Capping device for filling container

A technology of container and power device, which is applied to flange-type bottle caps and other directions to achieve the effect of stable working performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

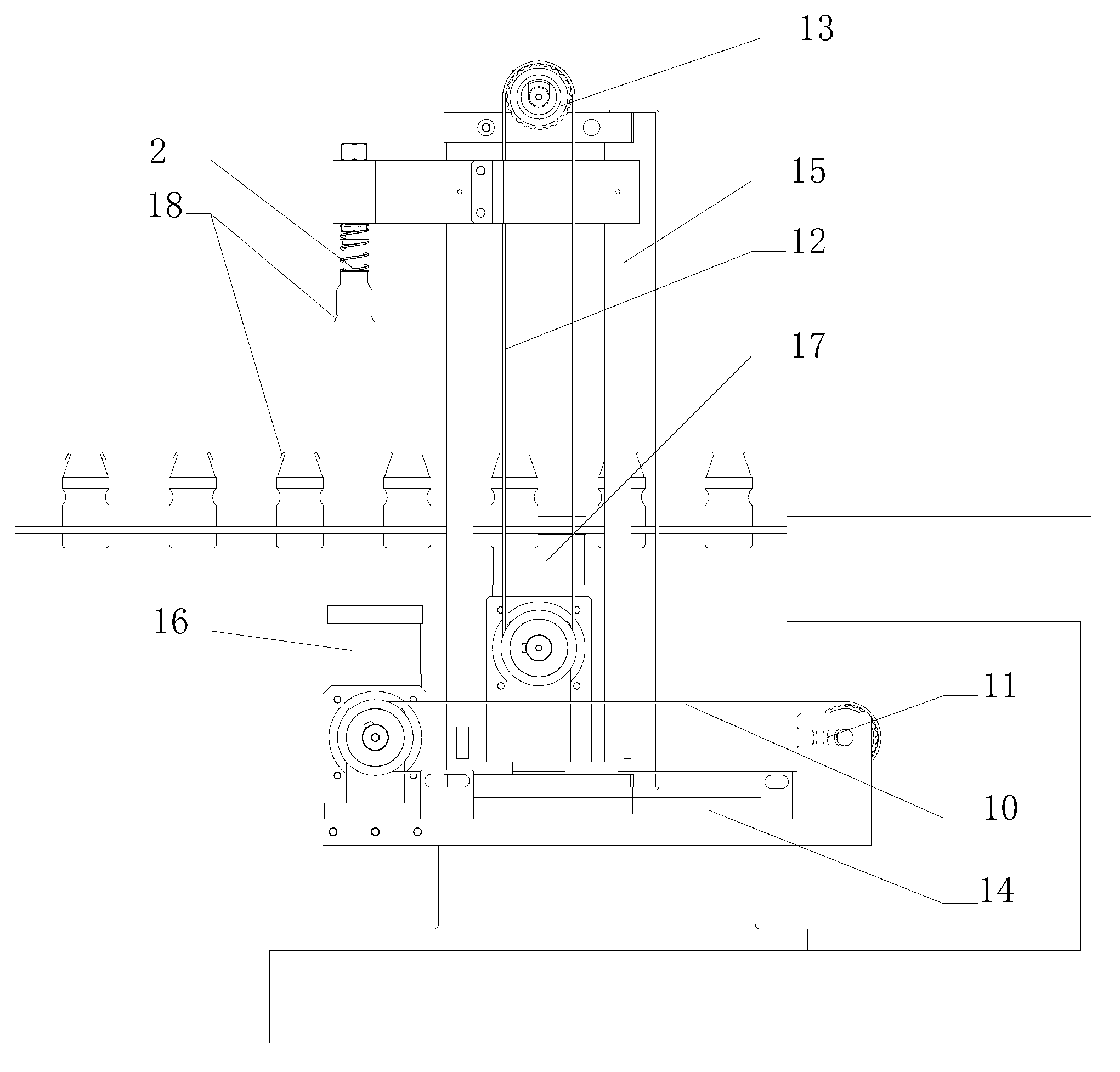

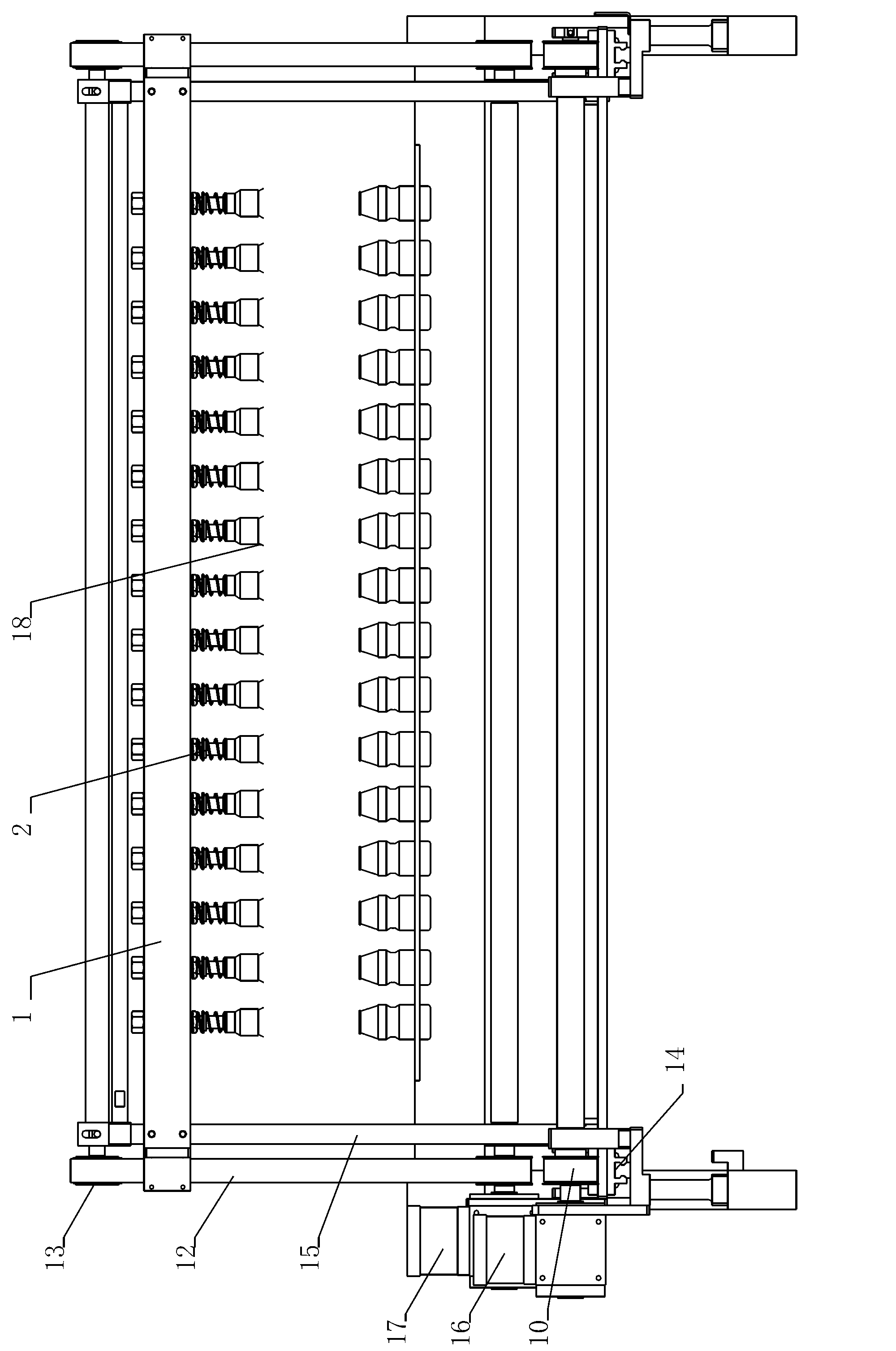

[0031] The first embodiment of the present invention, such as figure 1 , 2 As shown, the capping device for container filling includes a horizontal servo mechanism, a vertical servo mechanism and a capping mechanism. The horizontal servo mechanism and the vertical servo mechanism jointly constitute the station adjustment mechanism. The horizontal servo mechanism, the vertical servo mechanism and the capping mechanism are all installed on the frame of the capping device for container filling.

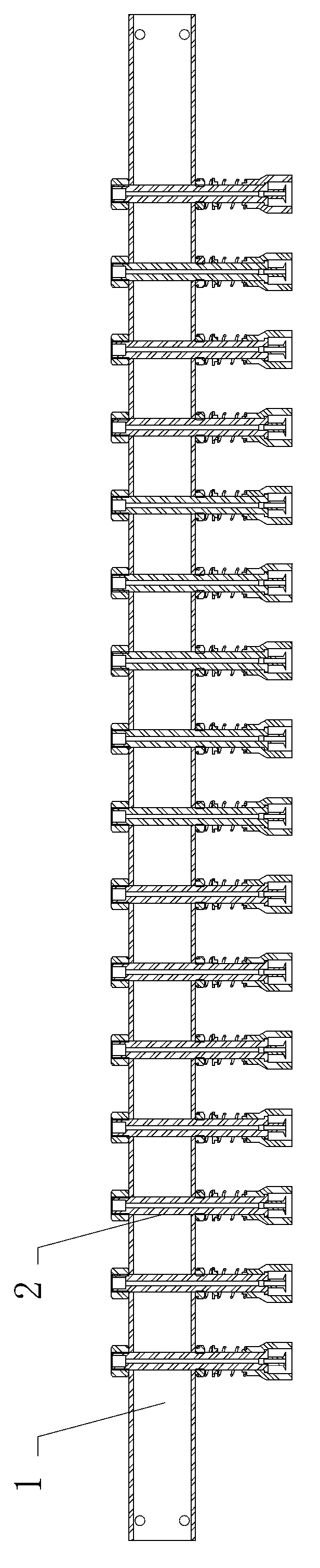

[0032] Such as image 3 , 4, Shown in 5, the capping mechanism includes a bracket 1, a capping head 2 for the suction pressure cap. The support 1 is a straight strip structure, and the suction and pressure capping heads 2 are vertically distributed on the support 1 at equal intervals, and the suction and pressure capping heads 2 and the support 1 are fixedly connected. The suction and pressure capping head 2 includes a vacuum suction pipe 3 and a capping head 4 . The vacuum suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com