Patents

Literature

513 results about "Bottles/feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

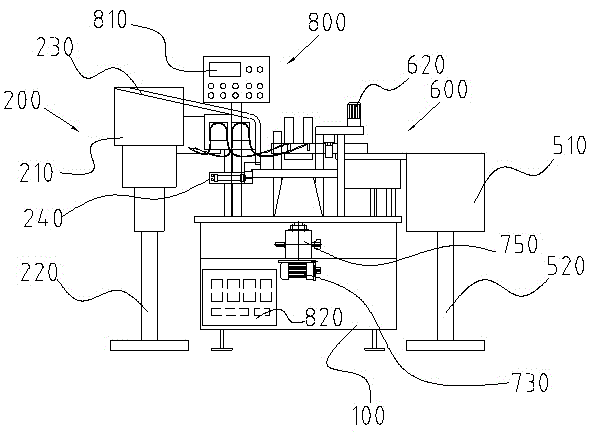

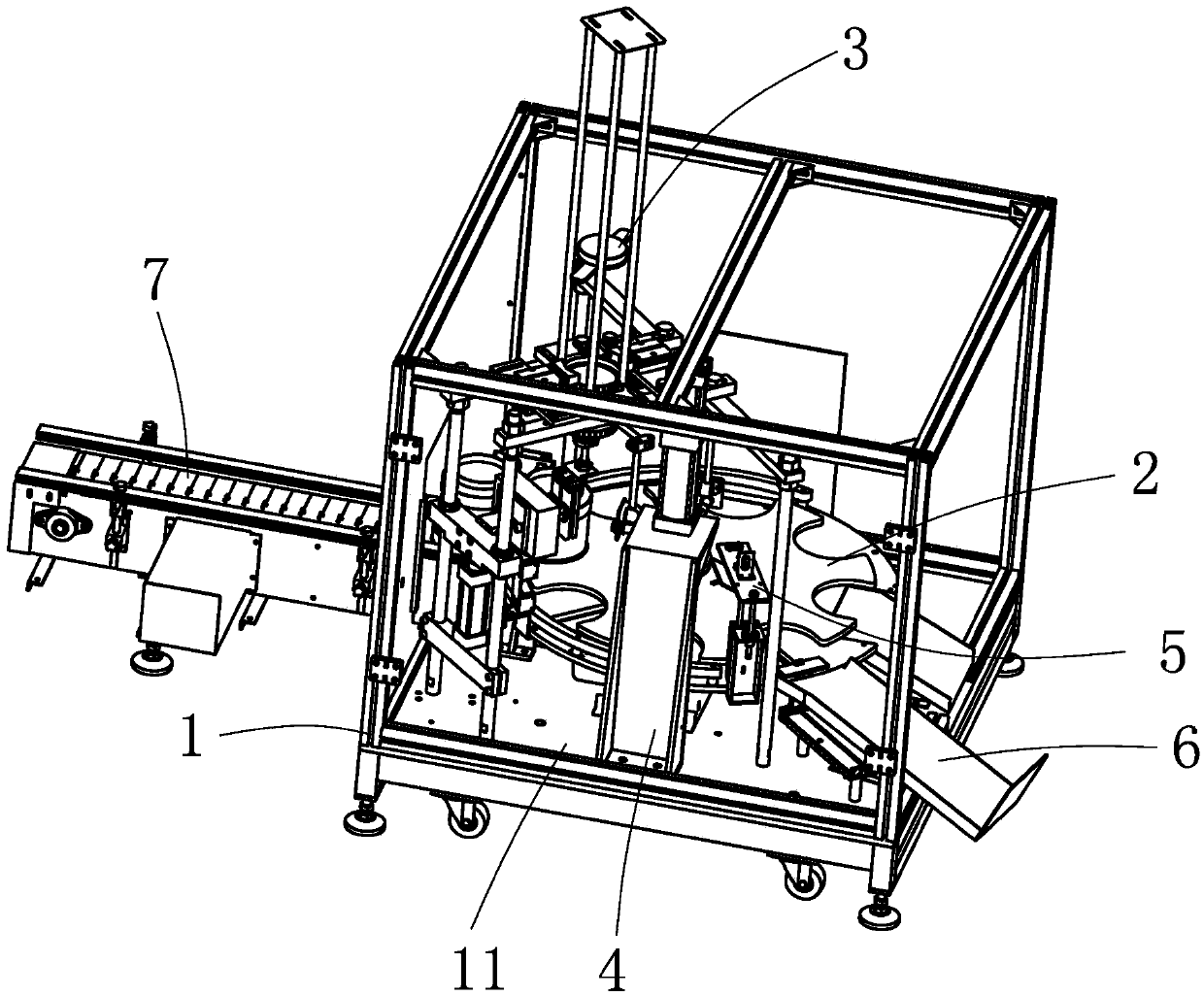

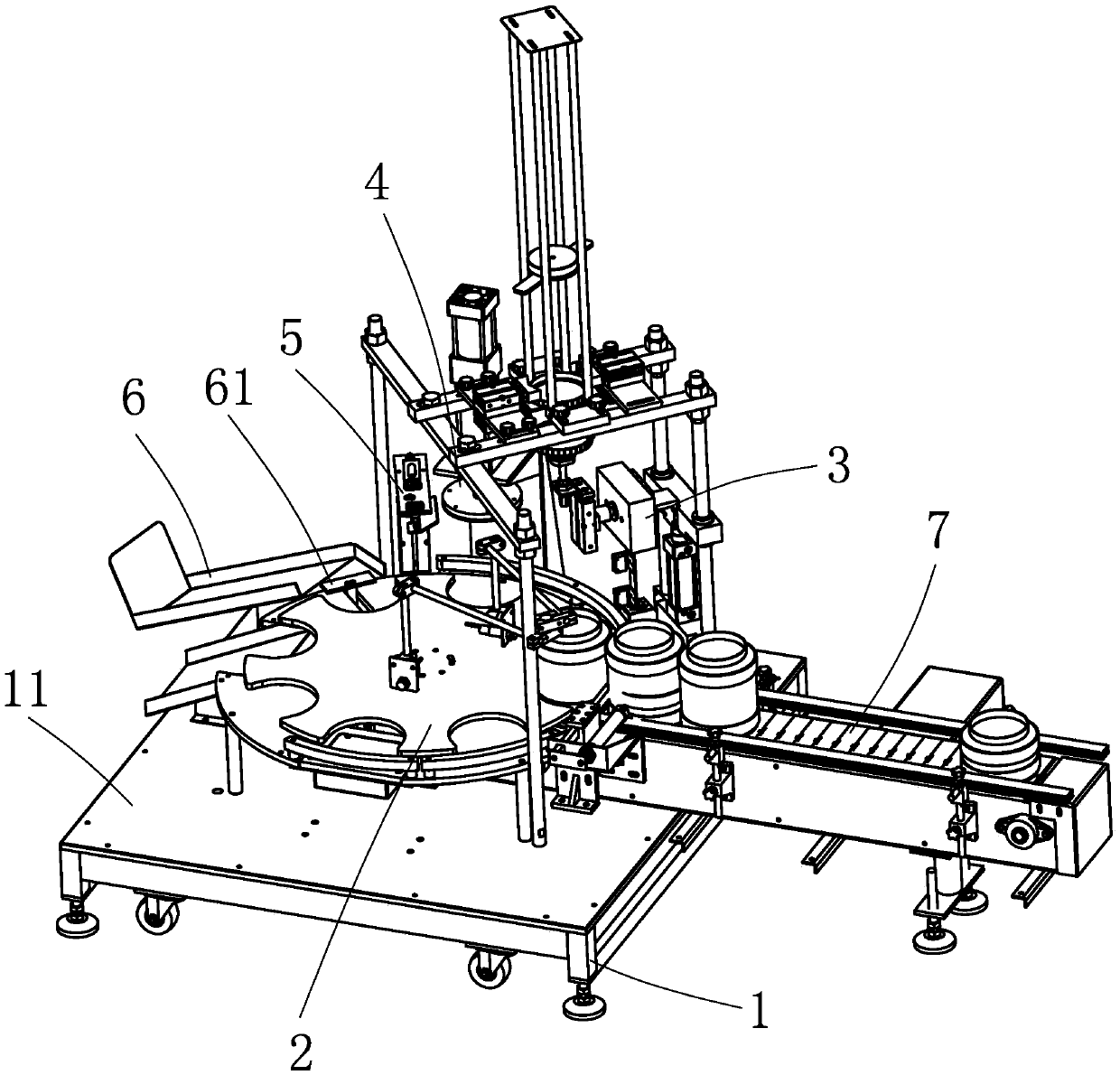

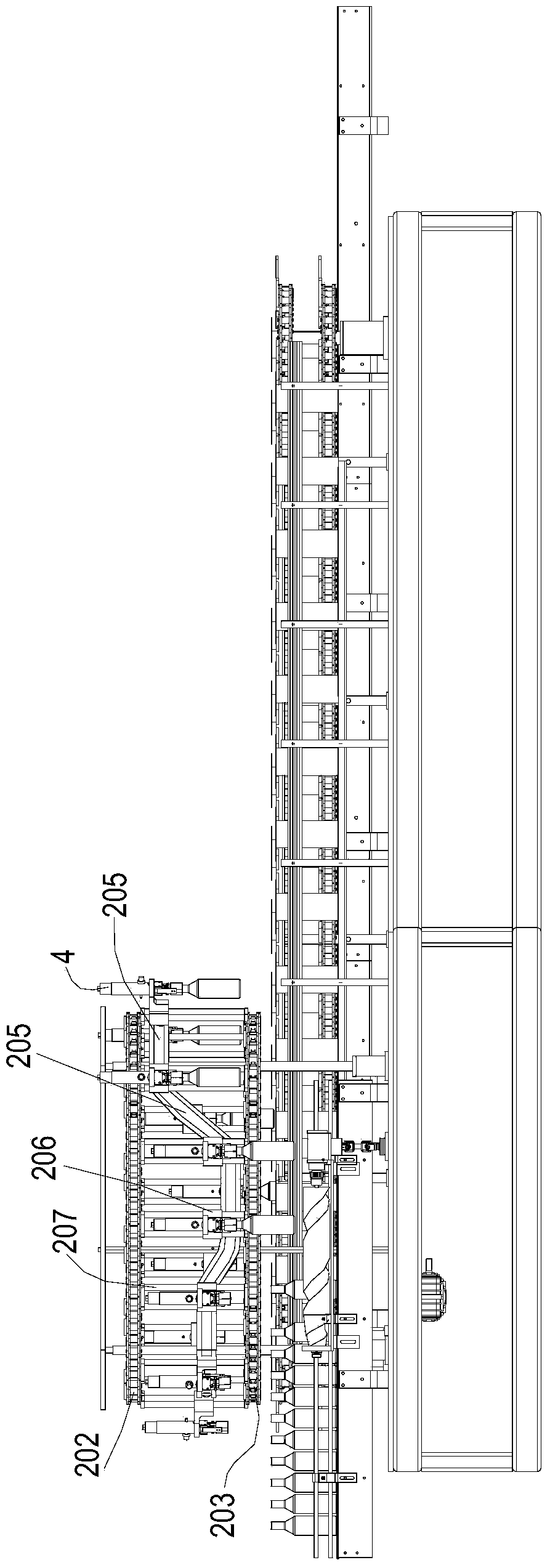

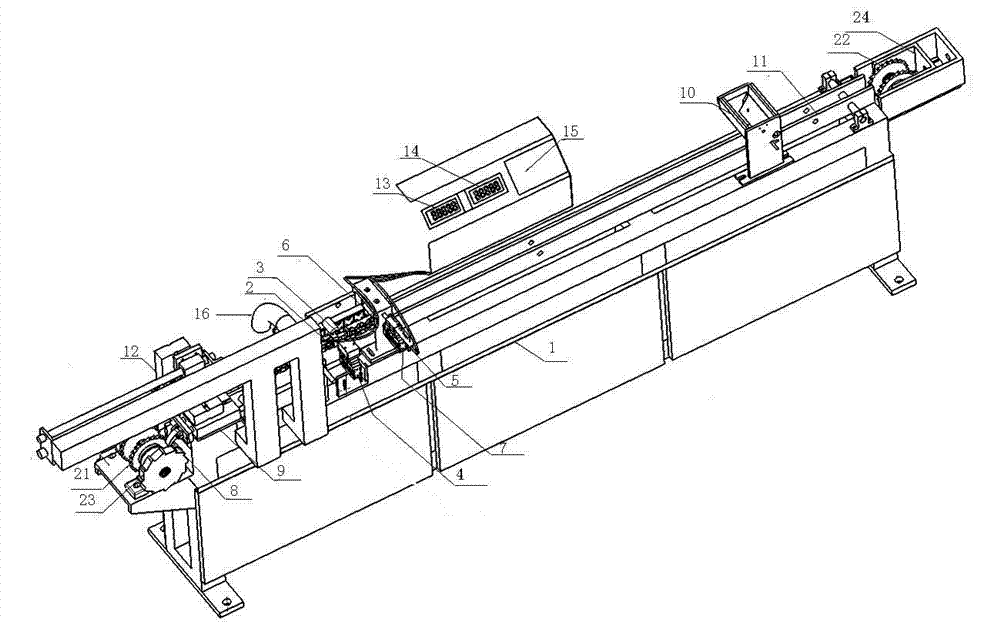

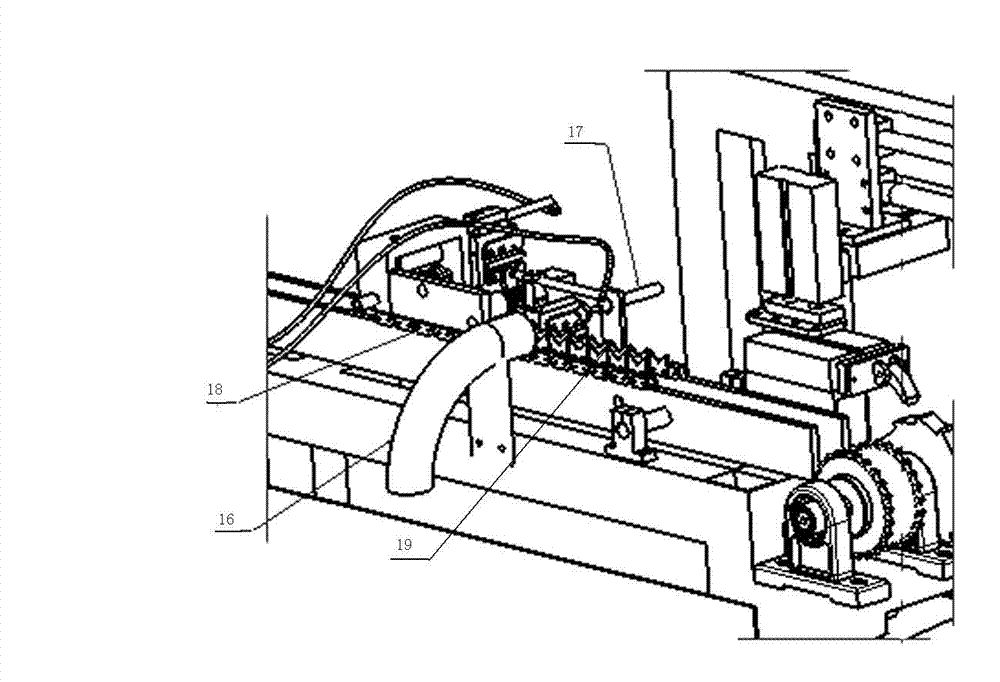

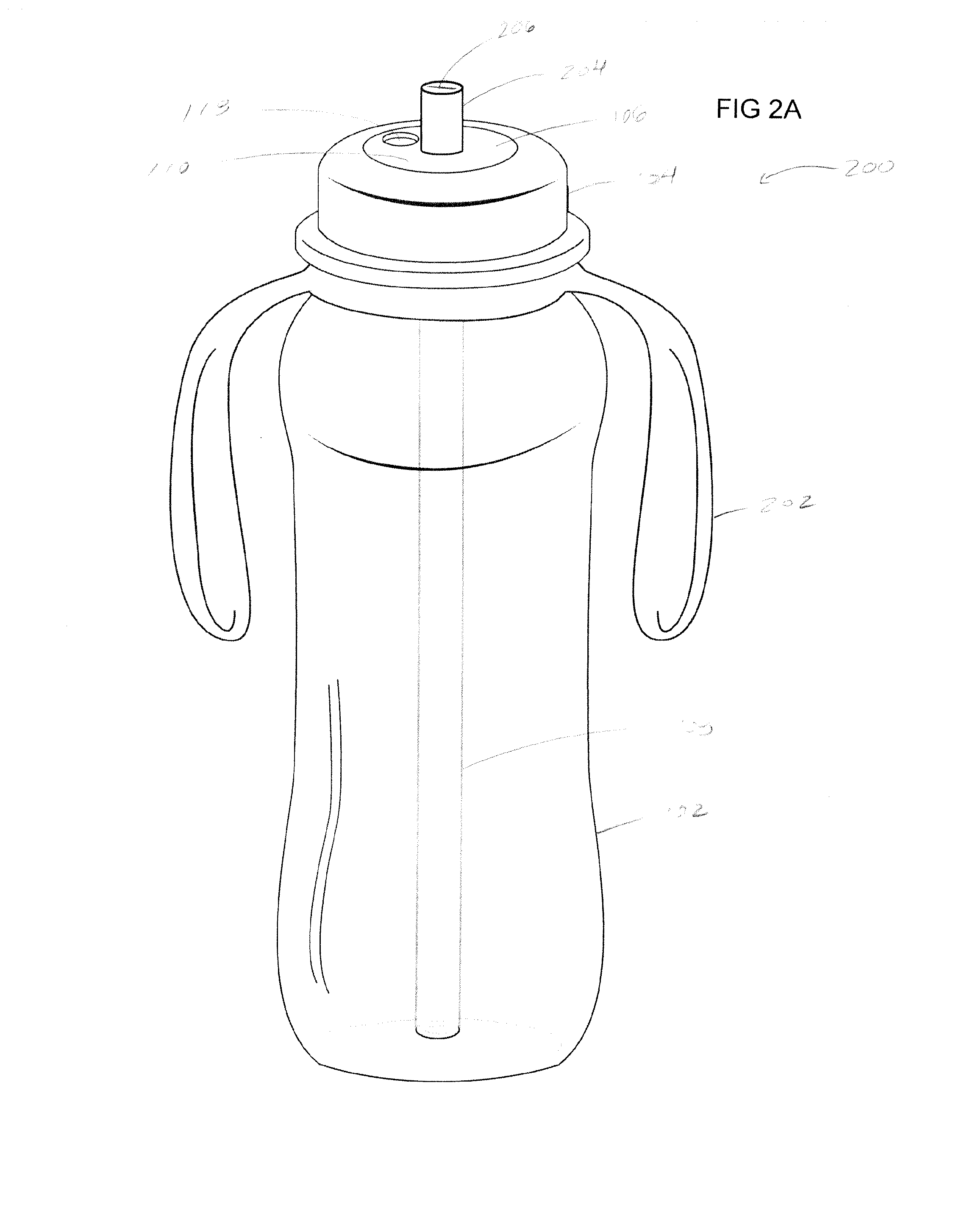

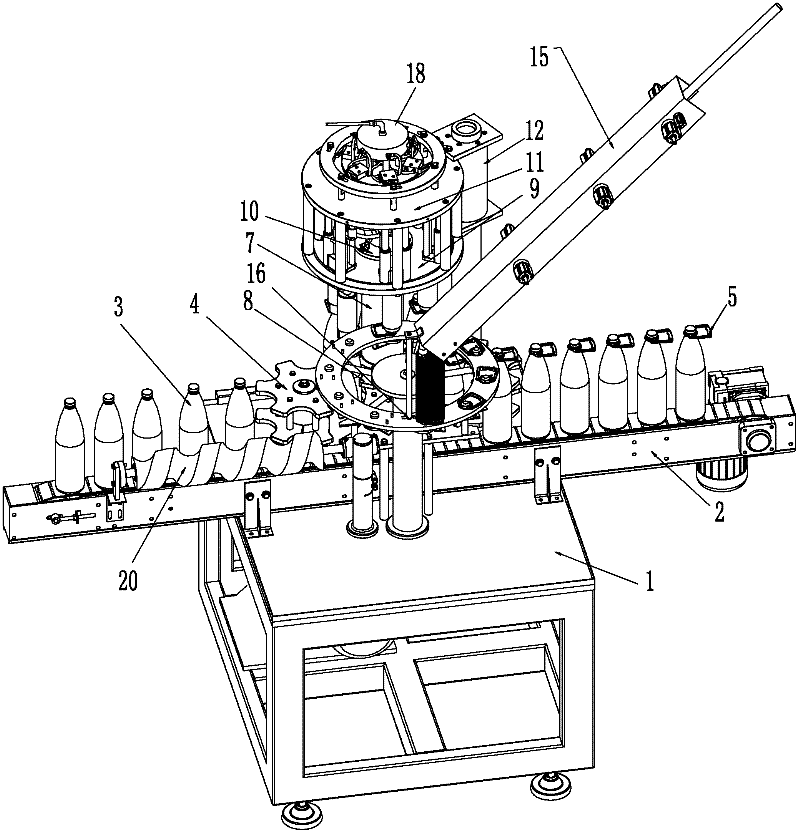

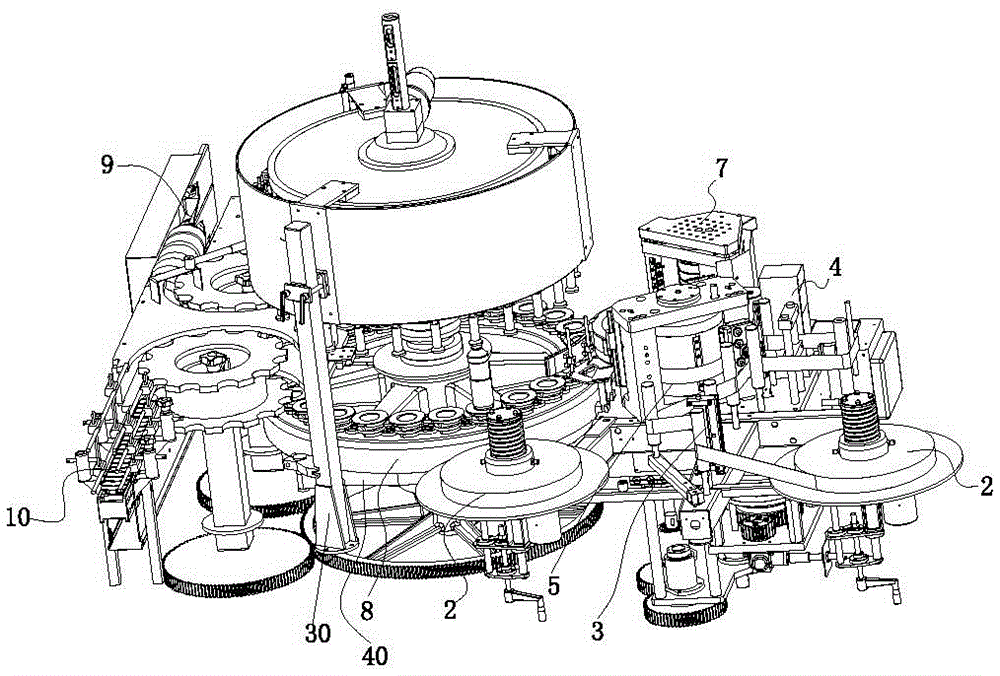

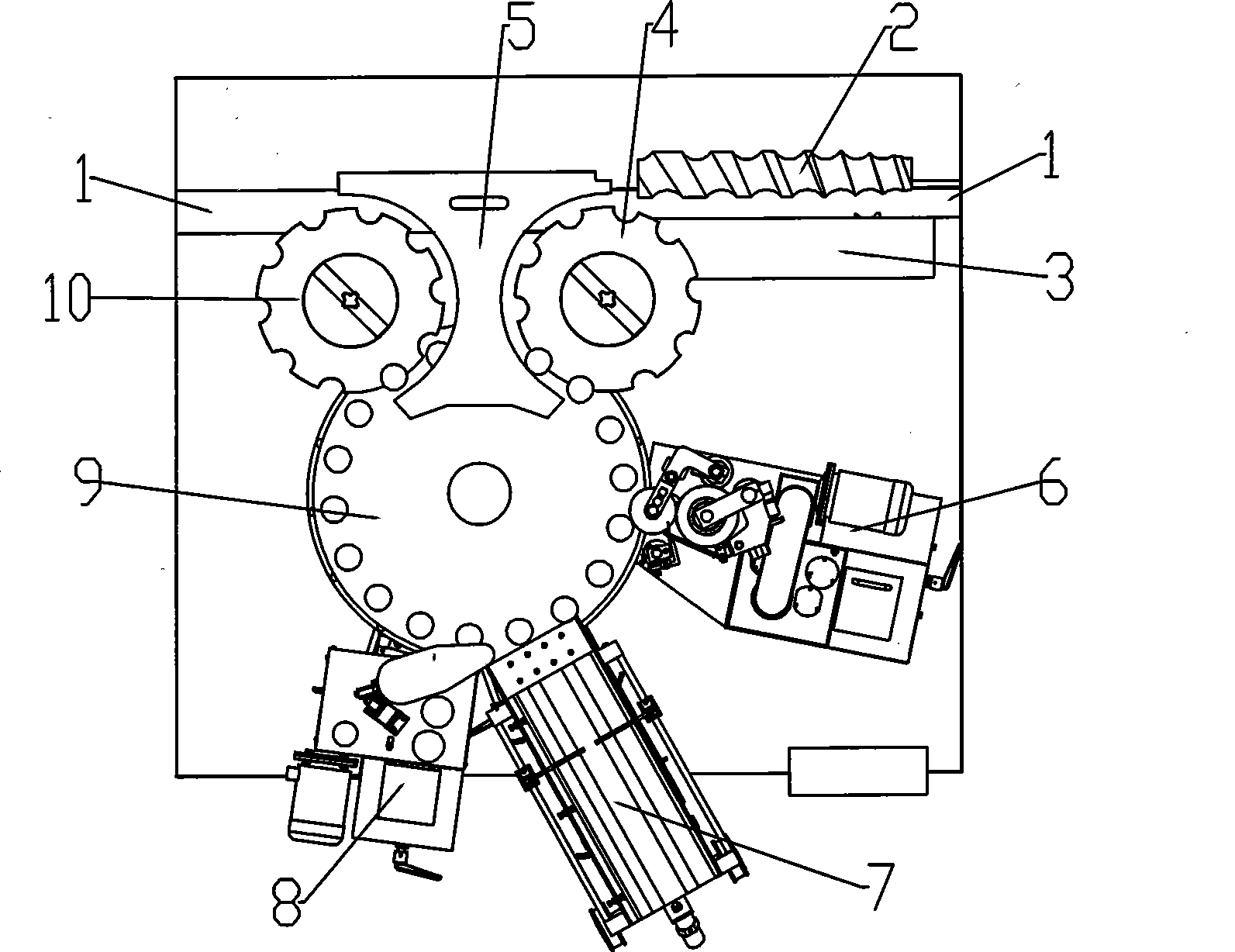

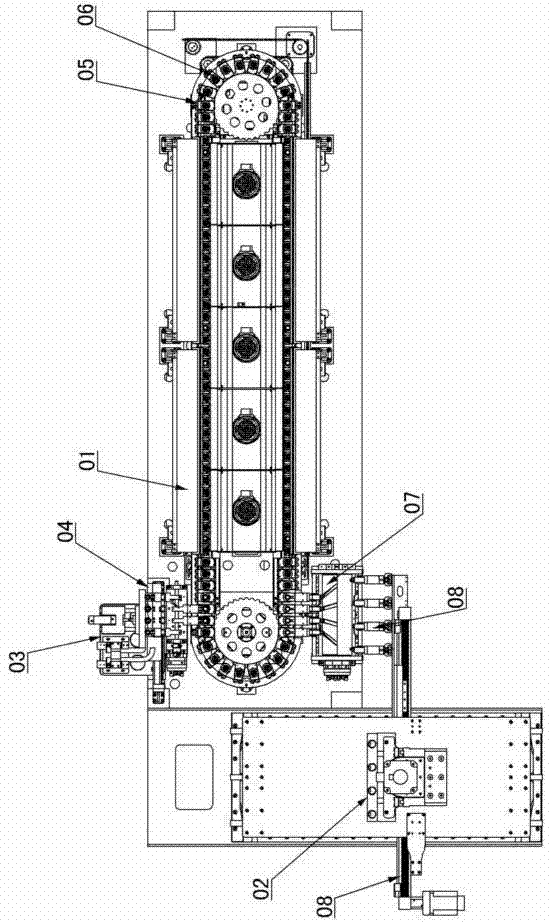

Automatic bottle feeding, filling, corking and capping integrated packaging machine

The invention discloses an automatic bottle feeding, filling, corking and capping integrated packaging machine which comprises a rack main body, a bottle arrangement and feeding system for arranging a bottle and placing the bottle on a bottle feeding station, an automatic filling system for filling the bottle on a filling station with a required material, an inner cork arrangement and corking system for pressing an inner cork in a bottle opening on a corking station, a bottle cap arrangement and capping system for capping the corked bottle opening on a capping station with a bottle cap, a cap twisting system for twisting the bottle cap arranged on the bottle opening on a cap twisting station on the bottle opening, a conveying system and a control system positioned in the rack main body. The automatic bottle feeding, filling, corking and capping integrated packaging machine is easy to operate, the great convenience is brought to a user, a product is high in quality consistency, and the systems and the mechanisms are compact and high in working efficiency, and sequentially act; the manual operation is replaced by the systems and the mechanisms, so that the risk of pollution is avoided.

Owner:GUANGZHOU BEAUTY STAR CO LTD

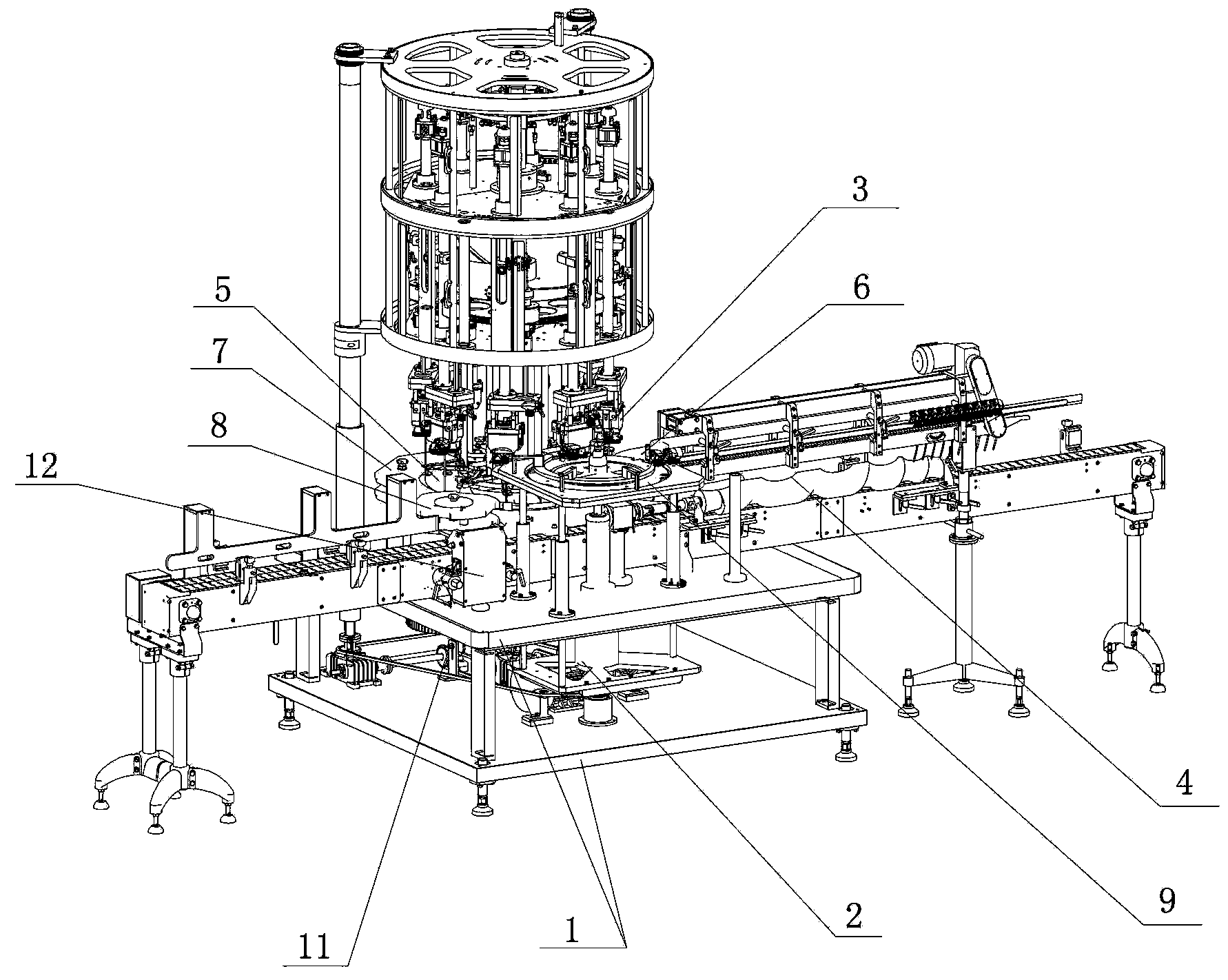

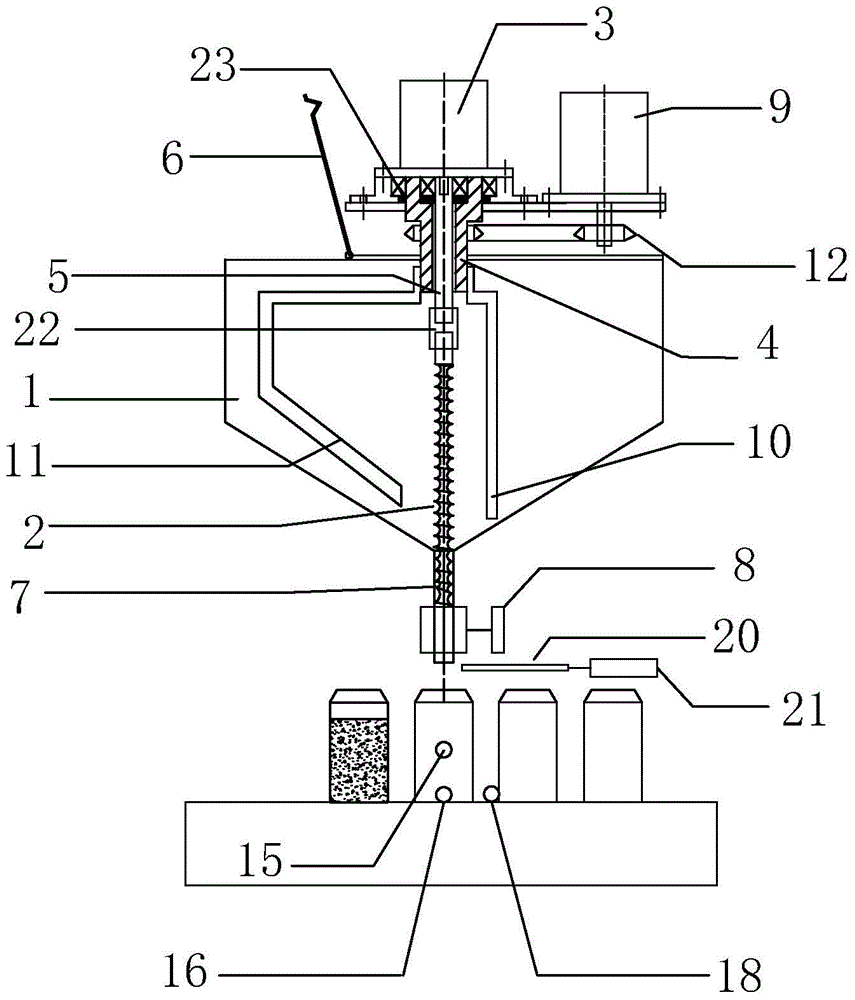

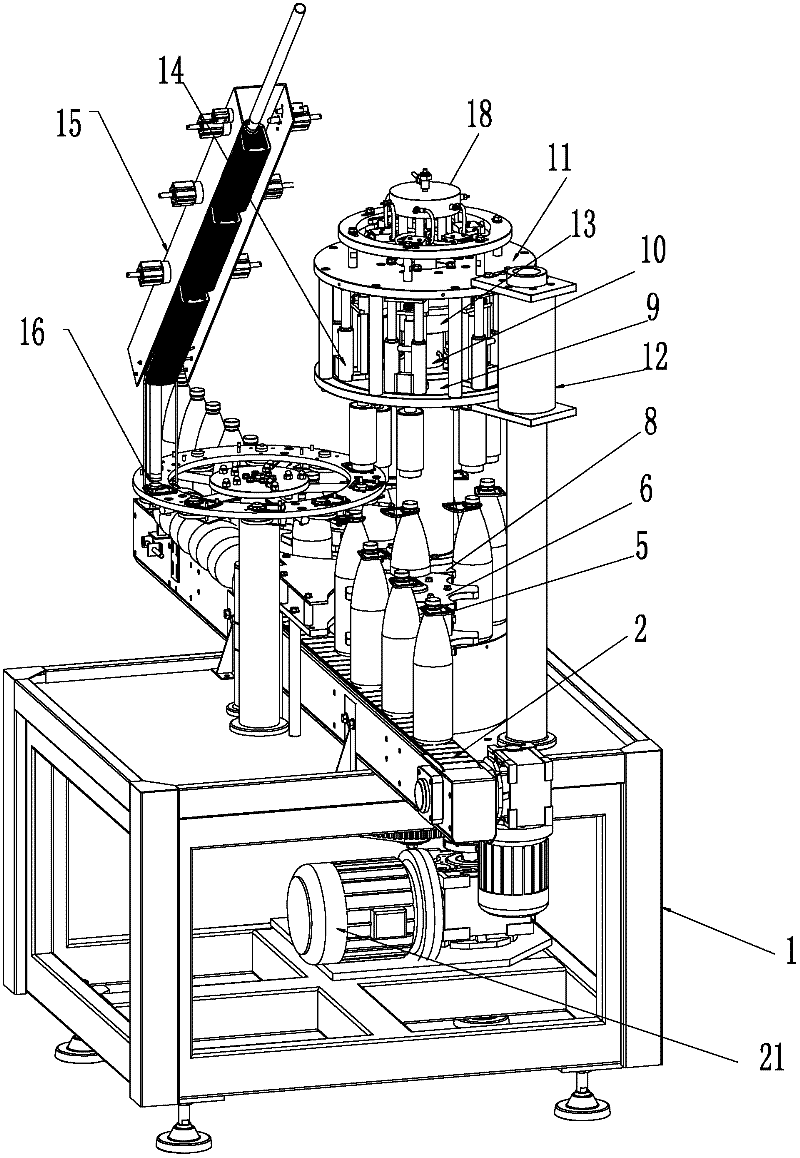

Full-automatic multifunctional cap screwing machine

ActiveCN103754807ARealize automatic positioningAdjustable tightening forceThreaded caps applicationCapping machinery safety/controlElectrical controlEngineering

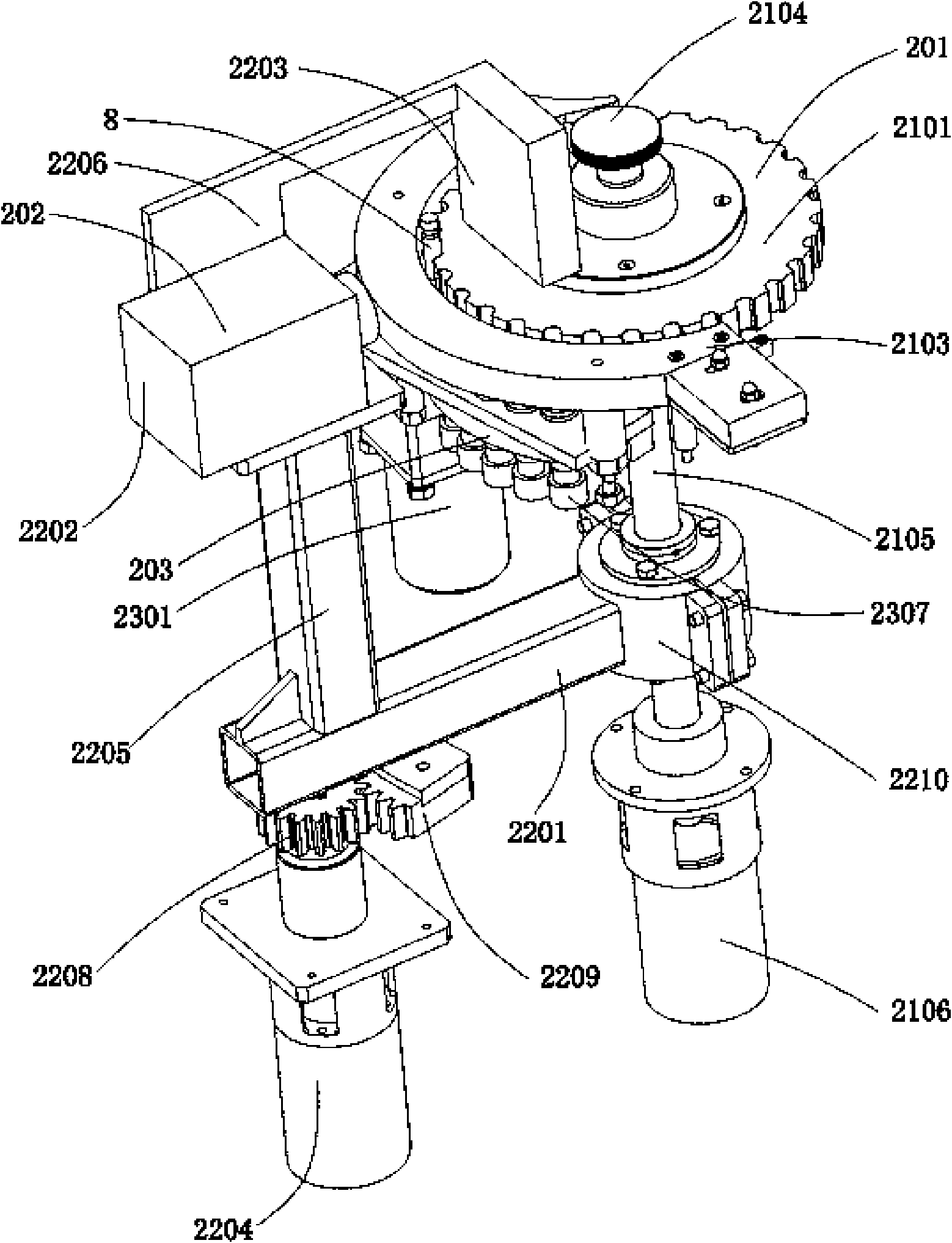

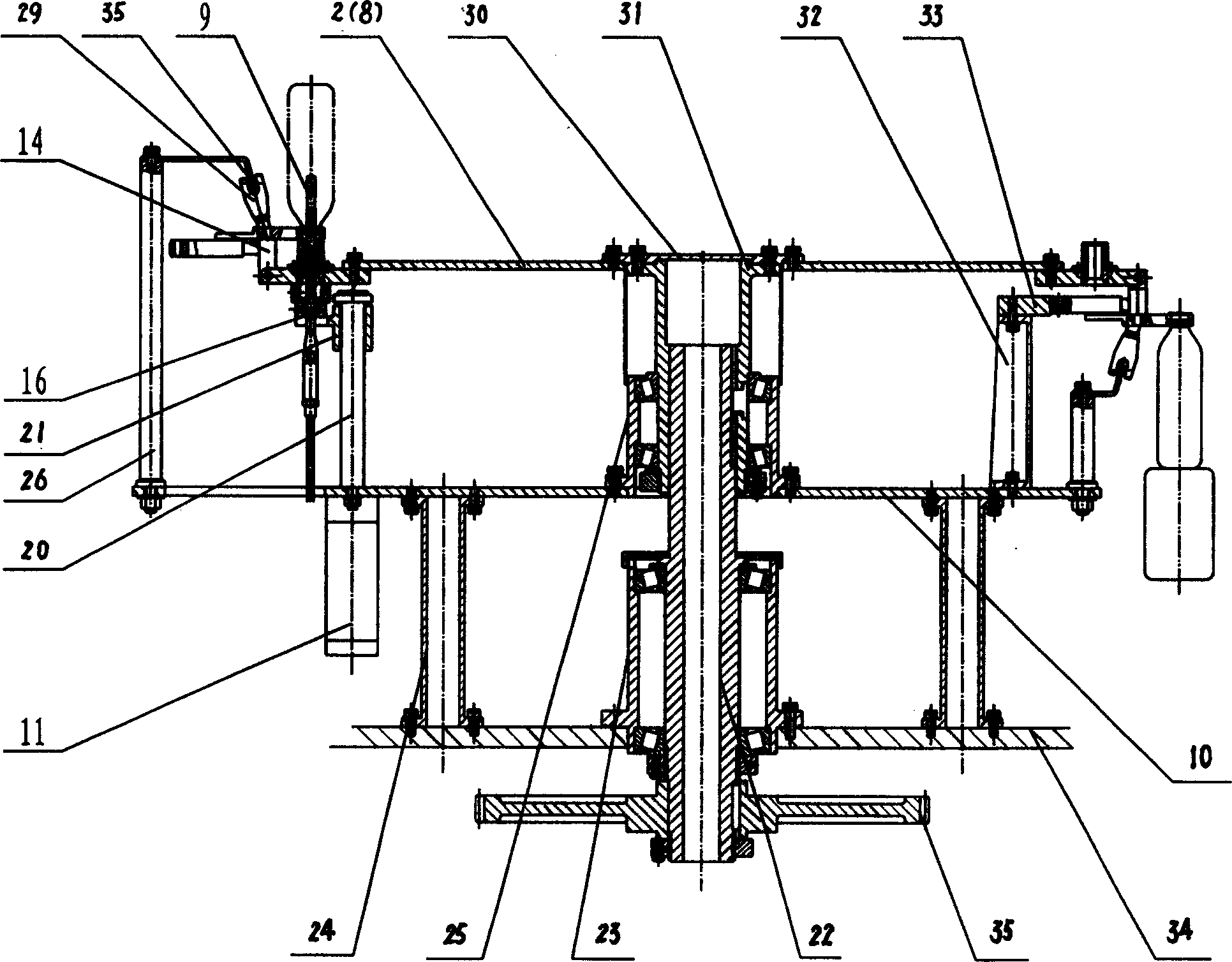

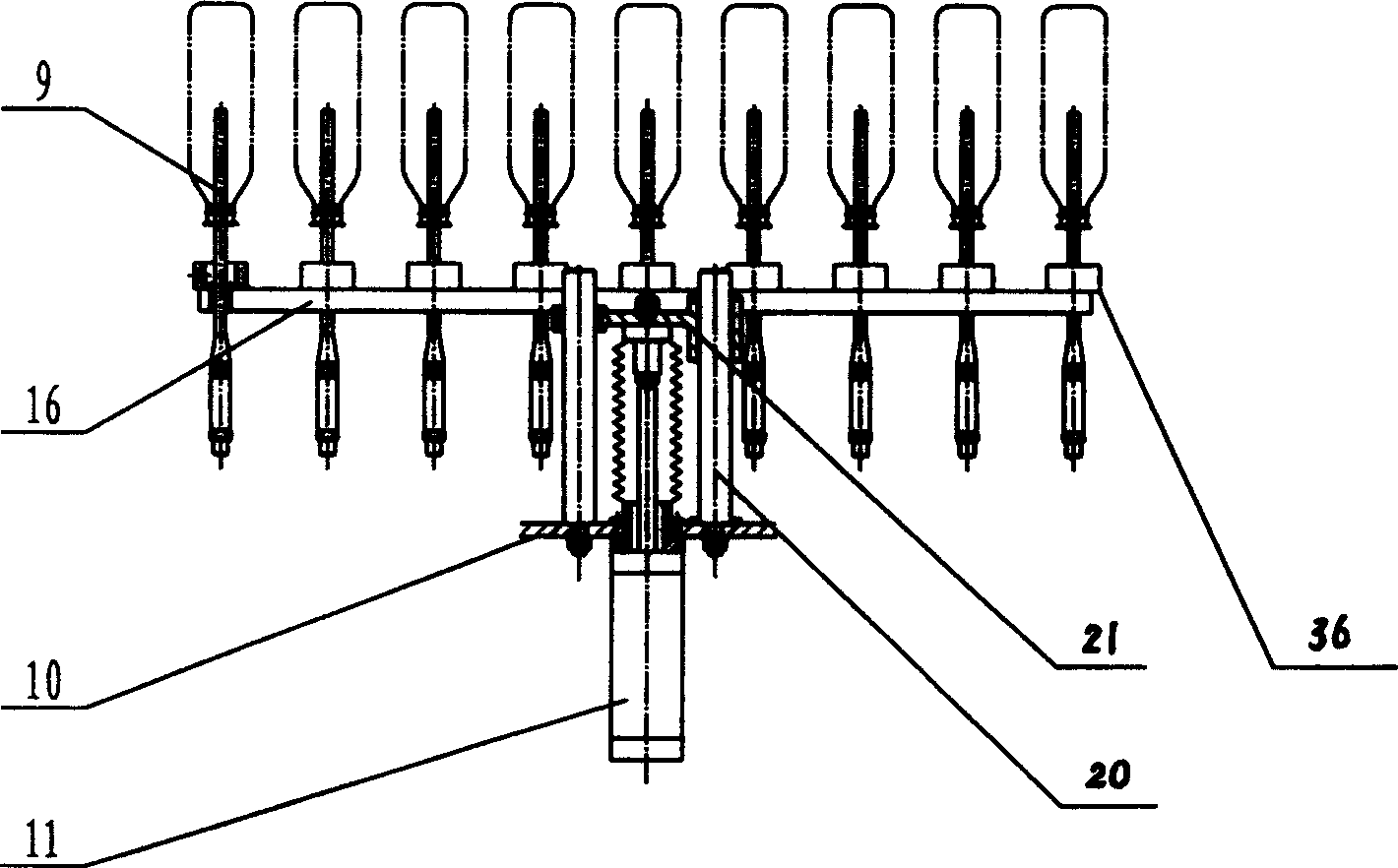

The invention provides a full-automatic multifunctional cap screwing machine. A power transmission device, a cap screwing assembly, a bottle supply device, a bottle guide device, a bottle feeding star wheel device, a bottle stopping device, a bottle discharge star wheel device, a cap supply device, a bottle output device, a lifting adjusting device and a removing mechanism are included and are arranged on a rack, and the cap screwing assembly comprises a main shaft, a hollow shaft sleeve, an upper shaft sleeve, a first lead screw, a bearing pedestal, a bottle supporting plate, a bottle driving plate, a bottom flower plate, a middle flower plate, a top flower plate, a supporting plate, a lifting portion, a cap grabbing and screwing portion, a transmission portion, a pipe clamping portion, a main gear, a cam, a lower fixing ring, a middle fixing ring and a stand column. PLC electrical control is adopted in the full-automatic multifunctional cap screwing machine, and cap supply, cap grabbing and cap screwing are completed at one step. Bottle caps are automatically located, the screwing force of the bottle caps is adjustable, and the full-automatic multifunctional cap screwing machine has the advantages of being high in automation degree, wide in product application range and the like.

Owner:CHANGZHOU HUITUO TECH

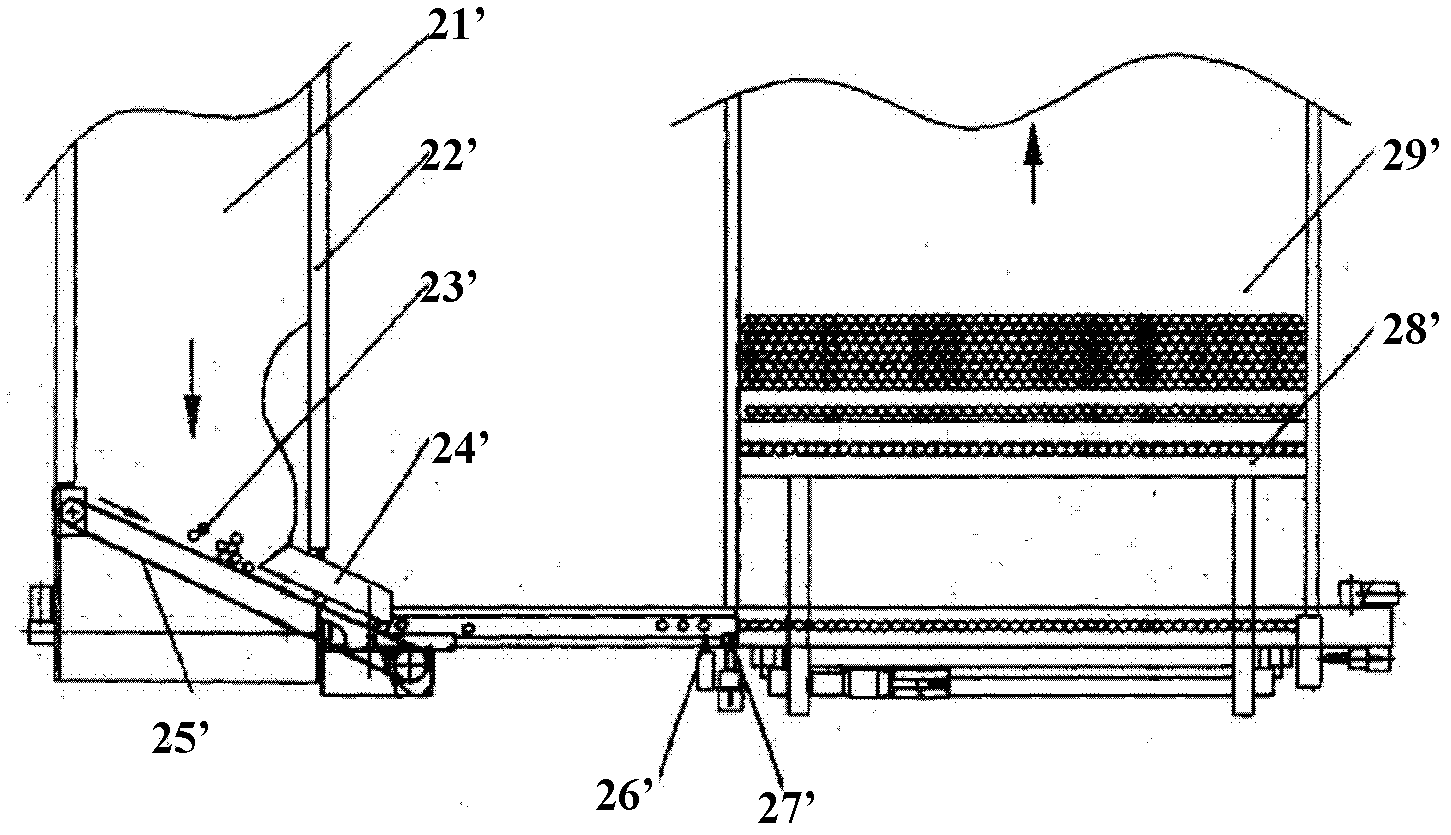

Automatic light inspection machine

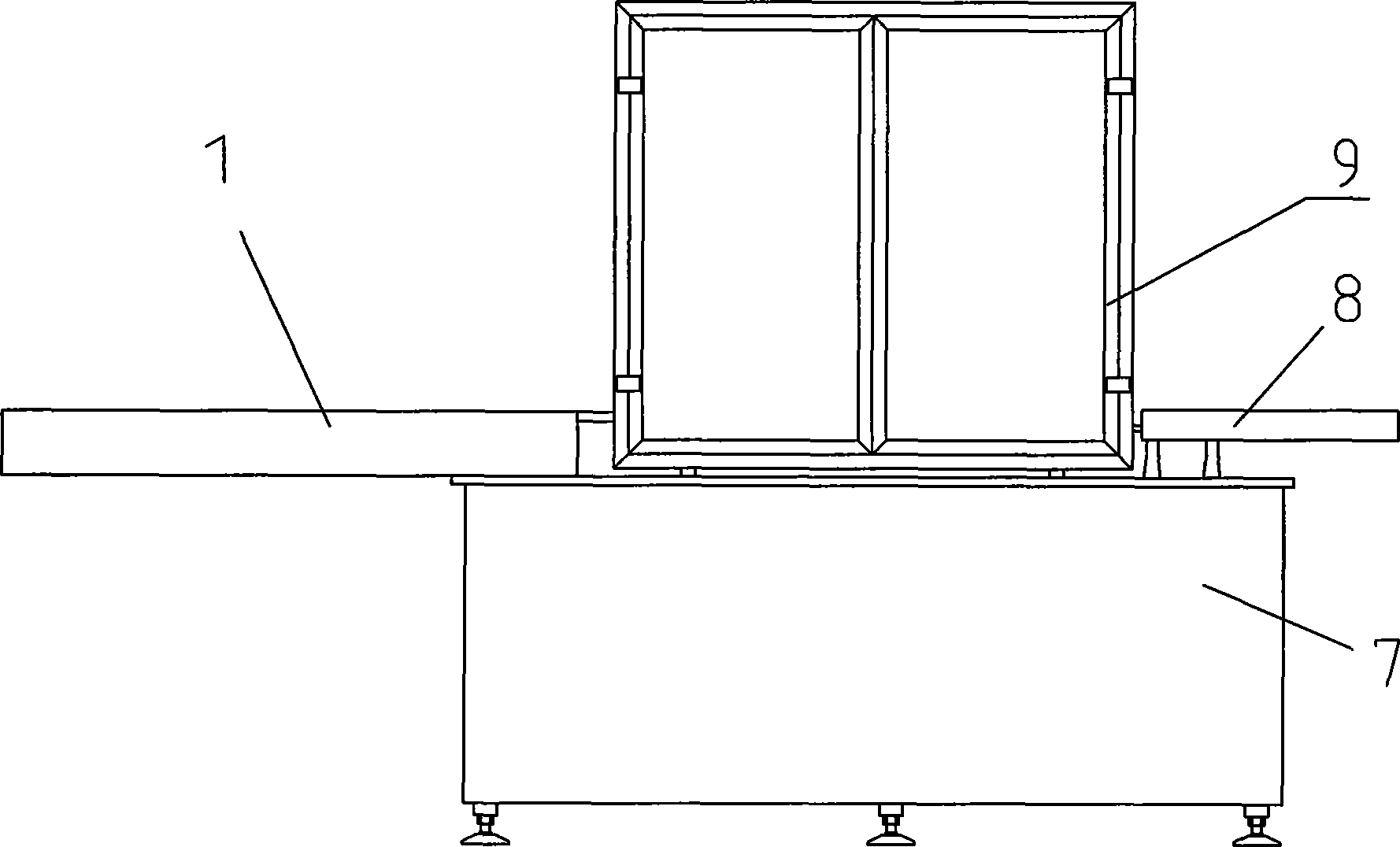

InactiveCN101644664ACompact structureLow costMaterial analysis by optical meansMachines/enginesForeign matterBottle

The invention discloses an automatic light inspection machine. The automatic light inspection machine comprises a bottle feeding mechanism, a foreign matter inspection mechanism, a bottle discharge mechanism, a bottle rejection mechanism and a control mechanism, wherein an appearance detection mechanism used for inspecting the appearance of a bottle body is arranged between the bottle feeding mechanism and the foreign matter inspection mechanism. The invention is the automatic light inspection machine which has the advantages of simple and compact structure, low cost and reasonable configuration and can simultaneously inspect the appearance and the interior of the bottle body.

Owner:TRUKING TECH LTD

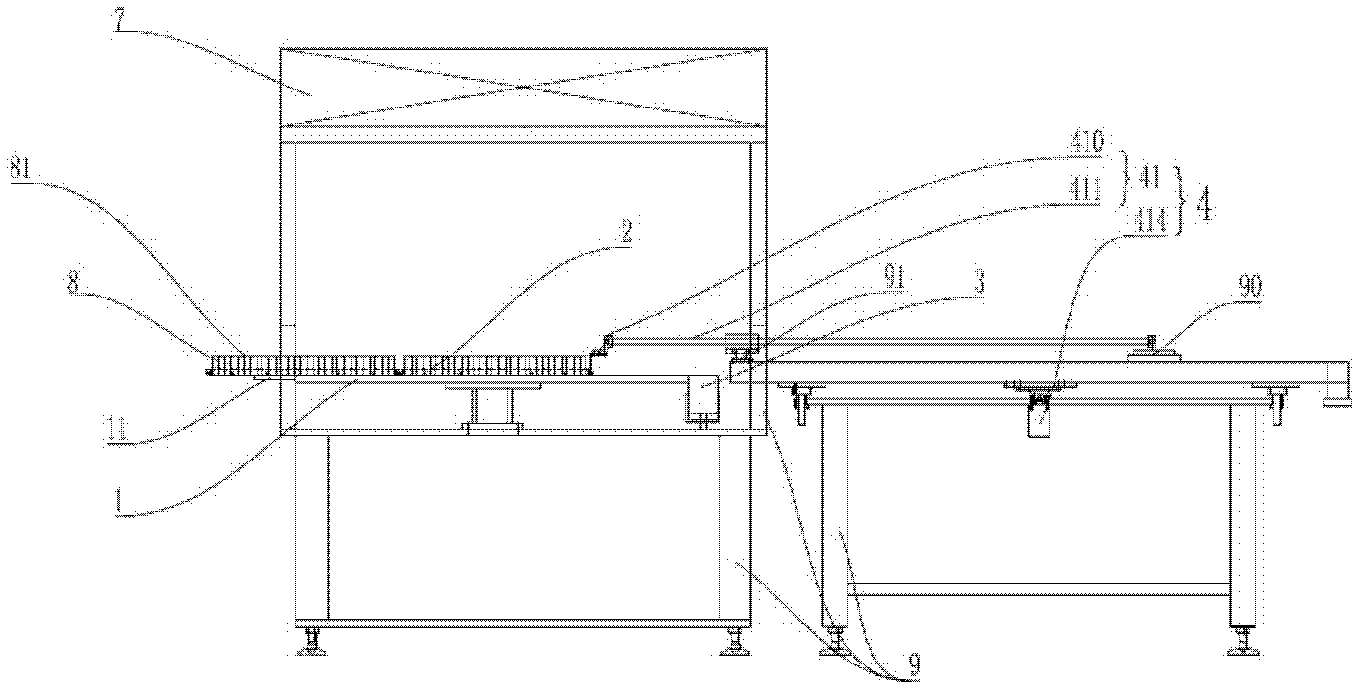

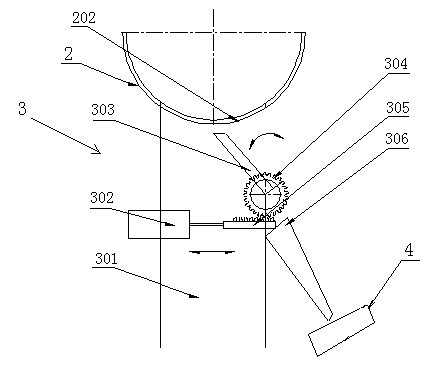

Foreign body automatic inspecting machine for small capacity injection or oral liquid

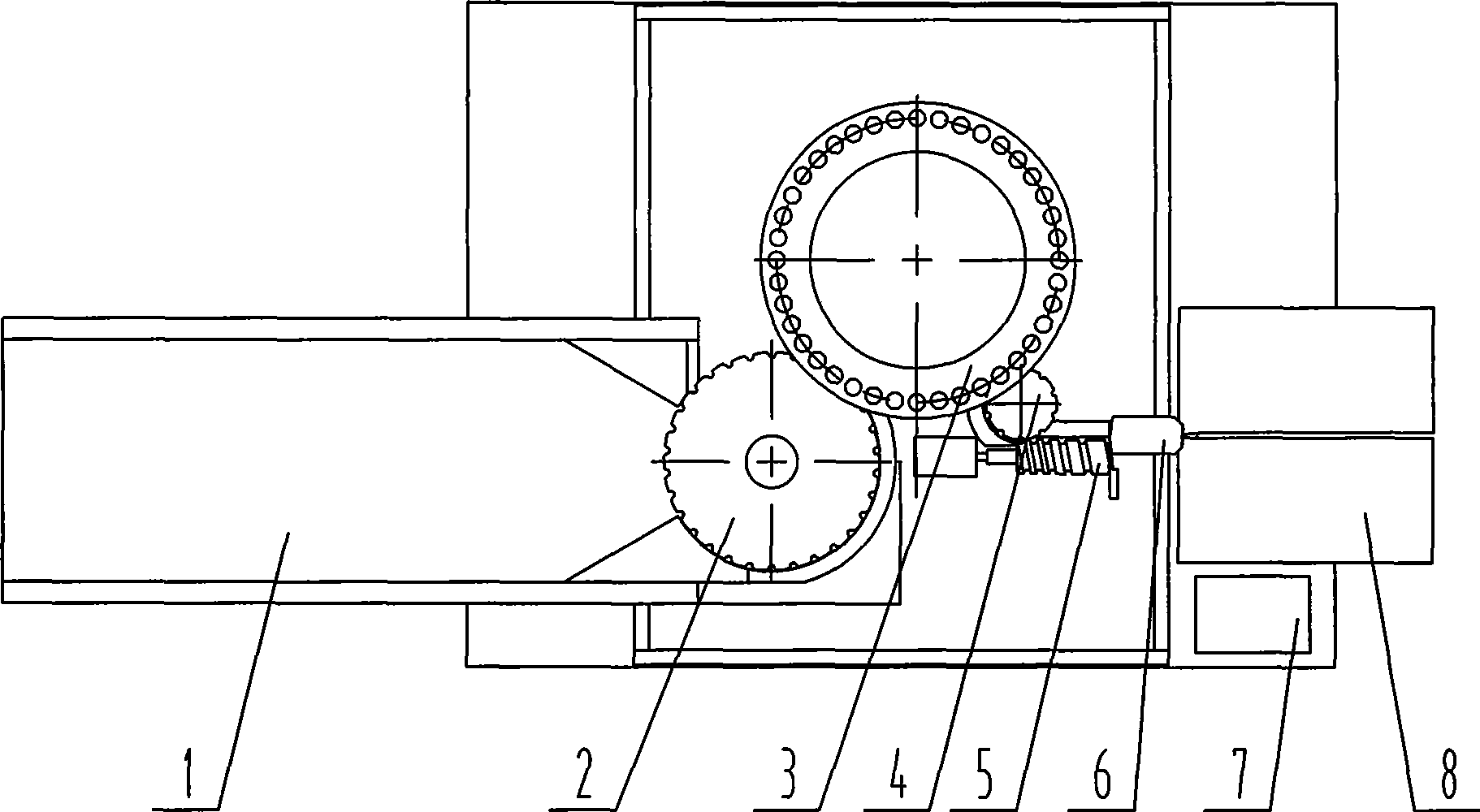

ActiveCN101368916AImprove detection accuracyThe detection process is fastOptically investigating flaws/contaminationEngineeringCam

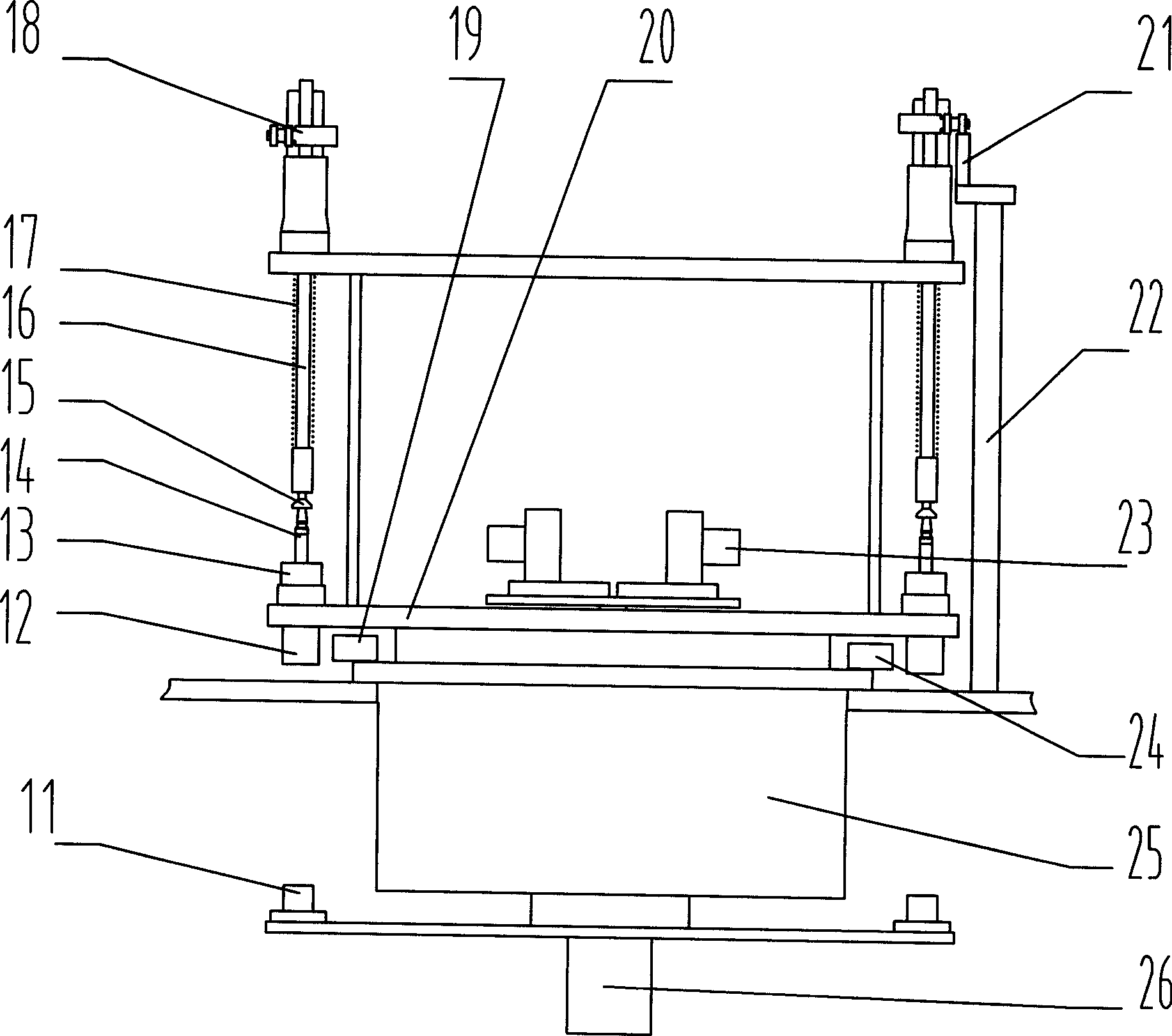

The invention discloses an automatic detection machine for detecting the foreign body in small-volume injection or oral liquid; a central detection area (3), a bottle feeding device and a bottle exit device are arranged on a machine rack (7); the central detection area (3) is provided with a turntable (20) on a machine base (25); a support body (13) and a bottle spinning base (12) are arranged on the turntable (20); the turntable (20) is provided with a pressure head (15) corresponding to the support body (13), a sliding rod (16), a pressure spring (17), a lifting block (18) and a cam (21) corresponding to the lifting block (18); the machine base (25) is provided with a bottle spinning device (19) corresponding to the bottle spinning base (12) and a braking device (24); a light source (11) and a camera (23) are arranged on the machine base (25); and the light source (11) and the camera (23) are driven by a servo motor (26) to make synchronous movement with the support body (13). The invention is a small-volume injection or oral liquid foreign body automatic detection machine which has high detection accuracy, fast detection speed and low detection missing rate.

Owner:HUNAN ZHENGZHONG PHARMA MACHINERY

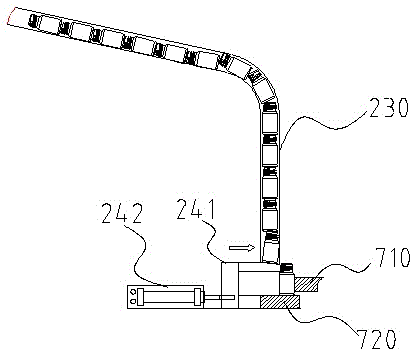

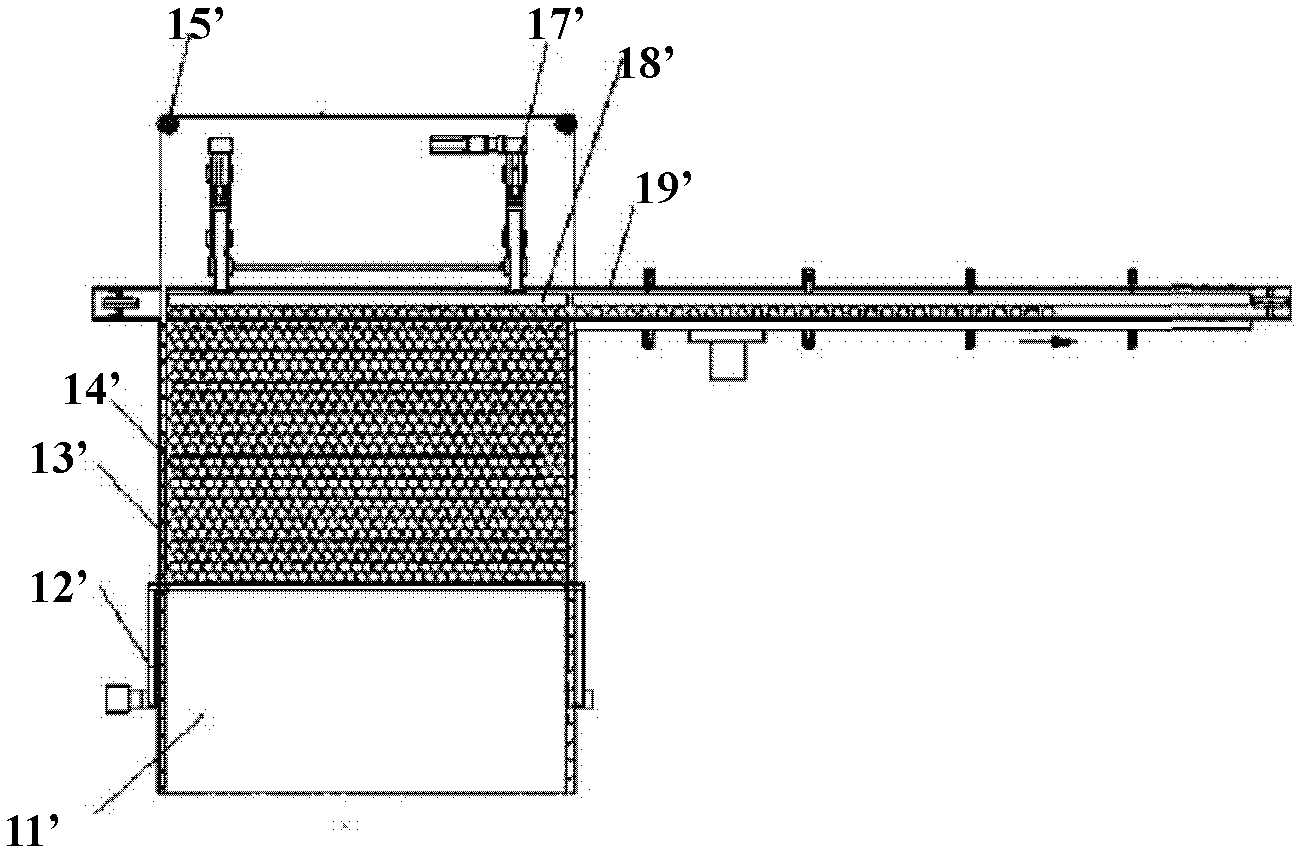

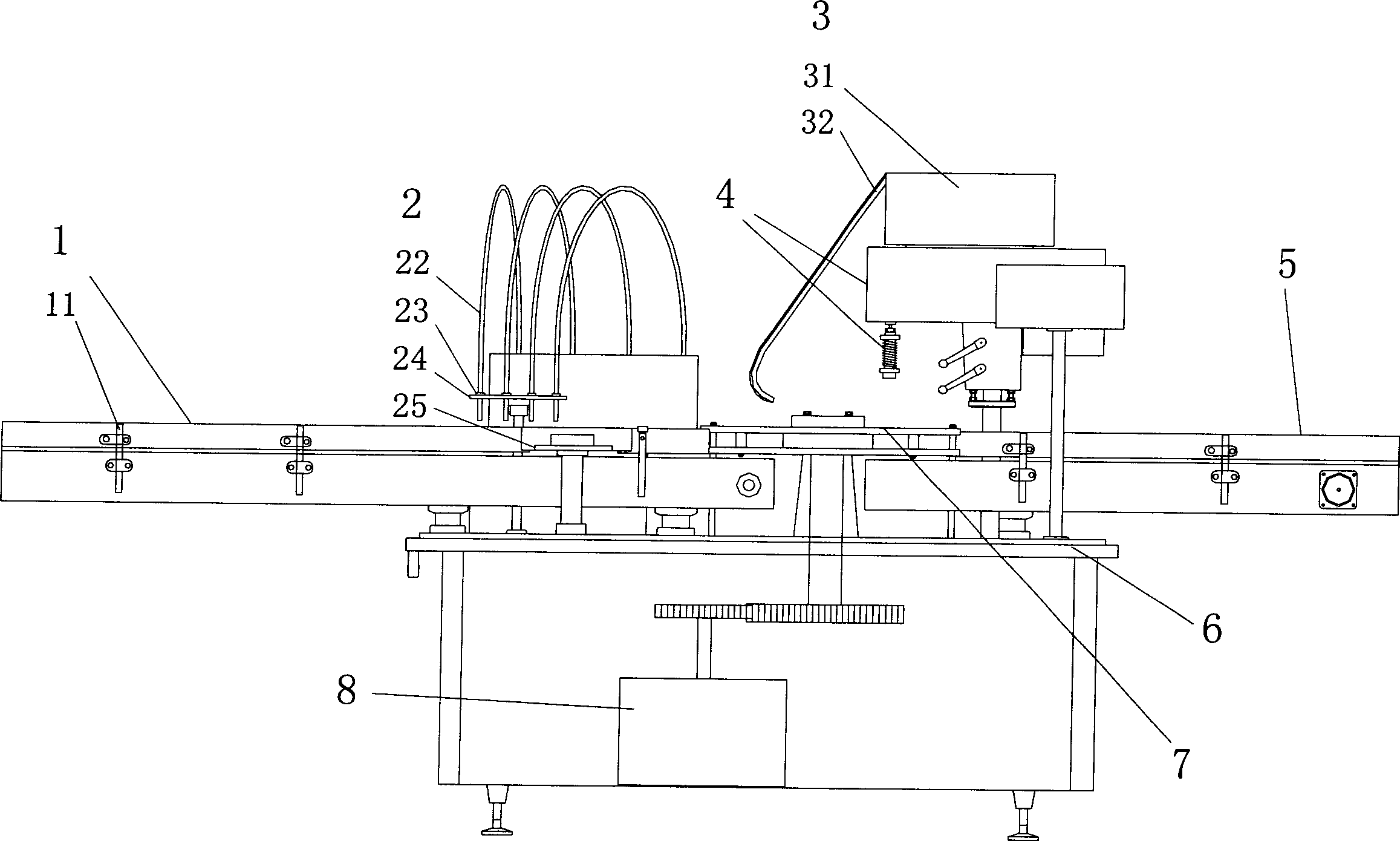

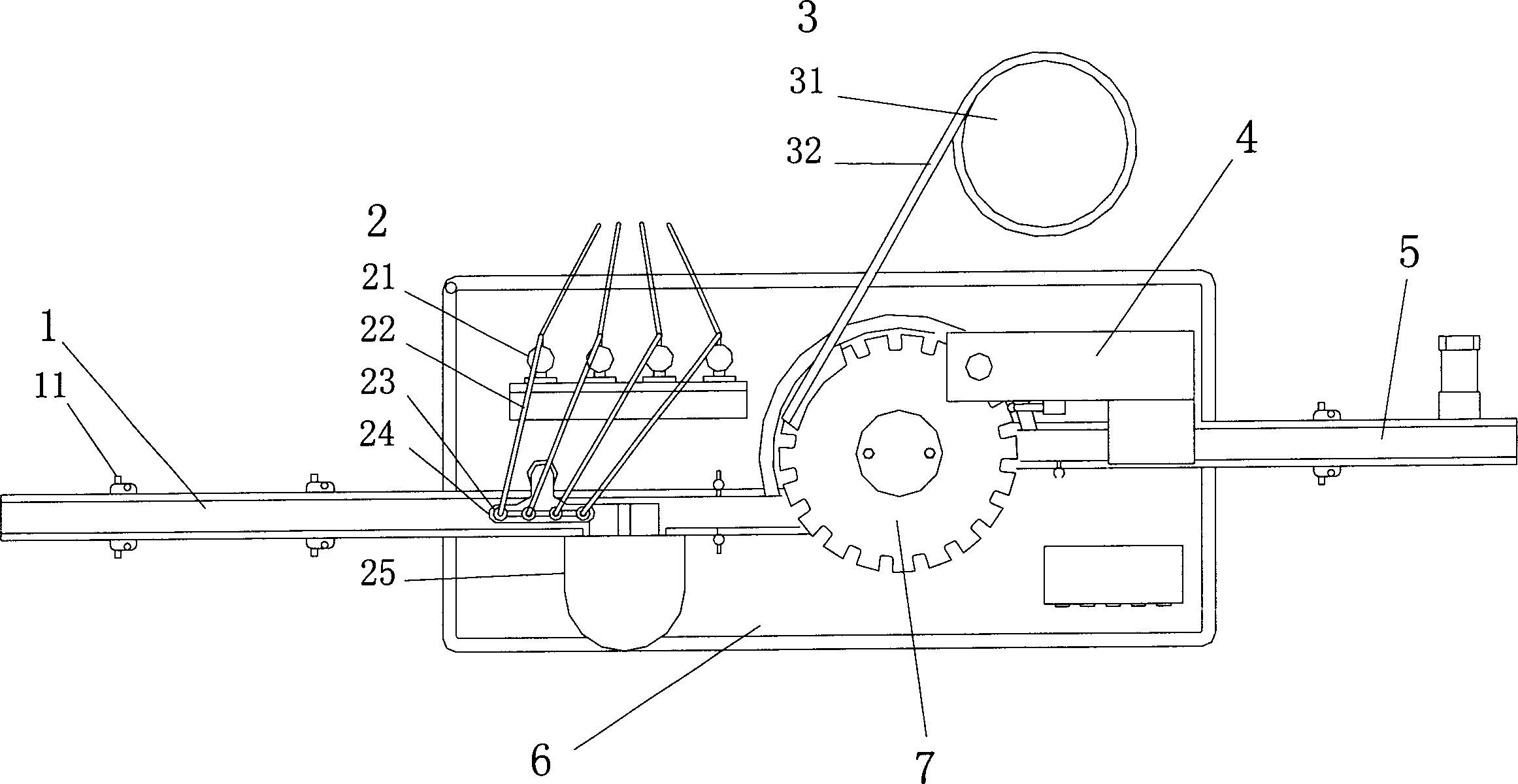

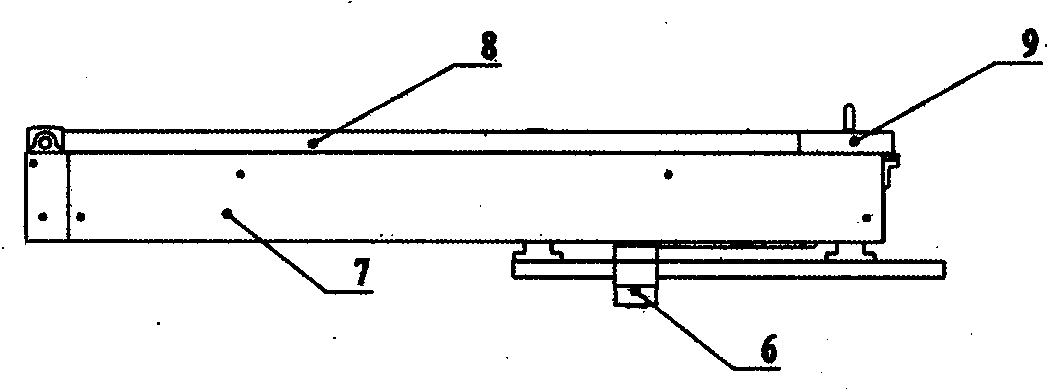

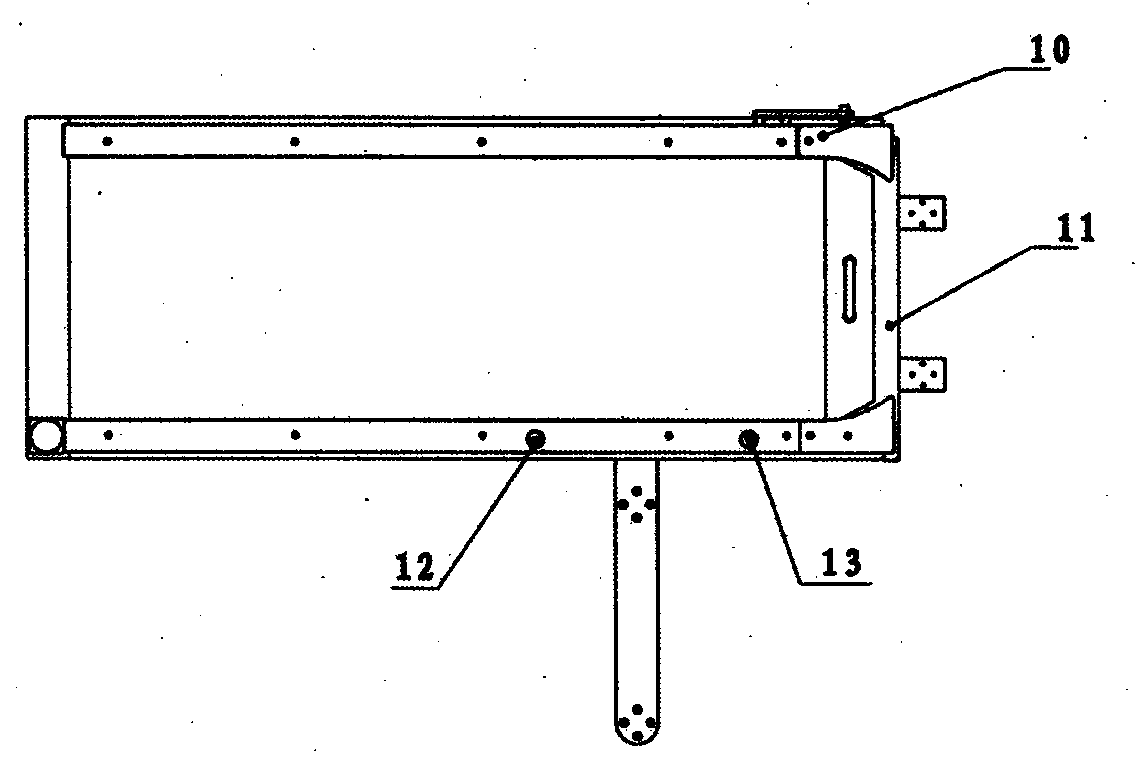

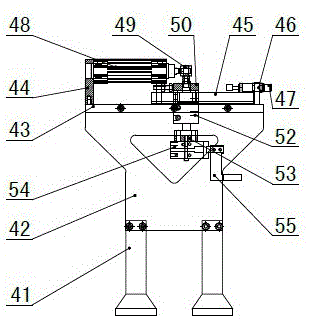

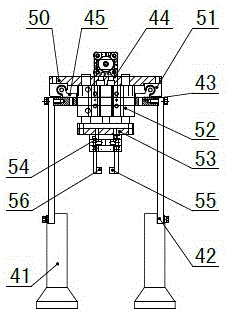

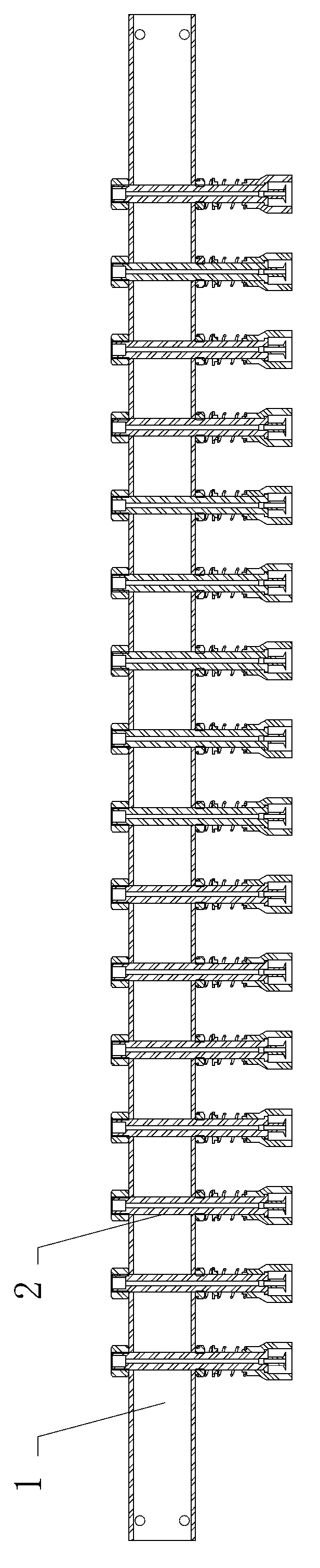

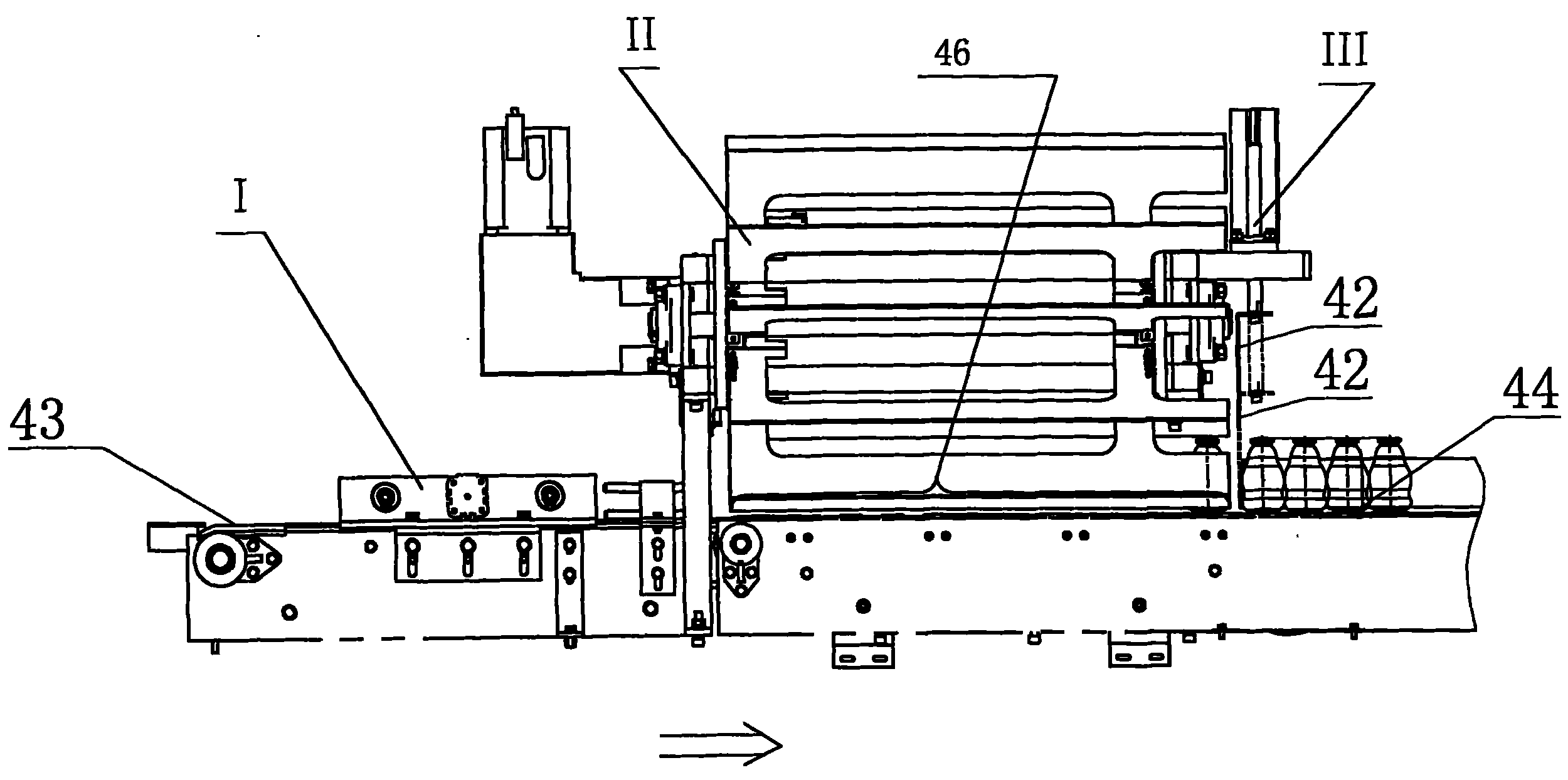

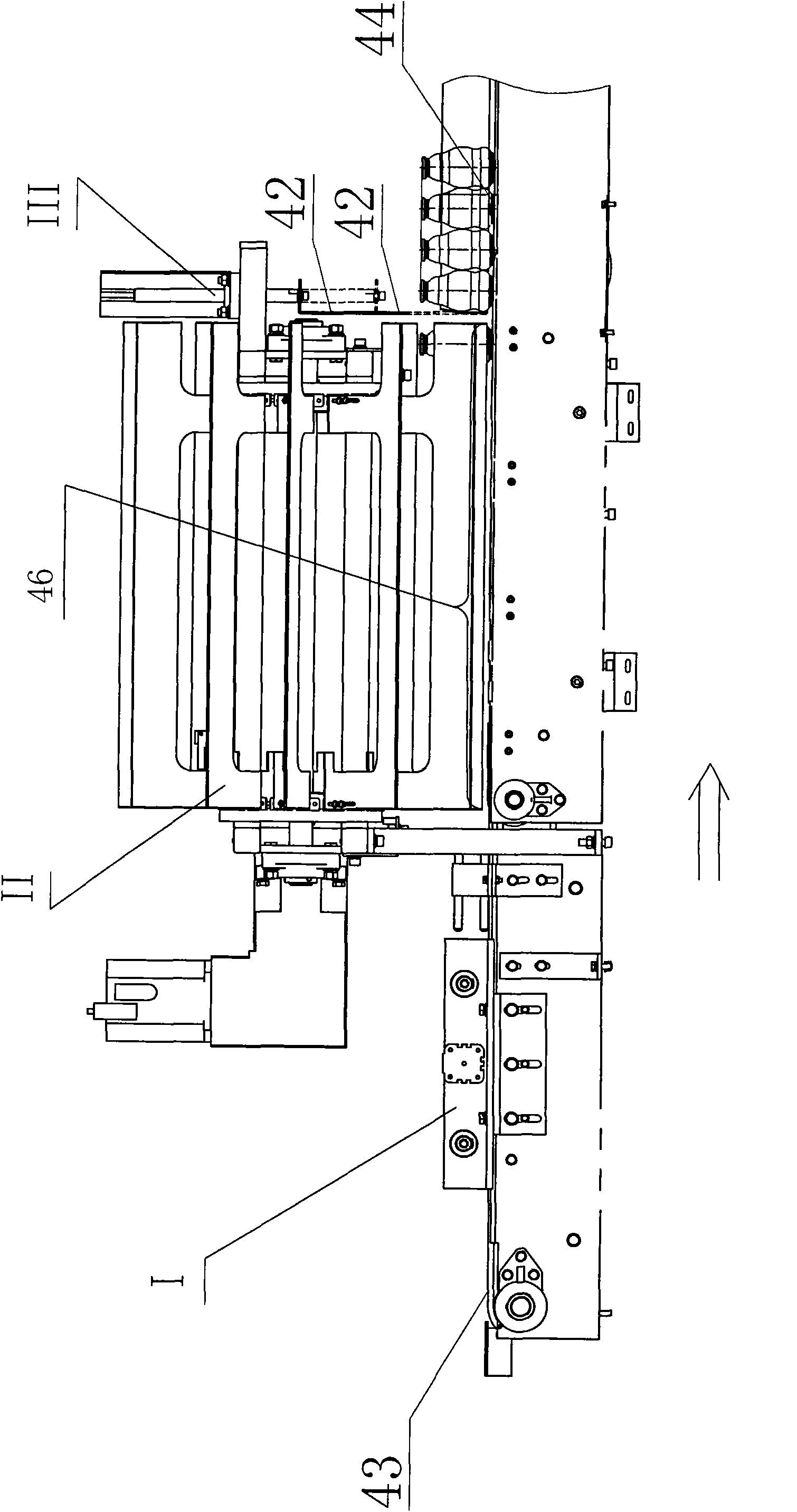

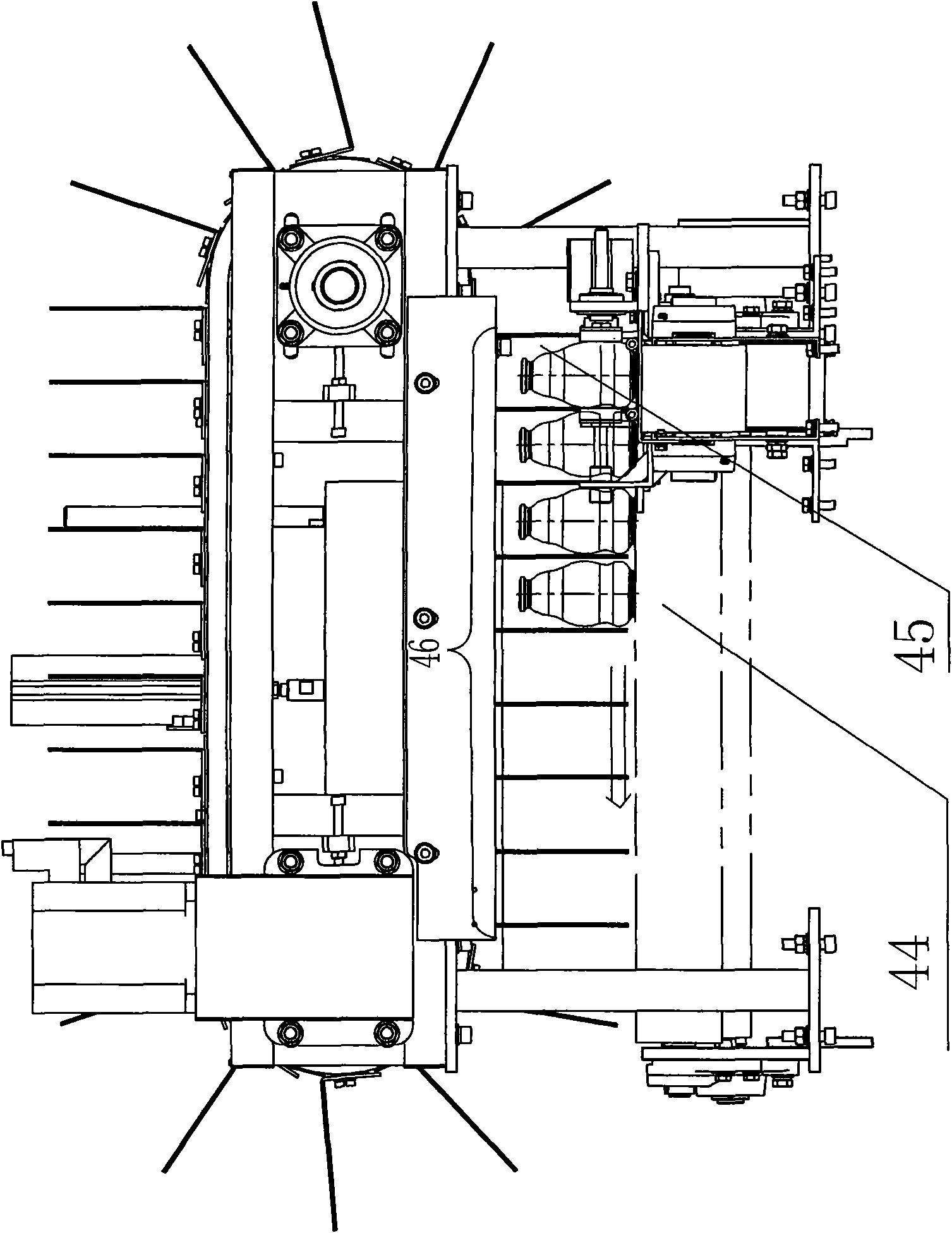

Device for controlling penicillin bottle to automatically enter and exit from freeze dryer

ActiveCN102230718ALow input costMaintain Medication HygieneDrying solid materials without heatPenicillinFreeze-drying

The invention provides a device for controlling a penicillin bottle to automatically enter and exit from a freeze dryer. The device is arranged at the inlet / outlet of the freeze dryer and comprises a frame, a push / pull mechanism, a bottle feeding track, a bottle storage platform and a bottle storage frame, wherein the bottle storage frame is arranged above the bottle storage platform; the bottle storage platform, the bottle feeding track and the push / pull mechanism are fixedly arranged on the frame in sequence from the inlet / out of the freeze dryer to the outside; the push / pull mechanism comprises a slide bar assembly which comprises a push / pull plate; the bottle storage frame moves up and down above the bottle storage platform and comprises a frame body covered on the penicillin bottle; the frame body is provided with a plurality of connecting parts; and one end of the push / pull plate is operably connected with the connecting parts. By adopting the device, entering and exiting processes can be finished with only one set of equipment, so that the equipment investment cost is saved. Contact of a person with a medicament is avoided, and the medicament is kept sanitary. The automatic one-time feeding amount is large, so that the production efficiency can be increased.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

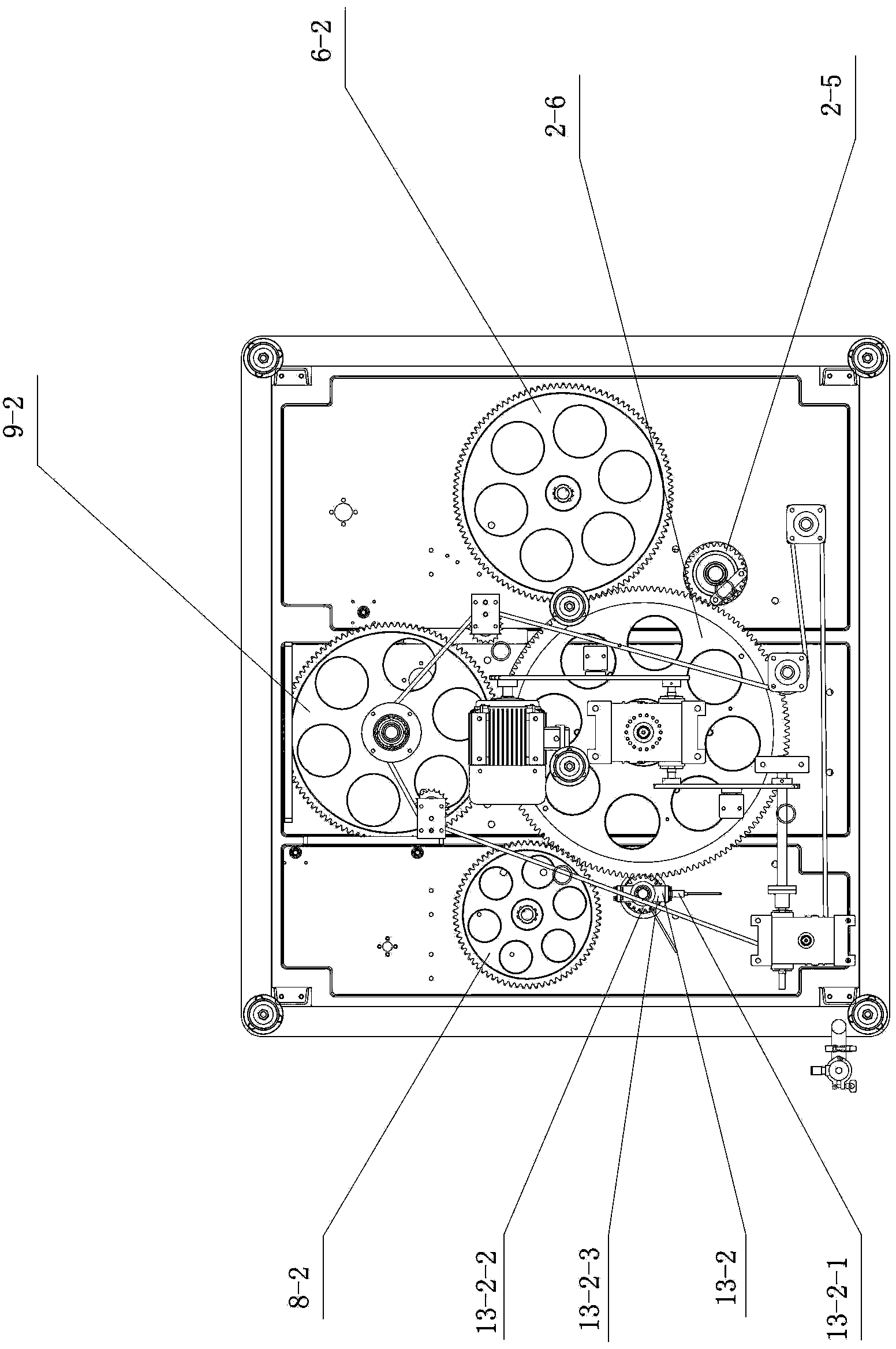

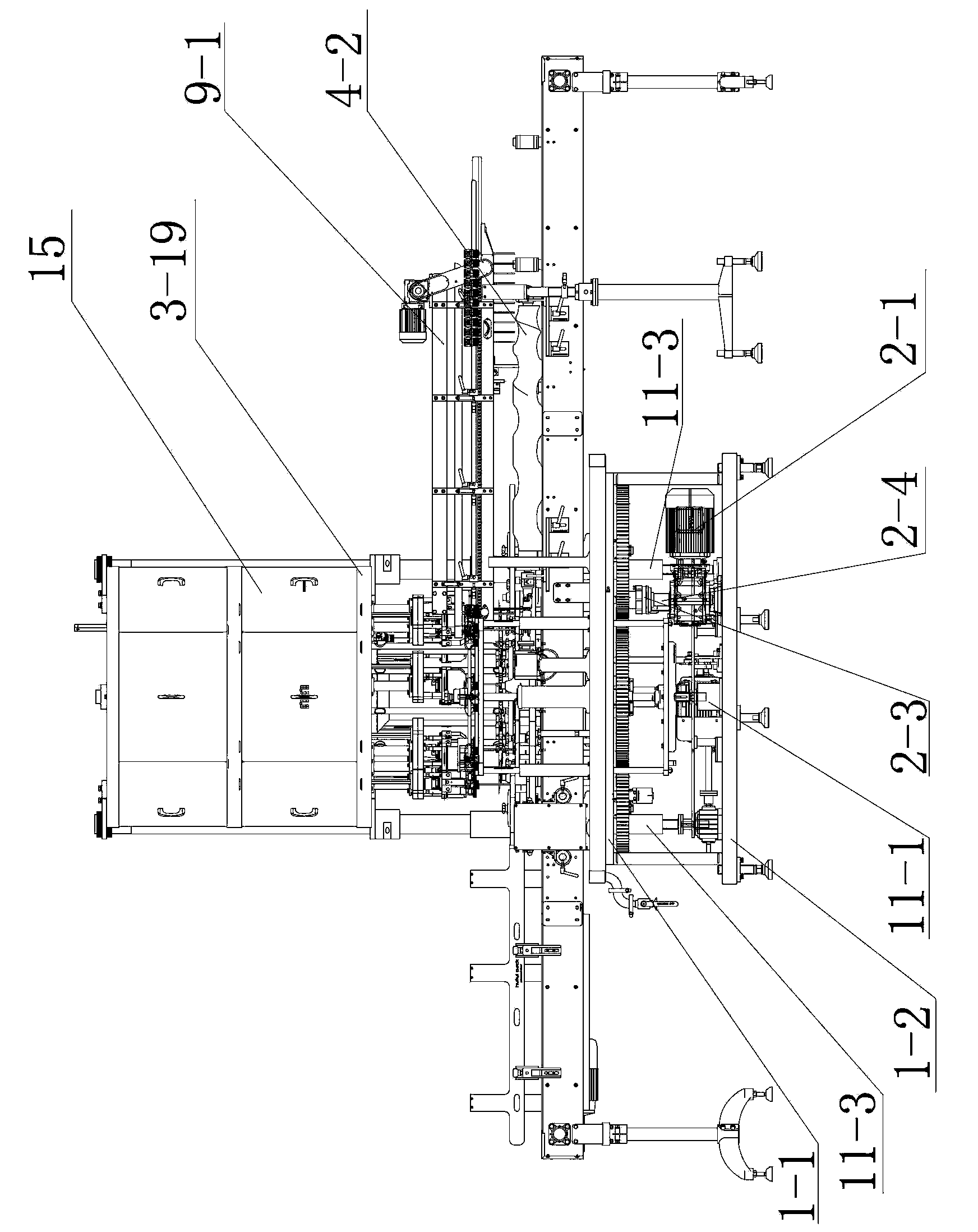

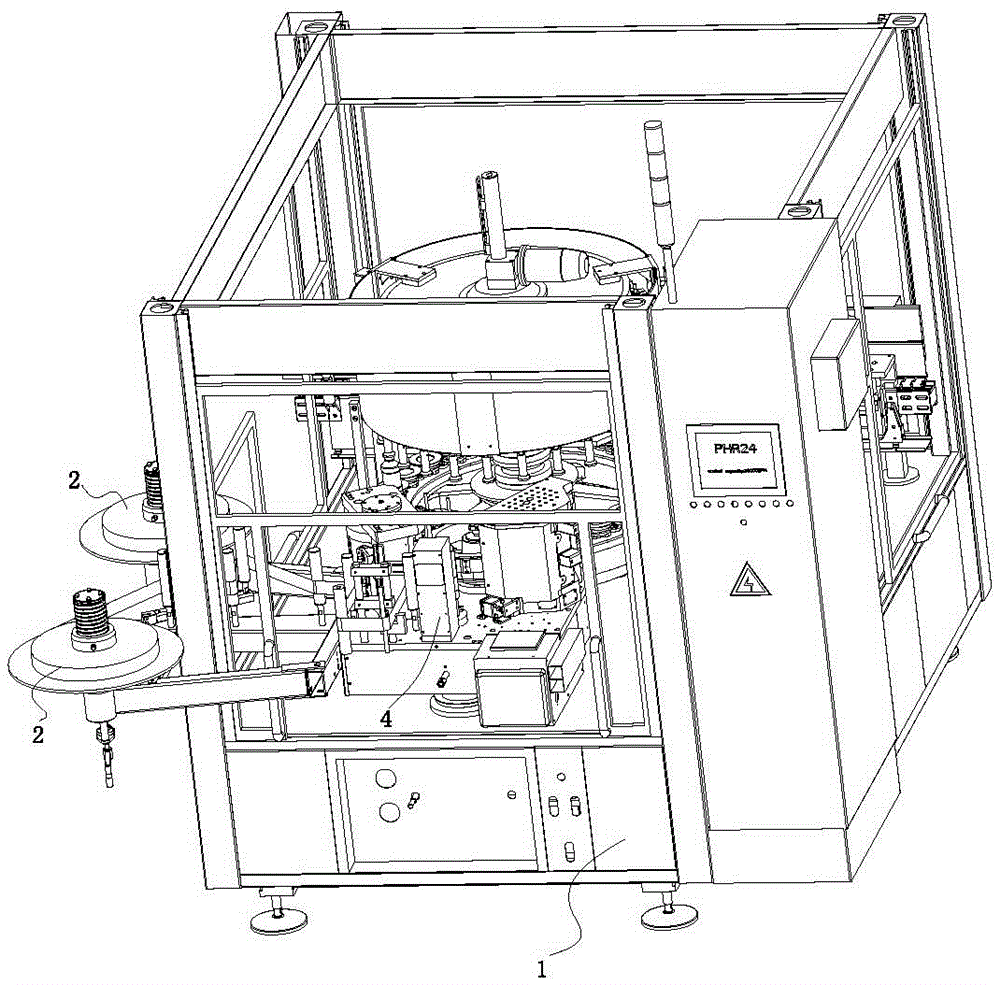

Automatic cover pressing/screwing machine capable of conducting self-adaption on high bottles and low bottles

The invention discloses an automatic cover pressing / screwing machine capable of conducting self-adaption on high bottles and low bottles. The automatic cover pressing / screwing machine comprises a rack, the rack is provided with a scale division bottle feeding mechanism, the periphery of the scale division bottle feeding mechanism is provided with a sample bottle feeding station, a high-low bottle recognition and cover placement station, a cover pressing / screwing station, a detection station, a removing station and an output station. According to the automatic cover pressing / screwing machine, after being subjected to automatic high-low bottle detection and recognition, automatic cover feeding, automatic cover pressing / screwing and cover pressure in-place detection, pressed / screwed covers are sent to a fully-automatic sample storage work station and sent to a sample storage and examination chamber or a test cabinet, and the automatic cover pressing / screwing machine has the advantages of being reasonable in structure, high in sample bottle packaging efficiency and the like.

Owner:XIAMEN SAIMO JISHUO TECH CO LTD

Automatic box packing machine

ActiveCN103640719AImprove packaging efficiencySuitable for applications in the field of wine makingIndividual articlesWine bottleEngineering

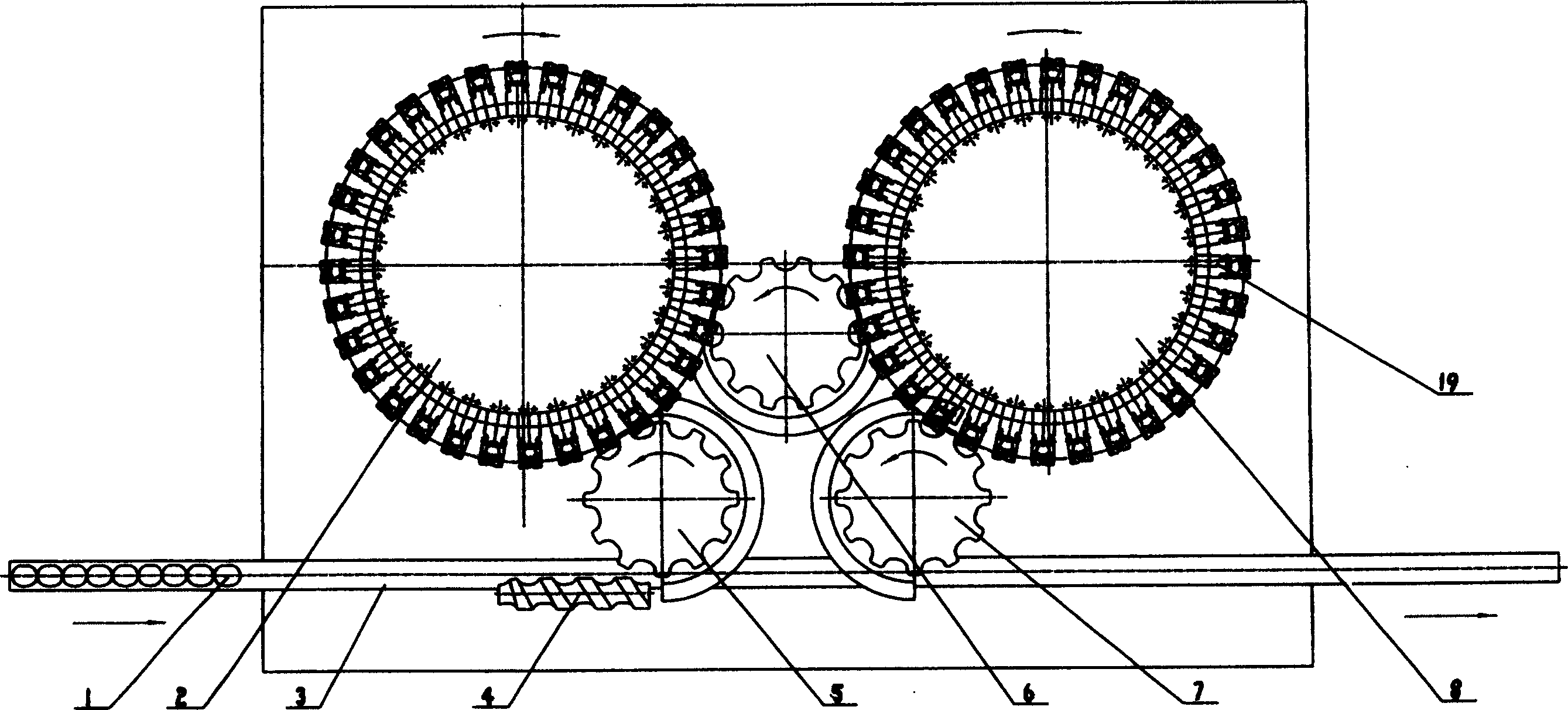

The invention discloses an automatic box packing machine which can improve the wine bottle box packing efficiency. The automatic box packing machine comprises a paper box conveying mechanism, a bottle feeding mechanism and a bottle placing mechanism. The paper box conveying mechanism comprises a first set of chain wheels and a second set of chain wheels. A rotary shaft of the first set of chain wheels or the second set of chain wheels is connected with a first driving mechanism, a paper box conveying chain is connected between the two sets of chain wheels, and a plurality of paper box locating frames are arranged on the paper box conveying chain in an equidistance mode; the bottle placing mechanism is arranged on the outer side of the second set of chain wheels, the bottle placing mechanism comprises a bottle placing machine frame, a third set of chain wheels and a fourth set of chain wheels are arranged at the two ends of the bottle placing machine frame respectively, a rotary shaft of the third set of chain wheels or the fourth set of chain wheels is connected with a second driving mechanism, a bottle body conveying chain is arranged between the third set of chain wheels and the fourth set of chain wheels, and a plurality of bottle grabbing devices are arranged on the bottle body conveying chain; the running direction of the bottle packing section is the same as the running direction of the bottle placing section and when the bottle grabbing devices enter the bottle placing section along with the bottle body conveying chain, the bottle grabbing devices are located above the bottle packing section; the bottle feeding mechanism is located below the bottle grabbing section.

Owner:LUZHOU HUIJIANG MACHINERY MFG

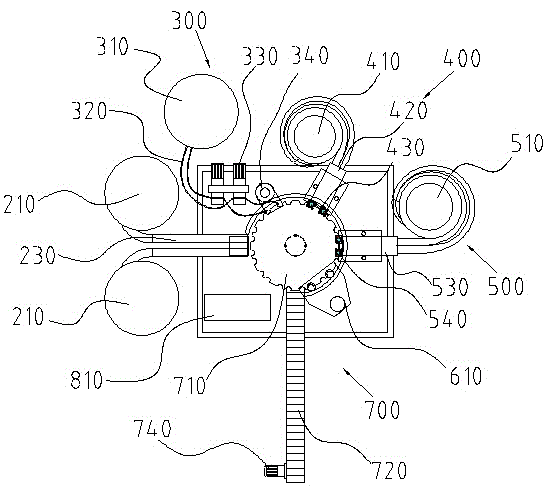

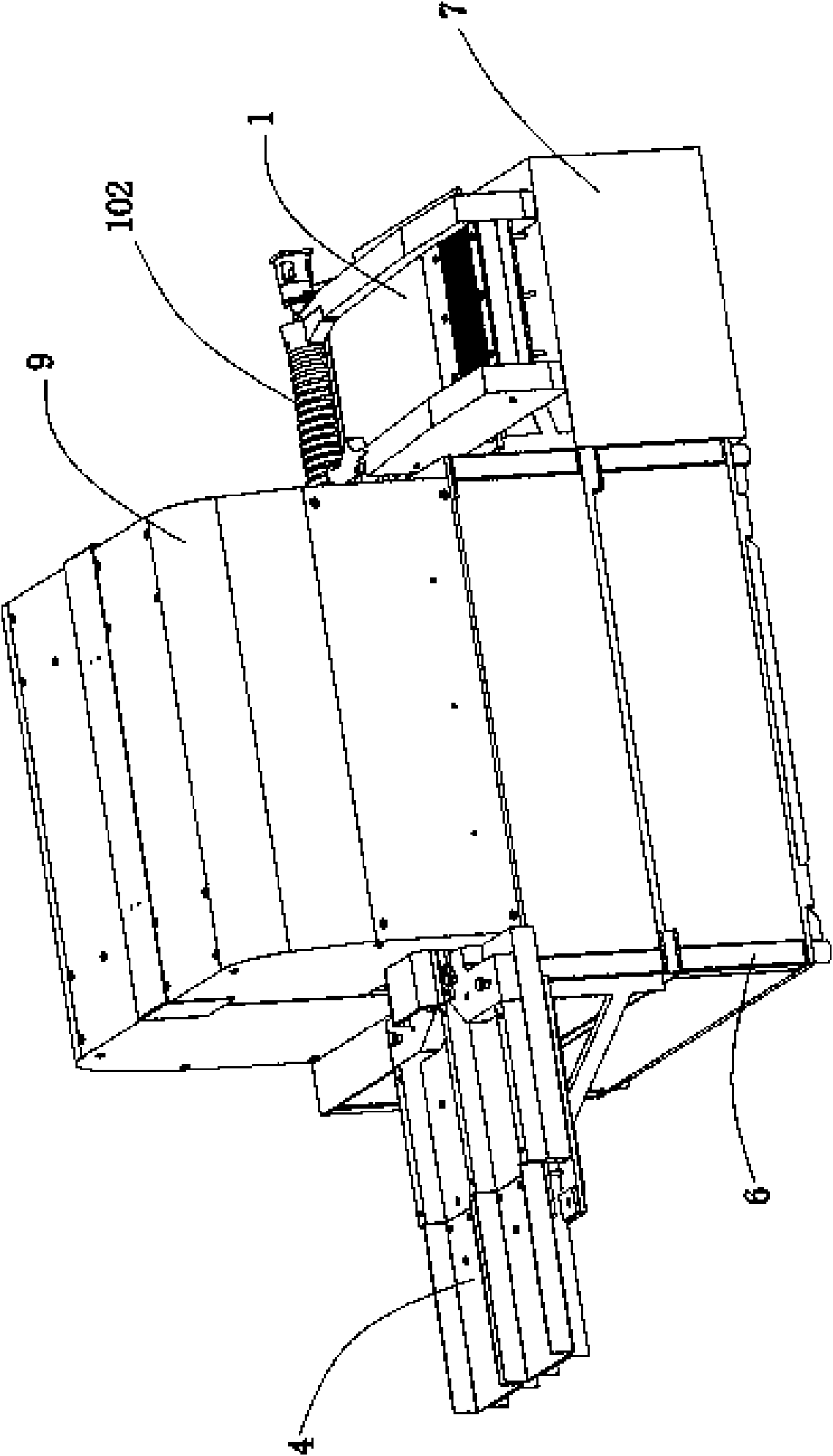

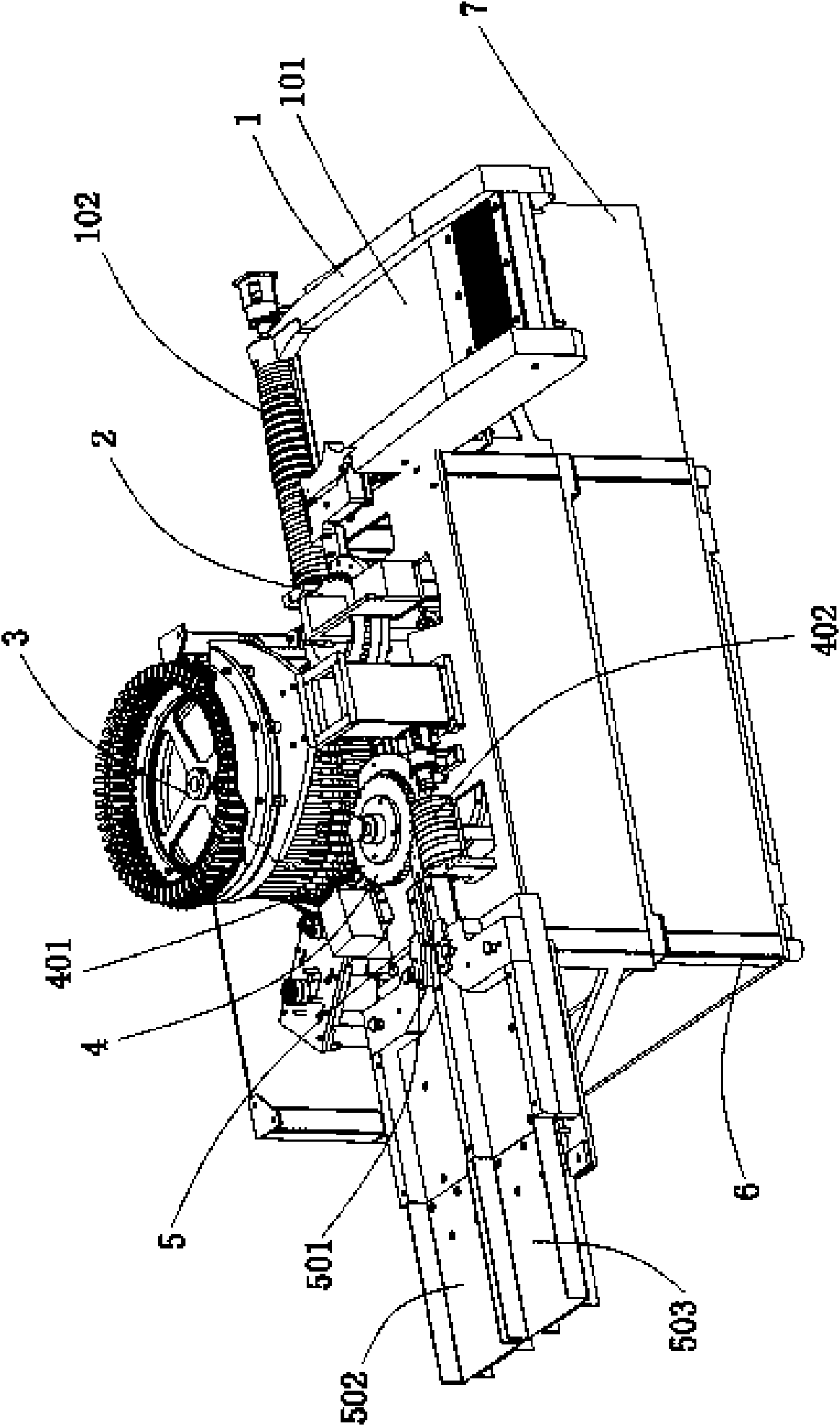

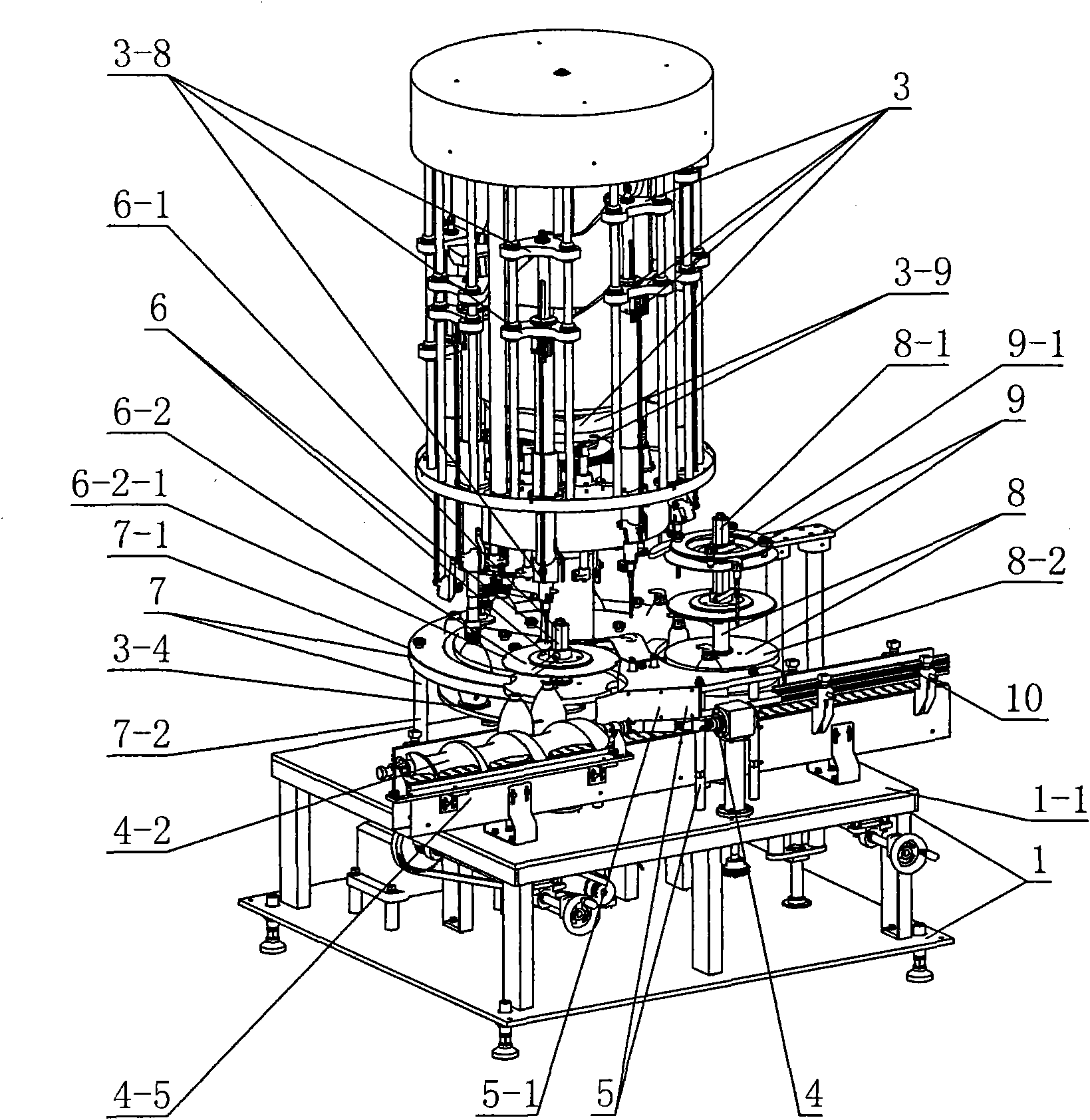

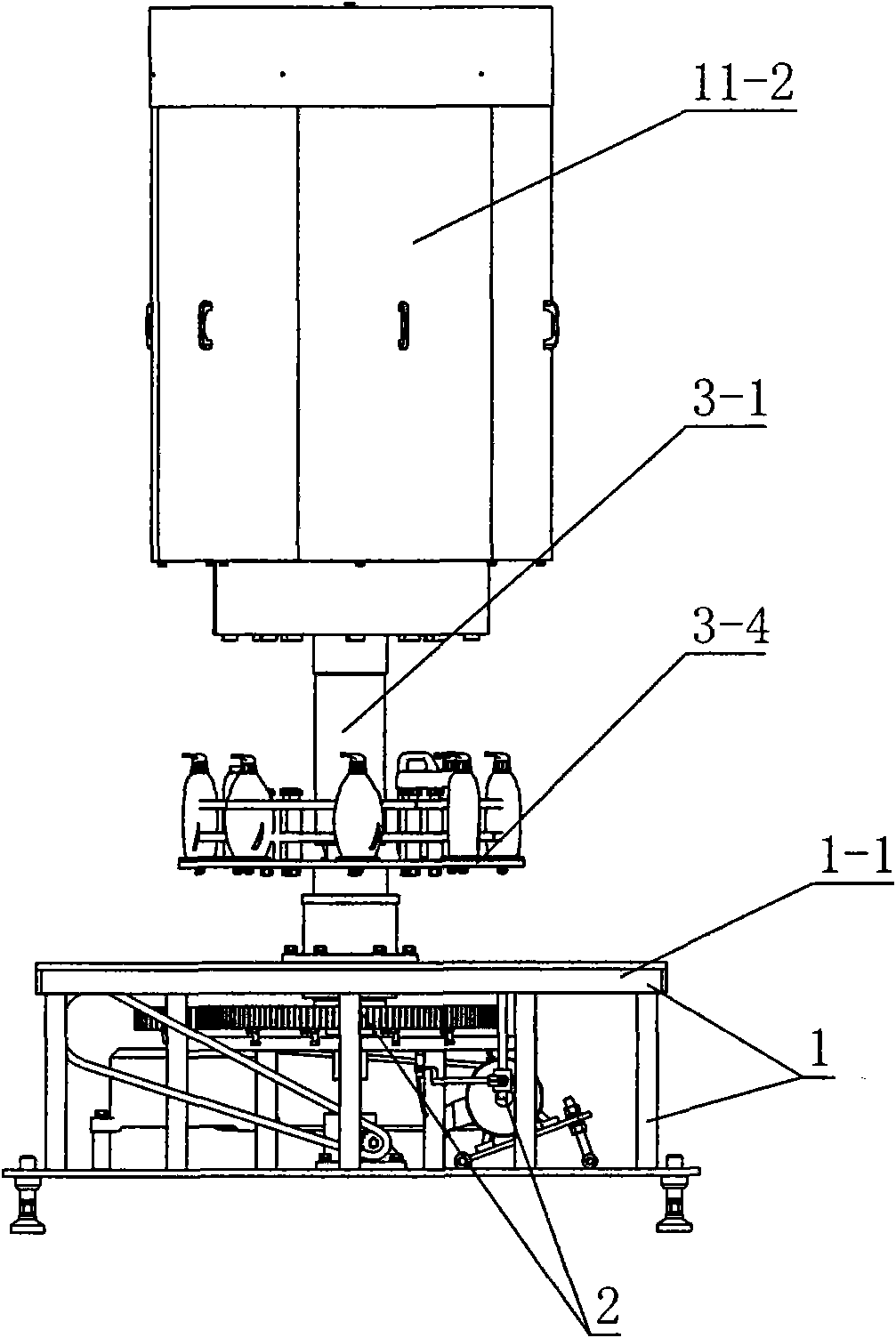

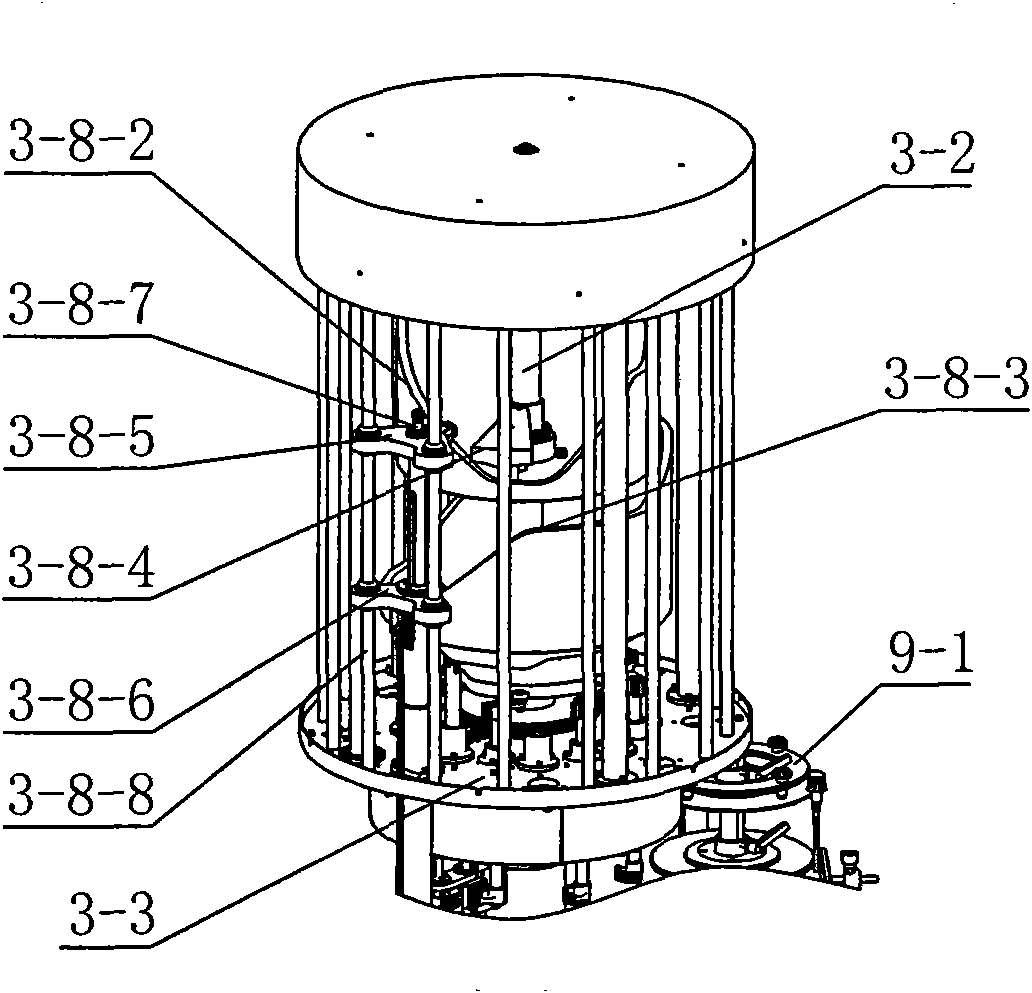

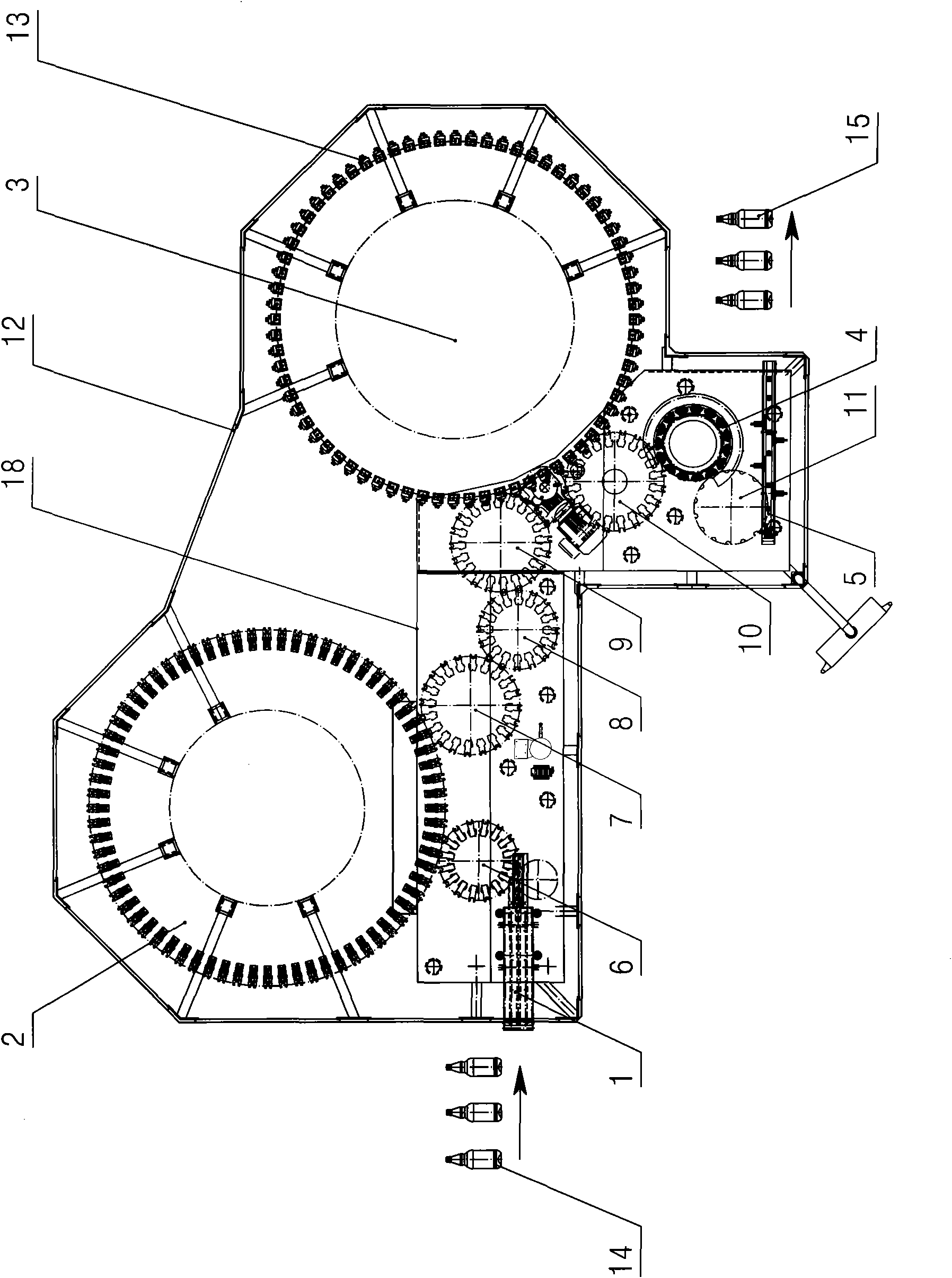

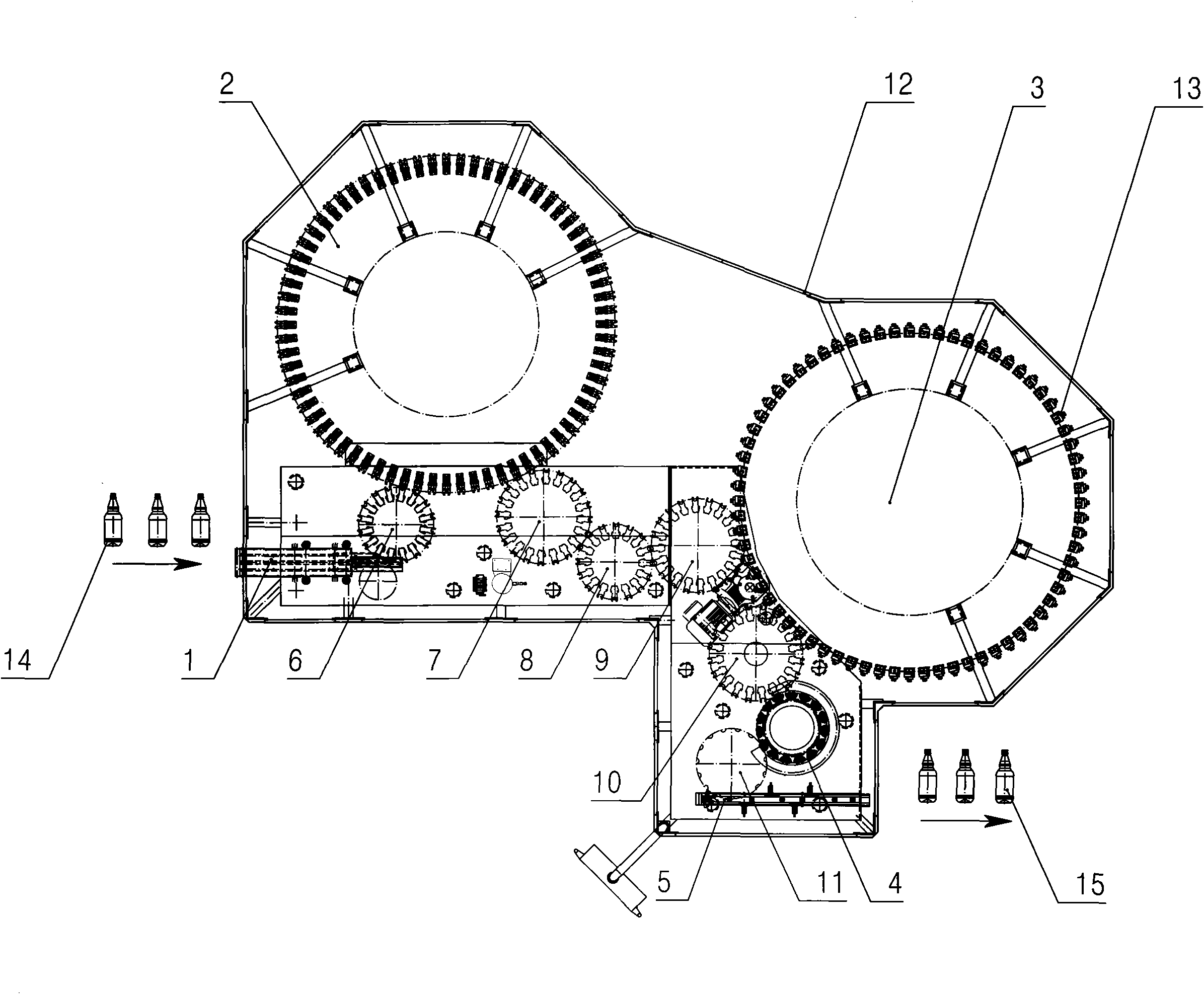

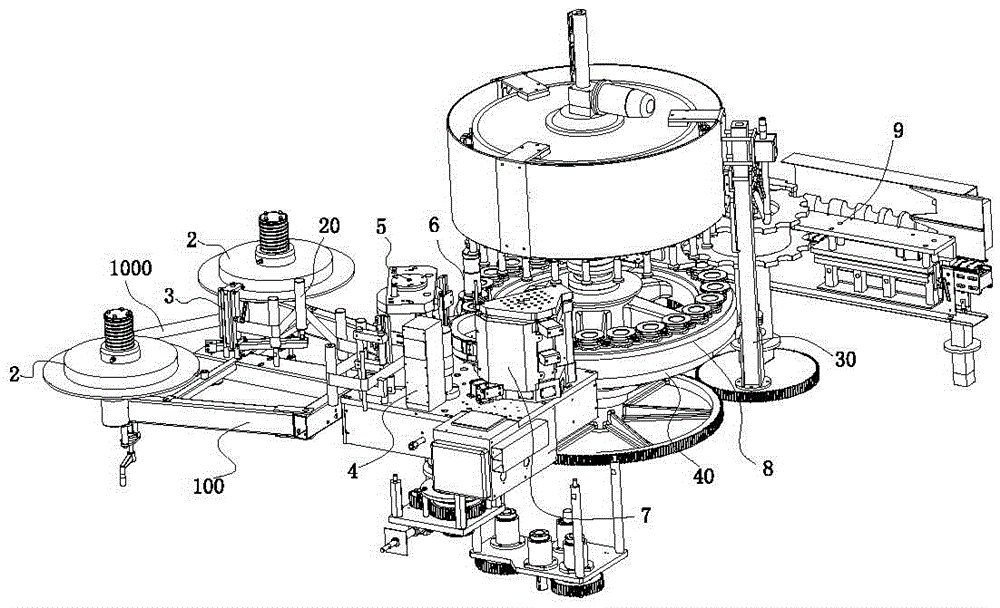

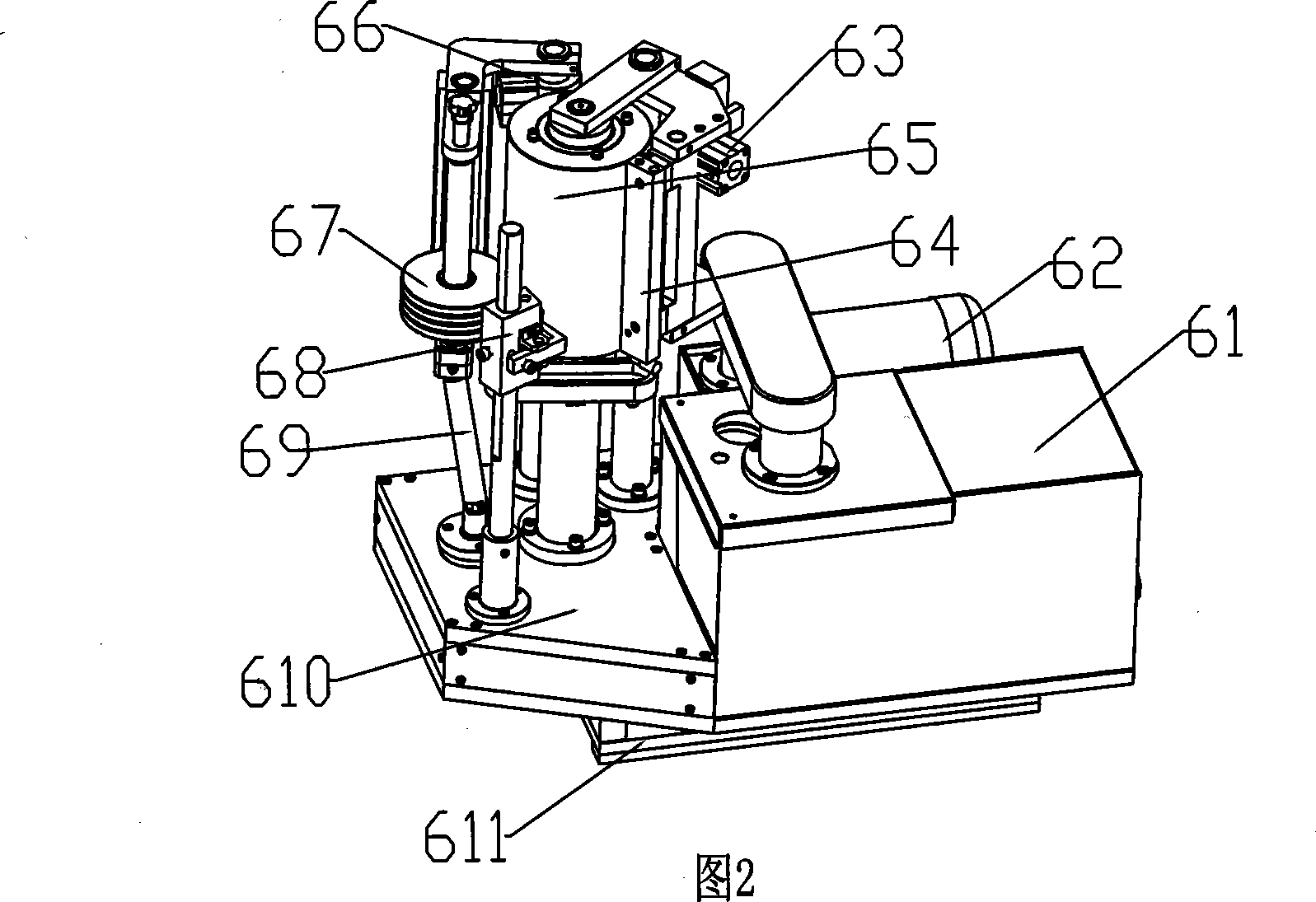

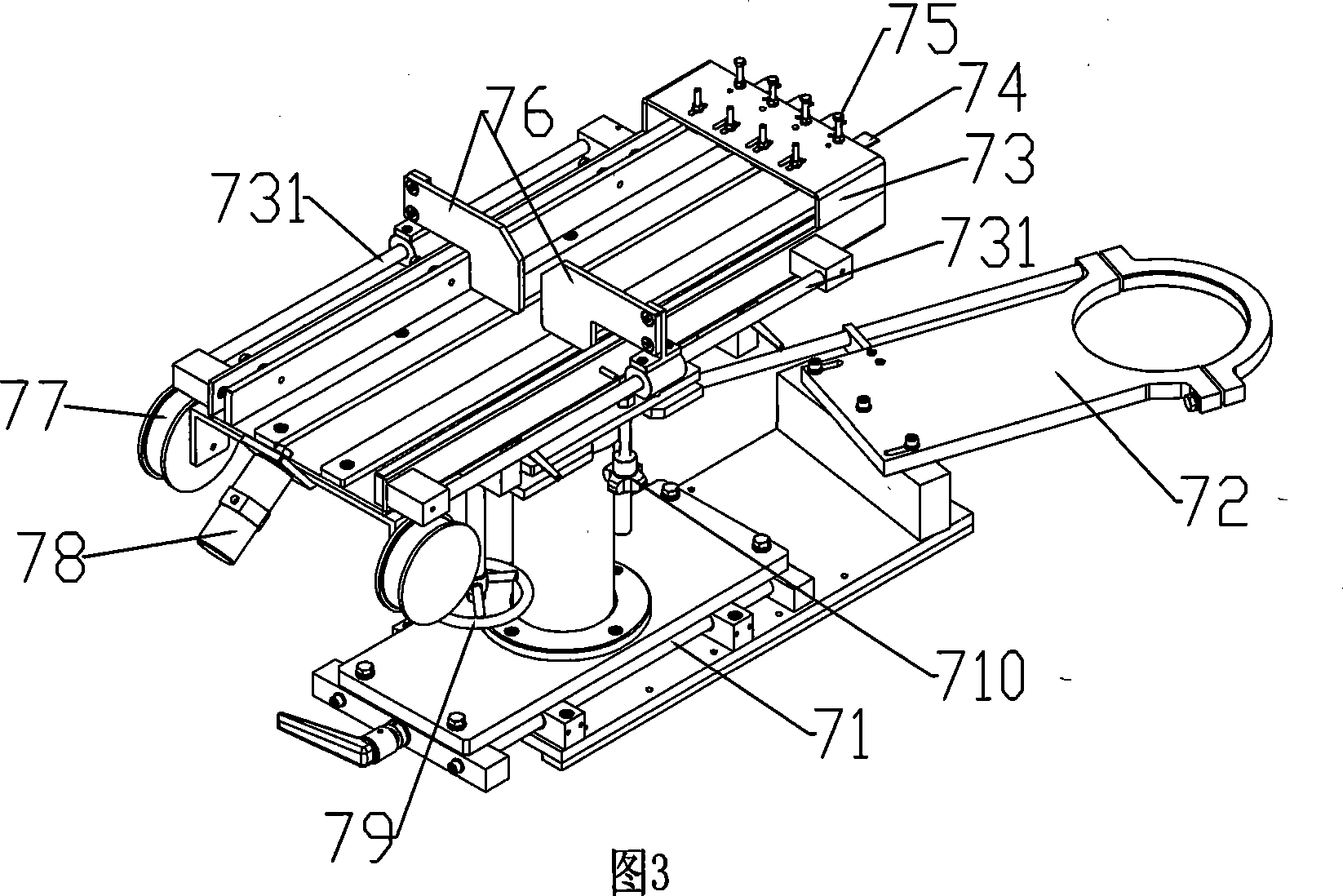

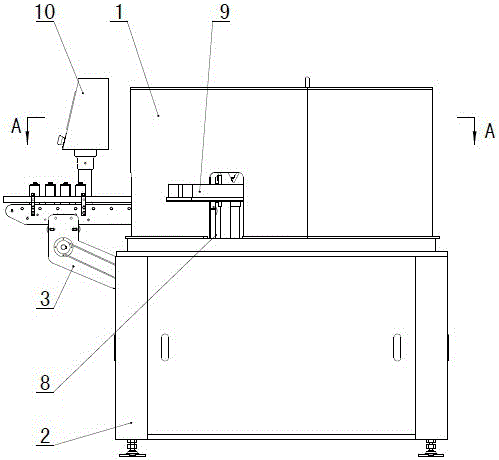

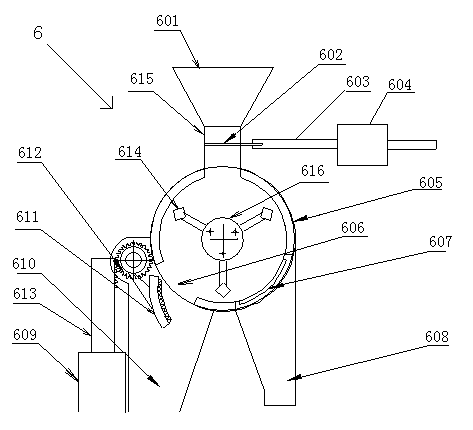

Full-automatic rotary capping machine

ActiveCN102336383ARealize automatic cappingCap screwing effect is goodCapsClosure using capsGear wheelEngineering

The invention relates to a packaging machine, in particular to a full-automatic rotary capping machine for capping a spraying pump bottle. The full-automatic rotary capping machine comprises a stand (1), a power driving device (2), a capping assembly (3), a bottle body supplying device (4), a bottle guiding device (5), a bottle feeding star wheel device (6), a bottle stopping device (7), a bottledischarging star wheel device (8), a cap supplying device (9) and a bottle outputting device (10), wherein the capping assembly (3) comprises a main shaft (3-1), an intermediate shaft (3-2), a rotarydisk (3-3), a bottle carrying plate (3-4), a clamping device (3-5), a capping disk (3-6), a gear wheel reversing and driving device (3-7), a cap grabbing device (3-8) and a capping assisting device (3-9); and the rotary disk (3-3) and the bottle carrying plate (3-4) are sleeved on the main shaft (3-1). The invention has the advantages of simple structure, high production efficiency, realization of automatically capping the spraying pump bottle and favorable capping effect.

Owner:CHANGZHOU HUITUO TECH

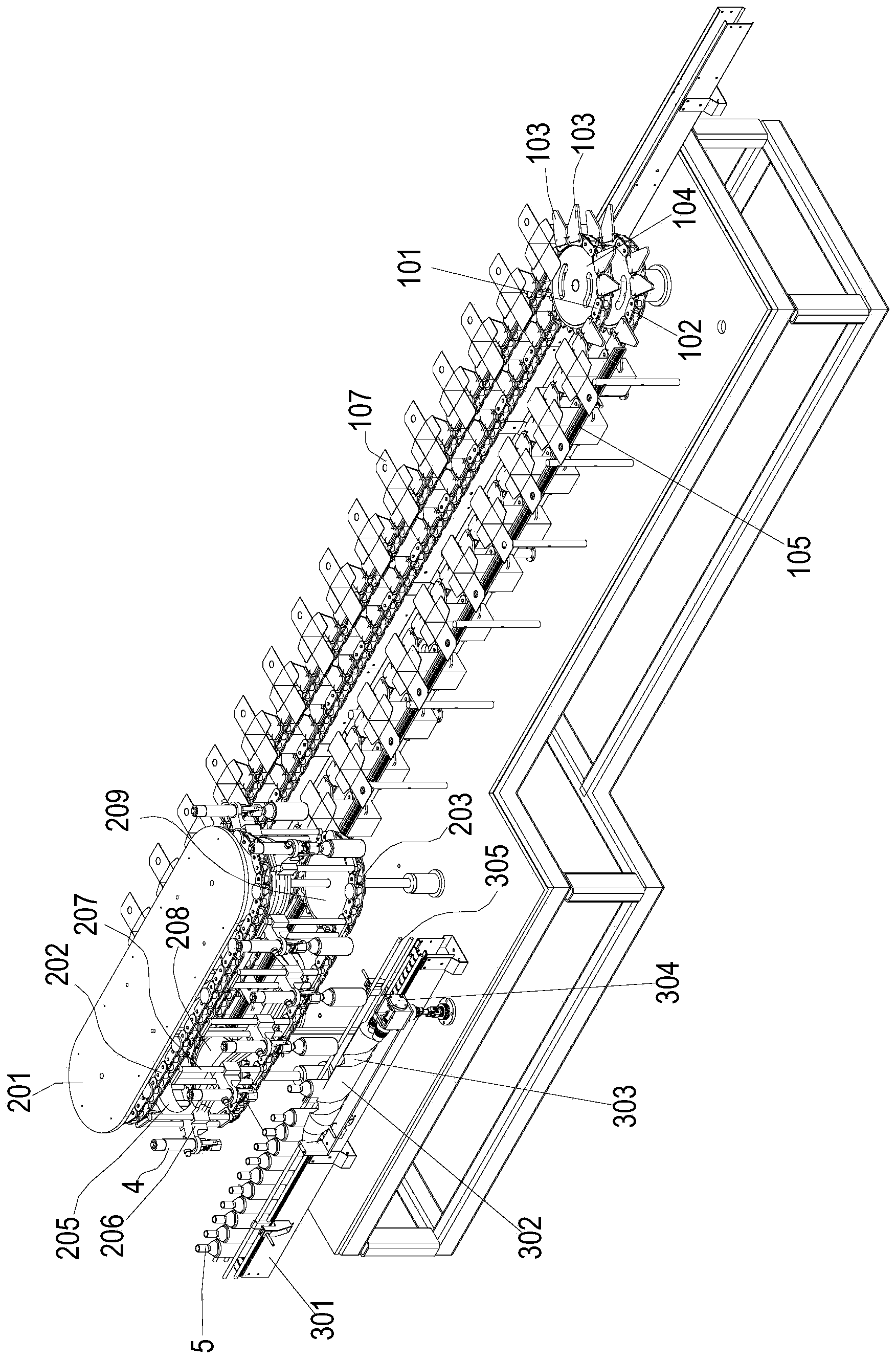

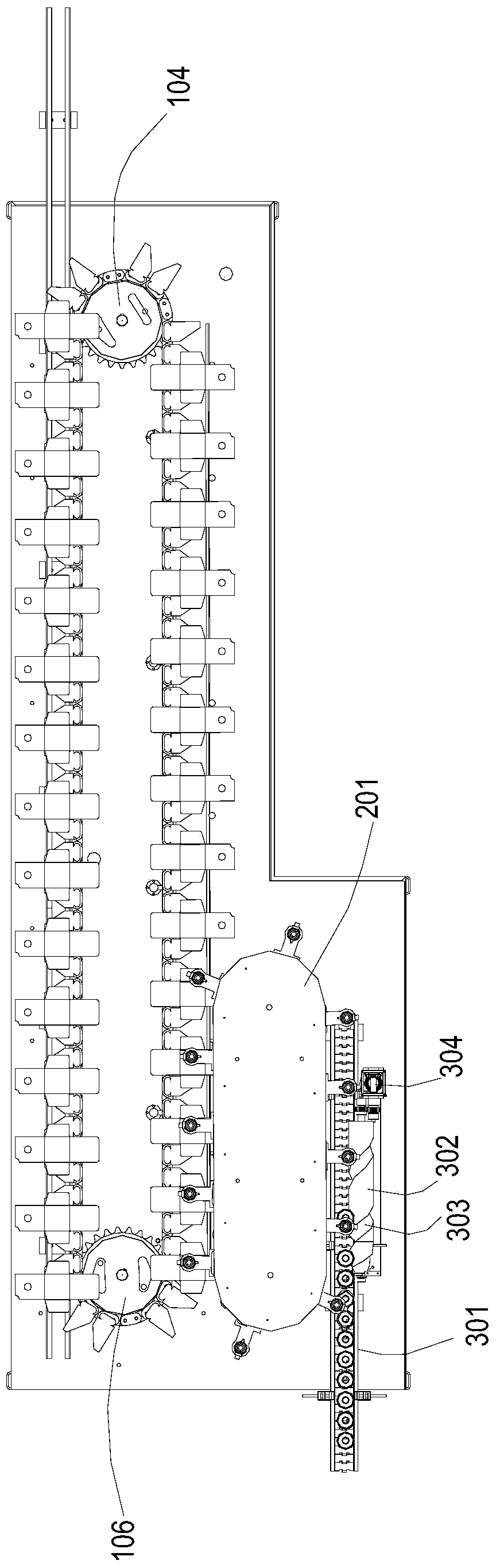

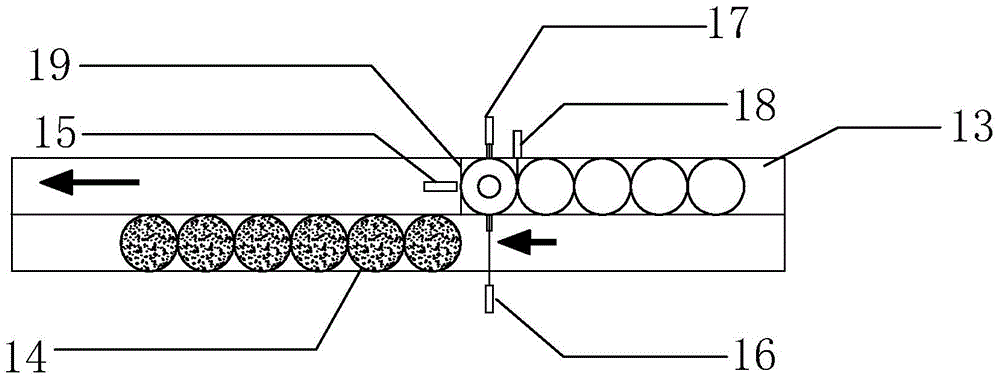

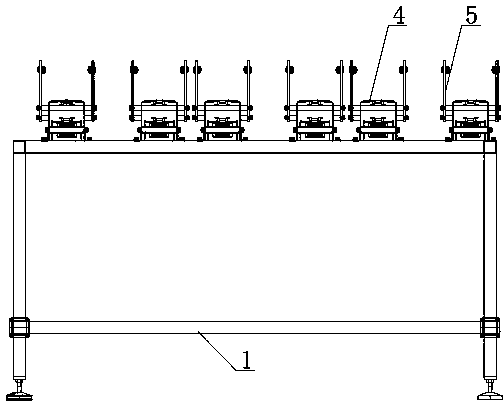

Medicinal glass bottle machine head conveying detection platform

The invention relates to a conveying detection system, and especially relates to a medicinal glass bottle machine head conveying detection platform. The platform comprises a conveyor belt main frame and the following components which are arranged on the conveyor belt main frame: a bottle feeding device, a bottle discharge device, a conveyor belt, a detection device, and a scrap bottle sorting device. A conveying synchronization ratchet and a conveyor belt driving wheel which cooperate with each other are arranged on one end of the conveyor belt. A pushing device is arranged on one side of the conveying synchronization ratchet. A conveyor belt driven wheel and a conveyor belt tensioning device are arranged on the other end of the conveyor belt. The detection device comprises a bottle inner diameter and outer diameter detection device and a bottle full height detection device which are sequentially arranged on the conveyor belt. The scrap bottle sorting device is arranged behind the detection device on the conveyor belt, and is electrically connected with the detection device. With the platform provided by the invention, product qualification rate is improved, manual detection labor intensity of a detection process is reduced, the structure is simple, and the cost is low.

Owner:肖特药品包装(浙江)有限公司

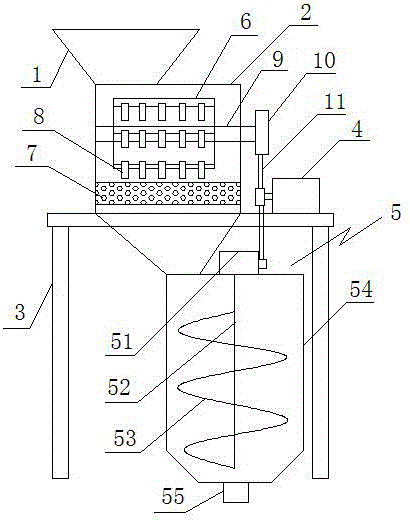

Automatic filling machine for filling of oil-prepared particle sauce material easy to layer

A disclosed automatic filling machine for filling of an oil-prepared particle sauce material easy to layer comprises a feeding mechanism, a stirring mechanism, a bottle feeding mechanism and a PLC controller, wherein the feeding mechanism comprises a feeding screw rod and a feeding servo motor driving the feeding screw rod to rotate, the stirring mechanism comprises two stirring paddles arranged in the material cylinder and a stirring motor driving the stirring paddles to stir, and the bottle feeding mechanism comprise a crawler belt device for conveying filling bottles. According to the automatic filling machine, during filling process, the sauce material is continuously stirred, so that the sauce material is always uniform, layering is avoided and the sauce material has relatively good fluidity; and by employing the feeding screw rod for quantitative feeding, the feeding uniformity and the filling precision accuracy are guaranteed, and the problems are solved that loaded oil-prepared particle sauce materials are bad in fluidity and slow in feeding speed.

Owner:FOSHAN HAITIAN GAOMING FLAVORING & FOOD +1

Liquid filling and sealing device

The liquid filling and sealing apparatus includes frame and successively connected bottle feeding mechanism, filling mechanism, cap regulating and setting mechanism, sealing mechanism and bottle discharging mechanism. Both the bottle feeding mechanism and the bottle discharging mechanism have bottle tracks fitting the size and shape of the bottles. Between the bottle feeding mechanism and the bottle discharging mechanism, one star turntable is set to connect the mechanisms in between and is rotated with a indexing cam mechanism. Compared with traditional filling and sealing machine, the present invention has simple and compact linkage between different work steps and stable and flexible bottle motion.

Owner:上海新特精密机械有限公司

Filling machine for beer packed by PET (polyethylene terephthalate) bottle

InactiveCN101823682AQuiet and smooth fillingReduce consumptionBottle-handling machinesPolyethylene terephthalateBottle neck

The invention discloses a filling machine for beer packed by PET (polyethylene terephthalate) bottles, which is suitable for PET bottles. The filling machine comprises a stand, a bottle feeding air flue, a bottle rinsing device, a filling device, a cap screwing device, a bottle discharging delivering chain, a transition bottle delivering device and a bottle discharging star wheel, wherein the bottle feeding air flue, the bottle rinsing device, the filling device, the cap screwing device and the bottle discharging delivering chain are arranged on the stand, the transition bottle delivering device connects the bottle feeding air flue, the bottle rinsing device, the filling device and the cap screwing device in series, and the bottle discharging star wheel connects the cap screwing device and the bottle discharging delivering chain together in series. The bottle rinsing device, the filling device, the cap screwing device and a bottle clamp in the transition bottle delivering device are all bottle-neck pincers, and a filling valve in the filing device is a long-tube filling valve. The invention is mainly used for filling beer packed by the PET bottles.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

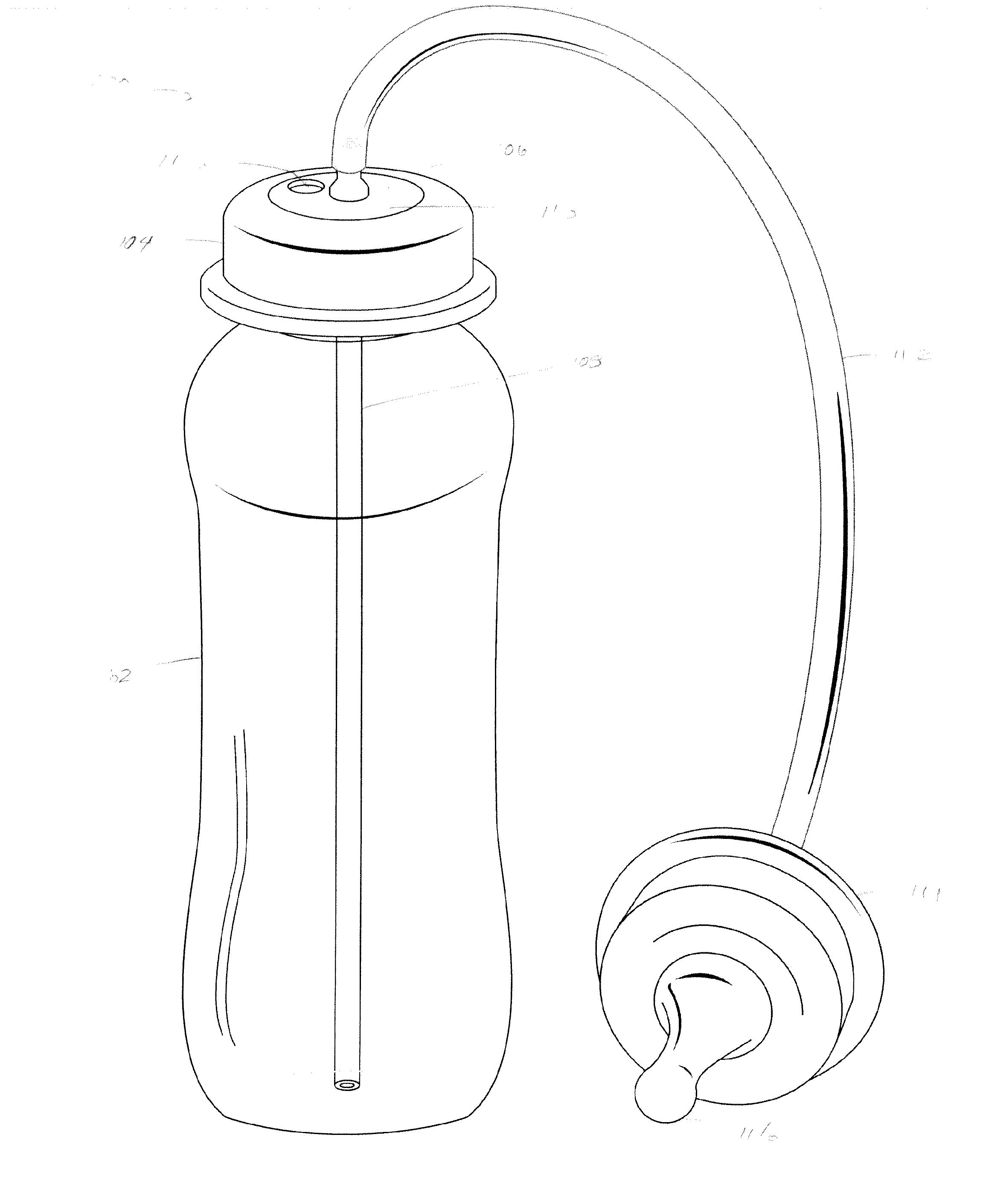

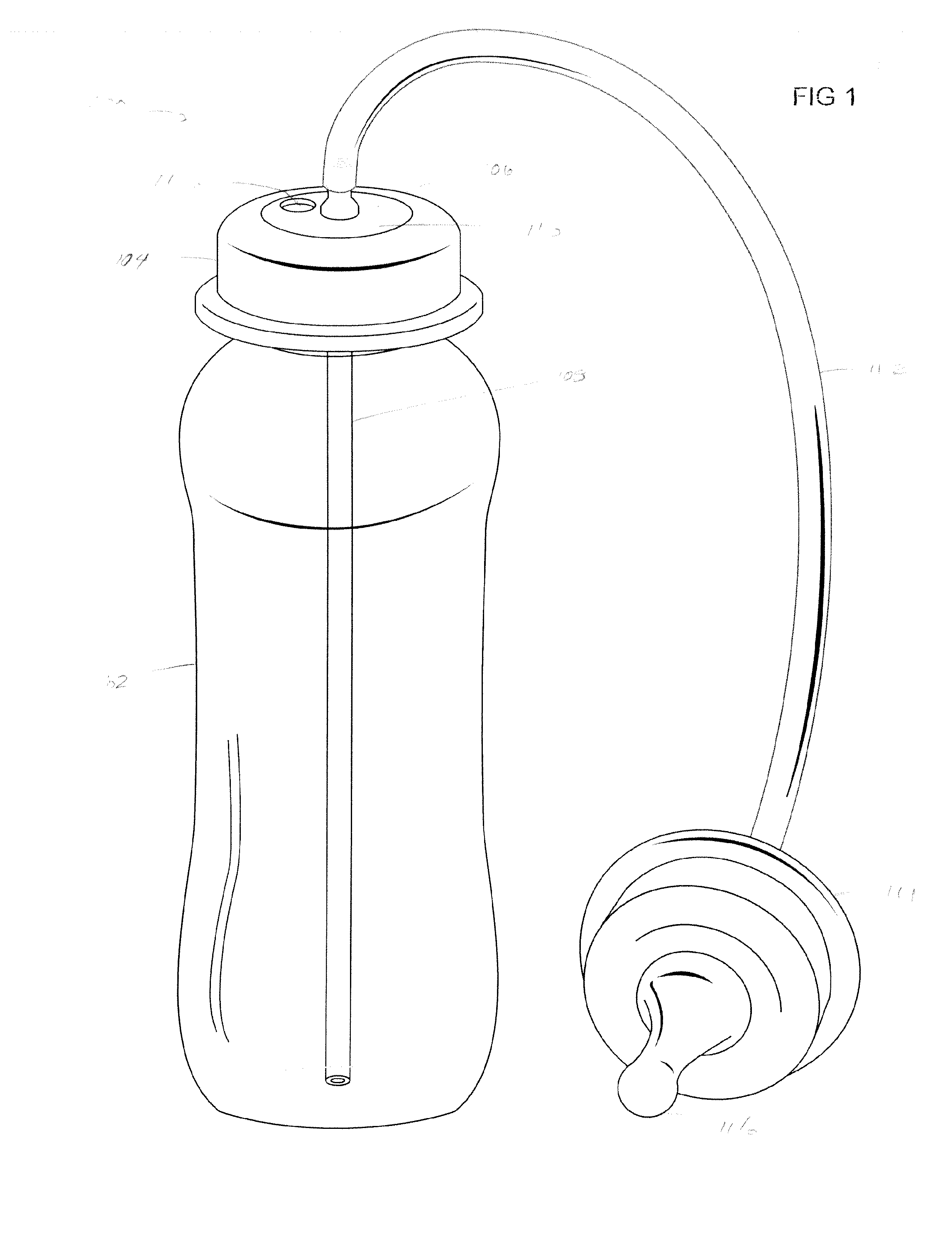

Modular feeding bottle

InactiveUS20110011819A1Easy to useComfortable to useDispensing apparatusFeeding-bottlesModularityEngineering

A modular feeding system assembled as an upright, hands-free feeding bottle or a traditional nurser bottle (which requires holding the bottle during feeding). The pressure equalization features of such an assembled device may have health benefits to the user or care giver. The other complementary, modular parts can be used to convert the bottle (or other suitable container) into a sippy cup or a sports bottle. The parts offer versatility in bottle feeding to the user, whether it is an infant, toddler, adult, elderly person or animal.

Owner:LEE KATHY GAYI

Rotary continuous lifting handle grabbing and pressing machine

The invention discloses a rotary continuous lifting handle grabbing and pressing machine which comprises a conveyer chain arranged on an underframe, a central supporting seat, a lifting handle storage groove, lifting handle releasing mechanism, a lifting handle separating disk and a transmission mechanism, wherein the a bottle feed mechanism and a bottle discharge mechanism are arranged on the lateral side of the conveyer chain; a central rotating spindle is arranged between the bottle feed mechanism and the bottle discharge mechanism; the upper end of the central rotating spindle is provided with a rotary disk; the rotary disk is fixed with a lifting handle grabbing mechanism; the lower end of the central supporting seat is installed on the rotary disk, and the upper end is used for supporting a top plate; a first cam is suspended below the top plate; the lifting handle grabbing mechanism is connected with the first cam; the underframe is also provided with a supporting guide rod; the upper end of the supporting guide rod locks the top plate; the lifting handle grabbing mechanism moves along a trajectory preset by the first cam; the lower part of the central rotating spindle is provided with a central transition star wheel, and the other side of the central transition star wheel meshes with the bottle discharge mechanism; the lifting handle storage groove, the lifting handle releasing mechanism and the lifting handle separating disk are used for feeding lifting handles; and the top plate is also connected with a gas source distributor. The invention enhances the work efficiency and lowers the cost of manpower.

Owner:广州俊升轻工机械有限公司

High-speed hot melt glue labeling machine

ActiveCN106742473AReliable cut-off deliveryReliable labeling actionLabelling machinesAgricultural engineeringHot melt

The invention discloses a high-speed hot melt glue labeling machine. The machine comprises a frame, a label disc, an automatic label receiving device, a label feeding device, a label cutting device, a labeling wheel device, a rubber roller device, a bottle support device, a bottle feeding device and a bottle discharge device; the automatic label receiving device includes two pivoted label receiving frames, a guide roller, a label cutting mechanism and a label receiving mechanism; the label cutting device includes a label cutting frame, a label cutting cylinder, a label cutting driving mechanism, a rotating movable cutter and a fixed cutter; the labeling wheel device includes a labeling wheel base, a labeling wheel shaft, a labeling wheel and a labeling wheel driving mechanism; the labeling wheel base is fixed on a support frame; the labeling wheel shaft penetrates through the labeling wheel base; the labeling wheel is mounted at the upper end of the labeling wheel shaft, and is near the label cutting cylinder; and a second vacuum hole is formed in the labeling wheel. The labeling machine can realize automatic label reception under the condition of no stop, can continuously work, realizes automatic production, and can reliably cut and convey labels to realize reliable labeling action.

Owner:广州市万世德智能装备科技有限公司

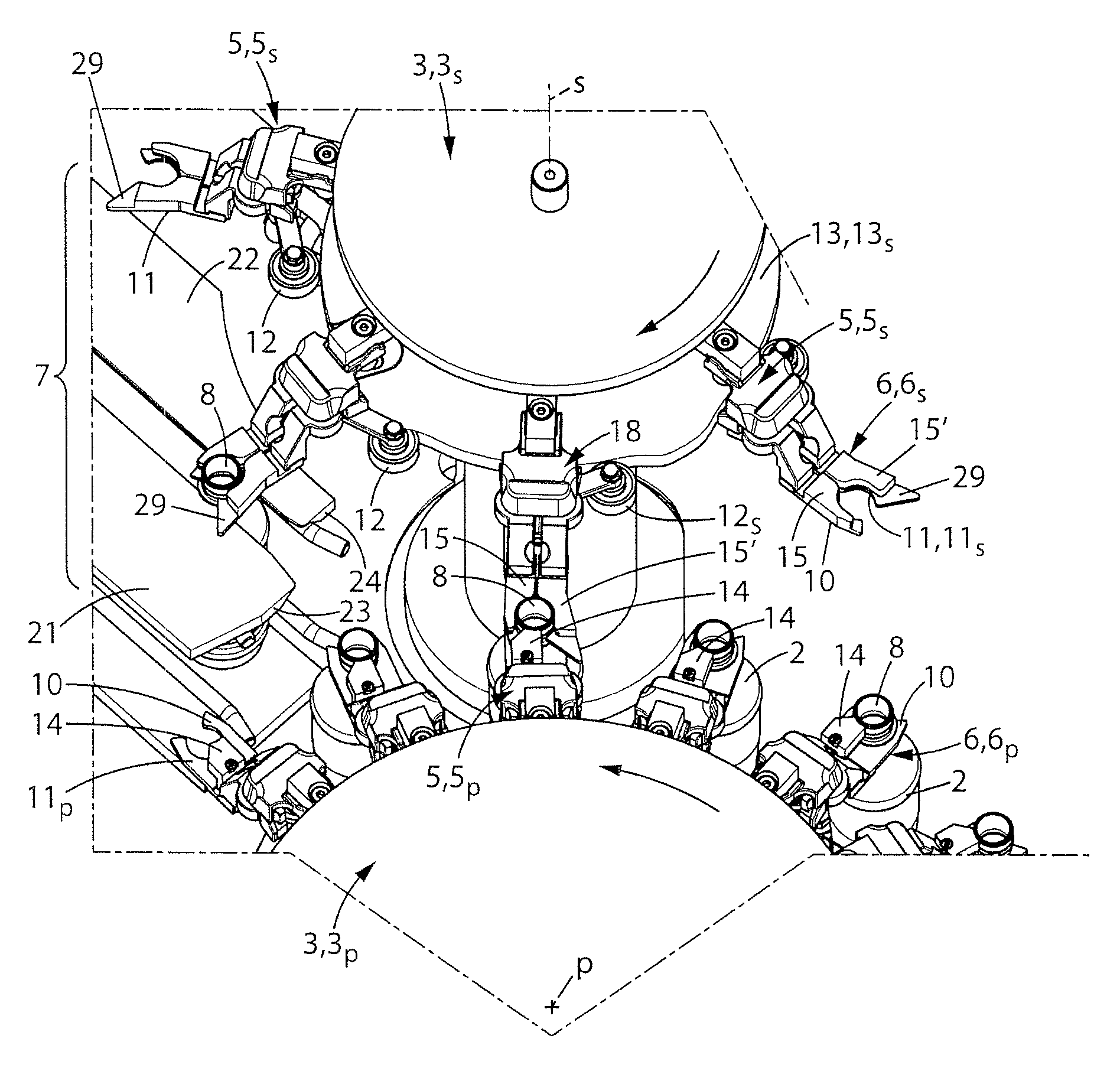

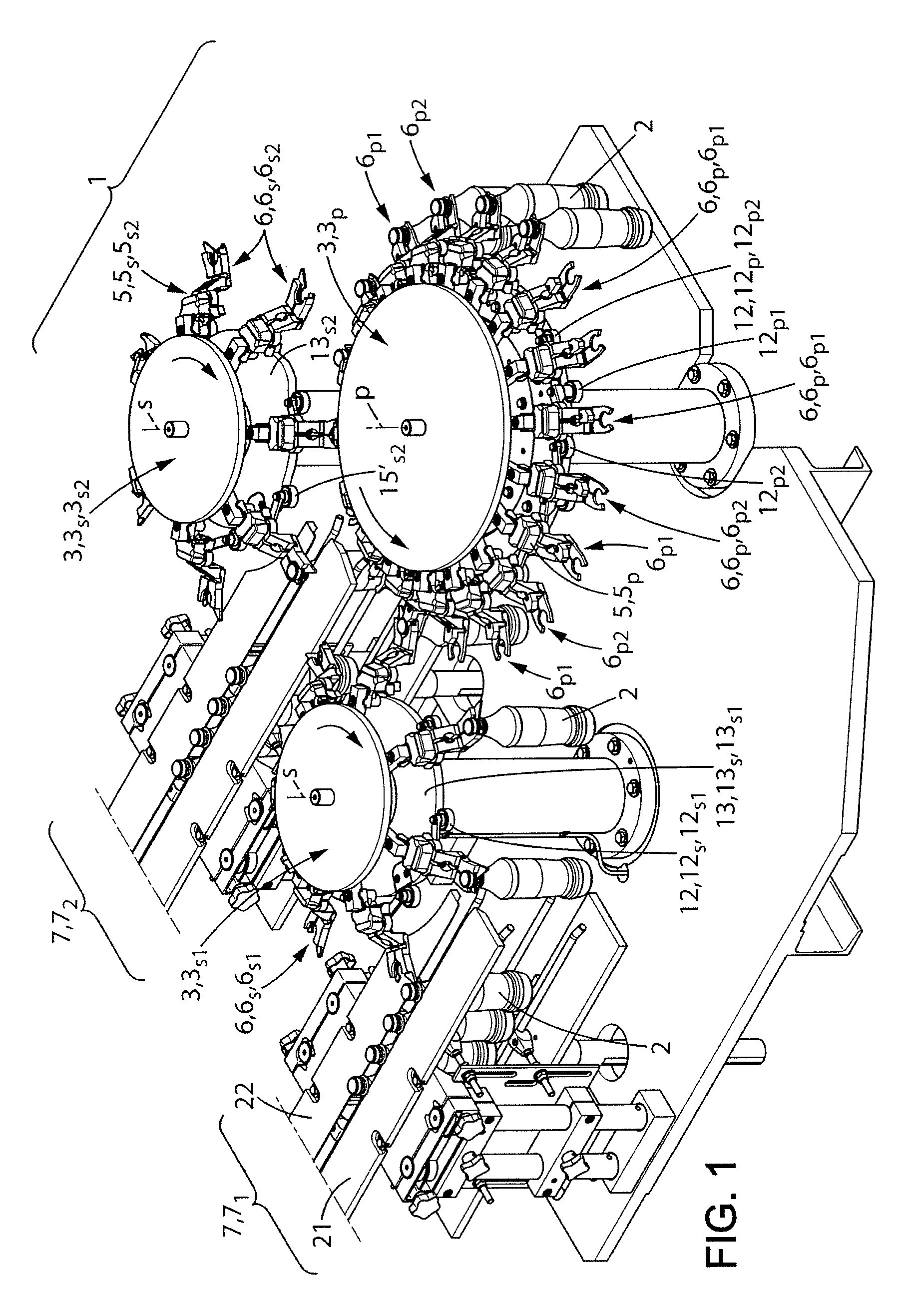

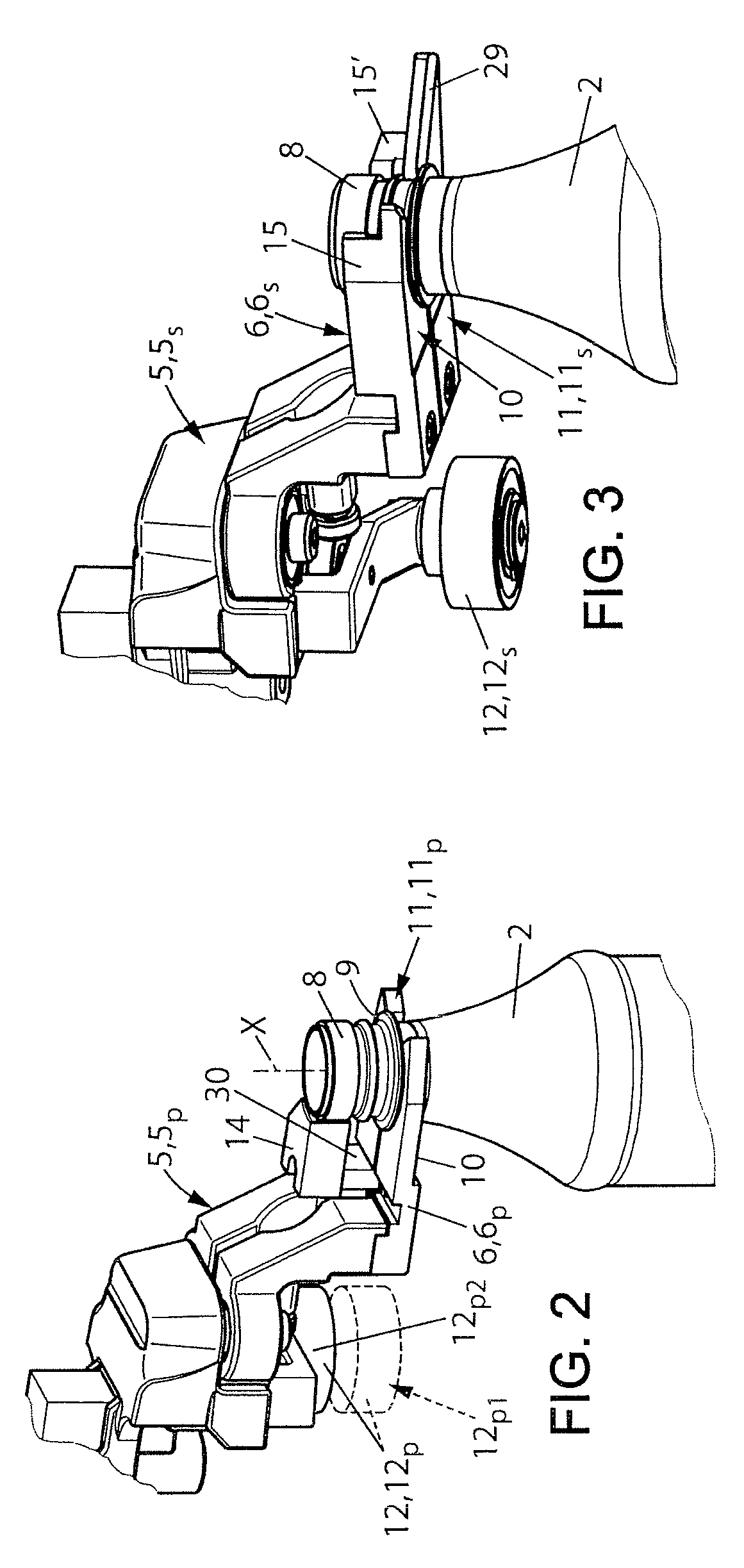

Vessel conveying device separating a main vessel flow into a plurality of secondary flows

InactiveUS8307977B2Simplify the bottle circuitEnsure reliabilityCharge manipulationConveyor partsBottleMain vessel

The invention relates to a device for conveying vessels of the bottle type, characterized in that it comprises: a primary wheel for conveying the bottles including a plurality of transfer arms; at least two secondary conveying wheels respectively capable of conveying the bottles fed by the primary wheel; the conveying path of the bottles grasped by the clamps of the transfer arms of each secondary wheel being at one point tangential to the conveying path of the bottles grasped by the transfer arms of the primary wheel, whereby the main flow of bottles conveyed by the primary wheel is divided into at least two secondary flows of bottles respectively conveyed by the secondary conveying wheels.

Owner:SIDEL PARTICIPATIONS SAS

Hot-melt adhesive brander

InactiveCN101456459AReduce manufacturing costSmall footprintLabelling machinesLabelling short rigid containersManufacturing cost reductionEngineering

The invention discloses a hot melt adhesive labeler, which comprises a machine frame, a gyratory part, a labeling part and a corresponding control part, wherein the gyratory part comprises a bottle input and output chain channel, a bottle feeding screw, a bottle stopping star wheel, a bottle input star wheel, a central guide plate, a bottle output star wheel, a bottle holder turnplate, a bottle holding component and a bottle positioning component which accurately position a bottle on the bottle holder turnplate; the bottle holding component is provided with a bottle rotating mechanism for driving the bottle to rotate around the axial line of the bottle according to certain rotating speed; and the central guide plate is arranged between the bottle feeding star wheel and the bottle output star wheel and the side of the bottle holder turnplate. The labeler is characterized in that the labeling part comprises front rubber roll devices which are sequentially arranged on the bottle holder turnplate side, are tangent to a rotary bottle, and roll adhesive on the bottle body, a label box device used for placing the pre-cut strip label paper and a small rubber roll device rolling adhesive on the tail part of the label paper, wherein the front rubber roll devices are arranged between the label box device and the bottle input star wheel. The labeler has the advantages of reducing the manufacturing cost and occupied space.

Owner:广州市万世德智能装备科技有限公司

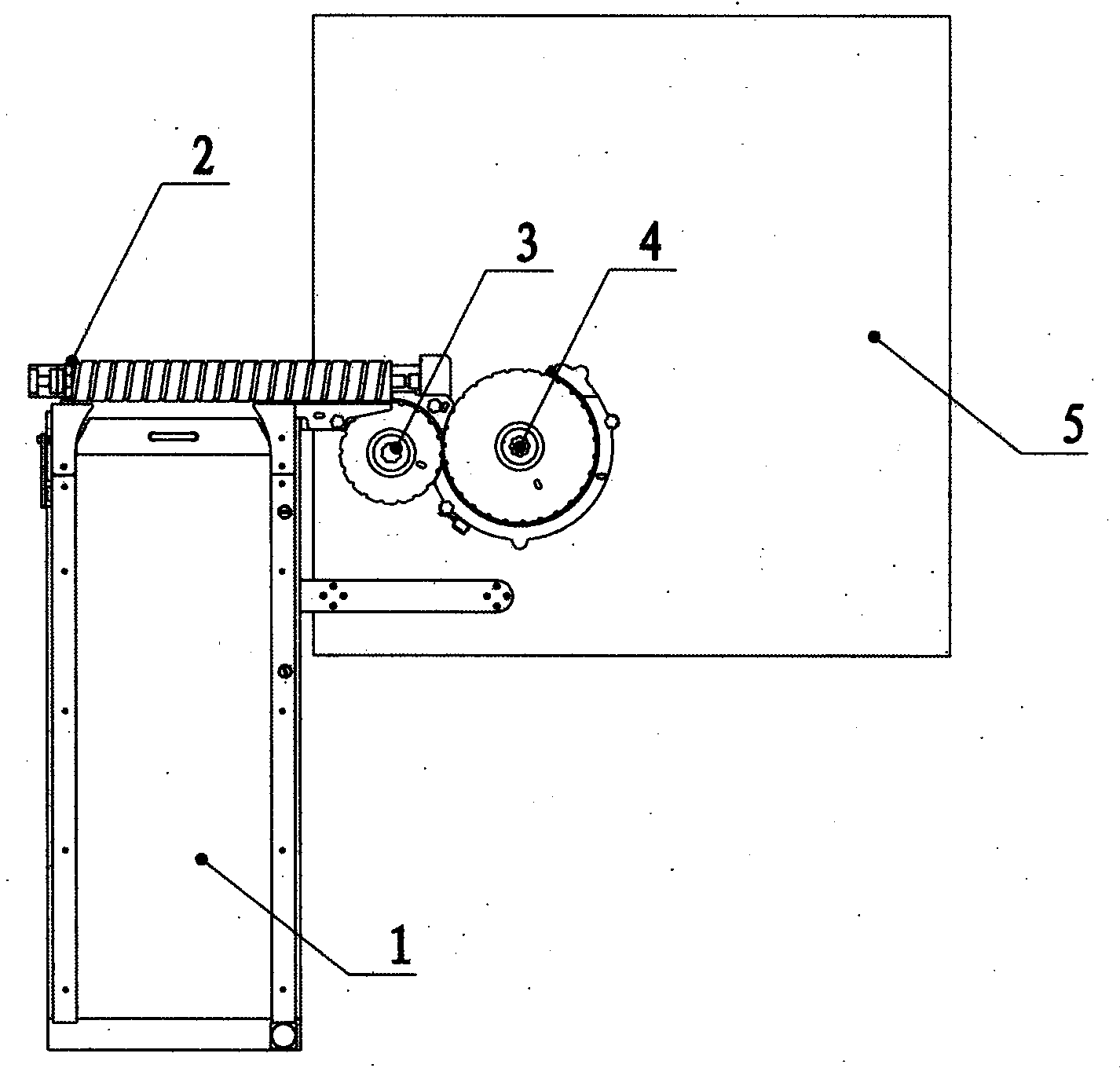

Ampoule bottle feeding device used for light examining machine

InactiveCN103508168AImprove installation positioning accuracyEasy to replaceOptically investigating flaws/contaminationMechanical conveyorsScrew systemEngineering

The invention provides an ampoule bottle feeding device for a light examining machine. The ampoule bottle feeding device is characterized by comprising a feeding conveyor belt system, a screw system, a screw matching star wheel system and a head detection star wheel system. The feeding conveying system and the screw matching star wheel system are arranged on one side of the screw system. The screw matching star wheel system comprises a first star wheel, the head detection star wheel system comprises a second star wheel, and the first star wheel is meshed with the second star wheel. Due to the adoption of the ampoule bottle feeding device, ampoule bottles which are manually well collected and loaded to a tray can be stably and quickly conveyed to a main shaft system of the light examining machine one by one to be automatically examined.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

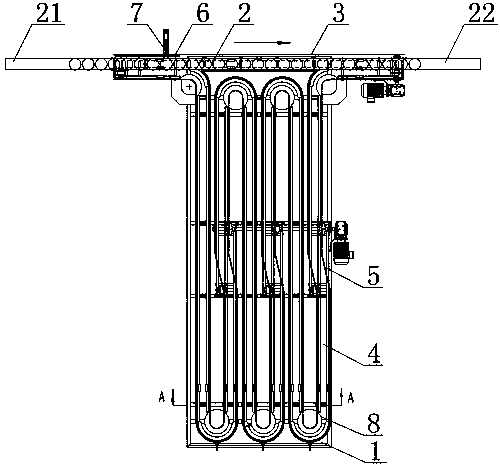

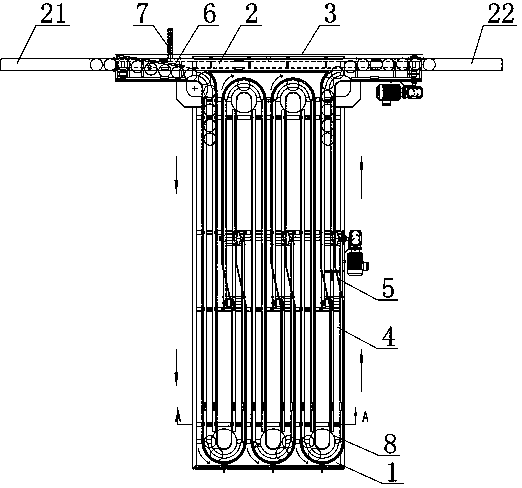

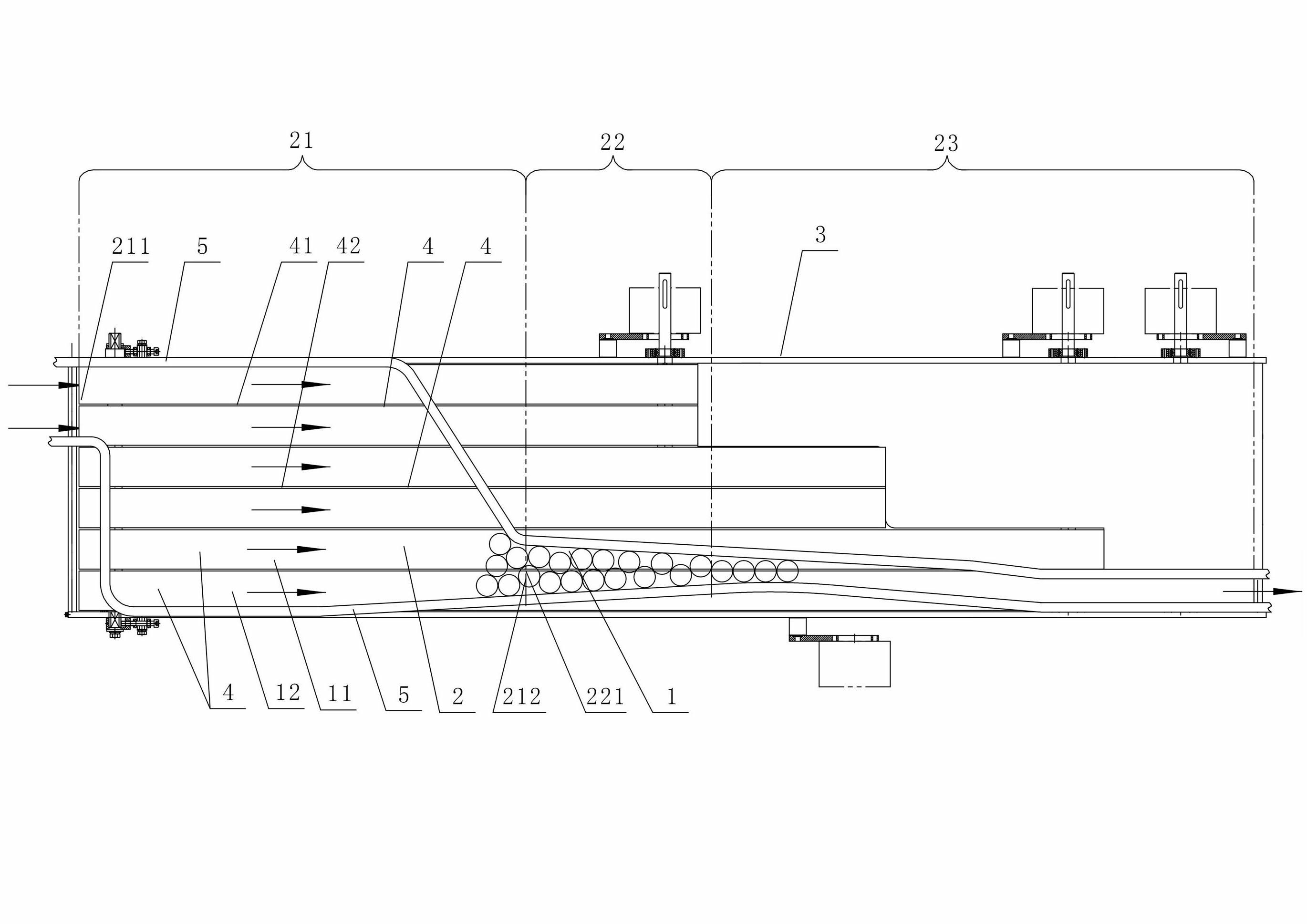

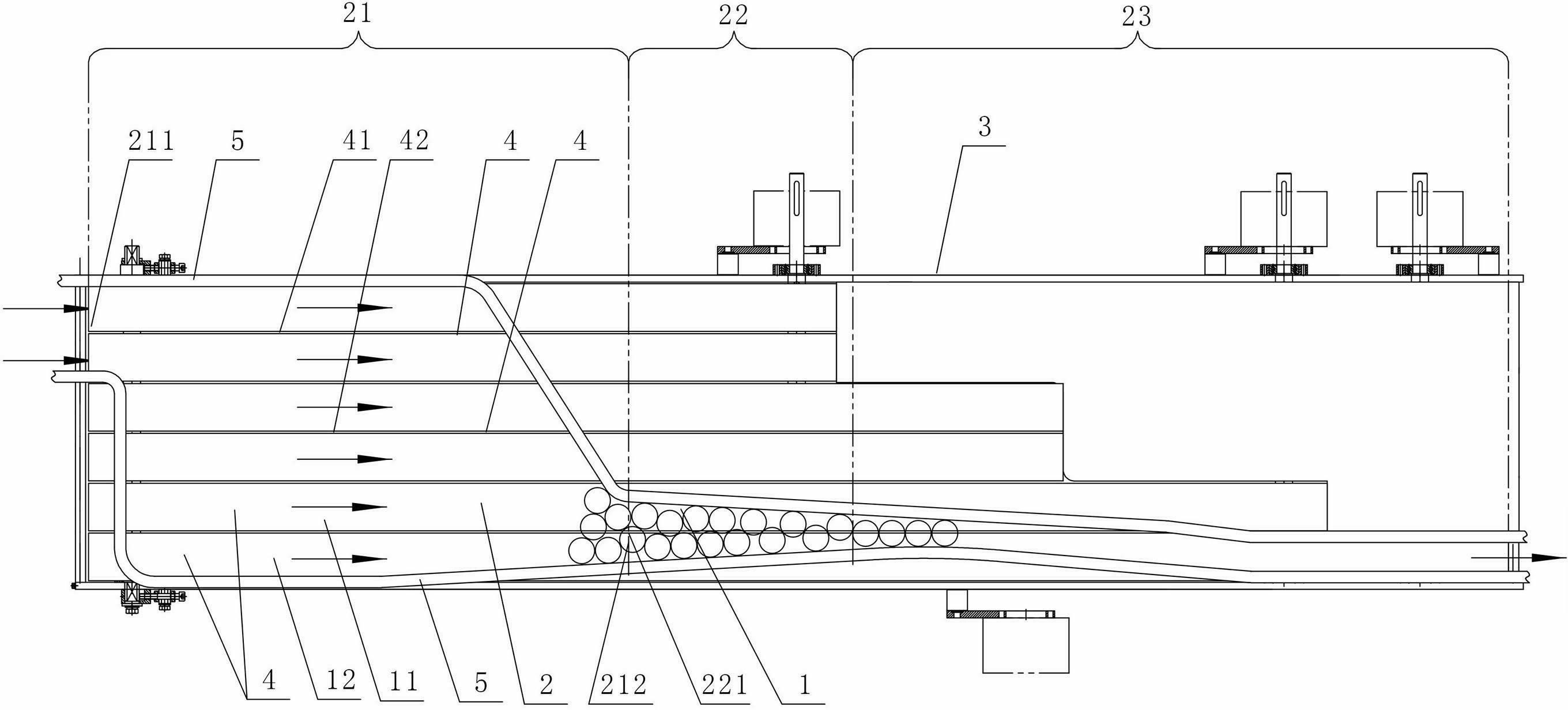

Conveying channel provided with buffering bottle-storage mechanism and arranged between bottle blowing machine and filling machine

The invention discloses a conveying channel provided with a buffering bottle-storage mechanism and arranged between a bottle blowing machine and a filling machine. The conveying channel comprises the buffering bottle-storage mechanism arranged on one side of a conveying chain board, wherein the buffering bottle-storage mechanism structurally comprises a buffering bottle-storage chain board which is arranged on an installation frame on one side of the conveying chain board and used for conveying bottles in a reciprocating and roundabout mode in the direction far away from the conveying chain board and the direction close to the conveying chain board, the bottle feeding end and the bottle discharging end of the buffering bottle-storage chain board are bent in an arc mode and communicated with the end portion of the bottle feeding end of the conveying chain board and the end portion of the bottle discharging end of the conveying chain board respectively, the buffering bottle-storage chain board is used for conveying bottles from the bottle feeding end of the buffering bottle-storage chain board to the bottle discharging end of the buffering bottle-storage chain board, and buffering bottle-storage guardrails are arranged at the positions, on two sides of the buffering bottle-storage chain board, of the installation frame; a guide baffle is further arranged on the outer side of the end portion of the bottle feeding end of the conveying chain board, and a driving device drives the guide baffle to be capable of enabling bottles entering from the bottle feeding end of the conveying chain board to be guided to the buffering bottle-storage chain board. The conveying channel has the advantages that after the filling machine is switched off, all bottles remaining in the bottle blowing machine can be discharged.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

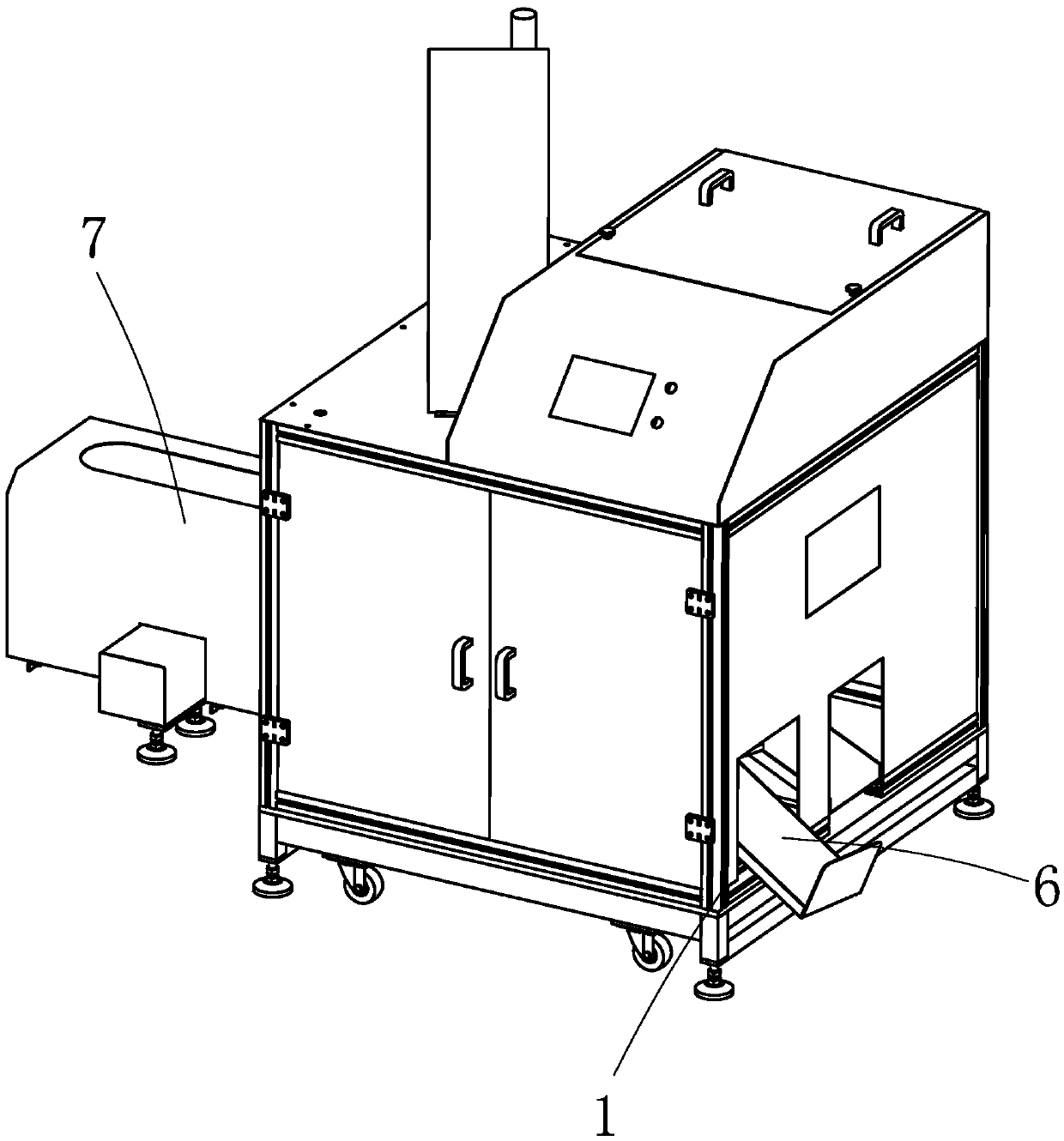

Full-automatic chemiluminescence reagent bottle cleaning machine

ActiveCN106111646AReduce the risk of contaminationEasy to cleanHollow article cleaningDrying gas arrangementsBiochemical engineeringFood packaging

The invention provides a full-automatic chemiluminescence reagent bottle cleaning machine and relates to the technical field of pharmaceutical machinery and food packaging machinery. The full-automatic chemiluminescence reagent bottle cleaning machine comprises a machine frame (2) and multiple groups of cleaning mechanisms. A rotating disk (5) is fixed to the upper side of the machine frame. The rotating disk (5) is connected with a main transmission device driving the rotating disk to rotate. Multiple rotating disk mechanical arms are arranged on the circumference of the rotating disk (5). A bottle feed conveying device (3) and a bottle discharge conveying device (9) are further fixed to the machine frame (2). The rotating disk mechanical arms receive reagent bottles on the bottle feed conveying device (3) and enable the openings of the reagent bottles to be downward. The multiple groups of cleaning mechanisms are annularly arranged around the outer side of the circumference of the rotating disk (5). The cleaning mechanisms comprise internal cleaning mechanisms (6) and external cleaning mechanisms (7), wherein the internal cleaning mechanisms (6) clean the inner walls of the reagent bottles, and the external cleaning mechanisms (7) clean the outer walls of the reagent bottles. The bottle discharge conveying device (9) receives the cleaned reagent bottles. The full-automatic chemiluminescence reagent bottle cleaning machine is simple in structure, reliable in work, stable in cleaning effect and high in cleaning efficiency, achieves full-automatic cleaning and lowers the contamination risk of the reagent bottles.

Owner:SHINVA MEDICAL INSTR CO LTD

Intermittent rotary type plastic bottle cleaning machine

ActiveCN1522803AEliminate return timeEasy to cleanHollow article cleaningDrive wheelIntermittent motion

The present invention relates to a gap rotary plastic bottle washing machine. It includes bottle-conveying guideway whose periphery is equipped with spiral groove, auger bottle-feeding mechanism positioned in the front of bottle-feeding driving wheel and bottle-discharge driving wheel, it also includes air-washing mechanism, water-washing mechanism, and turning mechanism. Said invention also provides their connection relationship. Its washing effect is good and production efficiency is high.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

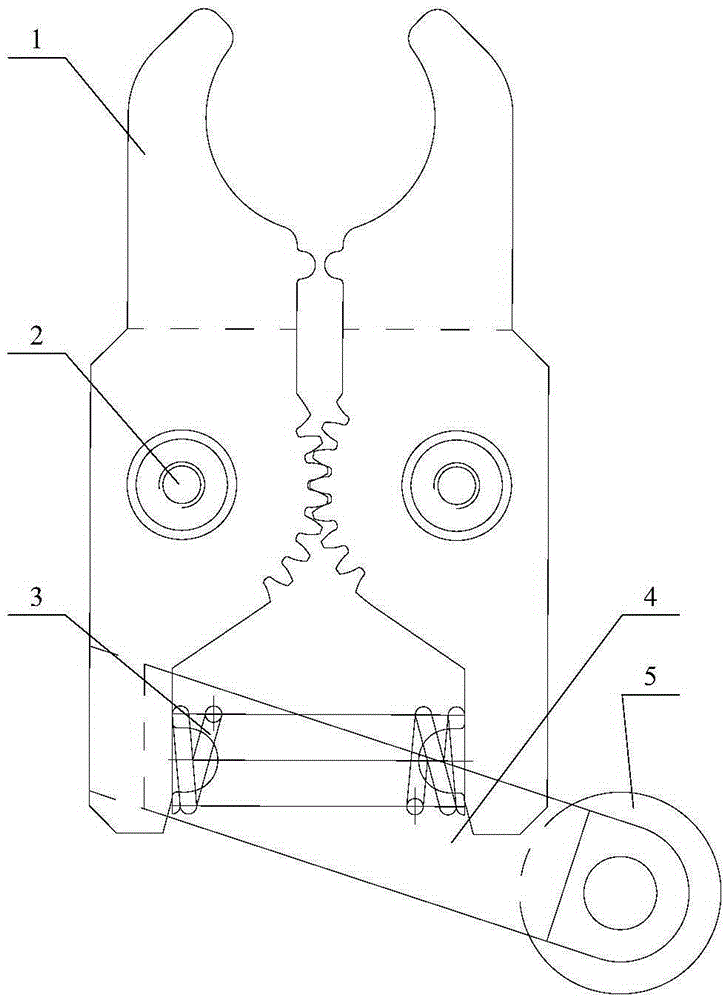

Bottle clamping mechanical arm

InactiveCN105252541ANot easy to wearAvoid dropping bottlesGripping headsHollow article cleaningIndependent motionReciprocating motion

The invention discloses a bottle clamping mechanical arm. The bottle clamping mechanical arm comprises a swing frame, a sliding block and a mechanical arm, wherein the swing frame is used for fixing the mechanical arm on a bottle feeding device of a bottle washing machine; the sliding block is arranged on the swing frame in a sliding manner; a reset device is arranged between the swing frame and the sliding block; a push rod is arranged on the sliding block; the mechanical arm comprises a left clamping arm and a right clamping arm which are rotatably arranged on the swing frame; the left clamping arm and the right clamping arm comprise driving ends and clamping ends which are positioned at the two sides of the per se rotation axes; sliding chutes are arranged at the driving ends of the left clamping arm and the right clamping arm; the push rod is inserted into the sliding chutes of the left clamping arm and the right clamping arm and is used for driving the opening and closing of the clamping ends of the left clamping arm and the right clamping arm through the reciprocating motion of the sliding block; the left clamping arm and the right clamping arm independently move under the driving of the push rod, the engagement relationship in the prior art does not exist between the left clamping arm and the right clamping arm, and the left clamping arm and the right clamping arm are unlikely to wear in a movement process, are long in service life and low in using cost; the left clamping arm, the right clamping arm and the push rod form an interlocking structure, which can provide stable clamping force and avoid bottle falling caused by vibration in a bottle body overturning process. The invention also discloses a bottle washing assembly line.

Owner:长沙汇一制药机械有限公司

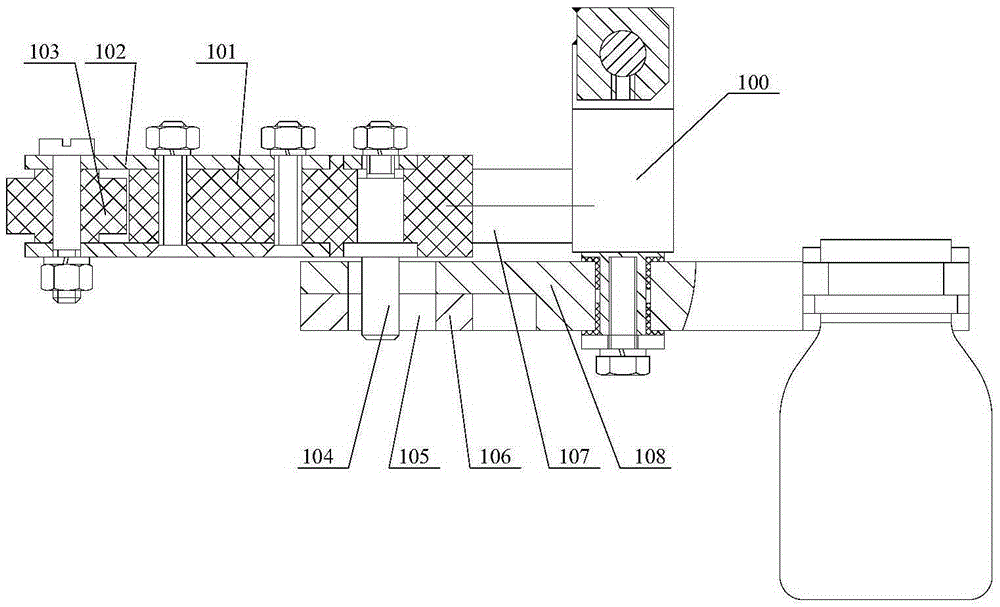

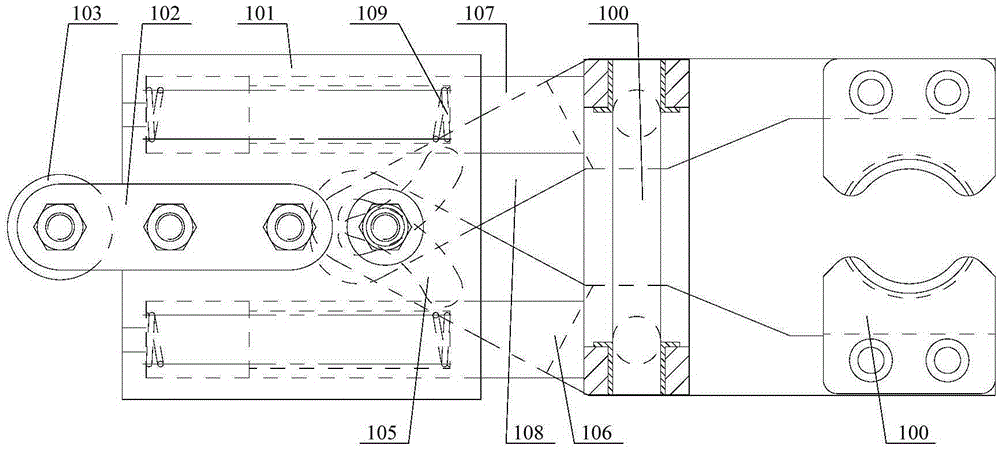

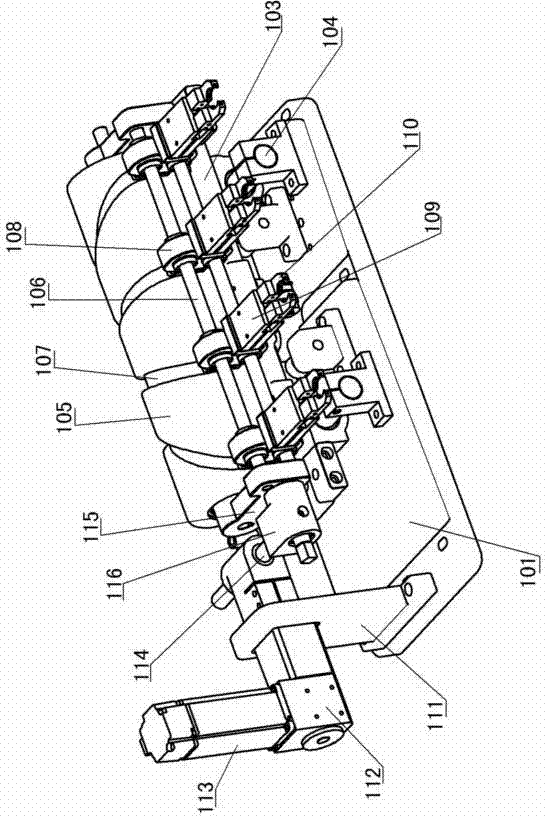

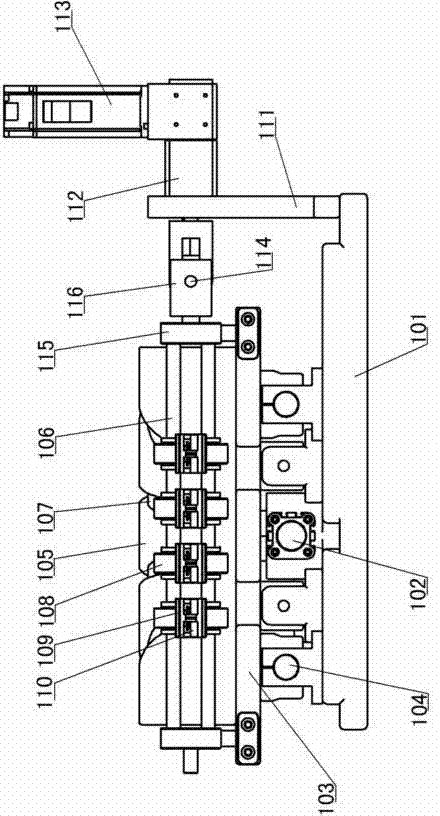

Capping device for filling container

ActiveCN102935990ASimple structureImprove work performanceFlanged caps applicationEngineeringWork Performances

The invention discloses a capping device for filling a container. The capping device for filling the container comprises a capping mechanism, a horizontal servo mechanism and a perpendicular servo mechanism, wherein the perpendicular servo mechanism is arranged on the horizontal servo mechanism and can do shift movement in a horizontal direction along with the horizontal servo mechanism, and the capping mechanism is arranged on the perpendicular servo mechanism and can do shift movement in a vertical direction along with the perpendicular servo mechanism; and the capping device for filling the container simultaneously adsorbs multiple covers through a negative pressure adsorbing technology so as to realize capping operation for containers of the same quantity, thereby meeting the operating requirements of capping multiple containers, and meanwhile, being suitable for a step-by-step in-row bottle feeding filling process. The capping device for filling the container provided by the invention has the advantages that the structure is simple, the working performance is stable, and the capping device is safe and efficient.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

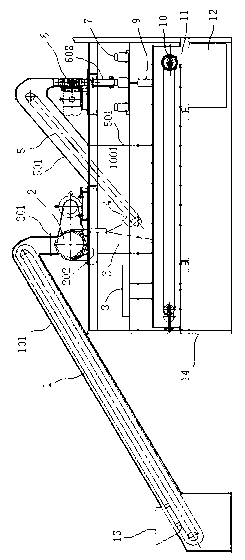

Full-automatic sampling machine for coal sample

InactiveCN102798559AEnsure fairness and justiceGuaranteed accuracyPreparing sample for investigationWorking environmentEngineering

The invention discloses a full-automatic sampling machine for a coal sample. The full-automatic sampling machine comprises a first coal sample conveying device, a crusher, an adjustable divider, a second coal sample conveying device, an automatic pulverizer, an automatic sample loader, an automatic sample bottle feeding machine and a waste conveying and recovering device, wherein the crusher is provided with a first feeding port and a first discharging port; the adjustable divider is provided with a second feeding port, a second discharging port and a dividing mechanism; a quantitative sample loading box is arranged on a conveyor belt of the second coal sample conveying device; and the automatic pulverizer is provided with a third feeding port, a third discharging port and a sundry discharging port. The full-automatic sampling machine disclosed by the invention is complete equipment which is used for producing a coarse and broken coal sample into an analytic coal sample for testing and is controlled in the full process by adopting a computer. The full-automatic sampling machine has the advantages that the automation of the full process of producing the sample is realized, the work efficiency of sampling is increased and the fairness and equity and accuracy of the sample are ensured; the equipment is fully sealed and is free from being polluted from dust; and waste materials of the crusher, waste sundries of the automatic pulverizer and dust of the conveying device respectively fall into the waste conveying and recovering device, and thus the work environment can be greatly improved.

Owner:杨程

Straightening track-dividing device for shrink film packaging bottles

InactiveCN101811582ANovel and reasonable structureFlexible and reliablePackaging automatic controlPackaging bottlesManufactured suppliesBottle

The invention relates to a straightening track-dividing device for shrink film packaging bottles. The invention aims to automatically separate shrink film packaging bottles which shrink into a row, thereby further realizing automatic boxing. The device has the characteristics of novel and reasonable structure, flexible and reliable motion, accurate track dividing, and high speed for changing varieties, thereby improving the work efficiency and avoiding bottle clamping. The invention has the technical scheme that the straightening track-dividing device for the shrink film packaging bottles is provided with a bottle feed conveyer belt and a buffer conveyer belt which are sequentially arranged in the motion direction of the bottles and move towards the same direction. The invention is characterized in that both sides of the bottle feed conveyer belt are provided with a counting and clamping mechanism; a bottle-poking track-dividing mechanism is hung above the buffer conveyer belt; and the outer side of the bottle-poking track-dividing mechanism is provided with a bottle blocking mechanism. The invention is suitable for manufacturing supplies before boxing in the industries of food, medication, daily health products and the like, and belongs to the technical field of packaging.

Owner:HANGZHOU WAHAHA GROUP

Waste glass bottle breaking and uncovering device

The invention discloses a waste glass bottle breaking and uncovering device. The waste glass bottle breaking and uncovering device comprises a bottle feeding bin, a bottle breaking bin, a rack, a motor and a stirring mechanism, wherein the motor and the bottle breaking bin are arranged on the rack; the top end of the bottle breaking bin is fixedly connected with the bottle feeding bin; the stirring mechanism is arranged below the bottle breaking bin; a rotary cage and an arc-shaped screen net are arranged in the bottle breaking bin; the arc-shaped screen net is arranged below the rotary cage; multiple breaking hammers are fixedly arranged on the rotary cage; the rotary cage is fixed on a rotary shaft; one end of the rotary shaft extends out of the breaking bin and is fixedly connected with a belt wheel; and the belt wheel is connected with the motor through a belt. The waste glass bottle breaking and uncovering device is simple and reasonable in structure and safe for use; waste glass bottles are put into the bottle breaking bin from the bottle feeding bin; the glass bottles are broken by the rotary breaking hammers in the bottle breaking bin, and enter the stirring bin after being screened by the arc-shaped screen net; water is injected into the stirring bin; and according to the density principle, broken glass sinks to the bottom of the stirring bin, and plastic floats on water, so that the broken glass is separated from plastic bottle covers.

Owner:吴义坡

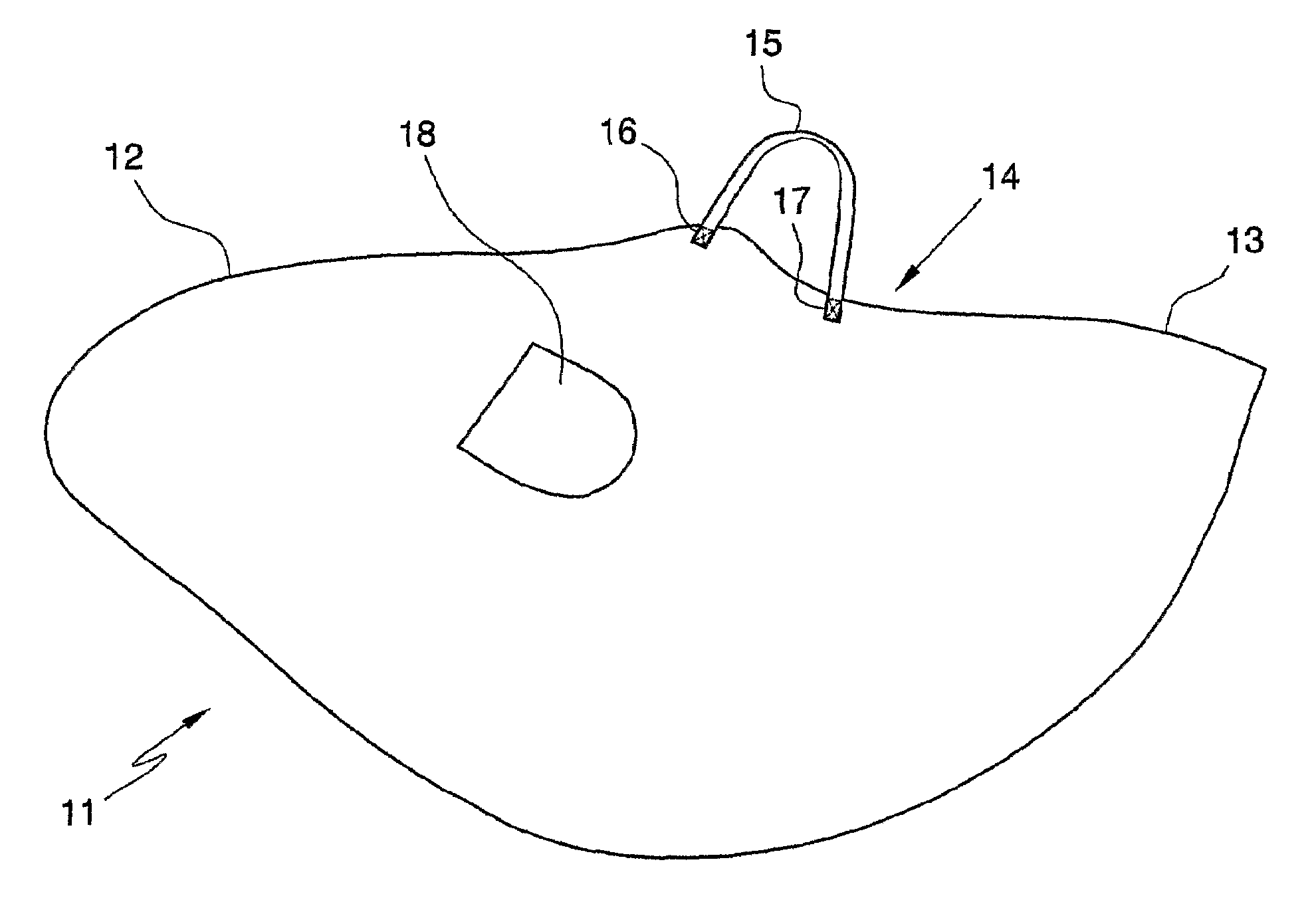

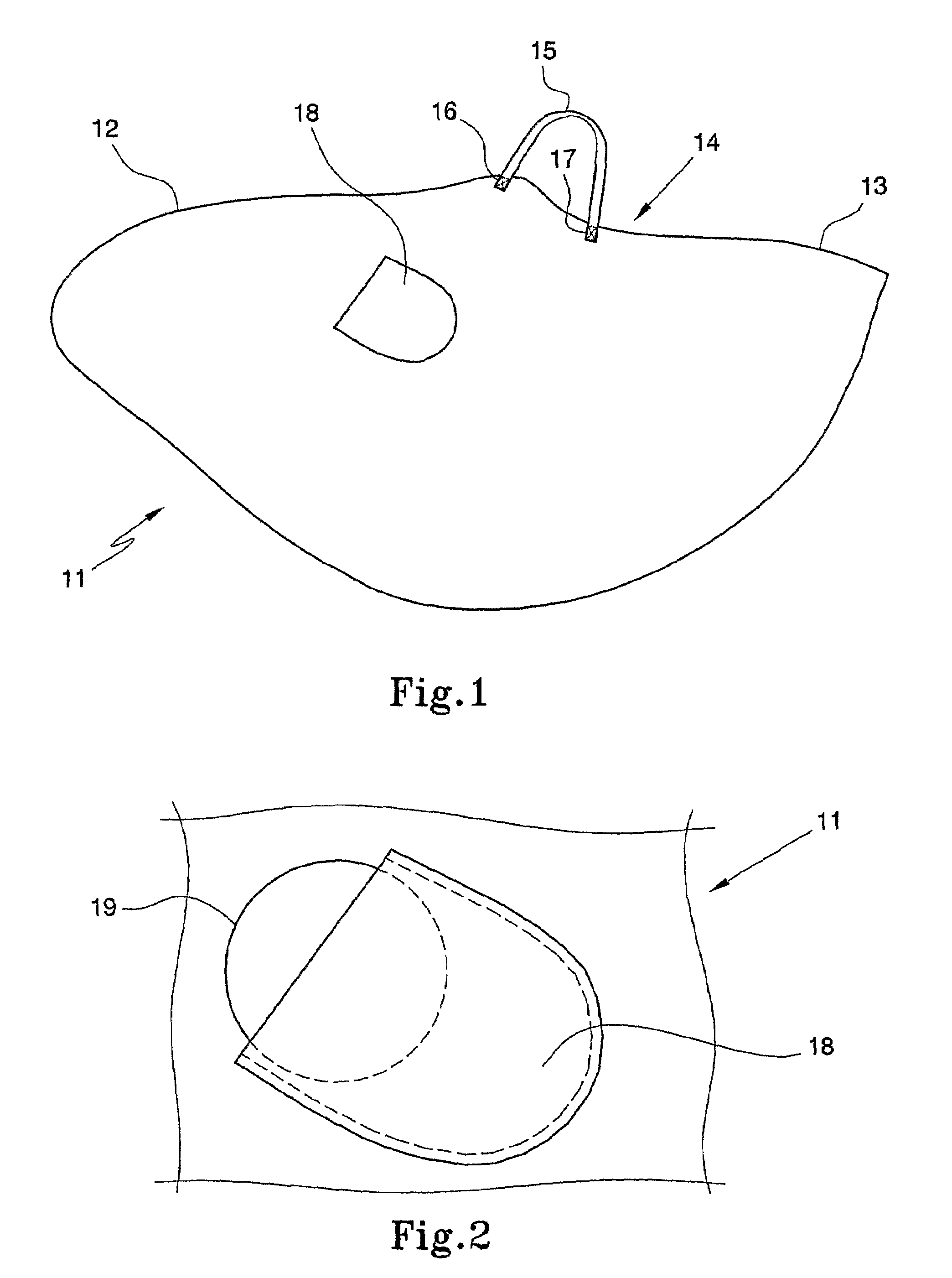

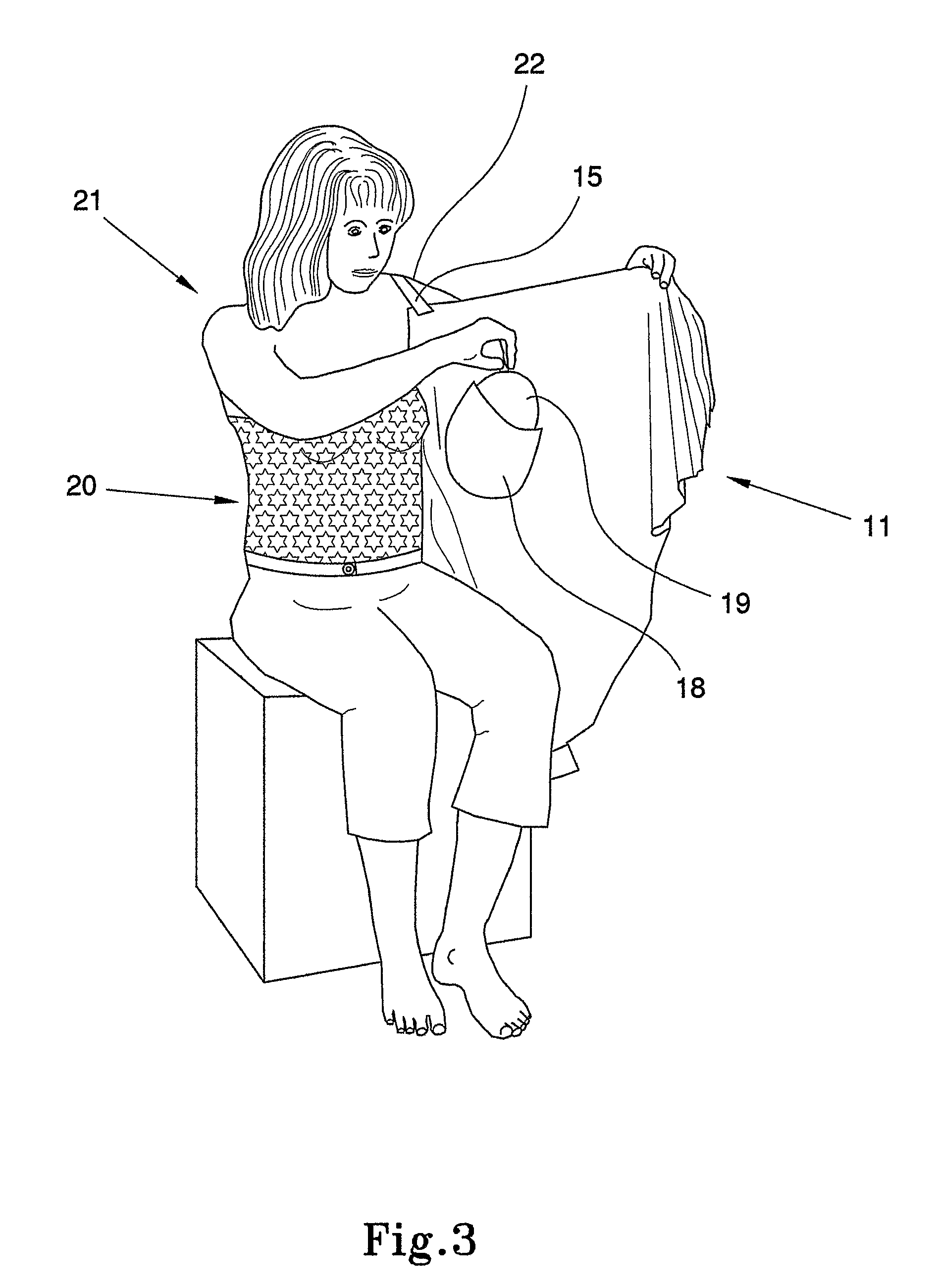

Breast feeding cover

A cover for use in breast feeding or bottle feeding an infant is disclosed, wherein the 5 cover (11) is formed from a sheet of fabric or the like shaped so that it may be comfortably draped around a mother's torso during breast feeding in order to allow discrete breast feeding of an infant. The cover is provided with a single strap means (15) to fit over a shoulder of the mother to prevent the cover from falling away from the torso. The cover may also be provided with one or more pockets (18) to hold nursing pads and the like.

Owner:OWEN JENNIFER

Servo motor driven fully-automatic plastic bottle blowing machine

The invention discloses a servo motor driven fully-automatic plastic bottle blowing machine, which comprises a heating device and a stretching-blowing mechanism, wherein a blank sorting mechanism and a blank loading mechanical hand are arranged at an inlet of the heating device; a conveyor chain is arranged in the heating device; bottle blank supporting seats are arranged on the conveyor chain; a blank taking and bottle feeding mechanical hand is arranged in the stretching-blowing mechanism; a variable pitch mechanical hand is arranged between an outlet of the heating device and the blank taking and bottle feeding mechanical hand. The scheme has the main characteristics that servo motors are adopted for providing rotating power for the variable pitch mechanical hand and providing die opening, closing and locking power for stretching-blowing dies of the stretching-blowing mechanism, and compared with the adoption of a cylinder for providing power in the prior art, the scheme has the advantages that the servo motors can accurately act, and have small errors, and bottle blanks can be accurately conveyed in place; the two servo motors are high in action synchronism, so that the two stretching-blowing dies can be simultaneously closed in place with a small gap and without expansion, and the product is high in stretching-blowing quality and production efficiency.

Owner:DEMARK (CHANGXING) INJECTION SYST CO LTD

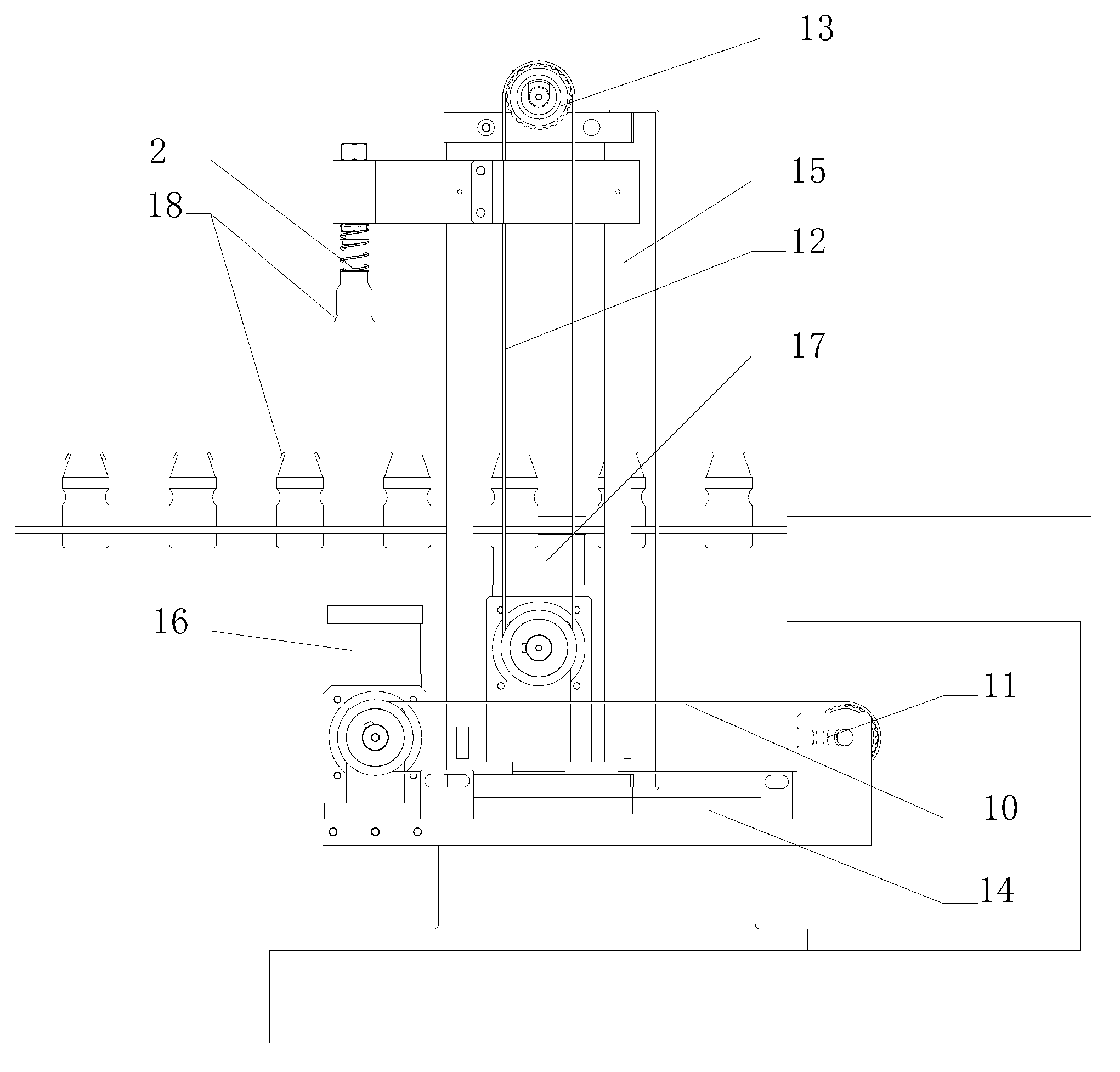

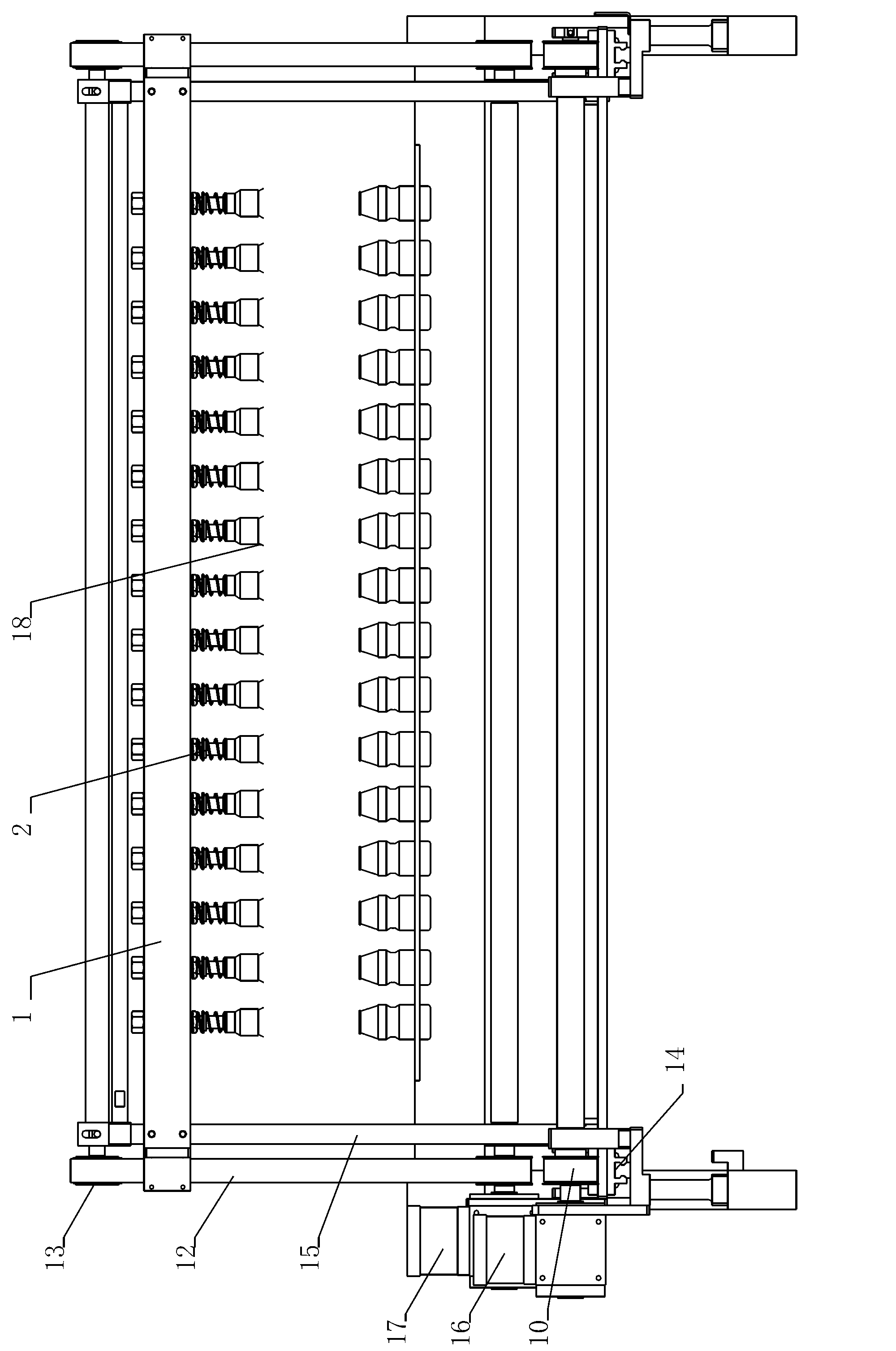

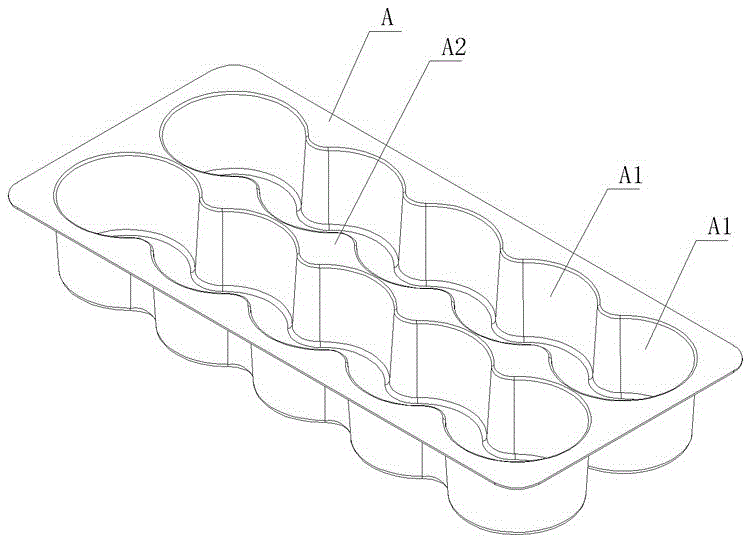

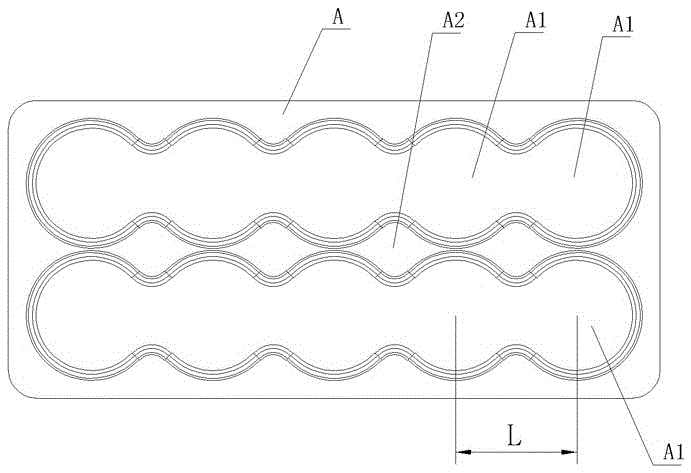

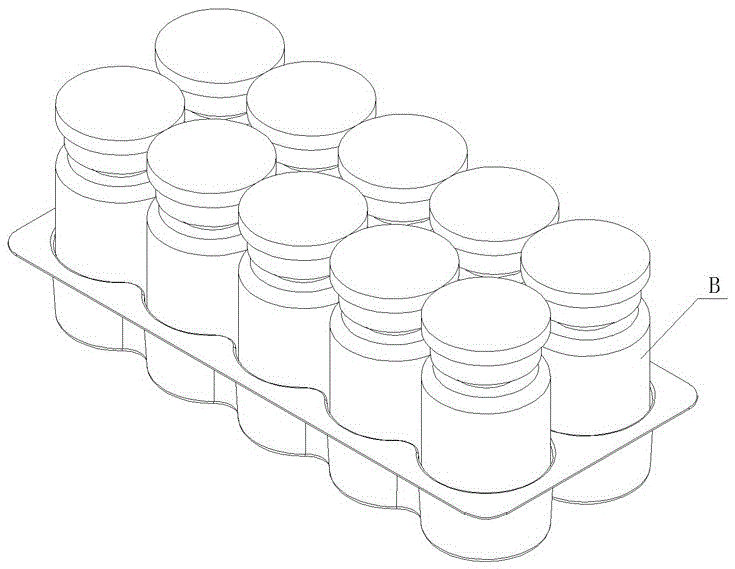

Automatic boxing production line for penicillin bottles

ActiveCN105644834ASmall sizeSimple structurePackaging automatic controlPackaging bottlesProduction linePenicillin

The invention discloses an automatic boxing production line for penicillin bottles. The automatic boxing production line is characterized in that a supporting box formed by a supporting box forming mechanism is a rectangular box, the rectangular box is provided with two rows of multiple bottle supporting cavities, a middle partition plate is arranged between the two rows of bottle supporting cavities, no middle partition plate is arranged between the bottle supporting cavities of each row, and the center distance of every two adjacent bottle supporting cavities of each row is equal to the outer diameter of bottle bodies of the penicillin bottles; the supporting box is transversely conveyed on a supporting box-entering conveying table; a penicillin bottle feeding mechanism is arranged on the inner side of the supporting box-entering conveying table, and a plurality of parallel discharge channels are arranged at a discharge port of the penicillin bottle feeding mechanism for discharging the penicillin bottles in columns; a penicillin bottle clamping mechanism is arranged above the discharge port of the penicillin bottle feeding mechanism and is provided with sucking heads for sucking the penicillin bottles at the discharge port of the penicillin bottle feeding mechanism from the tops and placing the penicillin bottles into the supporting box. According to the automatic boxing production line, the penicillin bottles can be placed into the supporting box and boxed for production without gaps, the boundary dimension of equipment is small, the structure is simple, the production cost is lowered, and the production efficiency is improved.

Owner:WENZHOU GAOGER MACHINERY TECH

Bottle straightening machine

InactiveCN102602692AAvoid bottle jammingContinuous and reliable bottle deliveryConveyor partsBottleBottles/feed

Owner:TRUKING TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com