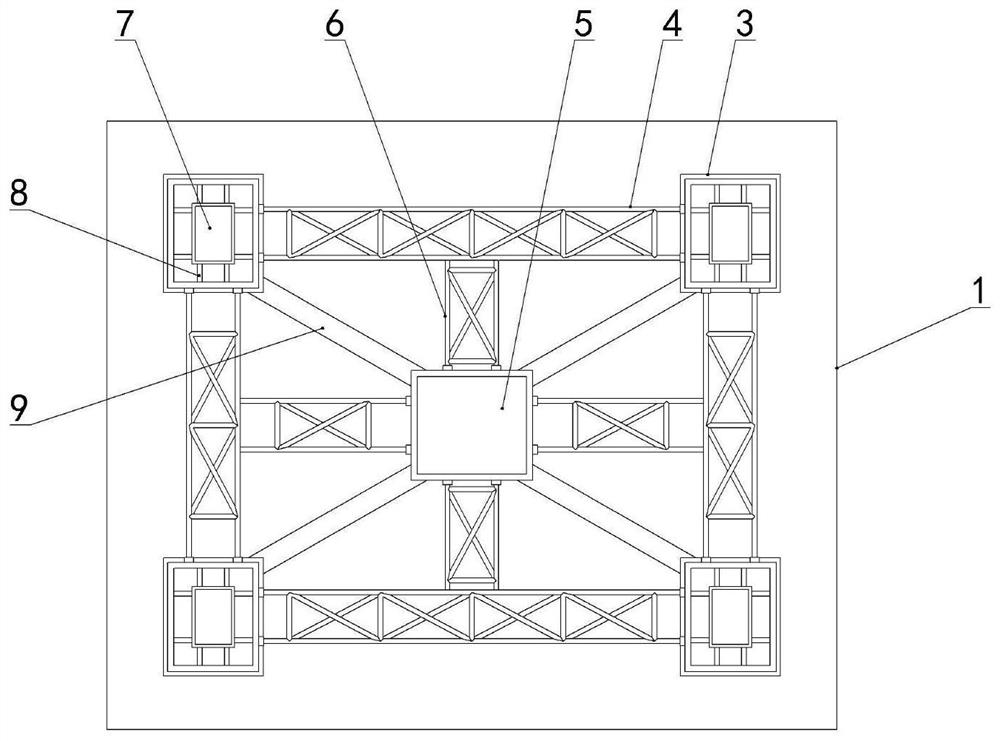

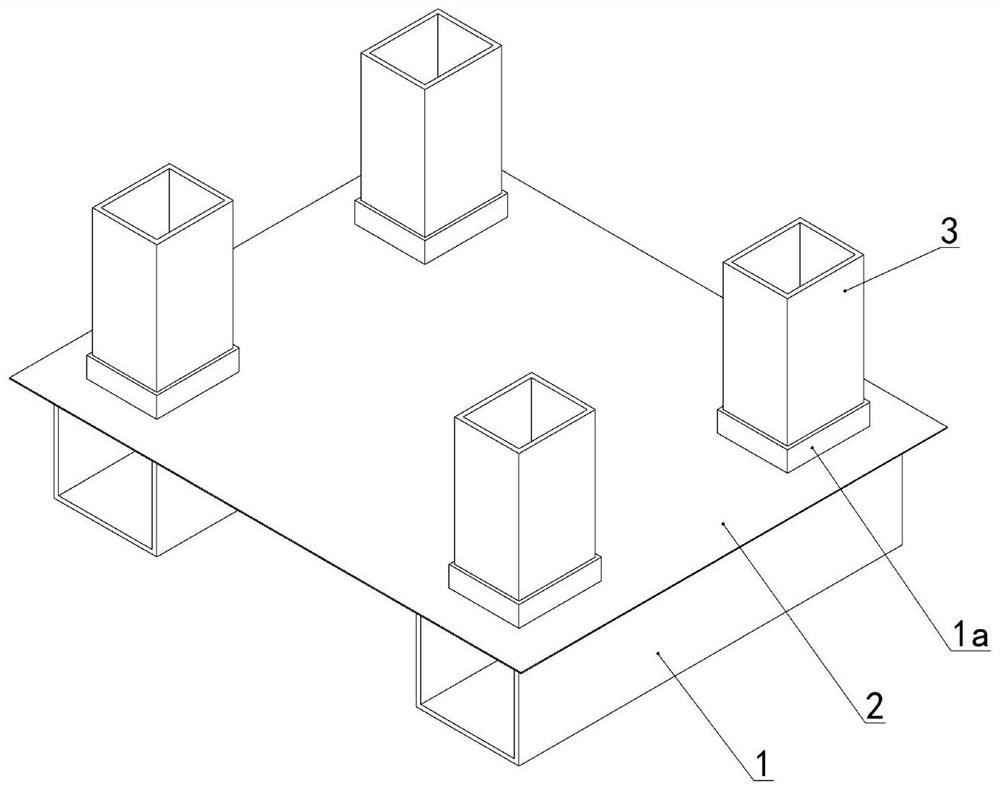

[0032] Such as Figure 1-2 As shown, a matching accuracy control device for multi-interface beam towers: including two steel beams 1, roof 2, four tower columns 3, four outer flower stands 4, core tube 5, four inner flower stands 6, four scissors Power cylinder 7, a plurality of transverse arms 8, four positioning frames 9. Wherein, the steel beam 1 and the roof 2 are part of the steel box girder of the cable bridge, the two steel beams 1 are located below the roof 2, and the beam body of each steel beam 1 is provided with two ports 1a and faces upward. A boss is formed through the top plate 2; the end face of each port 1a is inclined, and the pylons 3 are attached by welding, so that the four pylons 3 are distributed in four corners; between each pylon 3 The outer flower stand 4 is provided by spot welding; the core tube 5 is provided in the center of the four tower columns 3, and the core tube 5 is a hollow square beam structure, and its four sides pass through a 6 points o...

Embodiment 2

[0050] The difference between the present embodiment and the first embodiment is that the designed spacing of the contacts 4 a is limited so that it is close to the golden section ratio of the width of the tower column 3 .

[0051] Such as Figure 4 As shown, the outer flower stand 4 and the inner flower stand 6 are all rectangular truss welding members, and are attached to the tower column 3 with four contacts 4a at the ends, and each two laterally adjacent contacts 4a The distance between them is X, and the side width of the pylon 3 on which the contacts 4a are installed is L. By designing the distance between the contacts 4a, X:L=0.618. In addition, the distance between each two horizontally adjacent cross arms 8 is X`, and the side width of the tower column 3 installed by the cross arms 8 is L`, and the distance between the cross arms 8 is designed to make X`:L`= 0.618.

[0052] The position setting of the contact 4a in this embodiment is tested through the solidworks si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com