Rotary continuous lifting handle grabbing and pressing machine

A press-in machine and hand-grabbing technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity and low processing efficiency, and achieve the goals of reducing labor costs, improving work efficiency, and high operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

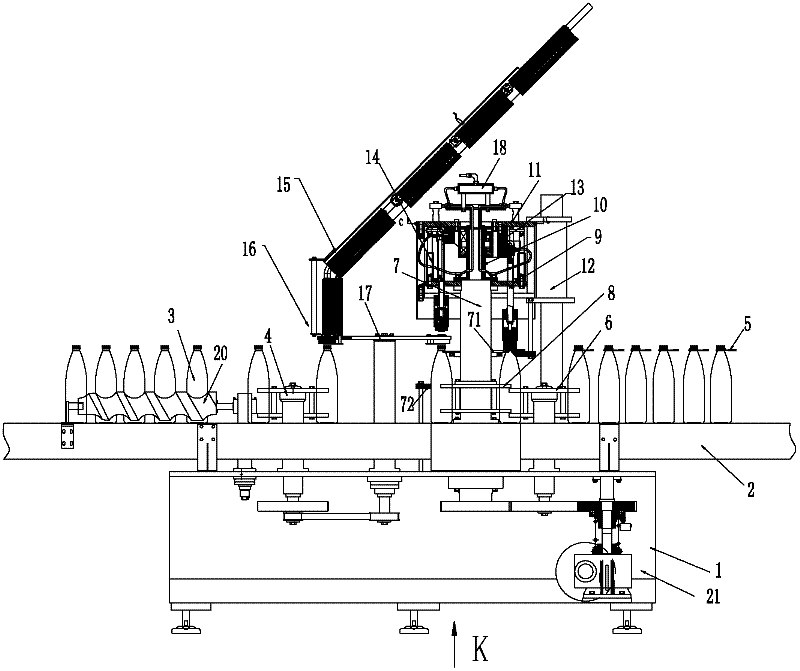

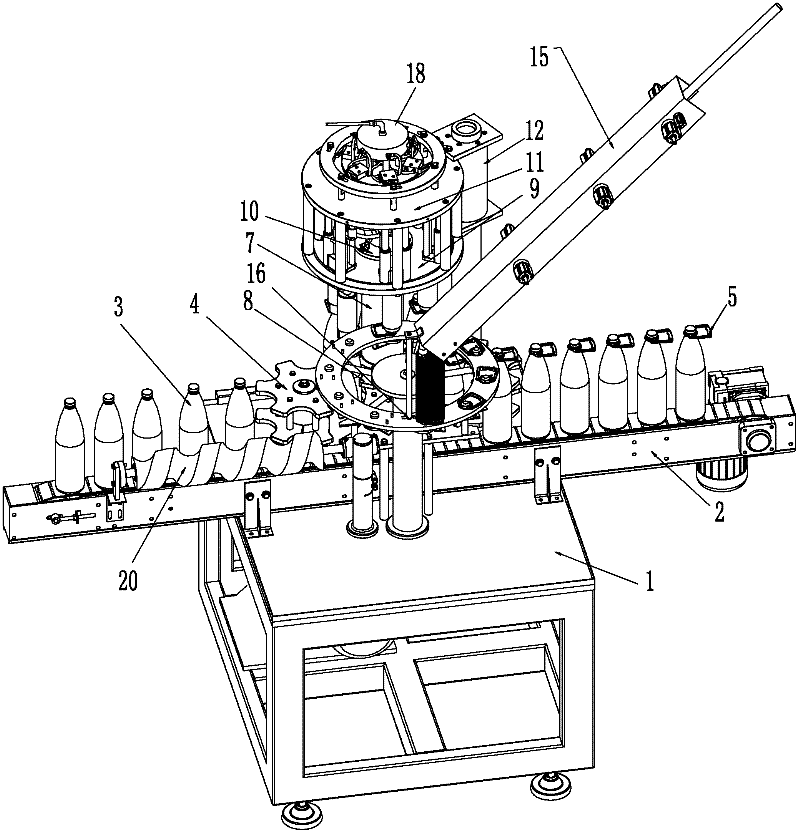

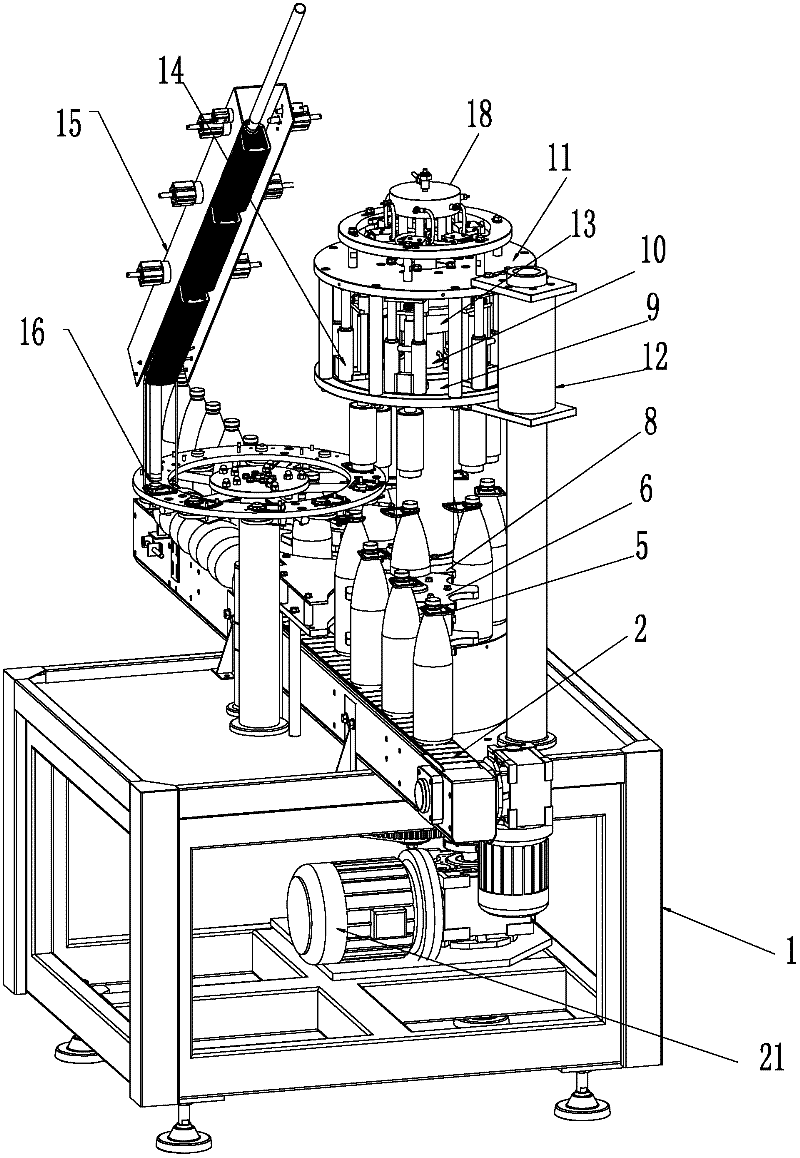

[0035] Please refer to Figure 1-a, Figure 1-b, Figure 1-c and figure 2 as well as Figure 10As shown, a rotary continuous handle grabbing and pressing machine includes a chassis 1, a conveyor chain 2 arranged on the chassis 1, and a conveyor chain 2 is provided beside the conveyor chain 2 for inputting 5 bottles that have not been pressed into the handle. 3 and the bottle-out mechanism for outputting the bottle 3 that has been pressed into the handle 5. In this embodiment, the bottle-in mechanism is the bottle-in star wheel 4, and the bottle-out mechanism is the bottle-out star wheel 6. Before the star wheel 4, there is also a bottle-feeding screw 20, and the above-mentioned structures are all bottle-feeding and bottle-feeding technologies for which the applicant has applied for a patent, and will not be described in detail here;

[0036] The characteristics of this embodiment are: a central rotating main shaft 7 is provided between the bottle-in star wheel 4 and the bottle-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com