Ampoule bottle feeding device used for light examining machine

A feeding device and ampoules technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of blocking the light path, loss of pharmaceutical factories, shaking of ampoules, etc., achieving low friction resistance, high positioning accuracy, smooth speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

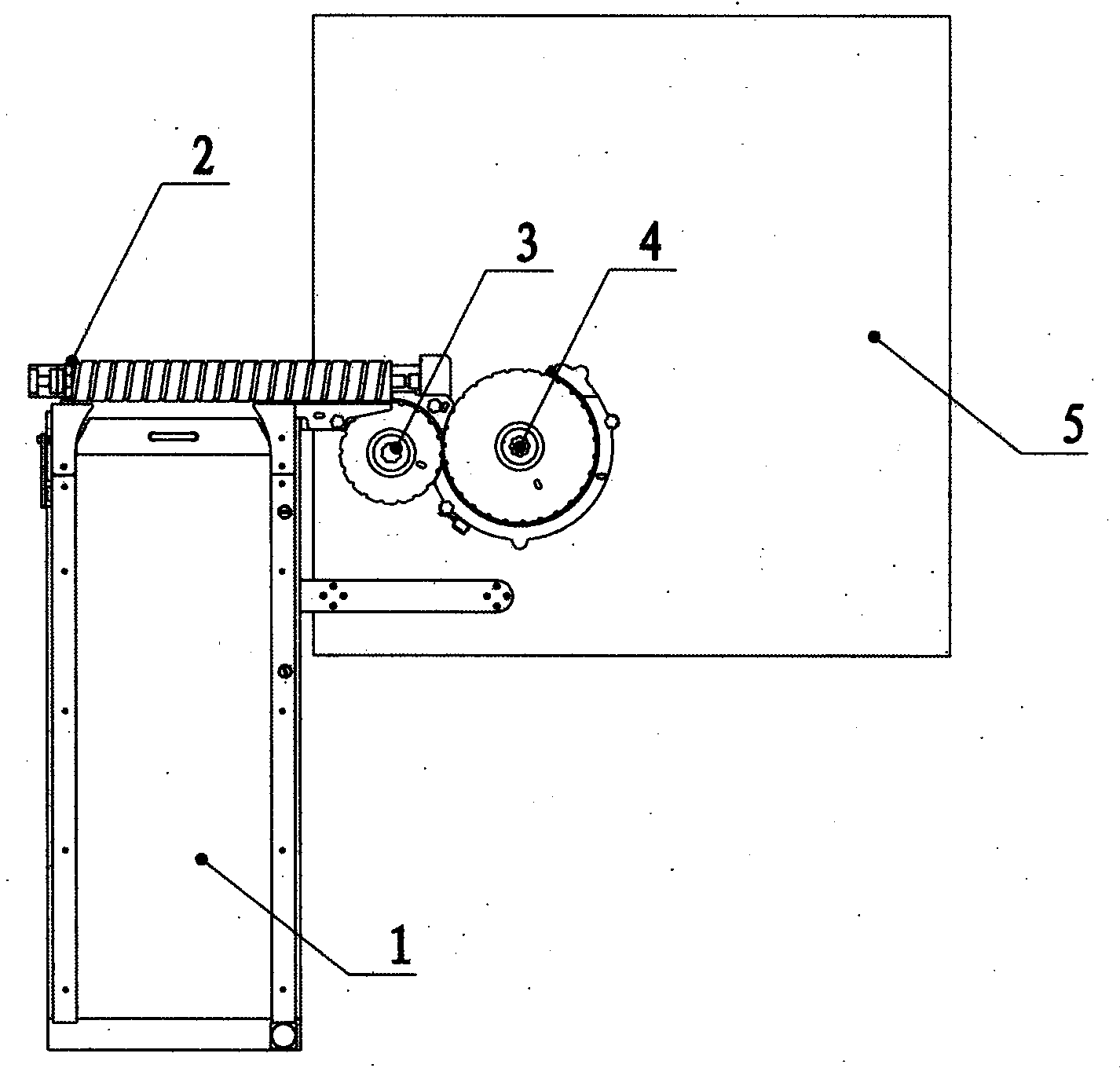

[0038] Such as figure 1 As shown, the ampoule feeding device for the light inspection machine of the present invention includes a feeding conveyor system 1, a screw system 2, a screw matching star wheel system 3, a head detection star wheel system 4 and a main base plate 5, and The material conveyor belt system 1, the screw system 2, the screw matching star wheel system 3 and the head detection star wheel system 4 are fixed on the main base plate 5, and the feeding conveyor system 1 and the screw matching star wheel system 3 are arranged on the side of the screw system 2. On one side, the screw system 2 is used to feed ampoules from the feed conveyor system 1 into the screw-cooperating star-wheel system 3, the screw-cooperating star-wheel system 3 includes the first star-wheel, the head detection star-wheel system 4 includes the second star-wheel wheel, the first star wheel and the second star wheel mesh.

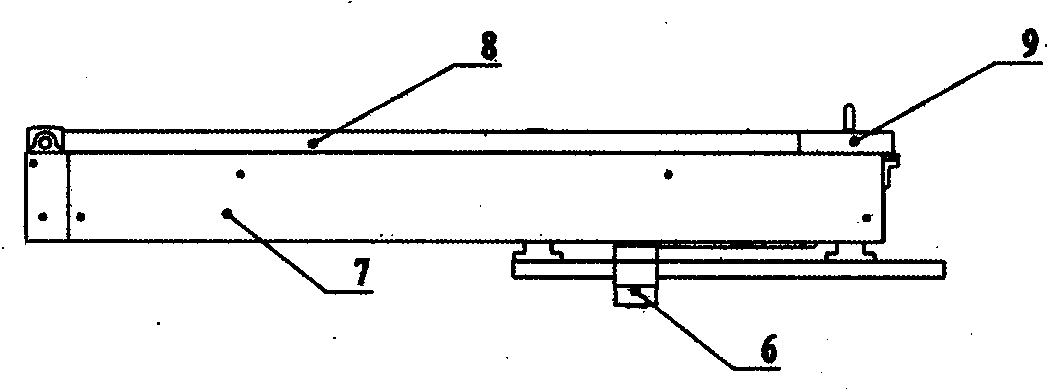

[0039] The feed conveyor belt system includes a frequency conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com