Automatic box packing machine

A technology of automatic cartoning machine and driving mechanism, applied in the direction of packaging, transportation and packaging, single objects, etc., can solve the problems of boxing efficiency, wine bottle weight, production hidden dangers, etc., and achieve the effect of improving boxing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

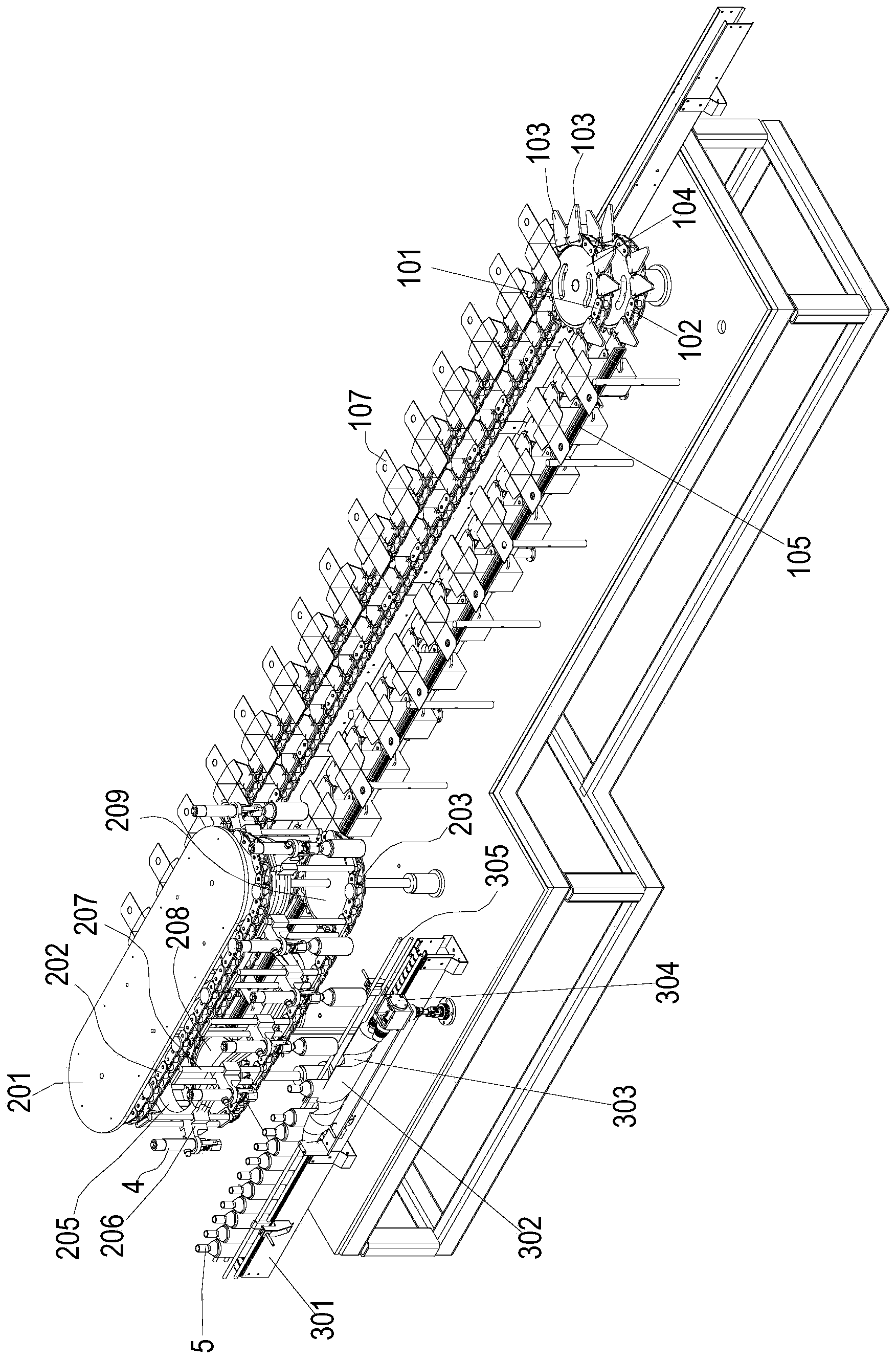

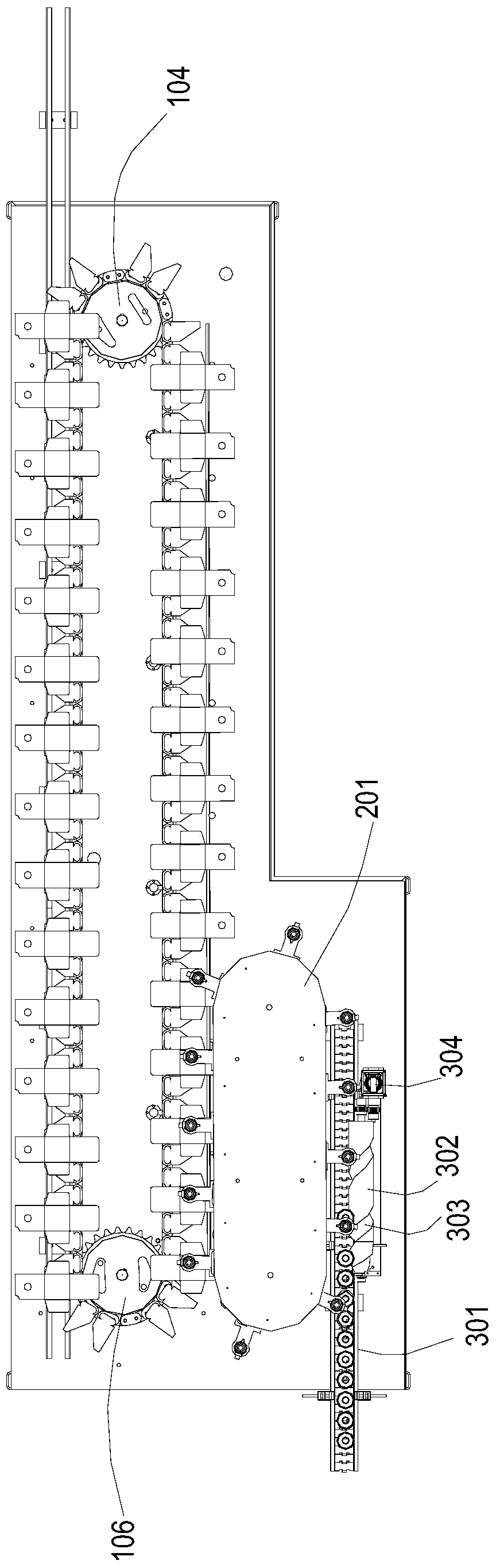

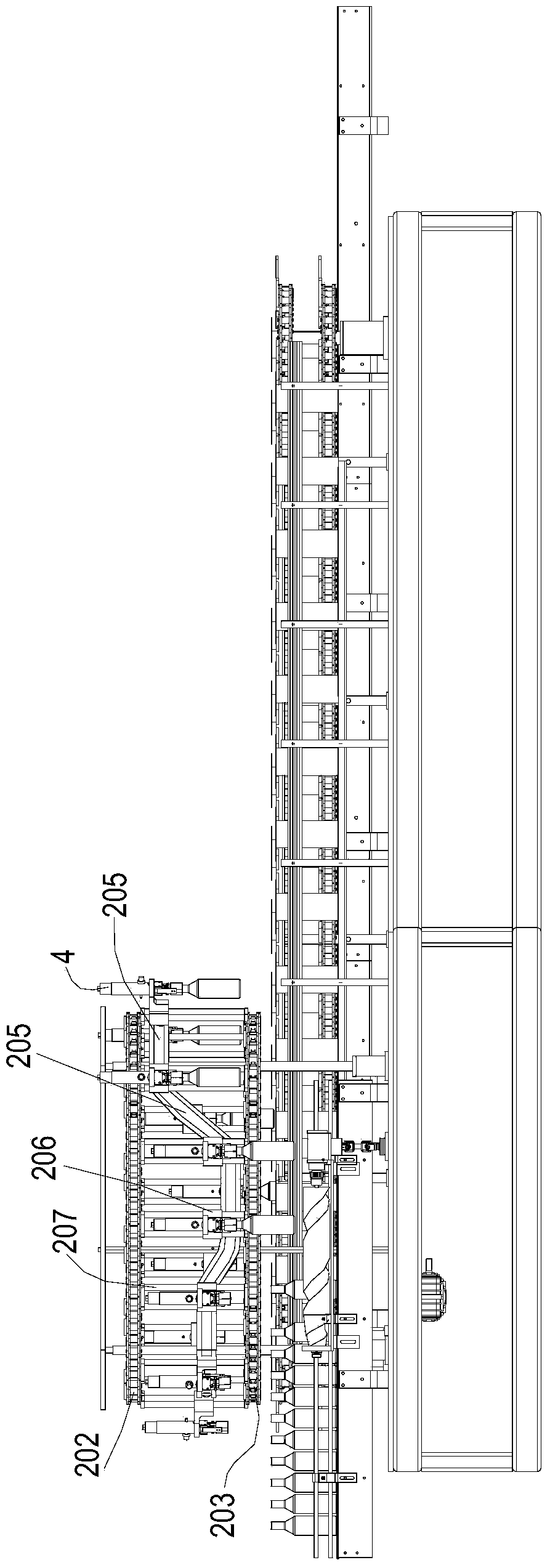

[0037] Such as Figure 1 to Figure 4 As shown, the automatic cartoning machine of the present invention includes a carton conveying mechanism, a bottle feeding mechanism and a bottle releasing mechanism. Group of sprockets 106, the rotating shaft of every group of sprockets is vertically arranged, wherein the rotating shaft of one group of sprockets links to each other with the first driving mechanism, is connected with the carton conveying chain between two groups of sprockets, and the equidistant arrangement on the carton conveying chain There are a plurality of carton positioning racks; the outside of the second group of sprockets 106 is provided with the bottle-putting mechanism, and the bottle-putting mechanism includes a bottle-putting frame 201, and a third group of sprocket wheels 208 and a bottle-putting frame two ends are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com