Patents

Literature

58 results about "Manufactured supplies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

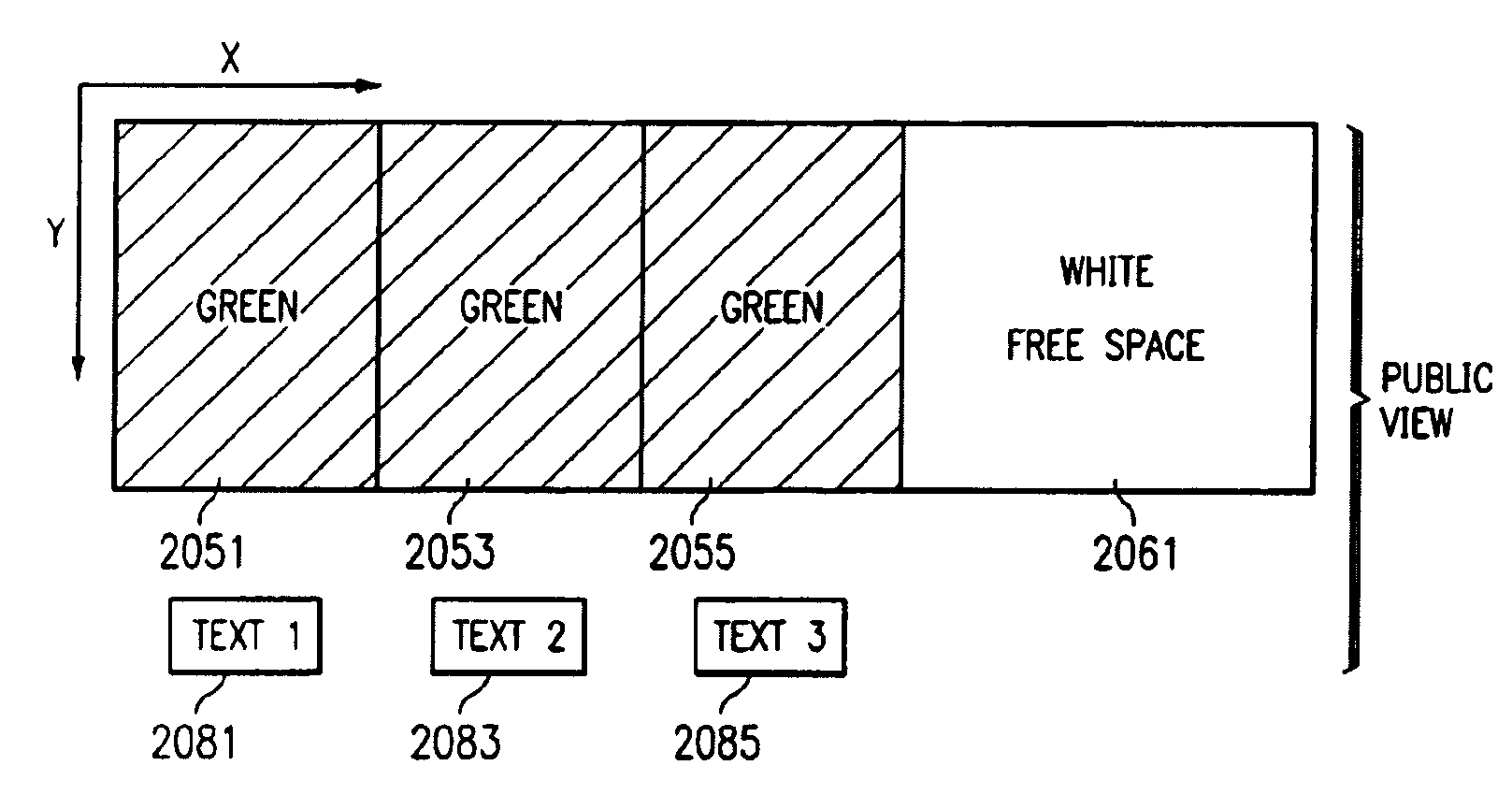

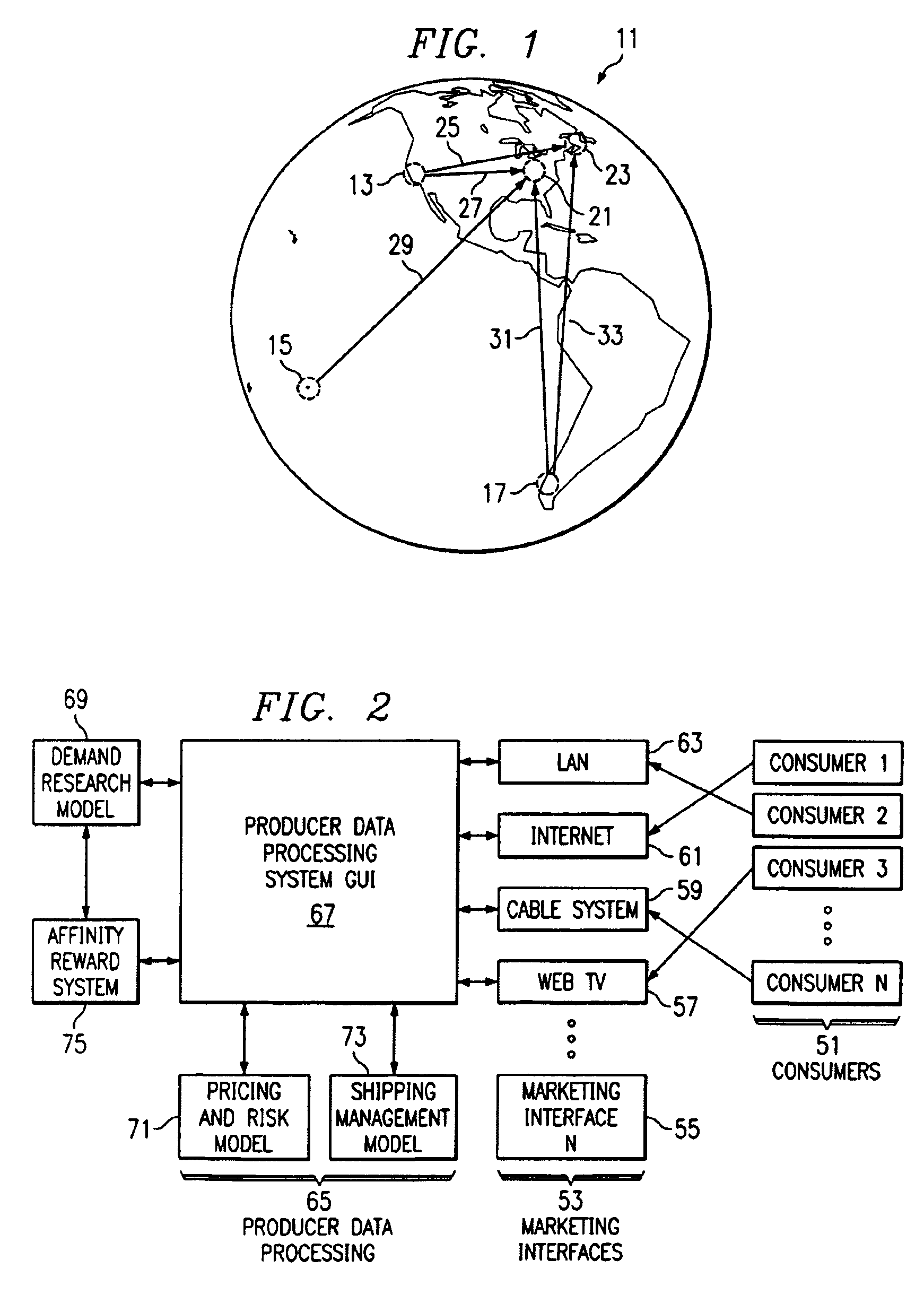

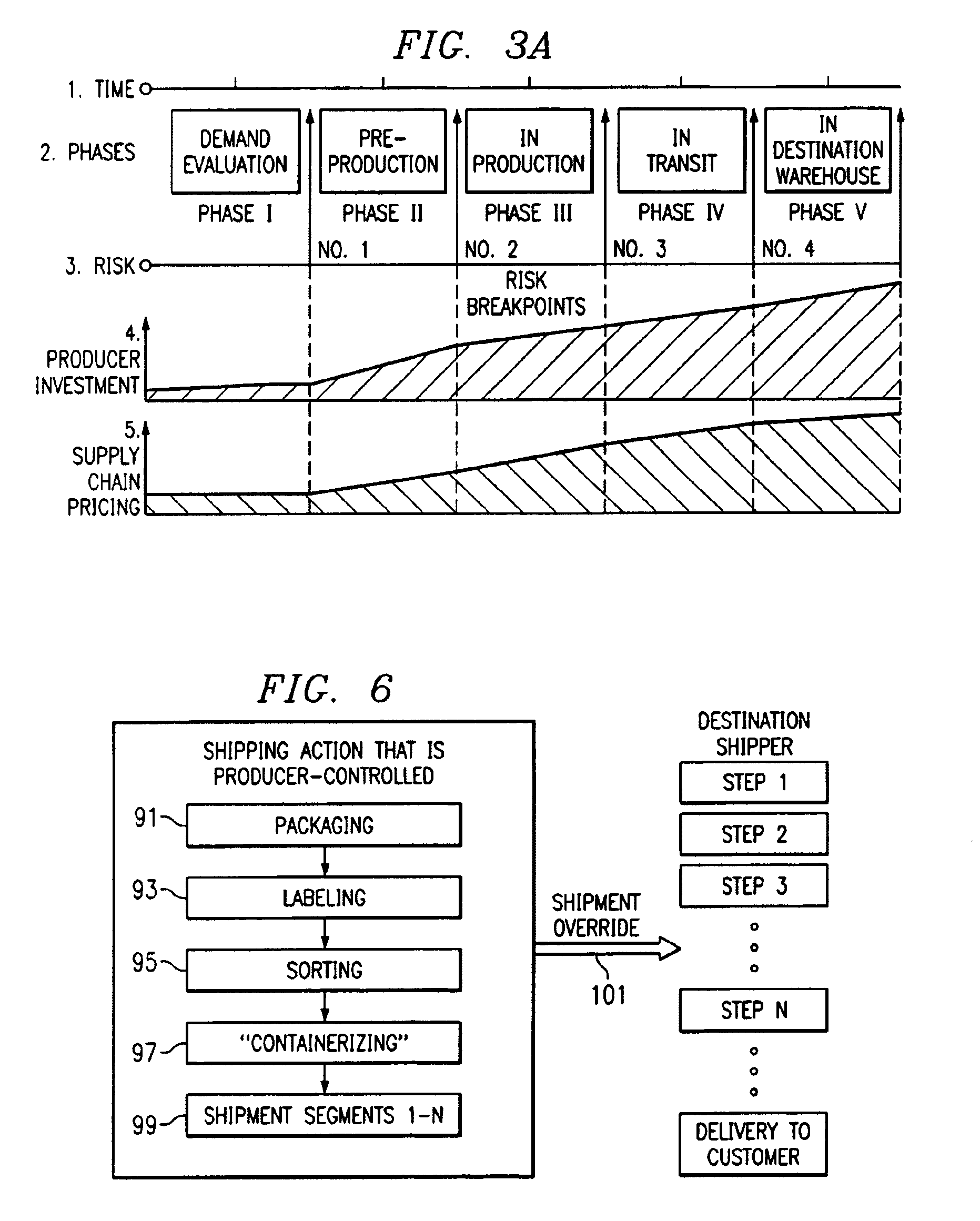

Method of producing, selling, and distributing articles of manufacture through the automated aggregation of orders and the visual representation of standardized shipping volumes

InactiveUS7136830B1Simple preparation conditionsLess riskBuying/selling/leasing transactionsSpecial data processing applicationsManufactured suppliesIndustrial engineering

The present invention also provides a dynamic on-line order gathering system that enables sellers to offer one or a combination of goods whose availability (production and / or shipping) may be economically linked in some ways with other items and which facilitates aggregation of demand across related items so as to enable the ability to reach critical mass of demand for the related goods by a more efficient means than currently available.

Owner:LAKESOUTH HLDG LLC

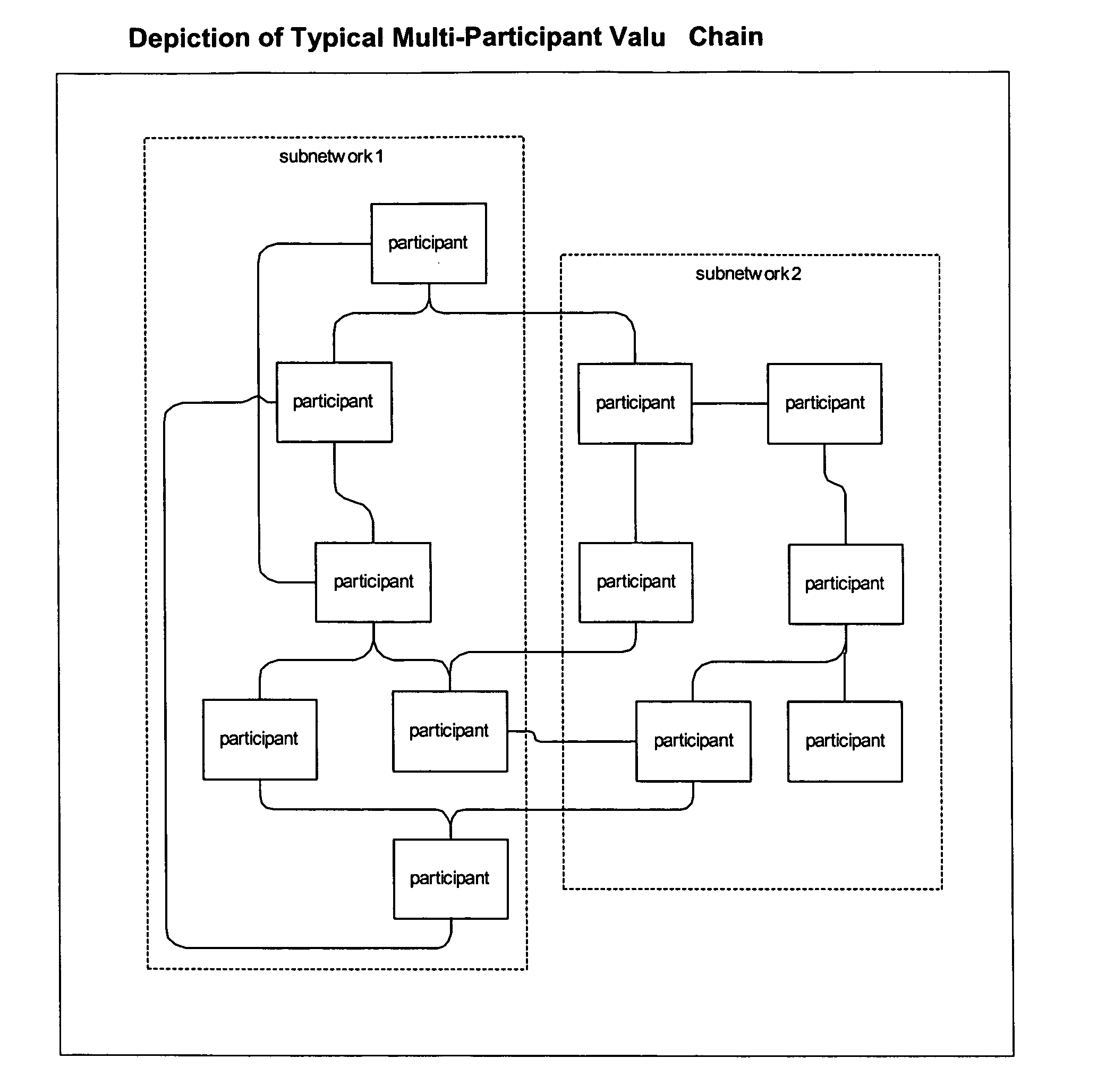

System for resource accounting for multiple entities in an arbitrary value chain

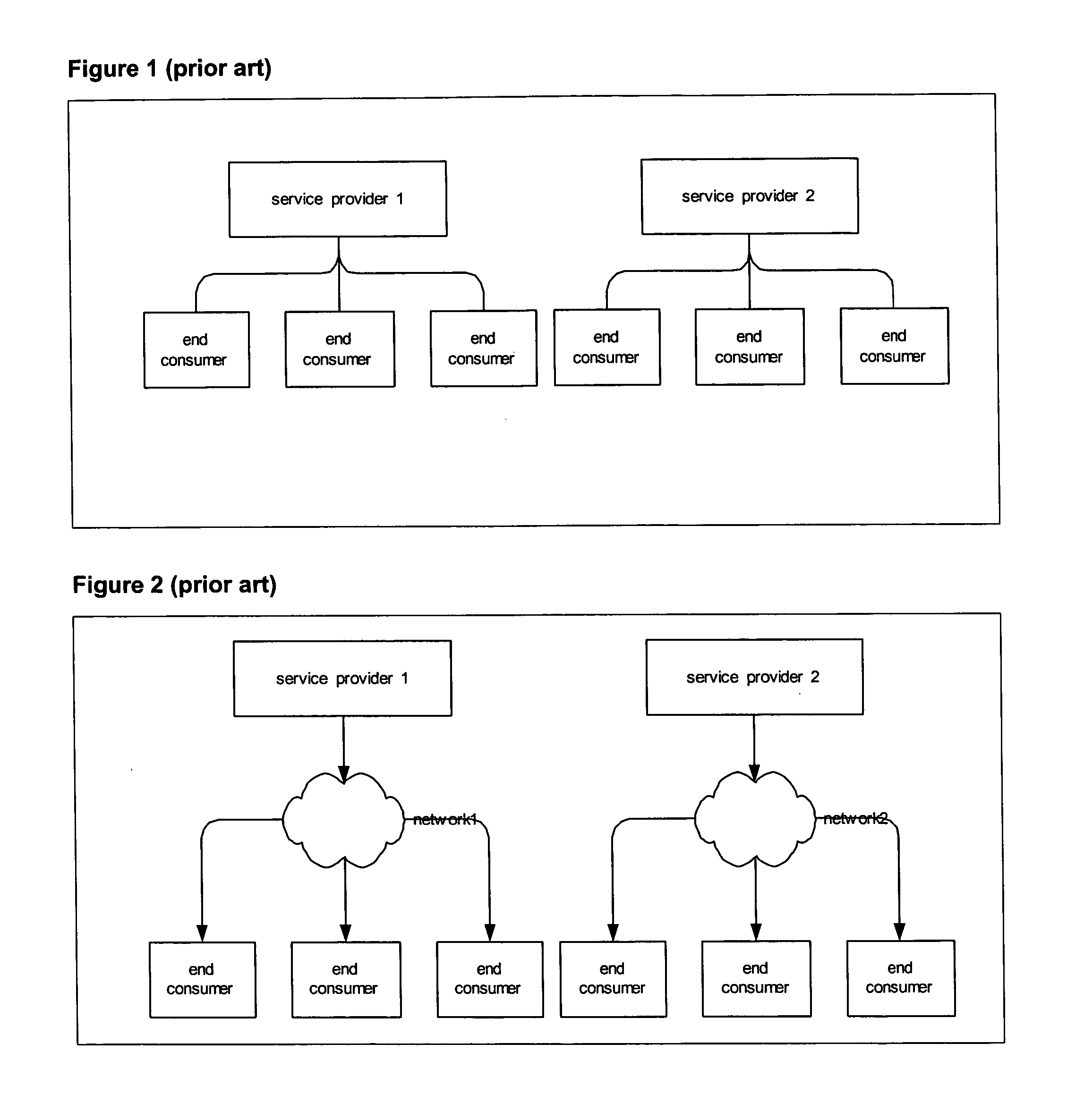

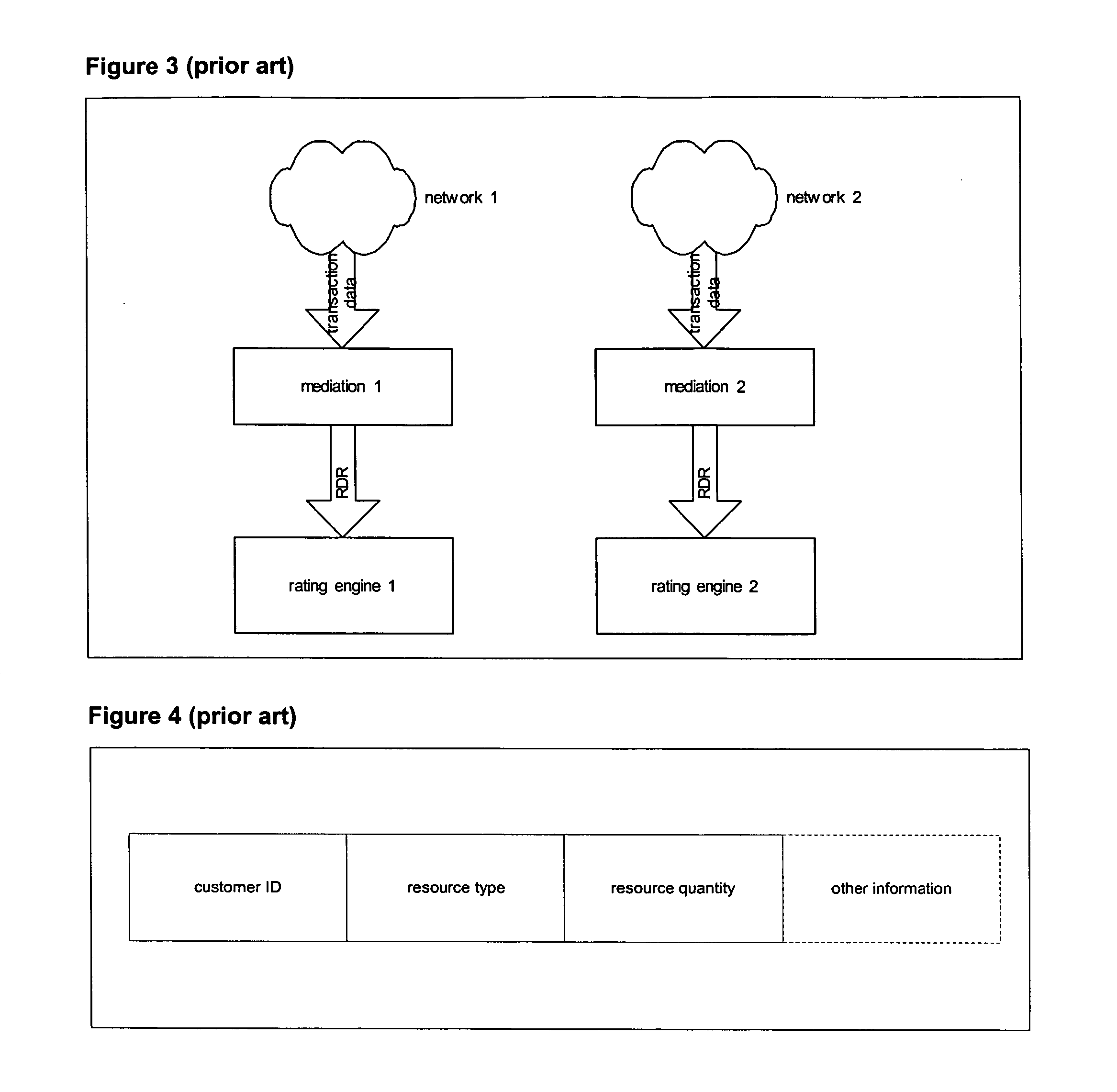

The inventive system includes a method to let participants in a value chain of digital and physical goods to package resources into sellable services and products, keep track of consumption of the resources and calculate charges to the end users and revenues to all participants. The participants to such supply chain include but not limited to resource suppliers, distributors, aggregators, resellers and service providers. The resources include but not limited to digital goods such as computing capacity, storage, content, software applications, data depository or special data acquisition instruments and physical goods such as commodity and manufactured items. Through this invention, resource supplies and consumptions and thus charges and revenues can be tracked and accounted for simultaneously. Any participants to the supply chain can host such system on behalf of itself and other participants. A participant can package resources into sellable units, track the resource supply by its suppliers and consumption by its customers, determine end users charges and revenues according to pricing structures and business rules including end user charges, loyalties, commissions, reseller fees, and roaming tariff, etc. When compared with the traditional methods, this invention tracks in real time all resource supplies and consumptions across the value chain simultaneously, in both actual resource unit and economic value. The invention can be realized in a combination of both hardware and software.

Owner:XCERIA

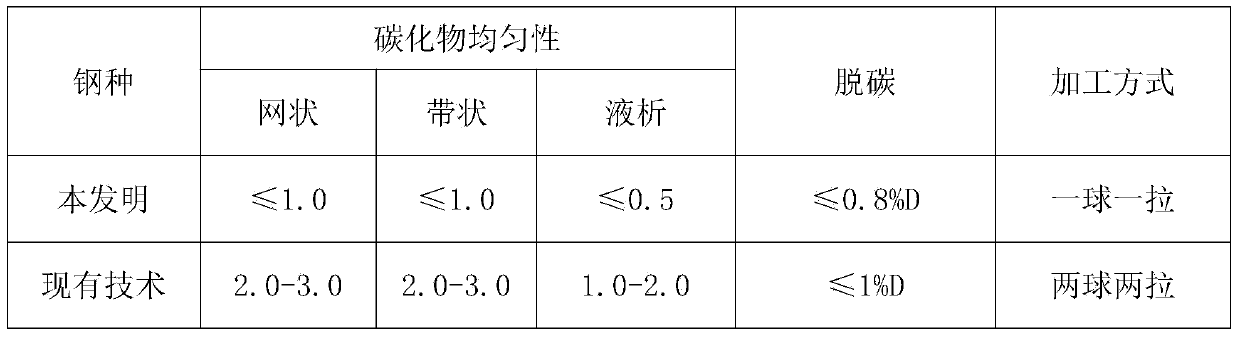

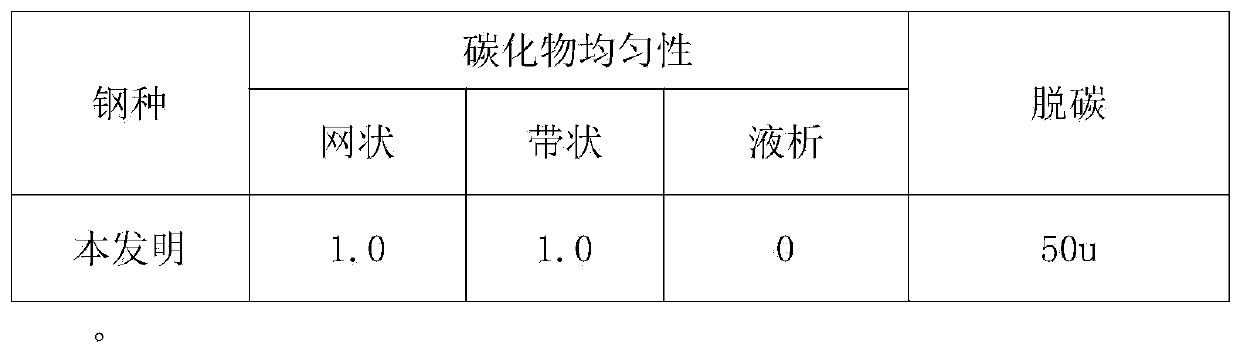

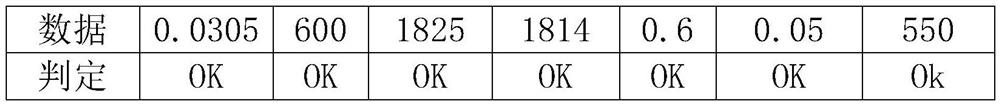

Production technology for bearing steel wire rod

InactiveCN104190705AChemically stableSlight surface decarburizationMetal rolling arrangementsHigh pressureAir cooling

The invention discloses a production technology for a bearing steel wire rod. The production technology comprises the following working procedures of blank pretreatment, billet steel heating, high-pressure water de-scaling, rough and intermediate rolling and pre-finishing rolling, finish rolling, reducing and sizing rolling, on-line finish product diameter measurement, spinning, air-cooling and finishing. Bearing steel is composed of, by weight, 0.95 percent-1.05 percent of C, 0.25 percent-0.45 percent of Mn, 0.15 percent-0.35 percent of Si, less than or equal to 0.02 percent of P, less than or equal to 0.006 percent of S, 1.45 percent -1.6 percent of Cr, less than or equal to 0.1 percent of Ni, less than or equal to 0.13 percent of Cu, less than or equal to 0.002 percent of Ti, less than or equal to 0.04 percent of Al, 0.05 percent of Mo, less than or equal to 0.001 percent of Ca and the balance being Fe. By the adoption of the controlled rolling and cooling technology, the process control over the bearing steel wire rod is performed to obtain properly spheroidized granular P texture. Good Carbide uniformity is achieved, and surface quality and dimension accuracy are stable. In a bearing steel wiredrawing factory, one ball can be drawn to form the finished steel wire in a one-off mode, so that production efficiency is substantially enhanced, and meanwhile the production cost is lowered.

Owner:NANJING IRON & STEEL CO LTD

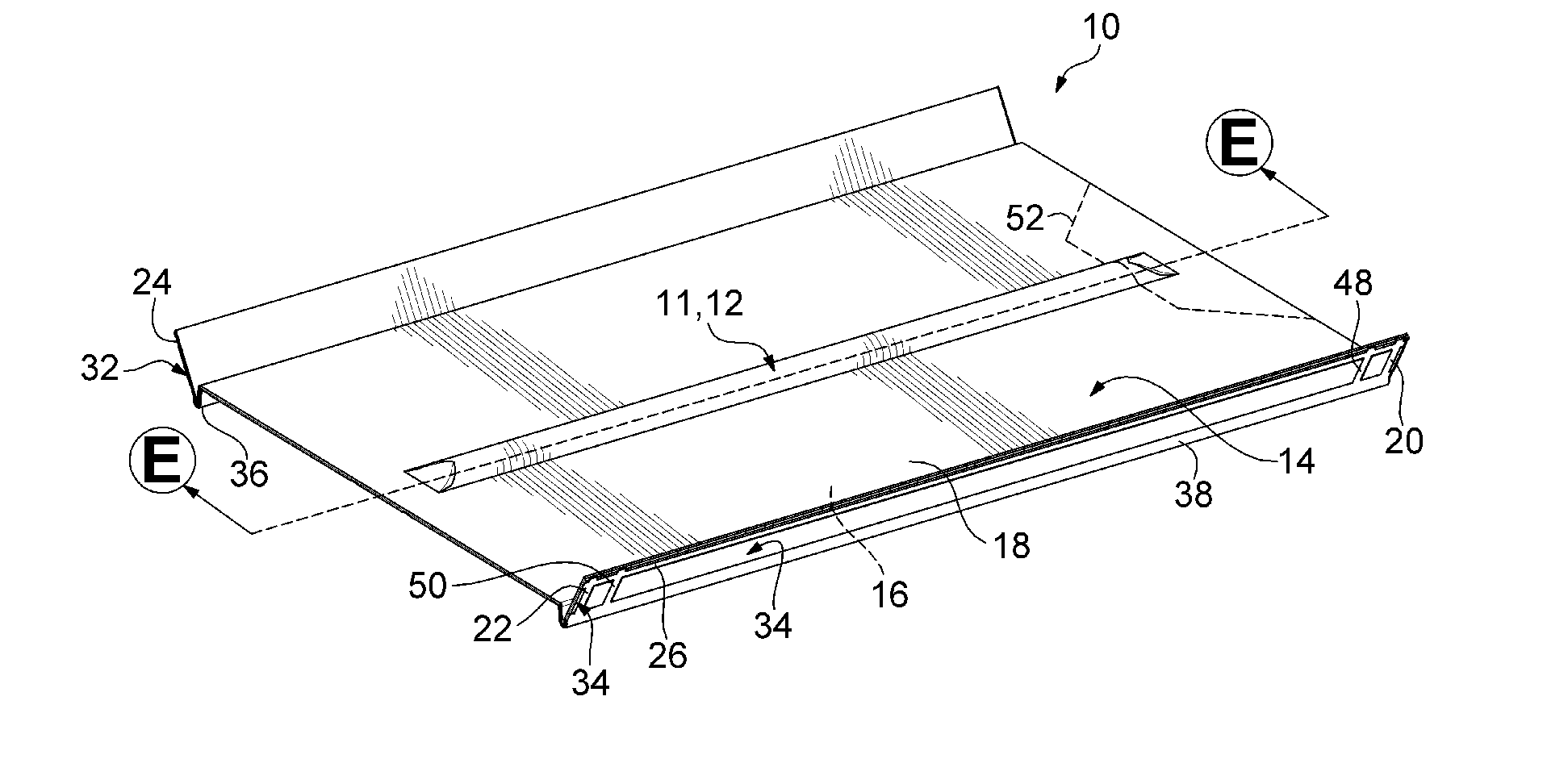

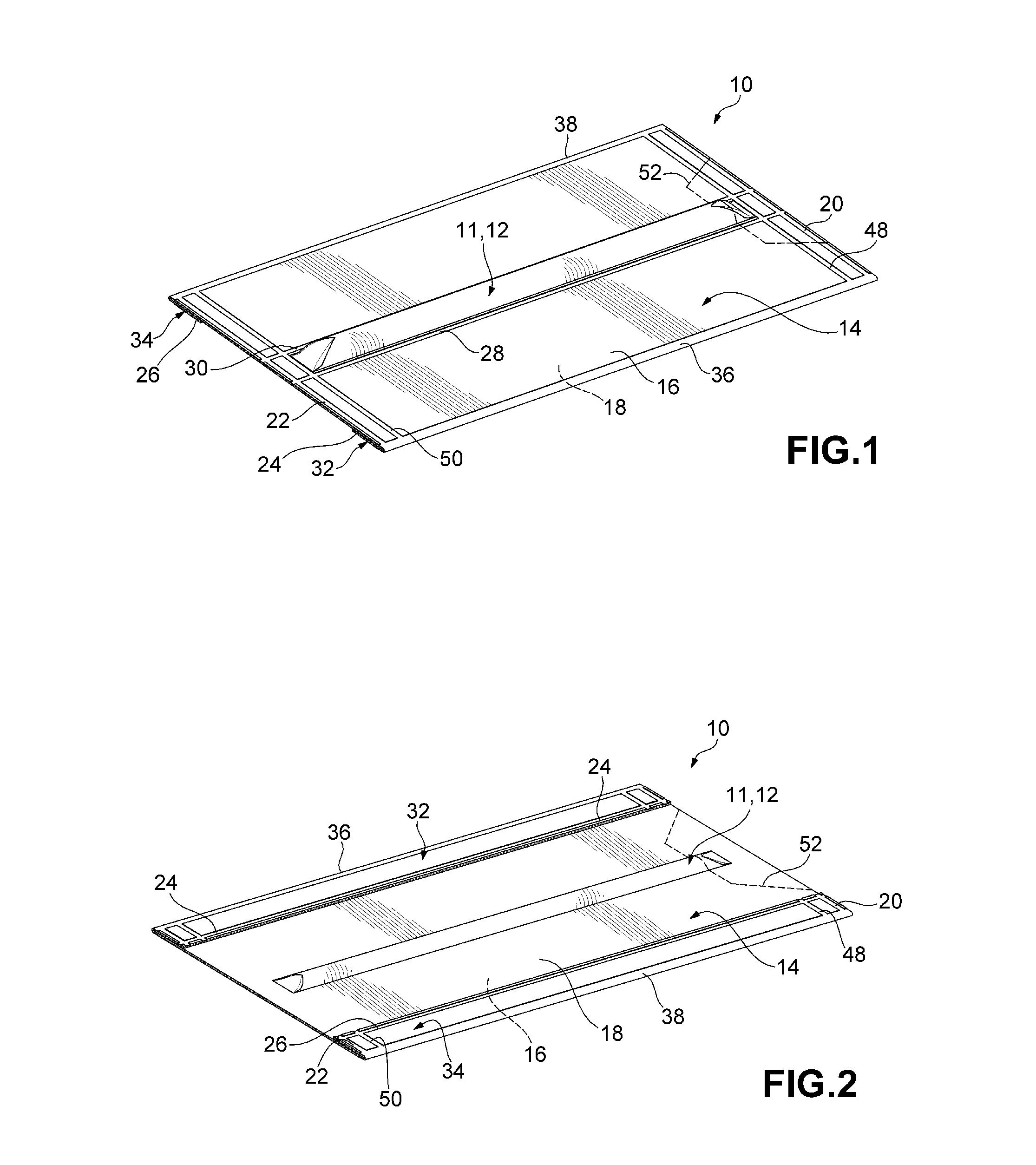

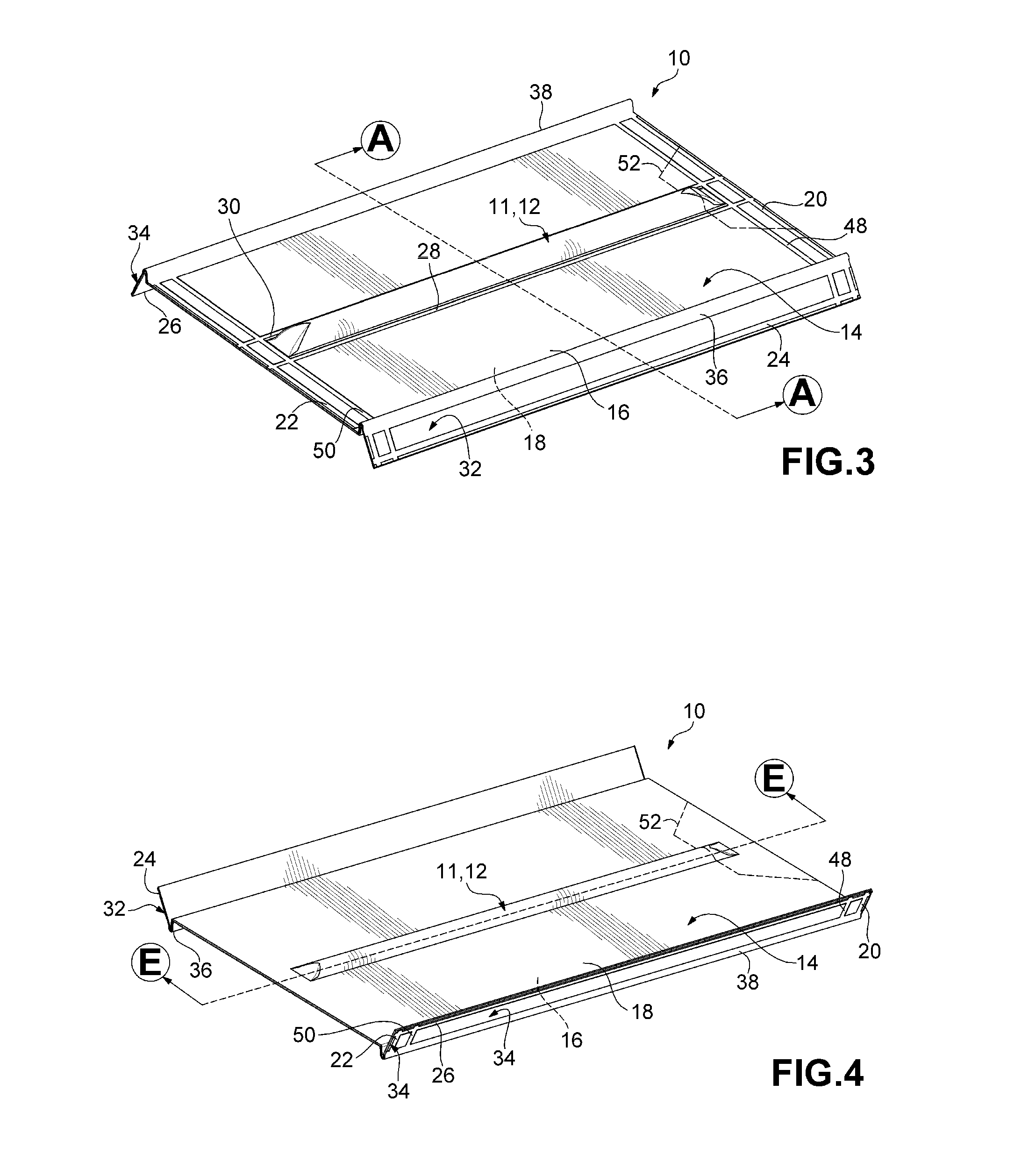

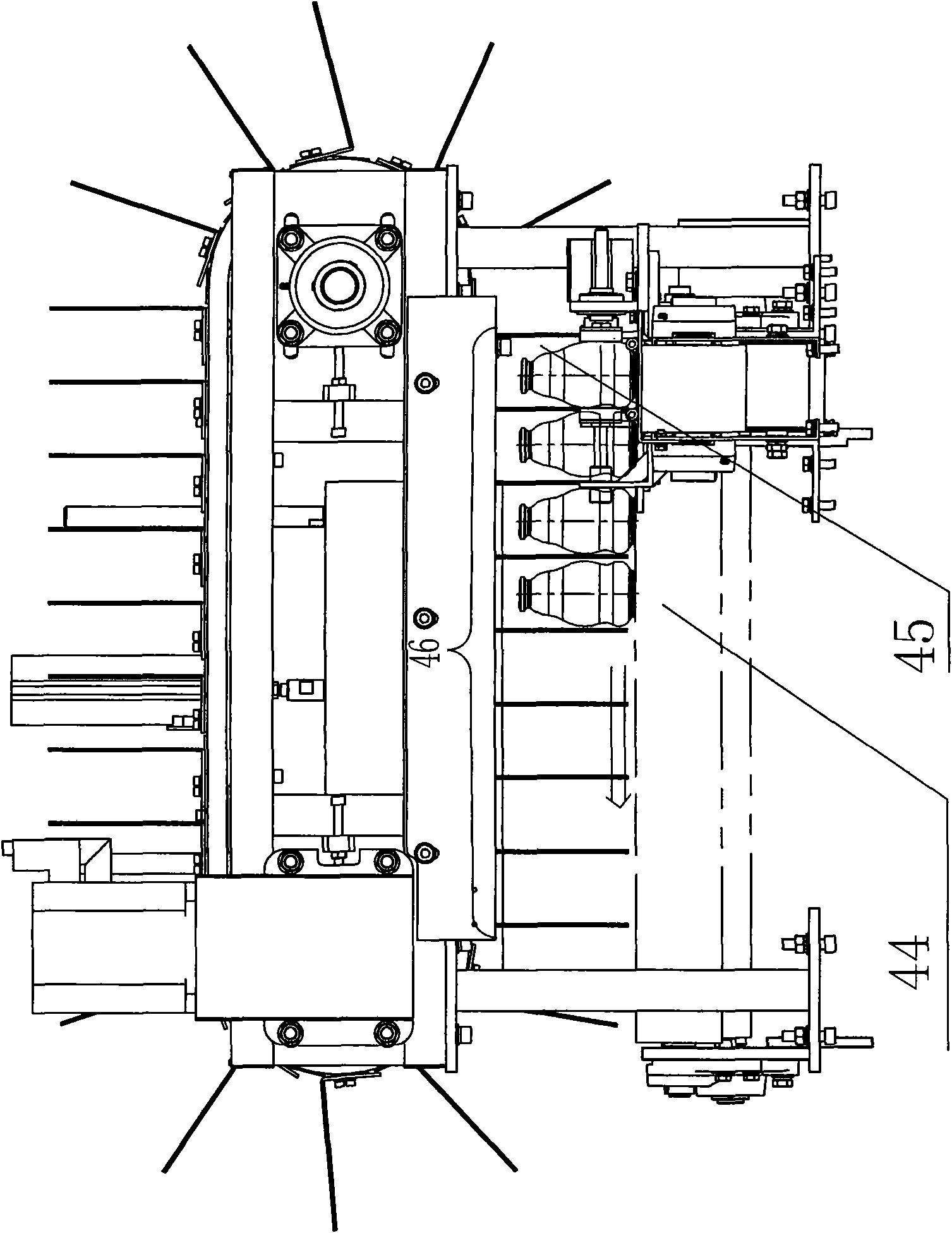

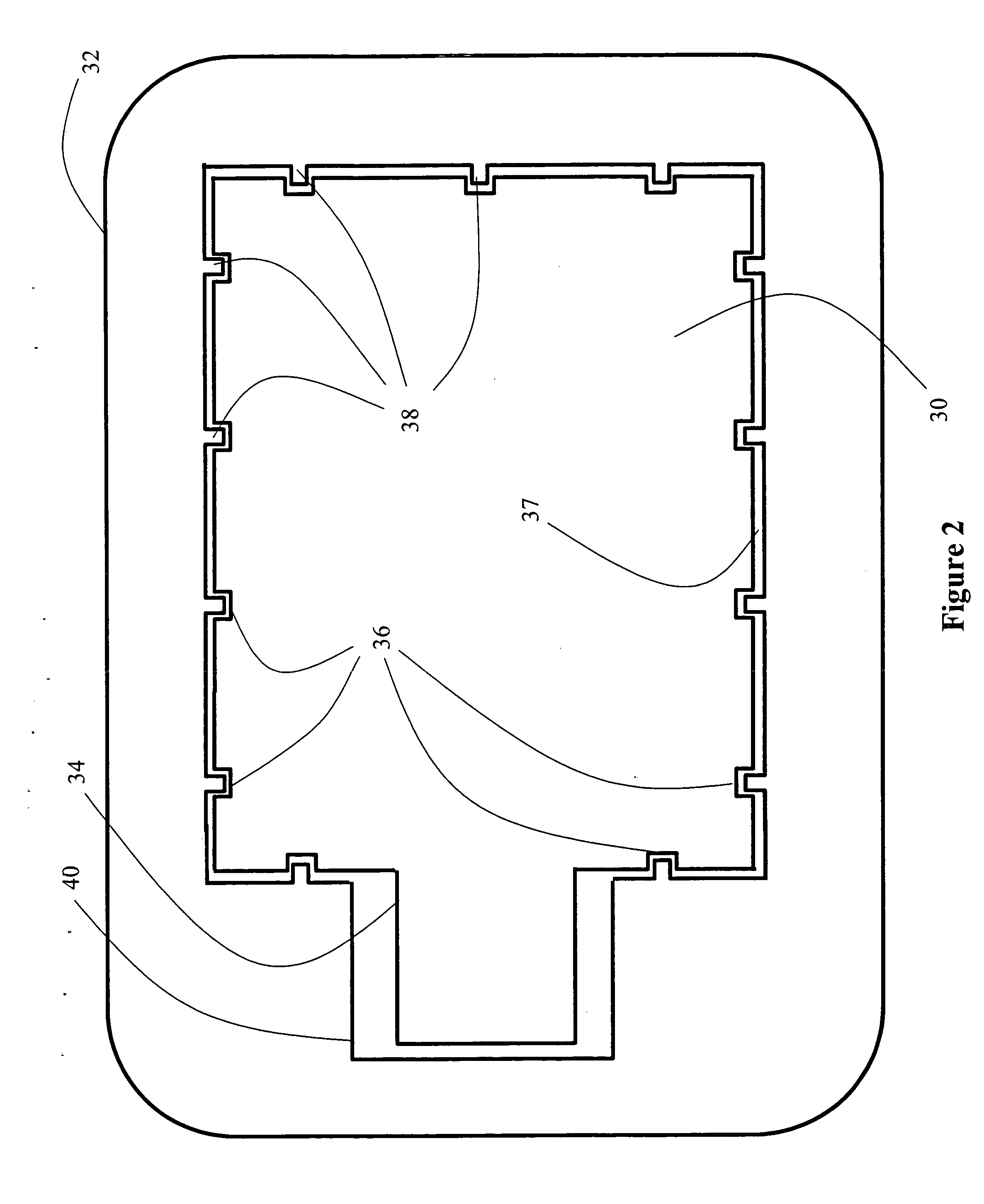

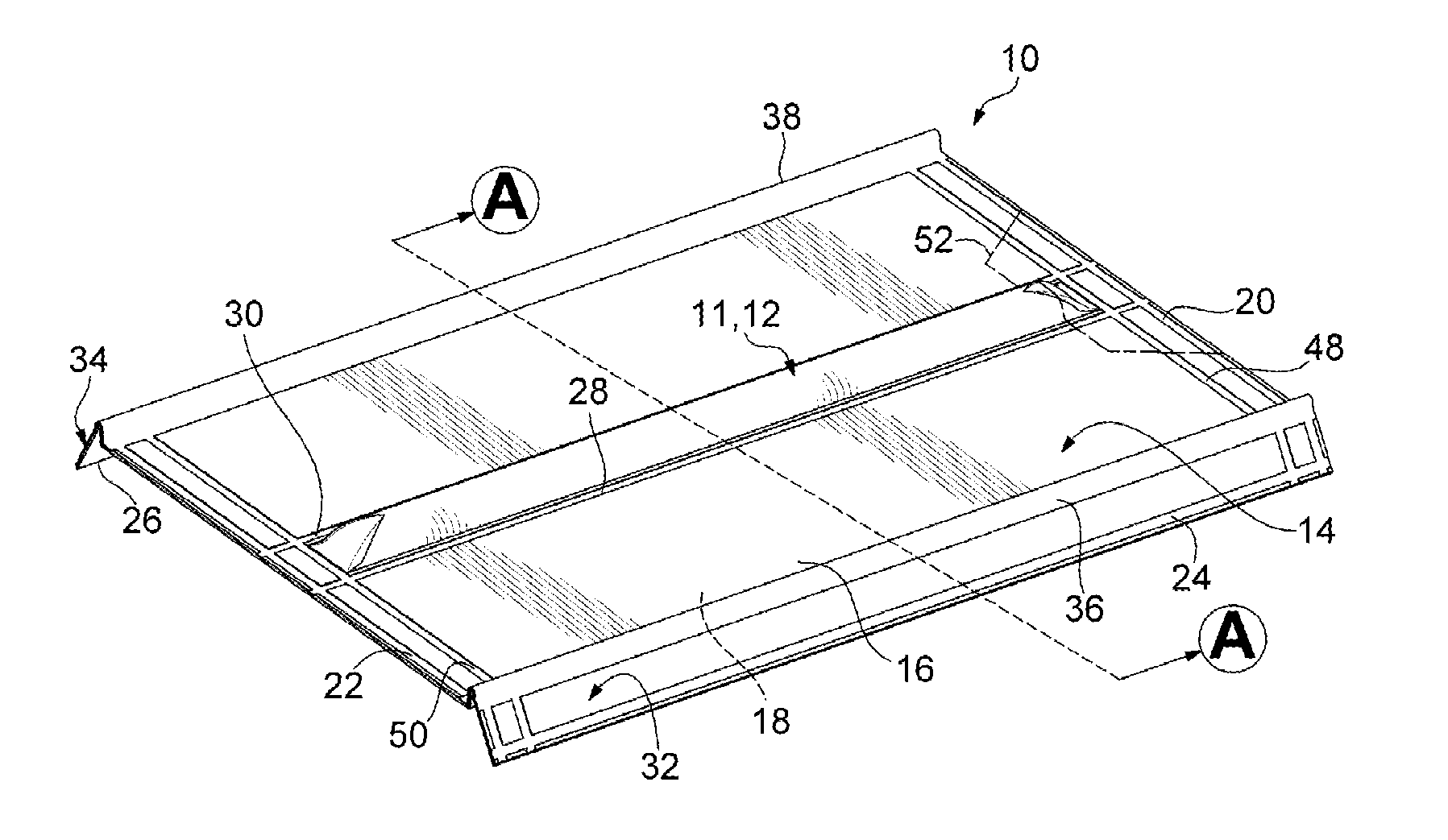

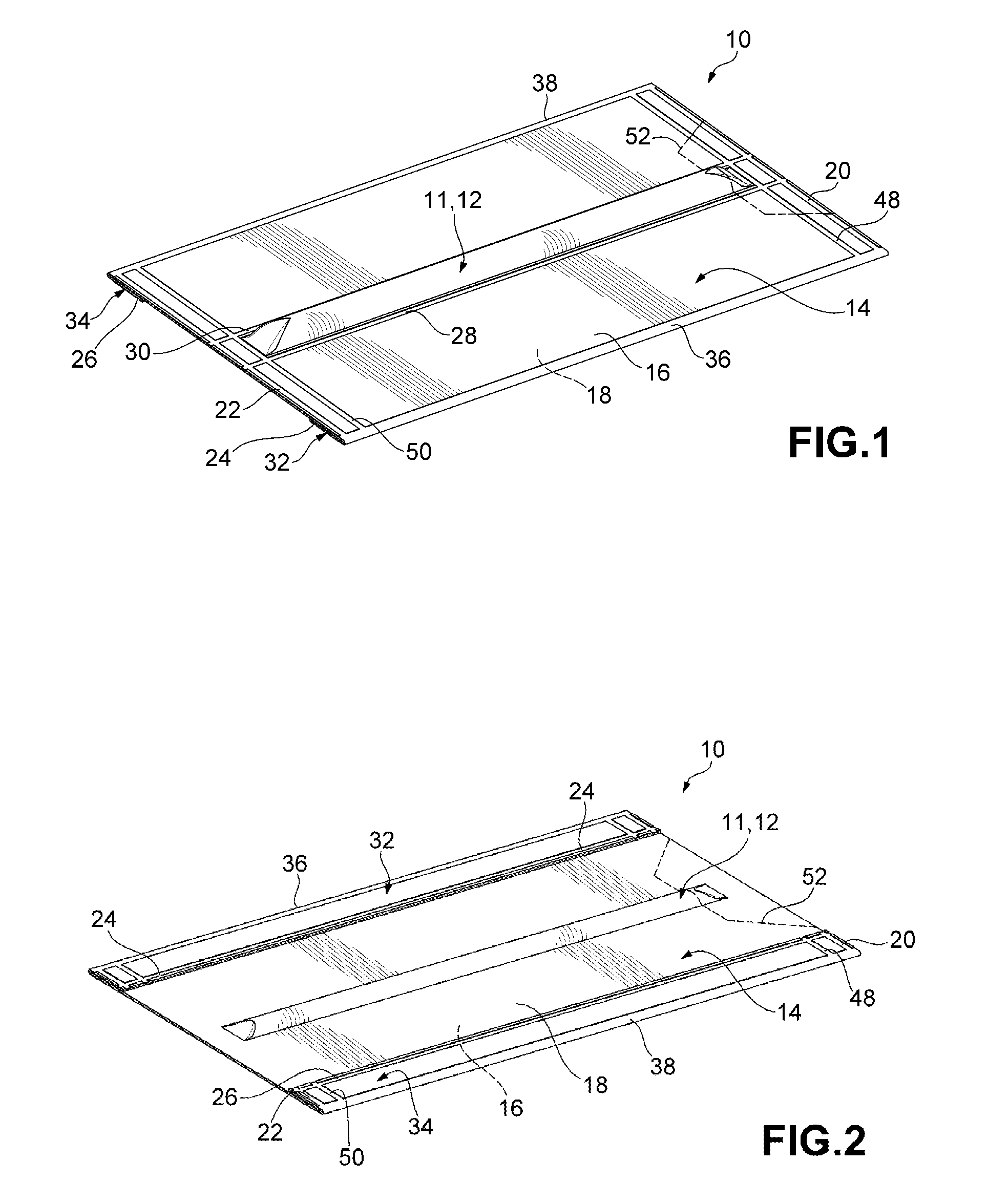

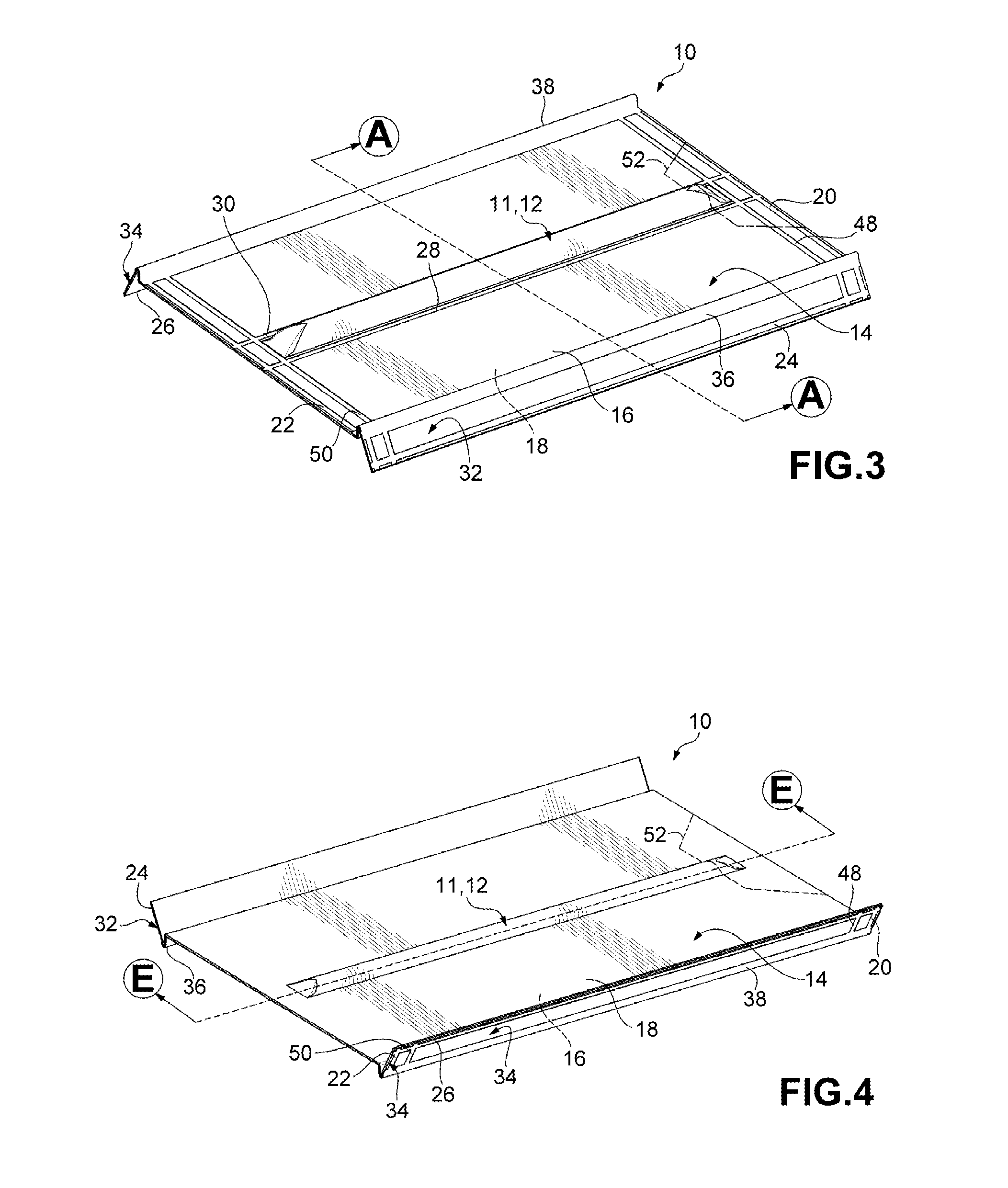

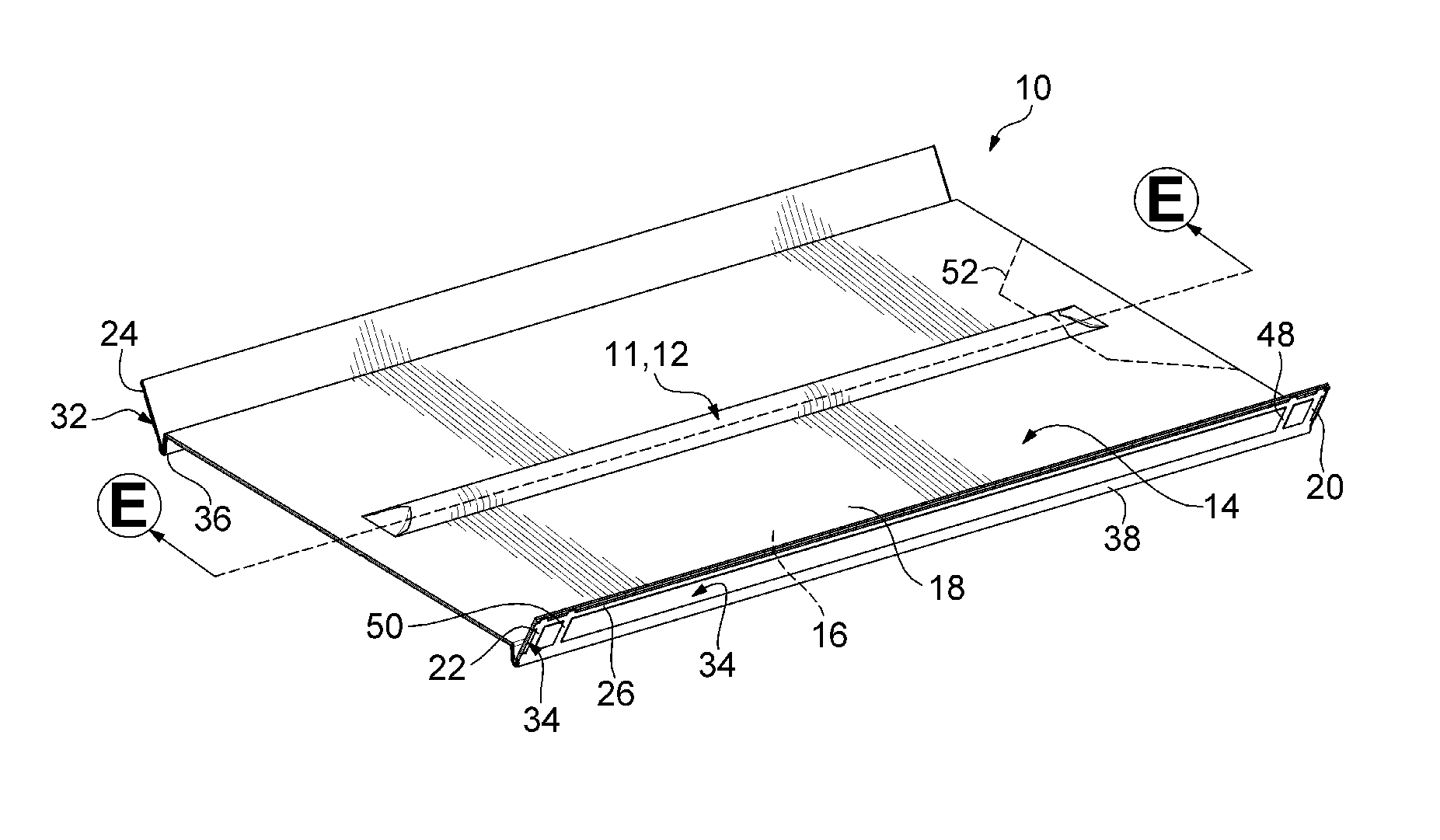

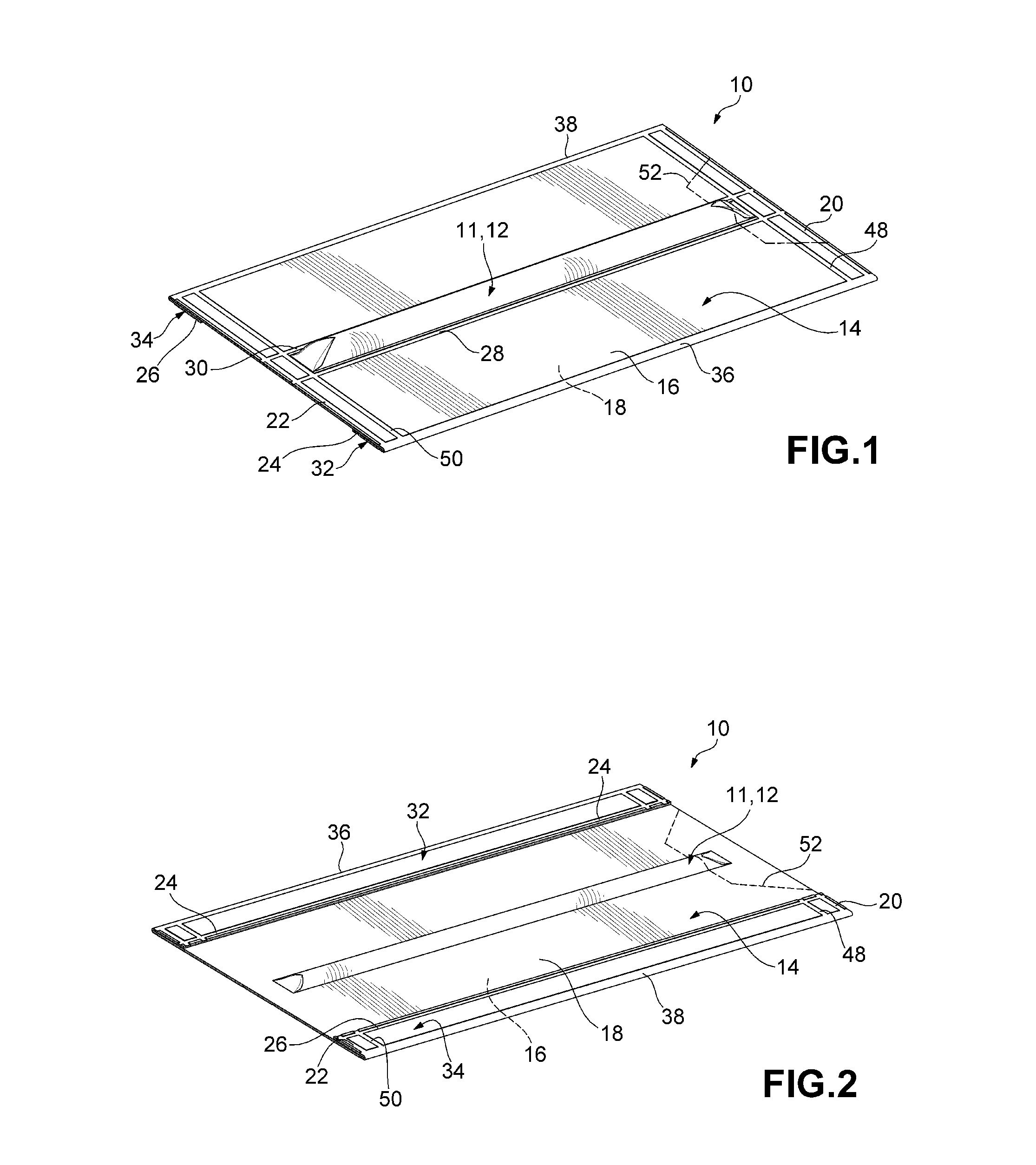

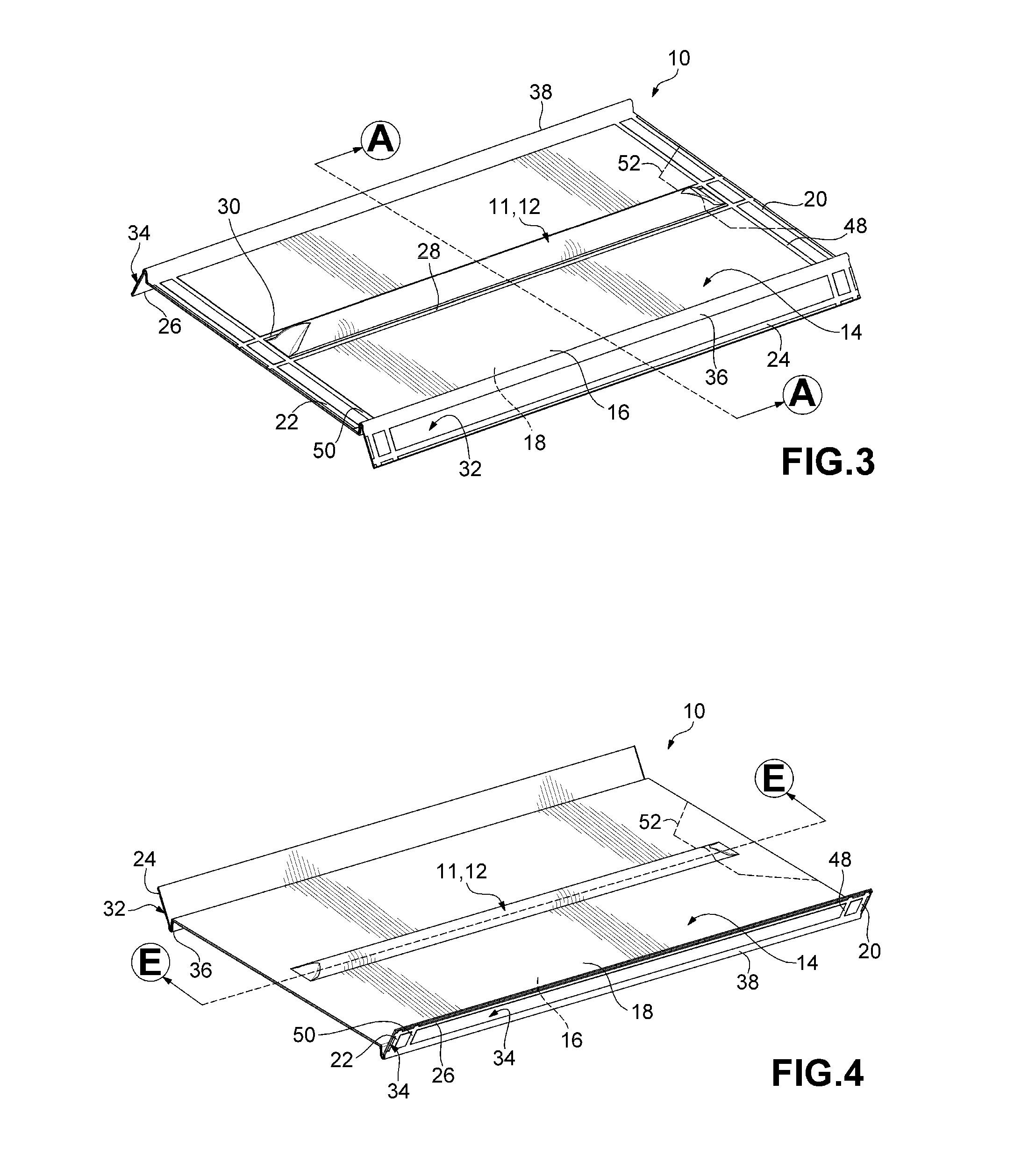

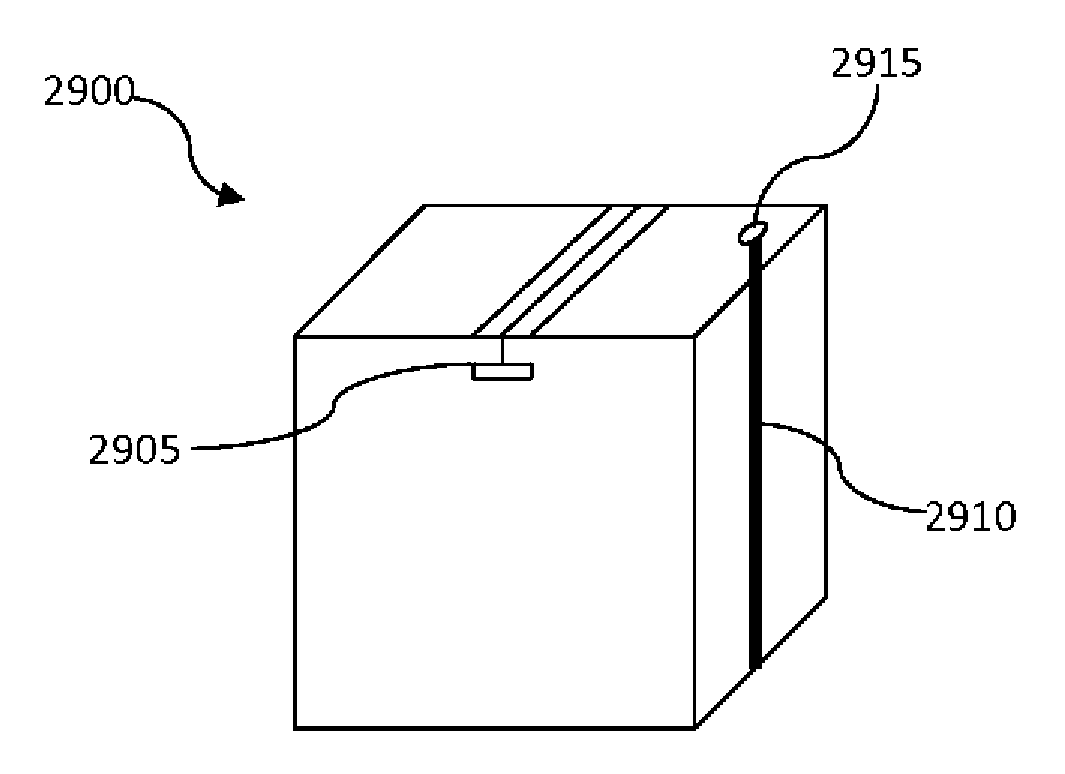

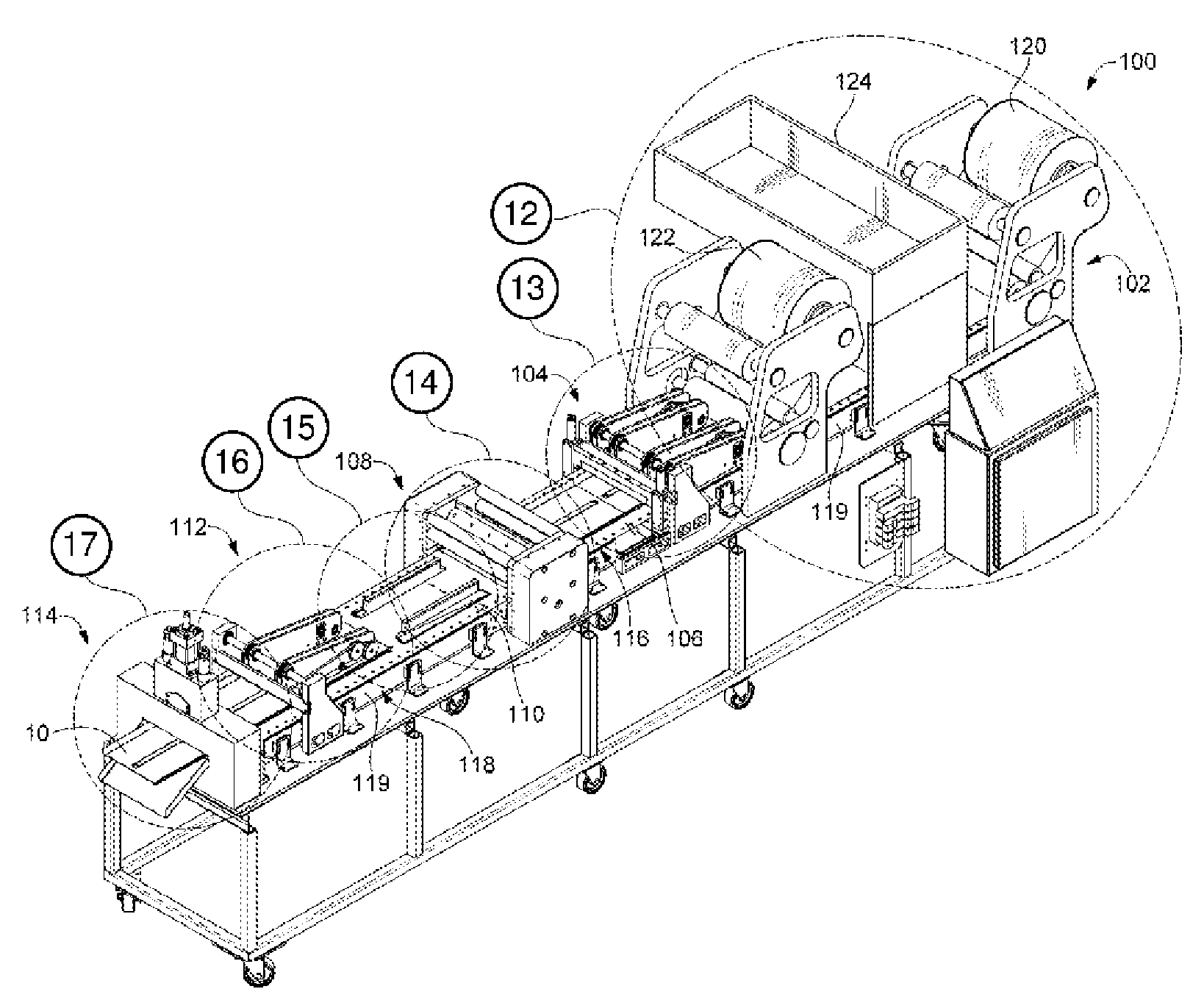

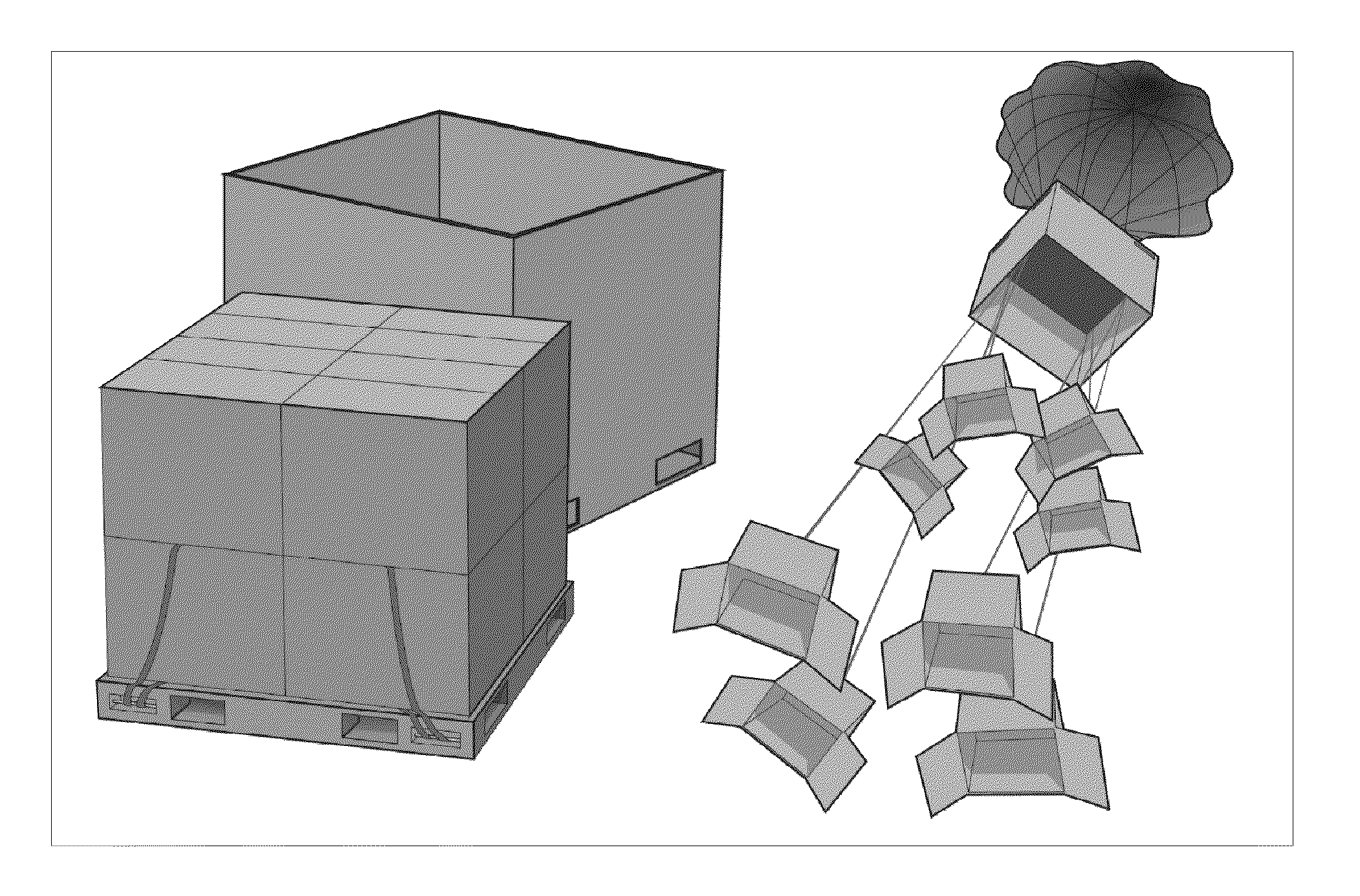

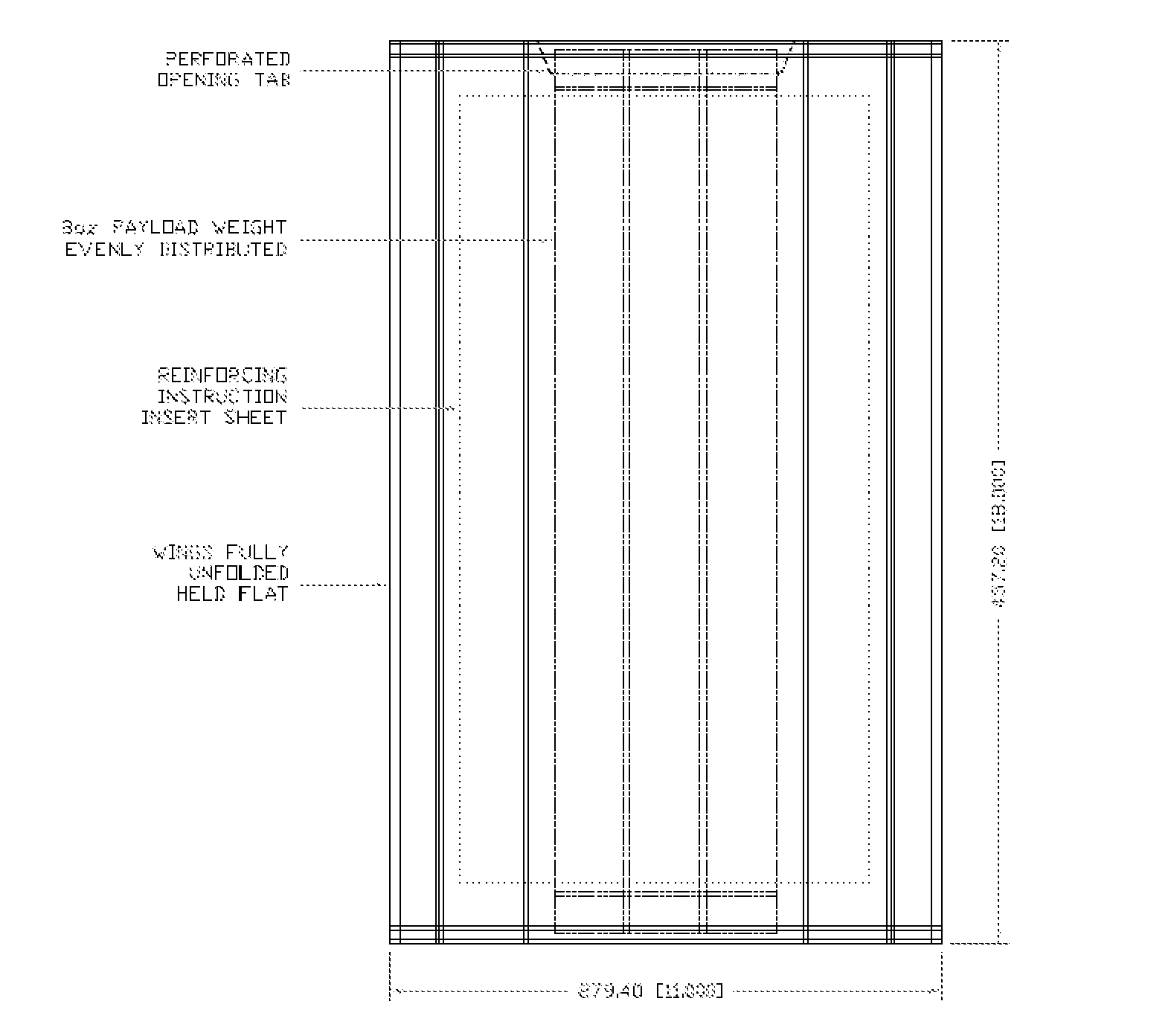

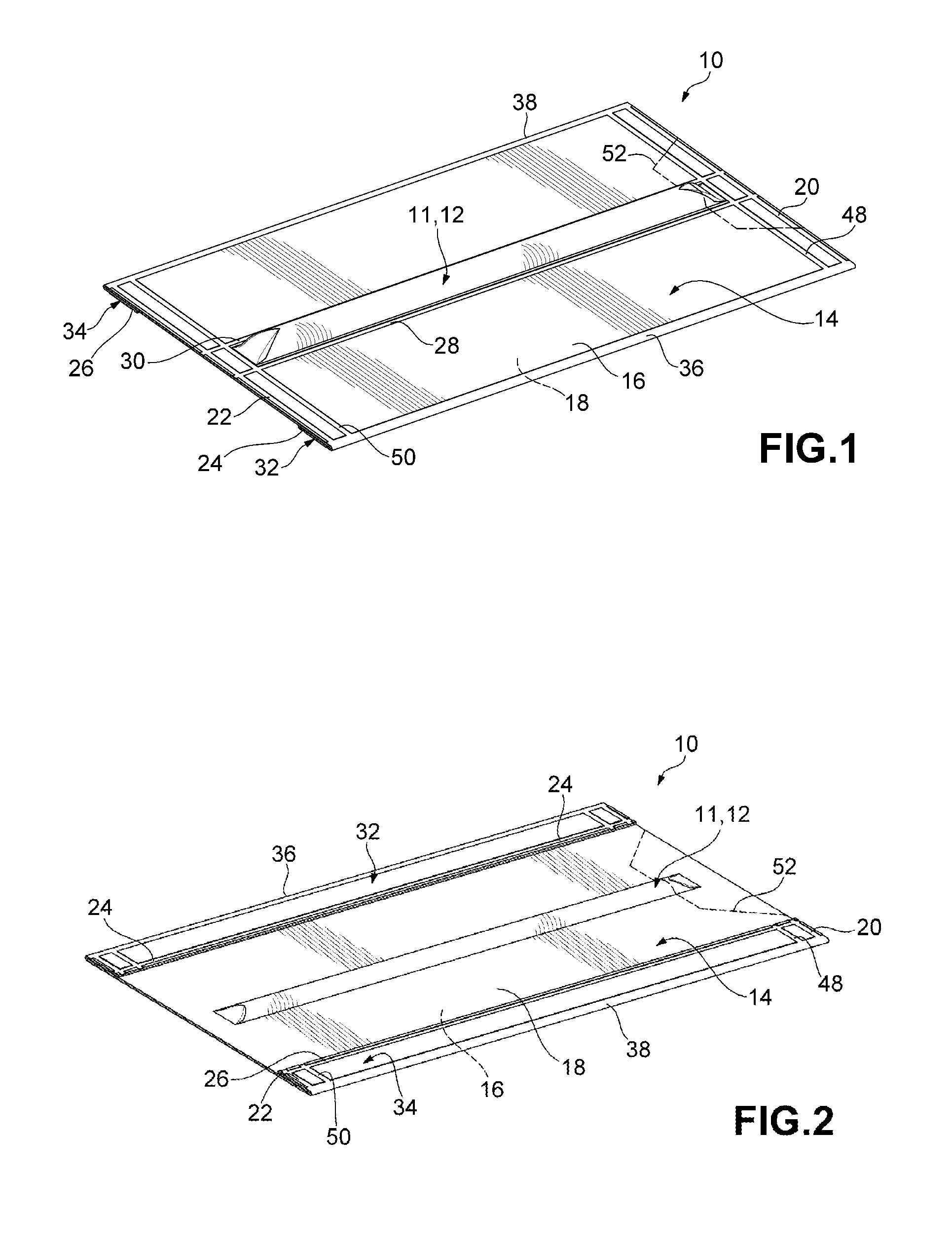

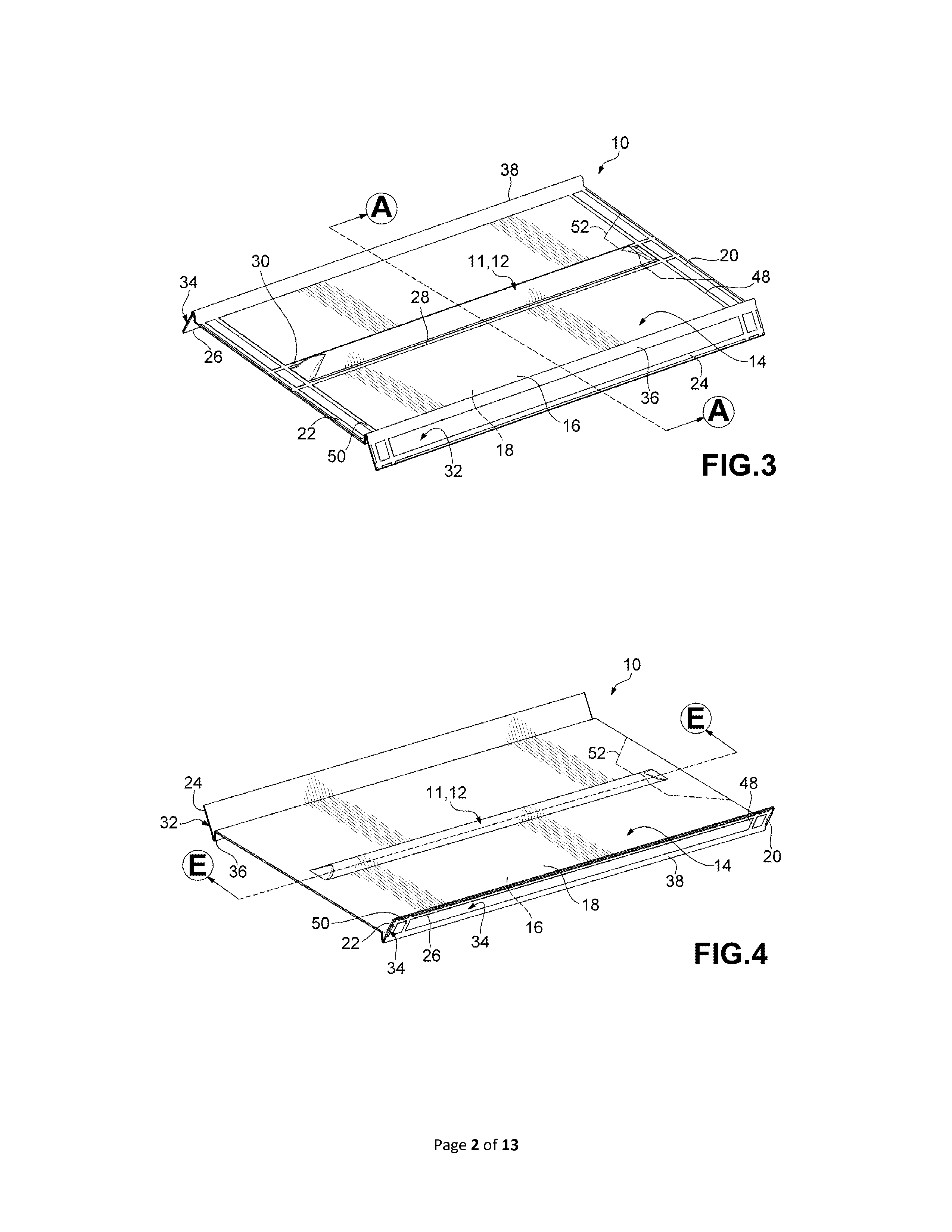

Supply packs and methods and systems for manufacturing supply packs

InactiveUS20120043426A1Easily air droppedImprove distributionOpening closed containersBottle/container closureCost effectivenessManufactured supplies

A cost-effective pack adapted to be distributed from an aircraft in the event of a natural, military, political, or other disaster includes an outer package, at least one item in the outer package for aerial delivery, and at least one aerodynamic component formed on the outer package and methods and systems for making the pack.

Owner:THE SKYLIFE COMPANY

Manufacturing method for integral plastic tap body component and plastic tap body component

ActiveCN101664980BEasy to prepareImprove manufacturing efficiencyValve housingsManufactured suppliesProcess engineering

The invention is suitable for a manufacturing method for an integral plastic tap body component and a product thereof. The manufacturing method mainly adopts the technical scheme of molding a tap by twice injection molding, wherein the primary injection molding is used for molding a first component on a middle connection part of the tap body component; the first component is placed into a mold toundergo secondary injection molding so as to mold a second component on both sides of the tap body component; the second component properly coats and connects the first component; and required holes are reserved as a water inlet, a water outlet and a valve seat. The technical scheme can simplify the complicated and lengthy manufacturing method of the conventional copper casting, improves production efficiency and product quality, reduces cost, reject ratio and product weight, and greatly reduces transportation cost. Compared with the conventional manufacturing method for forming the componentby individual injection molding and then sticking, the method can effectively reduce manual assembly cost, improves production efficiency and product quality, and ensures that the component has better structural strength.

Owner:东莞成霖安博制造有限公司

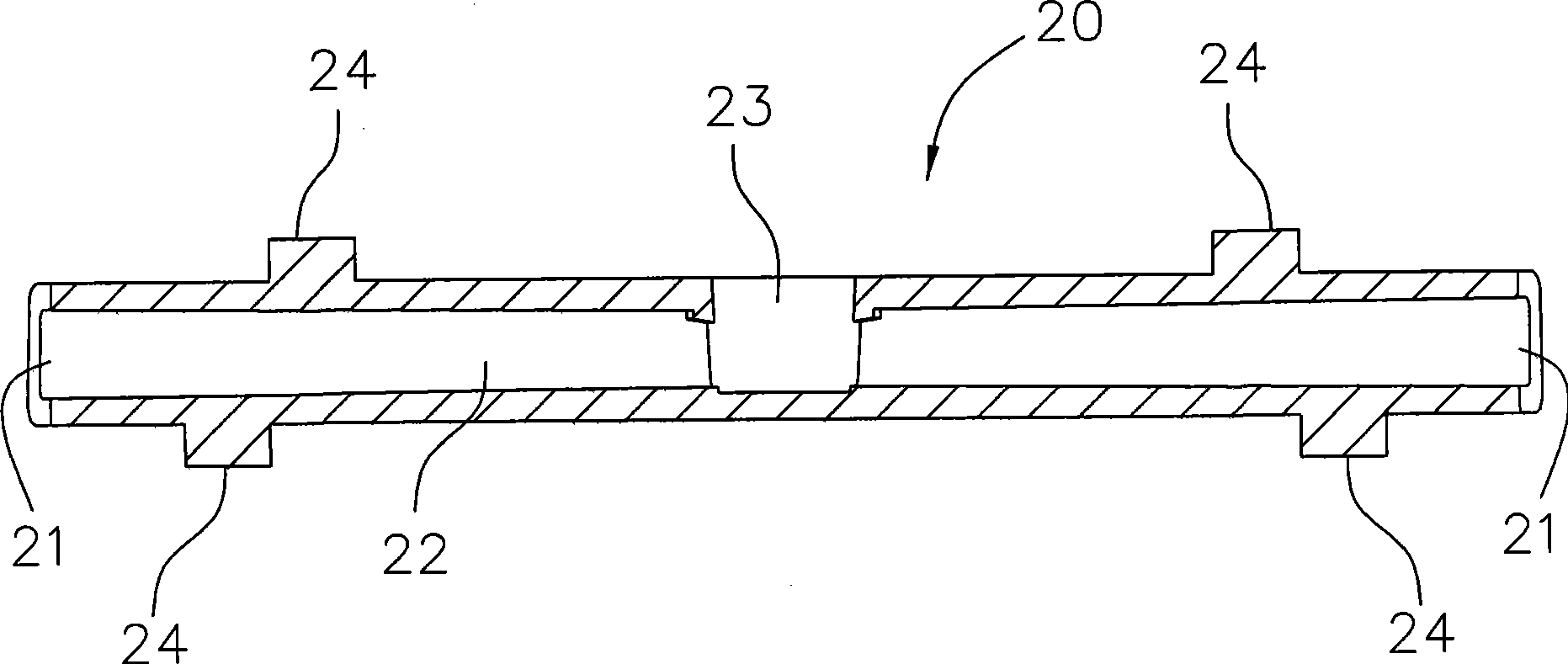

Manufacturing method of converter fly ash pressed balls

ActiveCN104593589AImprove ball pressing efficiencySimple production processProcess efficiency improvementAdhesiveDust control

The invention relates to a manufacturing method of converter fly ash pressed balls. The manufacturing method sequentially comprises the following steps: feeding converter fly ash to a #1 stock bin and feeding return mines to a #2 stock bin; feeding the converter fly ash and return mines to water spray double shafts to be stirred for pumping water and stirring, and then feeding the mixture to a digestion cabin to be digested through a shared bucket elevator; after digesting the converter fly ash and return mines in the digestion cabin for a time not shorter than half an hour, feeding the converter fly ash and return mines into a mixing machine and uniformly mixing with an adhesive; pre-pressing by using a prepresser, then primarily extruding and molding by virtue of a ball press machine, wherein after primary screening, overtails are primarily molded materials, which are fed into a return cabin; after the return cabin is filled, pressing finished products, adding a standby adhesive for the primarily modeled materials in a standby mixture, and pre-pressing by the standby prepressor, secondarily extruding and molding by using a standby ball press machine and secondarily screening to obtain overtails which are finished products; and after pressing the converter fly ash and return mines in the digestion cabin, re-filling the digestion cabin to start pressing. According to the manufacturing method provided by the invention, the ball pressing efficiency is not less than 12.5 ton / h.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

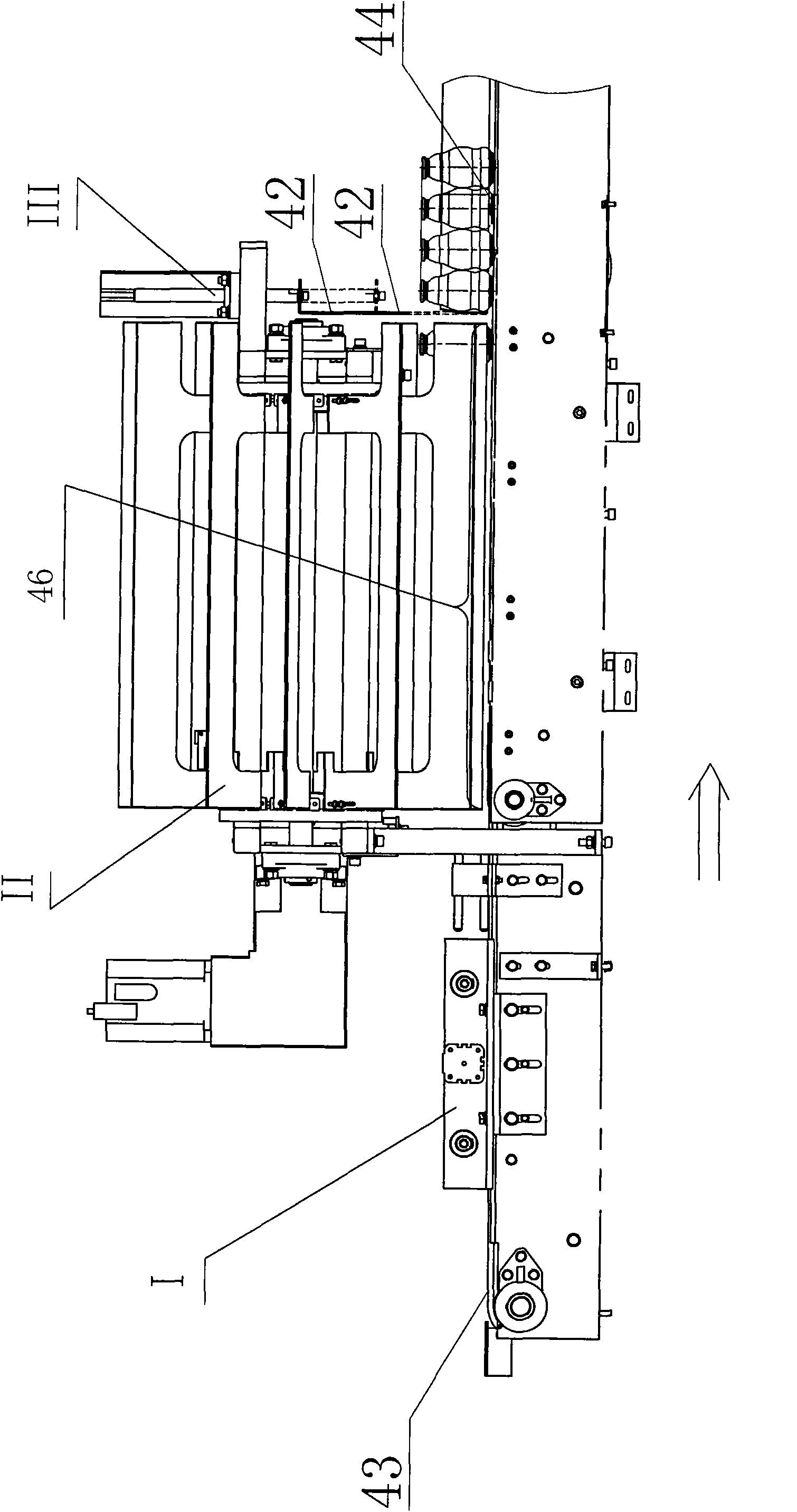

Straightening track-dividing device for shrink film packaging bottles

InactiveCN101811582ANovel and reasonable structureFlexible and reliablePackaging automatic controlPackaging bottlesManufactured suppliesBottle

The invention relates to a straightening track-dividing device for shrink film packaging bottles. The invention aims to automatically separate shrink film packaging bottles which shrink into a row, thereby further realizing automatic boxing. The device has the characteristics of novel and reasonable structure, flexible and reliable motion, accurate track dividing, and high speed for changing varieties, thereby improving the work efficiency and avoiding bottle clamping. The invention has the technical scheme that the straightening track-dividing device for the shrink film packaging bottles is provided with a bottle feed conveyer belt and a buffer conveyer belt which are sequentially arranged in the motion direction of the bottles and move towards the same direction. The invention is characterized in that both sides of the bottle feed conveyer belt are provided with a counting and clamping mechanism; a bottle-poking track-dividing mechanism is hung above the buffer conveyer belt; and the outer side of the bottle-poking track-dividing mechanism is provided with a bottle blocking mechanism. The invention is suitable for manufacturing supplies before boxing in the industries of food, medication, daily health products and the like, and belongs to the technical field of packaging.

Owner:HANGZHOU WAHAHA GROUP

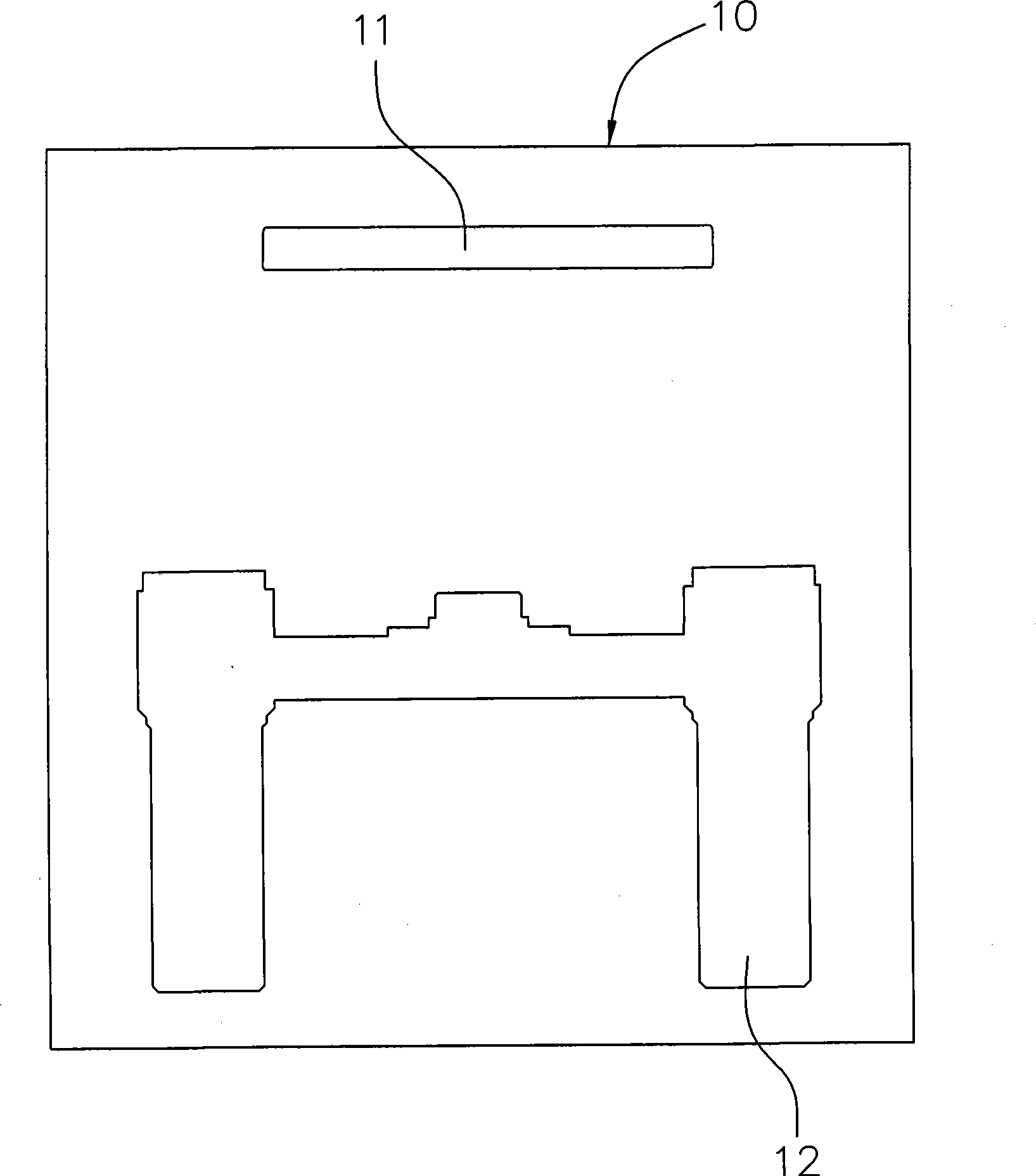

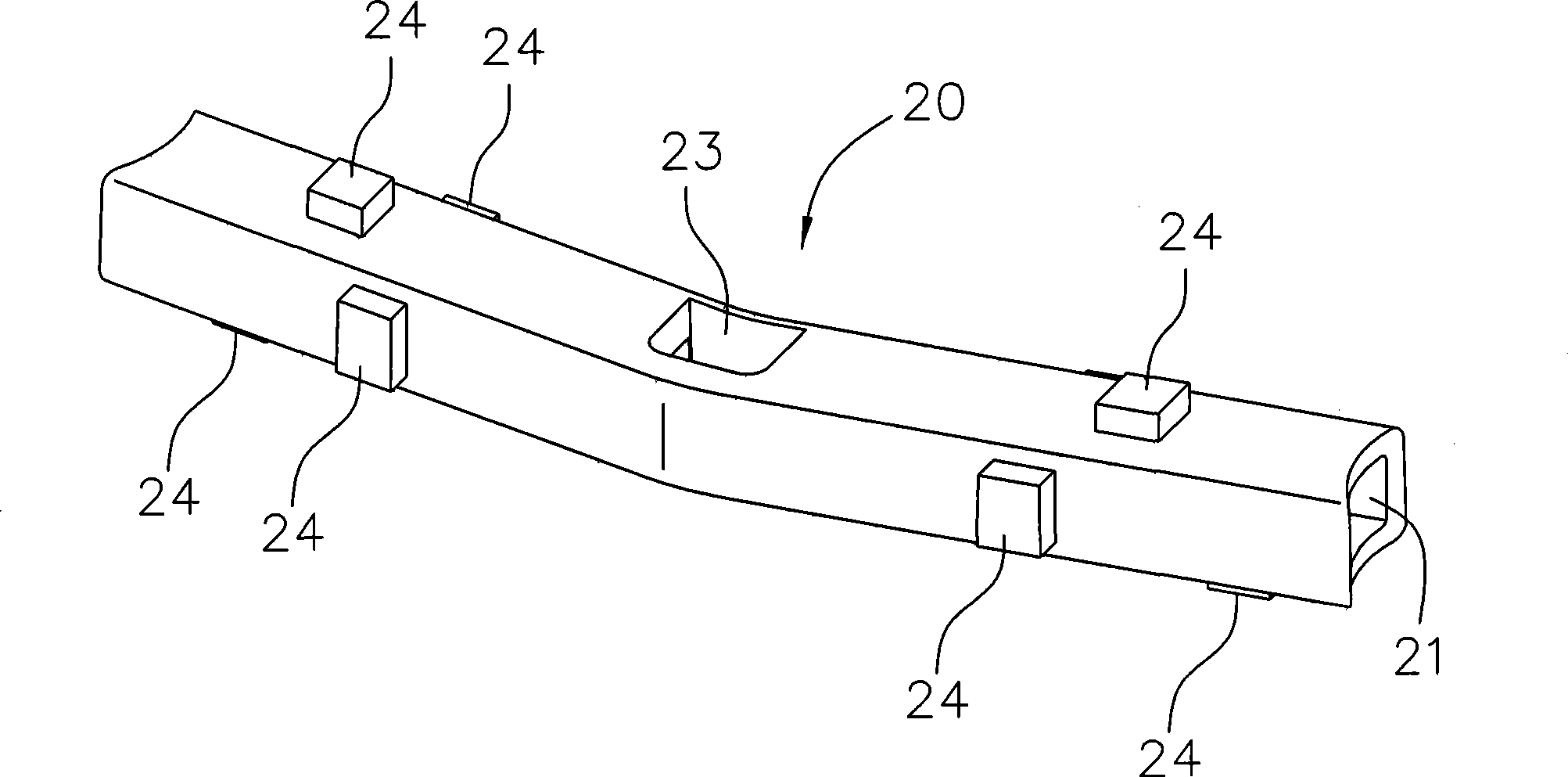

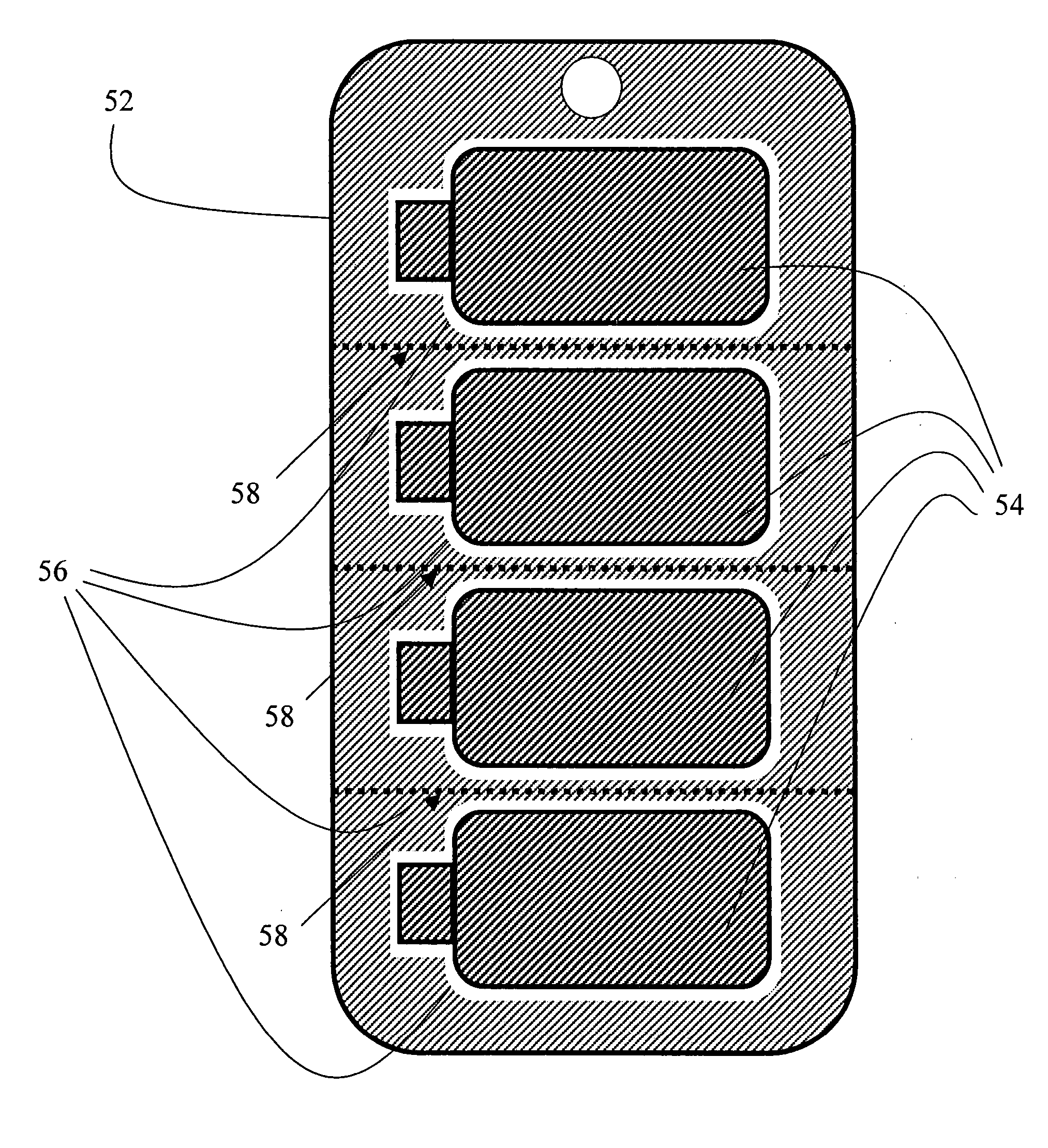

Package for a portable USB storage device

ActiveUS20070163913A1Prevent removalEasily grab both sidesClosuresOther accessoriesUSBManufactured Object

The present invention discloses systems and methods for packaging multiple articles of manufacture for display at a point of sale. The packaging allows the articles of manufacture to be grasped and felt by a consumer prior to purchase, while reducing the chance of unintended or illegal removal of the articles of manufacture from the packaging. The packaging also allows the articles of manufacture to be connected to a host device and tested prior to purchase without damaging the packaging. The articles of manufacture can be made of multiple components which can be attached to the packaging during the assembly of the components.

Owner:WESTERN DIGITAL ISRAEL LTD

Supply packs and methods and systems for manufacturing supply packs

InactiveUS8979030B2Easily air dropped and distributedRisk minimizationWrappingFreight handlingCost effectivenessManufactured supplies

A cost-effective pack adapted to be distributed from an aircraft in the event of a natural, military, political, or other disaster includes an outer package, at least one item in the outer package for aerial delivery, and at least one aerodynamic component formed on the outer package and methods and systems for making the pack.

Owner:THE SKYLIFE CO INC

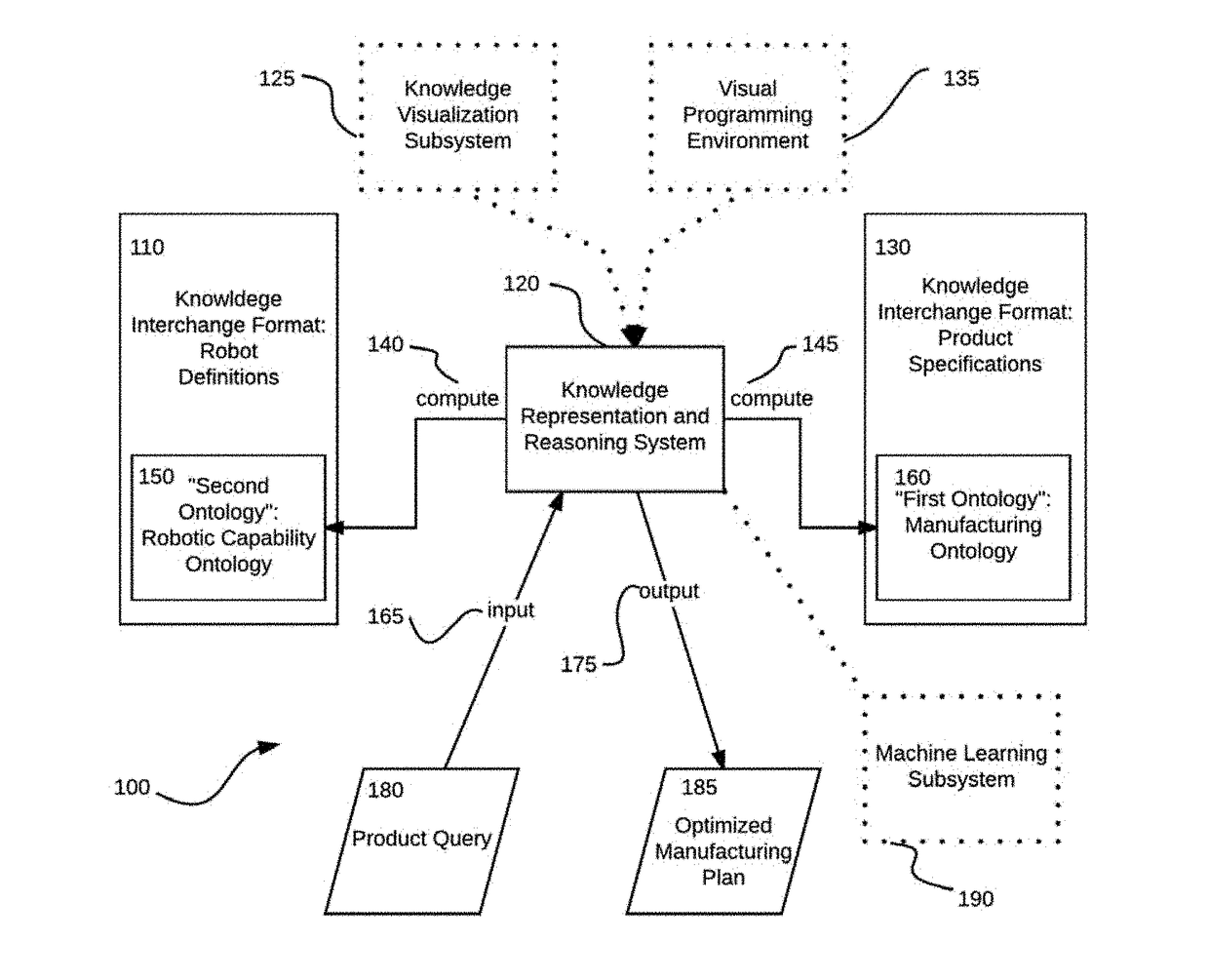

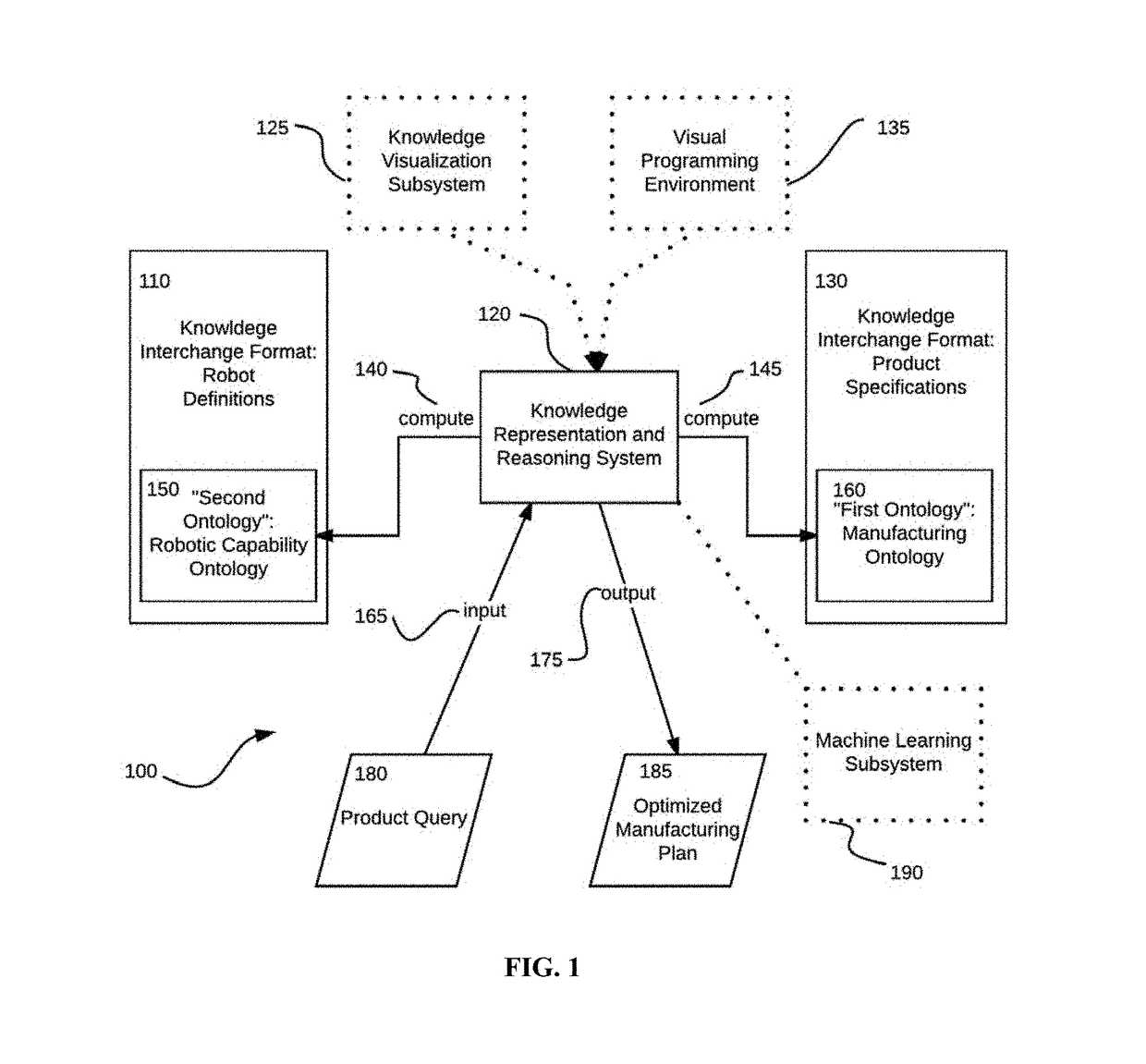

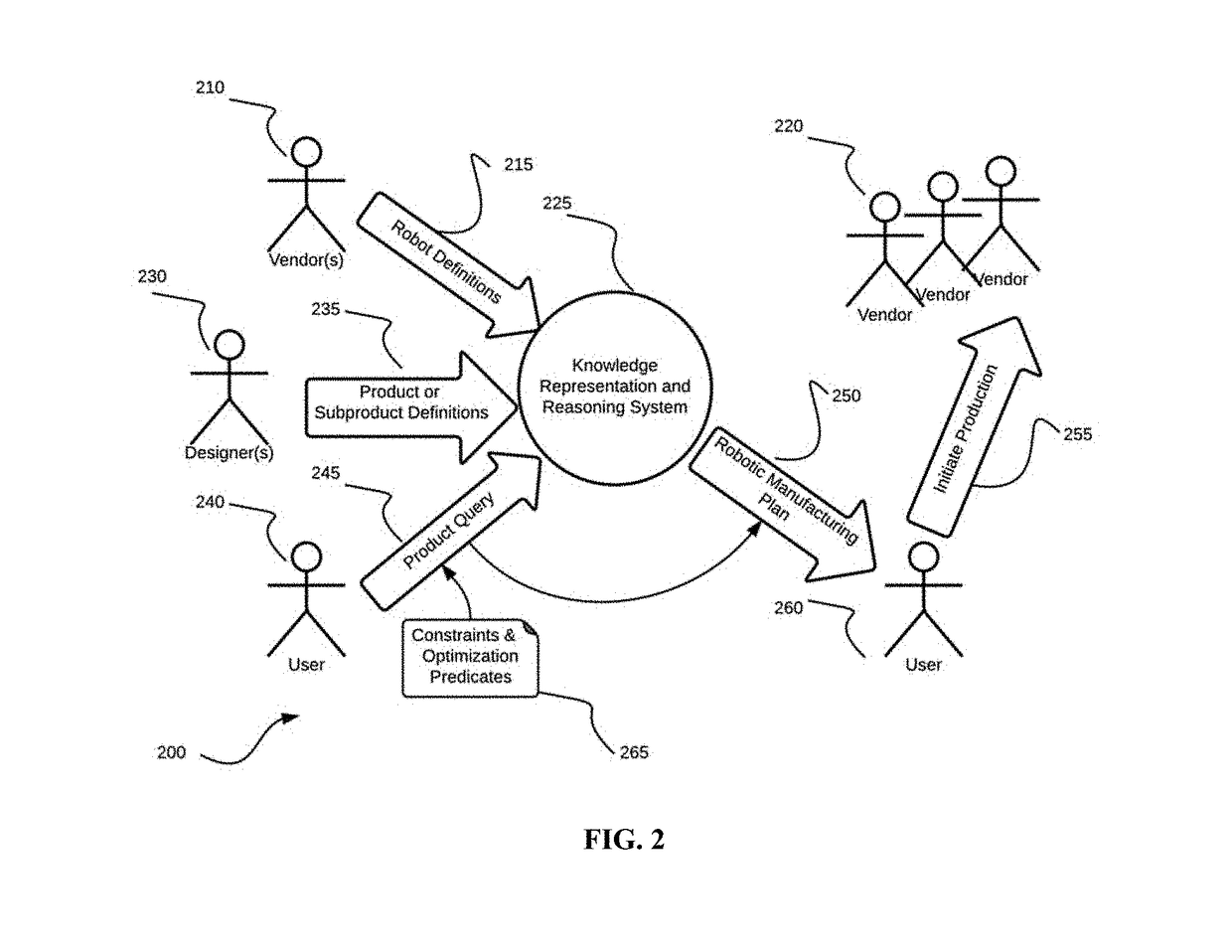

Robotic Capability Model for Artificial Intelligence Assisted Manufacturing Supply Chain Planning

InactiveUS20170278000A1Biological neural network modelsKnowledge representationReasoning systemOutput device

A computer-implemented method for automating manufacturing supply chain planning, comprising: (a) providing a computer processor for processing data; (b) providing at least one input device; (c) providing at least one output device; (d) providing a computer readable storage device; (e) providing a first ontology for defining a product in terms of the method of manufacture of said product or for defining a plurality of products in terms of the method of manufacture of said products; (f) providing a second ontology for defining the capabilities of a plurality of manufacturing facilities; and g) providing a knowledge representation and reasoning system executed on said computer processor.

Owner:KOHLHEPP CHRISTOPH ADAM

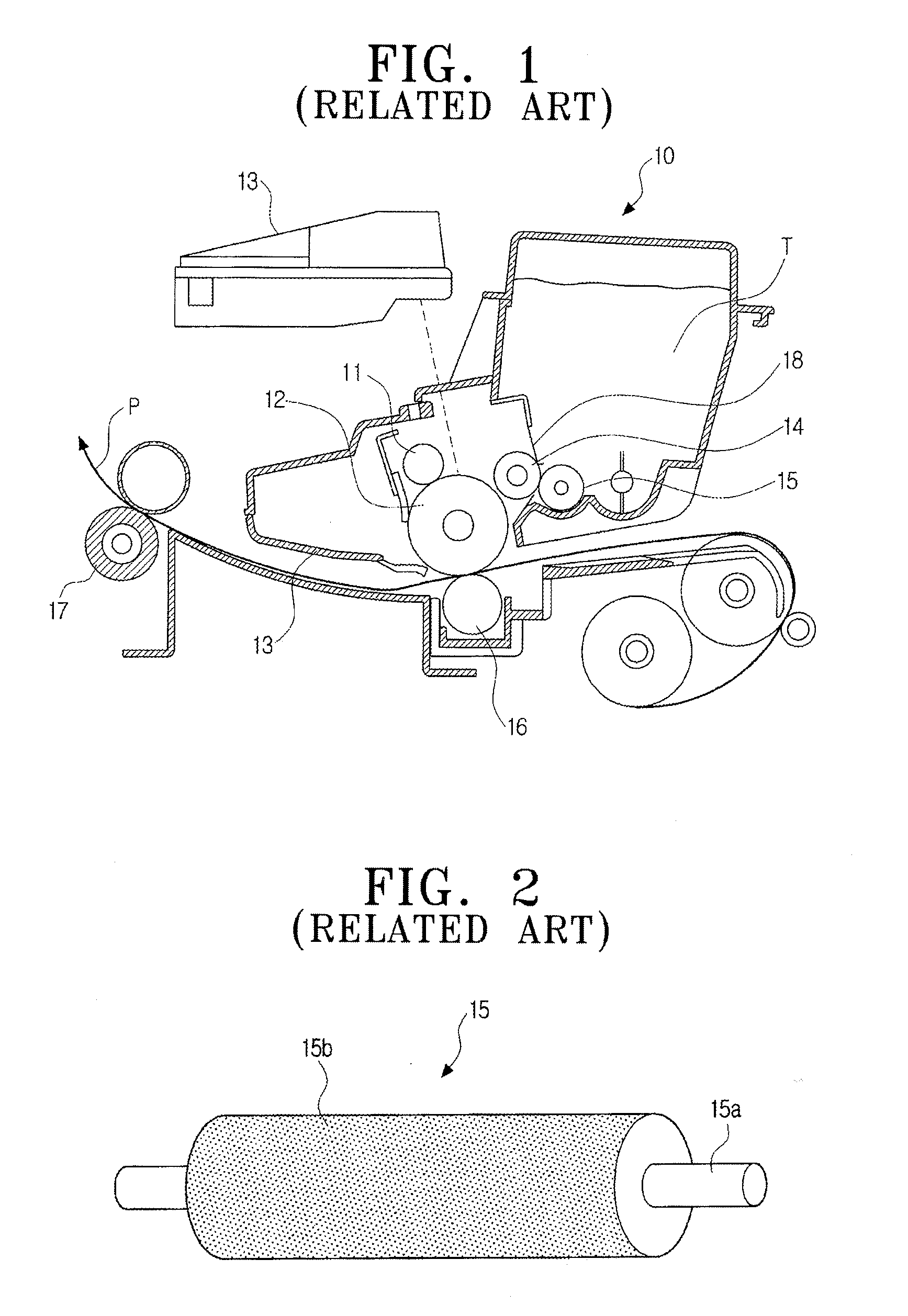

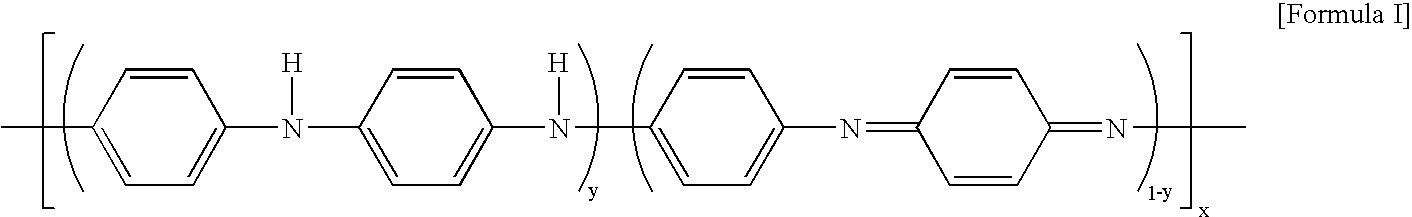

Conductive toner supply roller, method of manufacturing supply roller, and electrostatic recording apparatus having the supply roller

ActiveUS20090012196A1Non-conductive material with dispersed conductive materialElectrographic process apparatusConductive polymerManufactured supplies

A conductive toner supply roller and a method of manufacturing the supply roller. The method includes preparing a polyurethane foam, impregnating the polyurethane foam with an impregnation solution including an electroconductive polymer, a binder resin, an electroconductive agent and a solvent, and drying the resulting polyurethane foam, cutting the dried polyurethane foam, and inserting a shaft into the cut polyurethane foam, and polishing an outer surface of the resulting polyurethane foam. The resulting conductive toner supply roller has a low or medium resistance, and may be user in an electrostatic recording apparatus such as a printer, a facsimile machine, a copier or the like.

Owner:HEWLETT PACKARD DEV CO LP

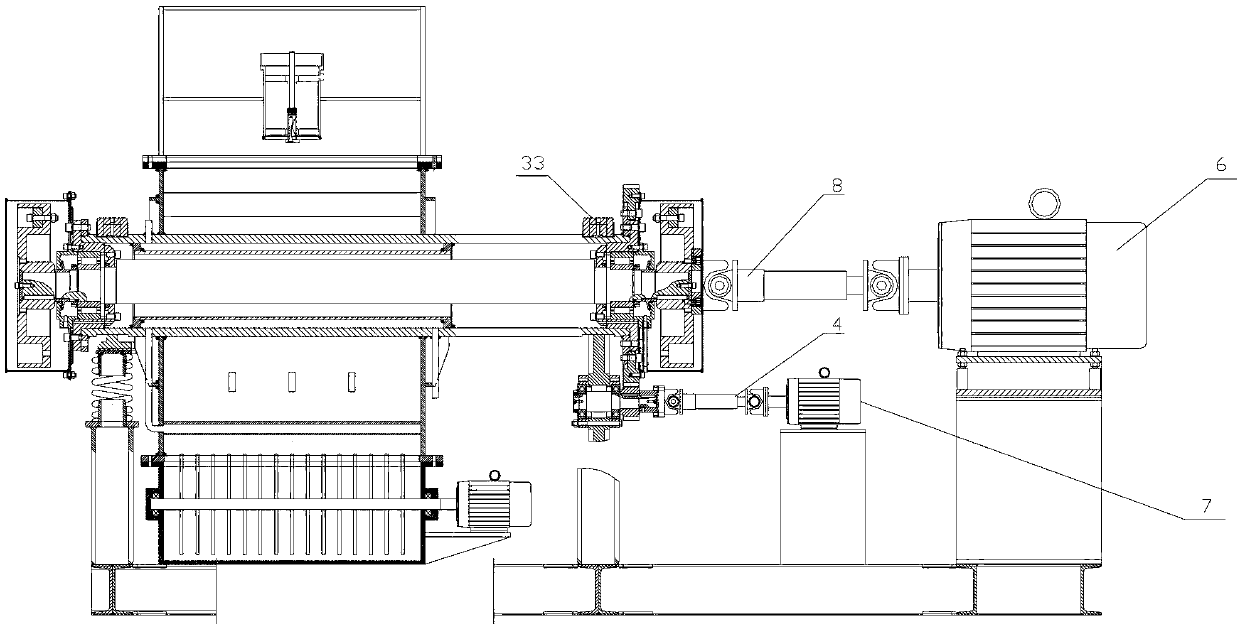

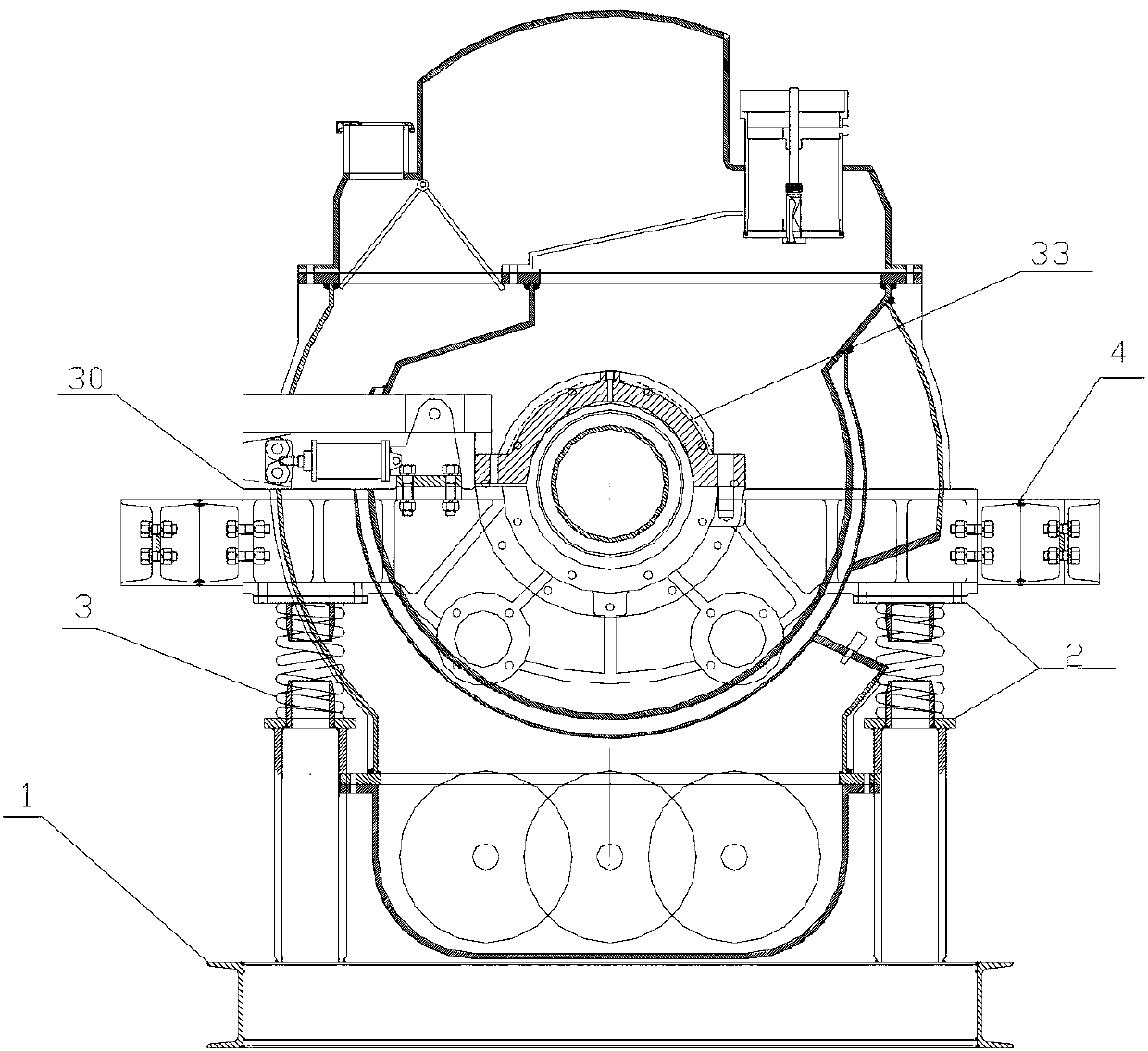

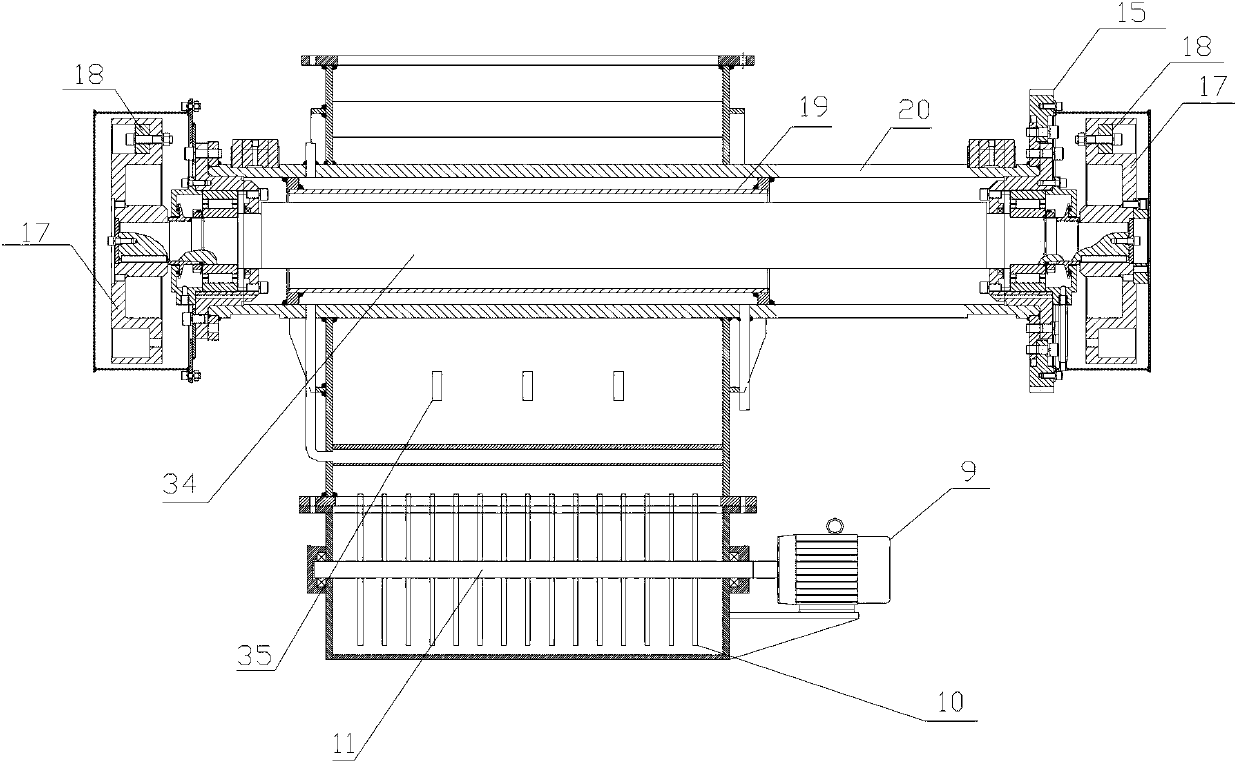

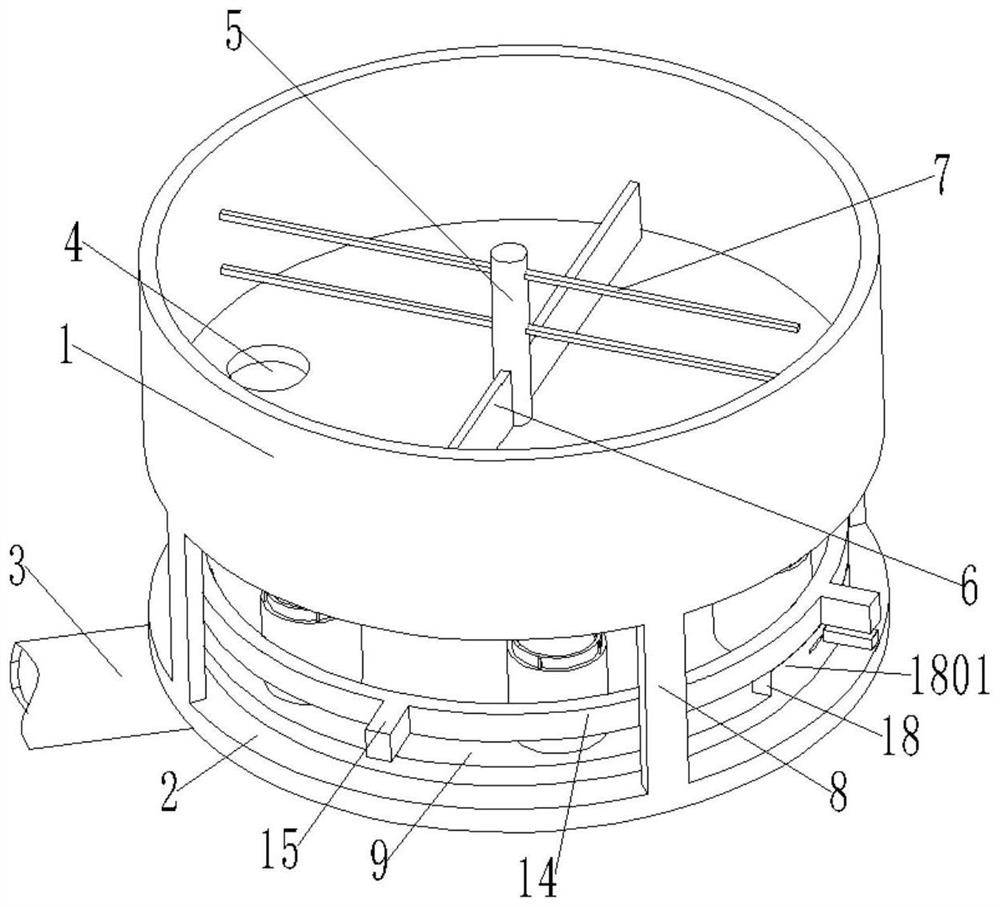

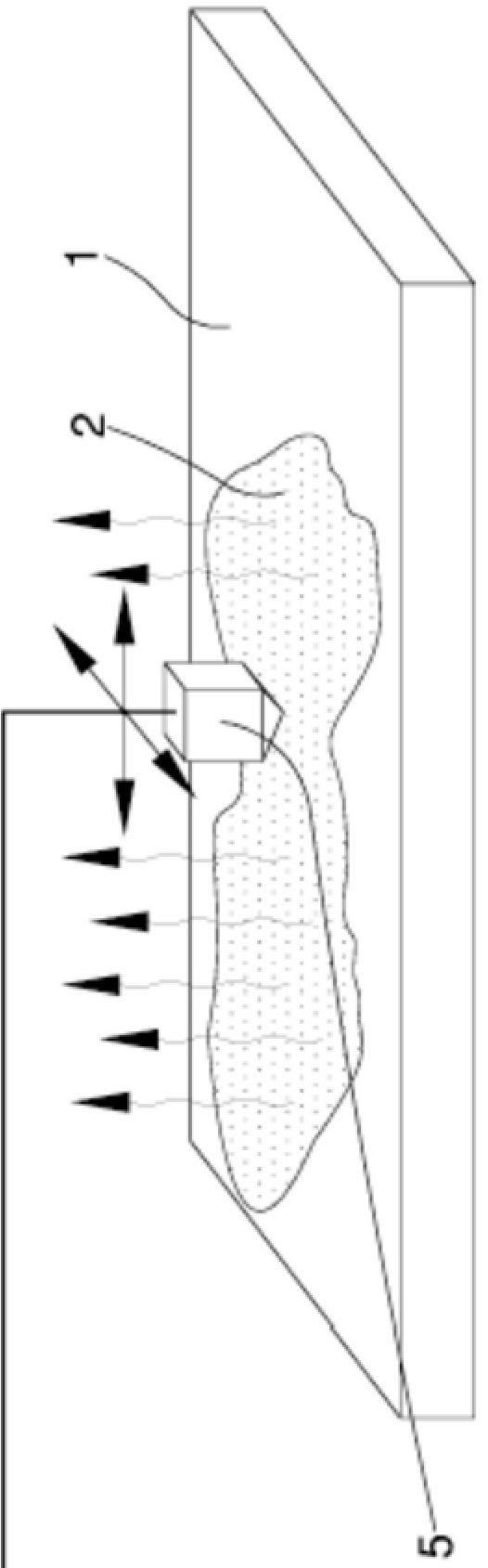

Vibration ball-milling pelletizer

InactiveCN103100347ASolve the shortcomings of high energy consumption, high dust and poor working environmentUniform particlesMechanical vibrations separationGranulation in stationary drums/troughsLocking mechanismEngineering

The invention provides a vibration ball-milling pelletizer, comprising a base, a shock excitation spring, a front support, a rear support and a main motor. The shock excitation spring is fixed between the base and the front and the rear support. The pelletizer also comprises the following parts: a barrel body assembly fixed on the front and the rear support; an overturning assembly; and a locking mechanism comprising a locking mechanism, a lever and a gland; and the locking mechanism is connected through the lever with the gland. Compared with the prior art, the pelletizer provided by the invention has the advantages of capability of crushing, dispersing and uniformly mixing any liquidity superfine material, and preparing the mixed material into uniform particles; the manufactured goods have advantages of large apparent value, good fluidity, little impurity mixing and excellent mixing characteristics, and can be prepared into a finished product or provide good processing characteristics for subsequent process. A whole set of production equipment can realize automatic closing, complete automation, no dust pollution and small investment.

Owner:HANGZHOU ZHONGYANG CHEM MACHINERY

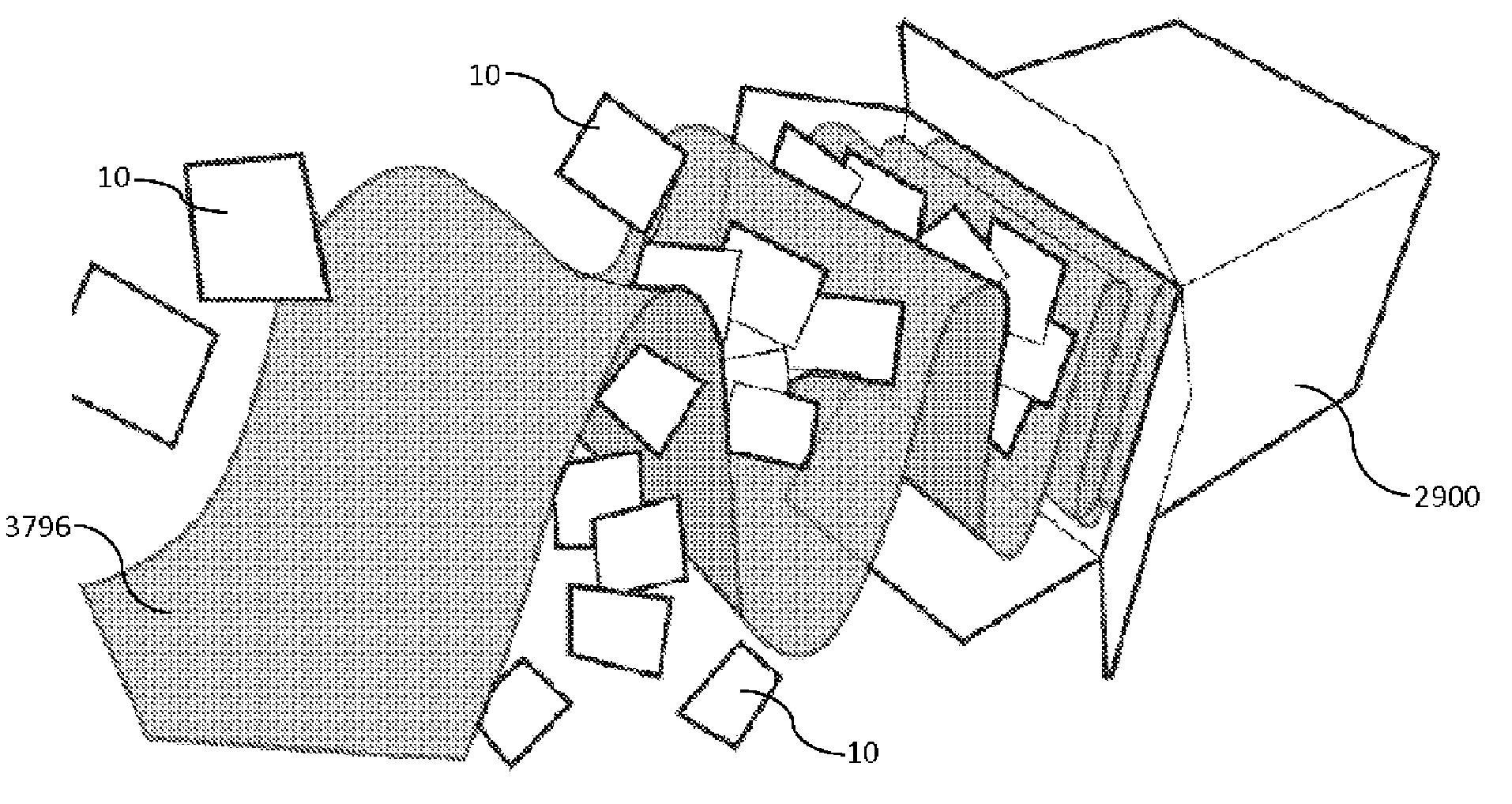

Supply packs and methods and systems for manufacturing supply packs

InactiveUS8794573B2Easily air dropped and distributedRisk minimizationOpening closed containersBottle/container closureCost effectivenessManufactured supplies

A cost-effective pack adapted to be distributed from an aircraft in the event of a natural, military, political, or other disaster includes an outer package, at least one item in the outer package for aerial delivery, and at least one aerodynamic component formed on the outer package and methods and systems for making the pack.

Owner:THE SKYLIFE CO INC

Hydraulic equipment for briquetting iron scrap and copper scrap

InactiveCN112606464ALabor savingGuaranteed normal operationPressesEconomic benefitsManufactured supplies

The invention discloses hydraulic equipment for briquetting iron scrap and copper scrap. In the briquetting process of iron scrap and copper scrap, when raw materials are fed from a feeding port in a discharging box, the feeding blockage is not caused, the labor force of workers is reduced, the normal operation of the briquetting work is ensured, and the quality of metal briquetting products is ensured. Through the arrangement of a movable disc and an equivalent feeding barrel, equivalent feeding can be carried out for iron scrap and copper scrap briquetting, then equivalent pressing work can be conducted, and the phenomenon that pressed finished products are uneven is avoided. Through the arrangement of a material collection auxiliary ring and a quantitative locking mechanism, the material collection amount of the equivalent feeding barrel can be regulated and controlled, so that production can be carried out according to actual requirements, the overall production working efficiency is improved, and the economic benefits of production work are guaranteed.

Owner:施继良

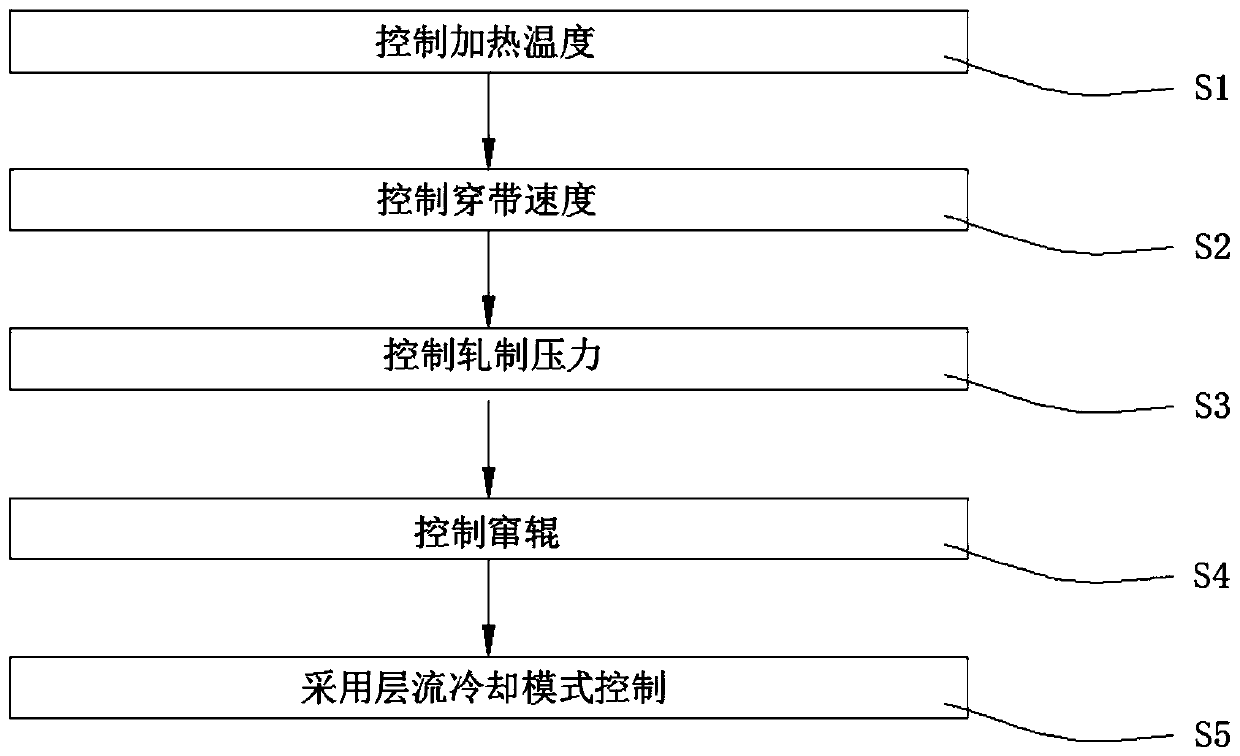

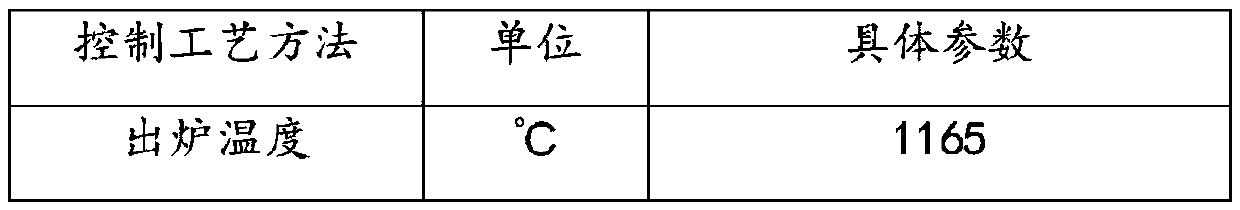

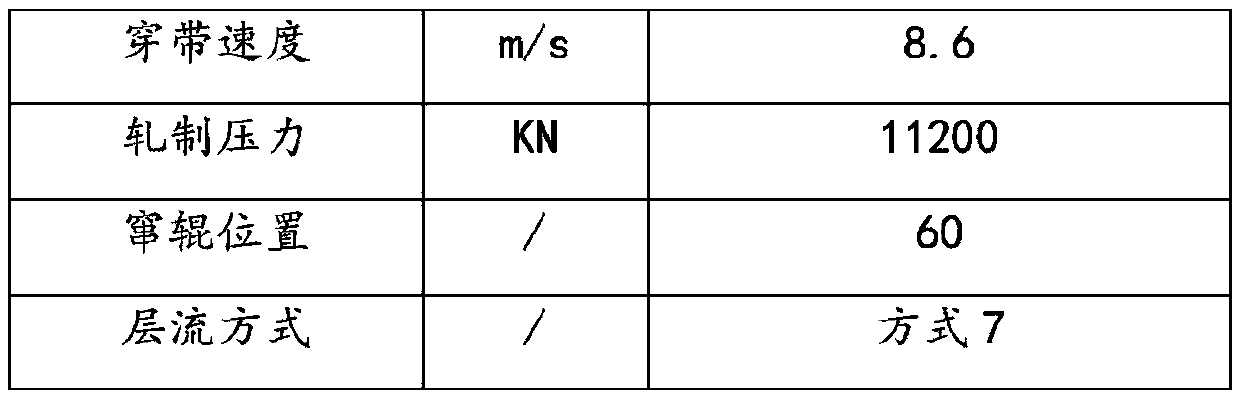

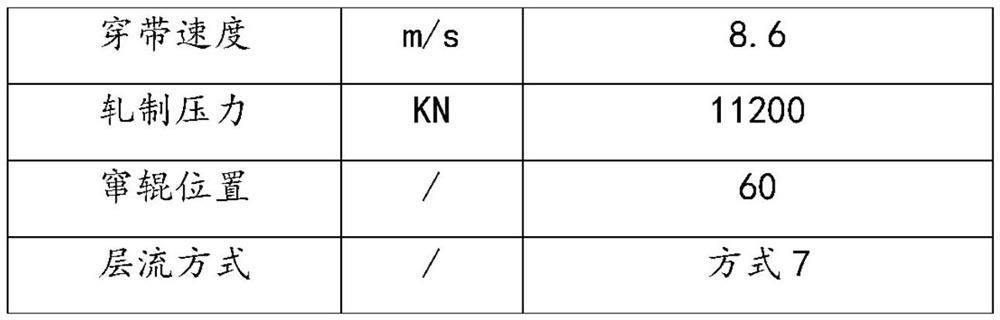

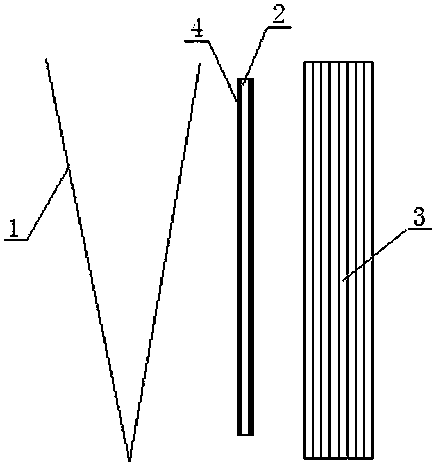

Method for producing thin-specification low-alloy high-strength diamond plate based on CSP process

ActiveCN110639950ASolve batch stability productionStable production controlTemperature control deviceWork cooling devicesProduction lineTemperature control

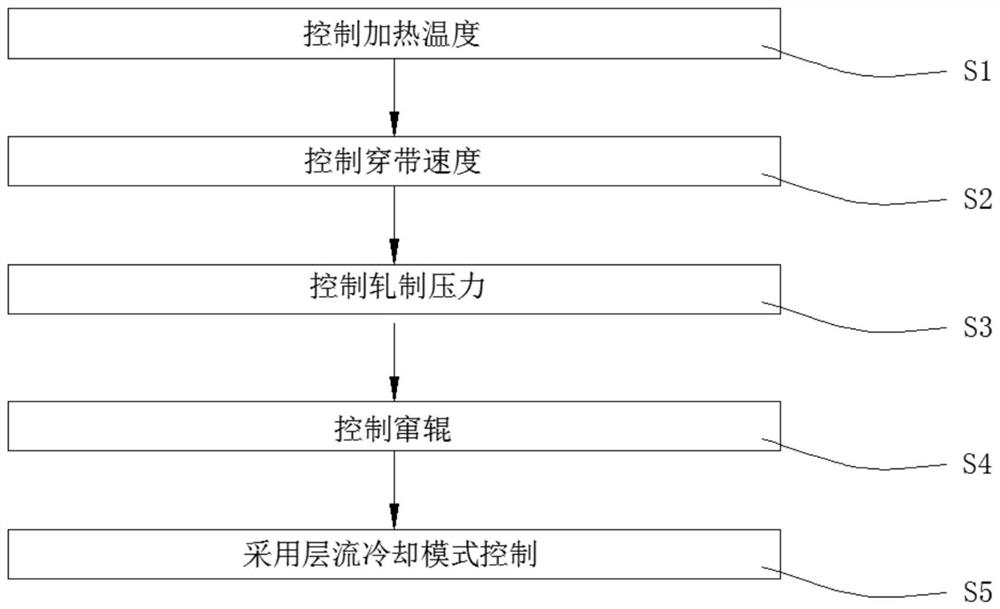

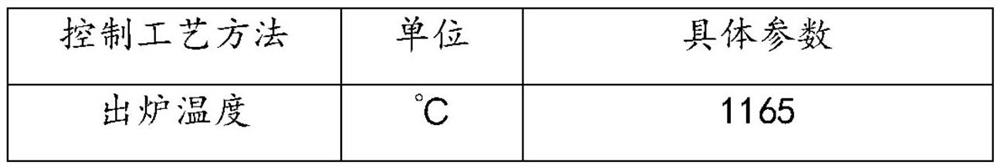

The invention discloses a method for producing a thin-specification low-alloy high-strength diamond plate based on a CSP process. The method comprises the steps of 1, controlling heating temperature,specifically, the charging temperature and the tapping temperature are controlled; 2, controlling threading speeds, specifically, the different threading speeds are controlled according to different thicknesses of rolled finished products; 3, controlling rolling pressure, specifically, rolling force parameters are adjusted according to different thickness specifications; and 4, controlling roll shifting, specifically, after roll changing calibration is finished, circulating roll shifting from a zero point position with steps of 20 mm, 25 mm and 30 mm is started. According to the method, by controlling the heating temperature, the threading speeds, the rolling pressure, and the roll shifting and by adopting a laminar cooling mode for control, the pattern integrity and the plate shape of thelow-alloy high-strength diamond plate are ensured, the related standards and user requirements are met, the stable batch supply is formed, the production process is controlled stably, no production accidents such as scrap steel, and broken casting occur, and the stable batch production of the thin-specification low-alloy high-strength diamond plate produced by the CSP production line is realized.

Owner:武汉钢铁有限公司

Supply packs and methods and systems for manufacturing supply packs

InactiveCN104364156AShow inner packagingAvoid destructionParachutesLarge containersManufactured suppliesEngineering

A cost-effective pack adapted to be distributed from an aircraft in the event of a natural, military, political, or other disaster includes an outer package, at least one item in the outer package for aerial delivery, and at least one aerodynamic component formed on the outer package and methods and systems for making the pack.

Owner:THE SKYLIFE COMPANY

Supply packs and methods and systems for manufacturing supply packs

ActiveUS9457902B2Easily air dropped and distributedRisk minimizationParachutes testing apparatusNon-canopied parachutesCost effectivenessManufactured supplies

A cost-effective pack adapted to be distributed from an aircraft in the event of a natural, military, political, or other disaster includes an outer package, at least one item in the outer package for aerial delivery, and at least one aerodynamic component formed on the outer package and methods and systems for making the pack.

Owner:THE SKYLIFE CO INC

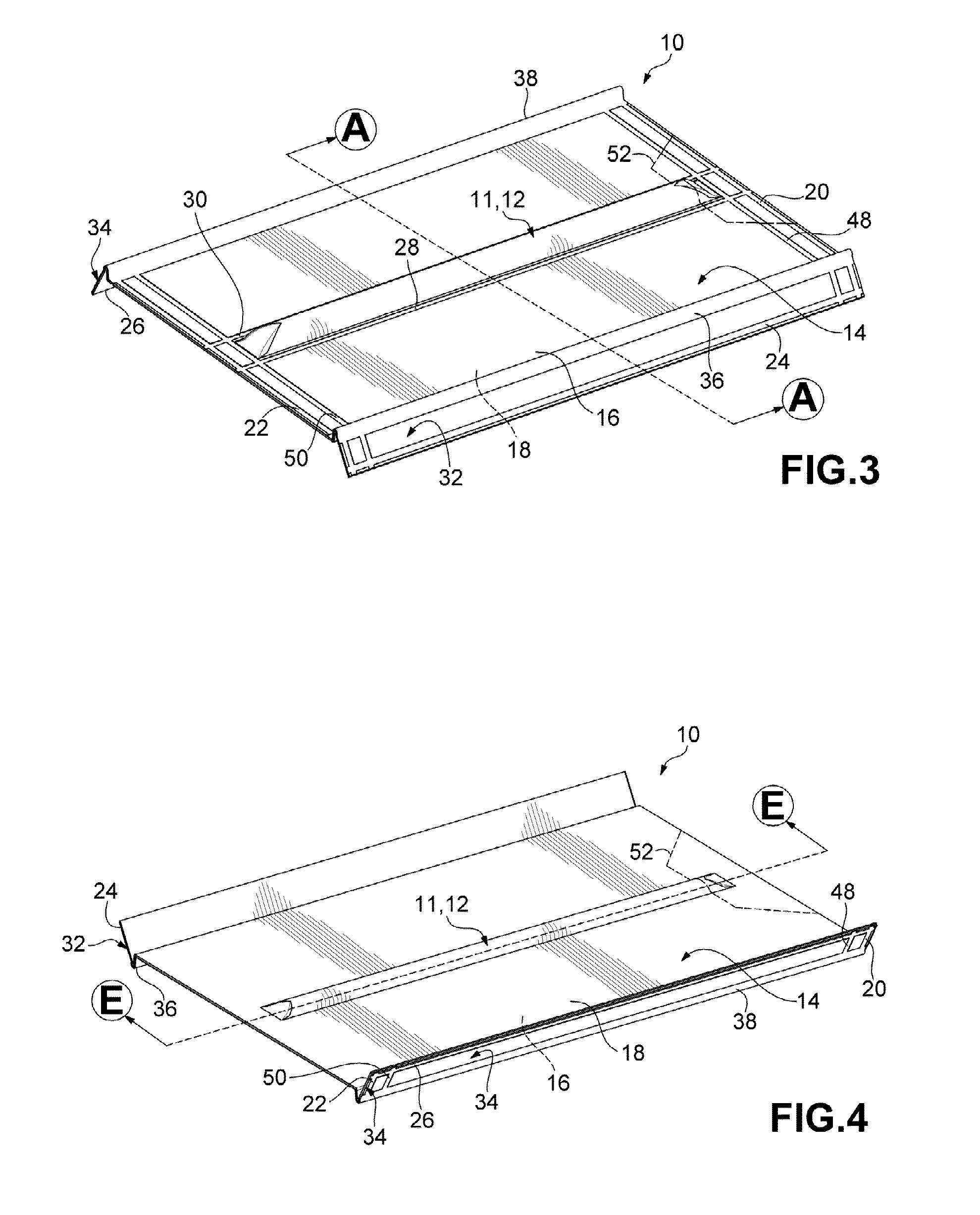

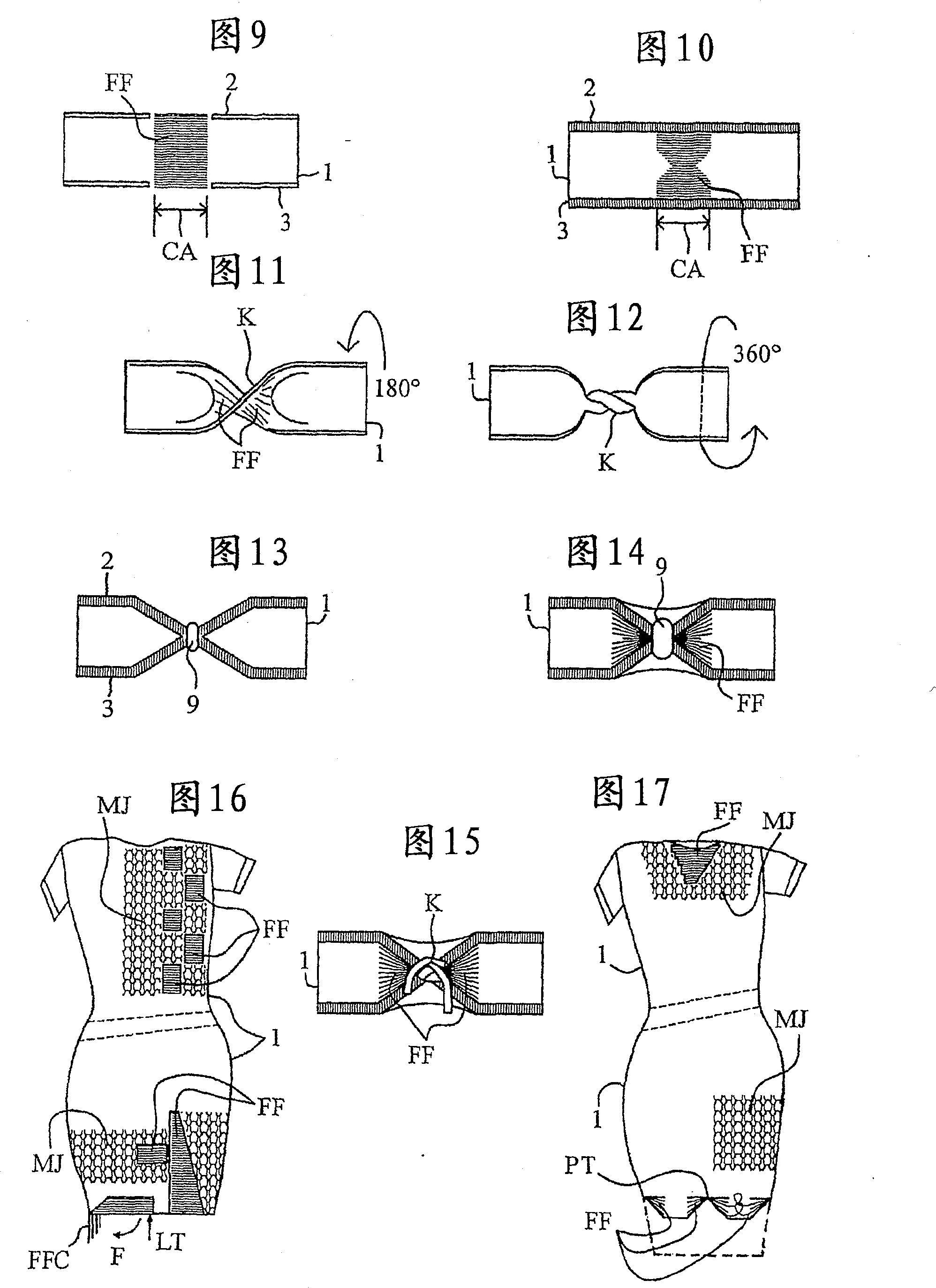

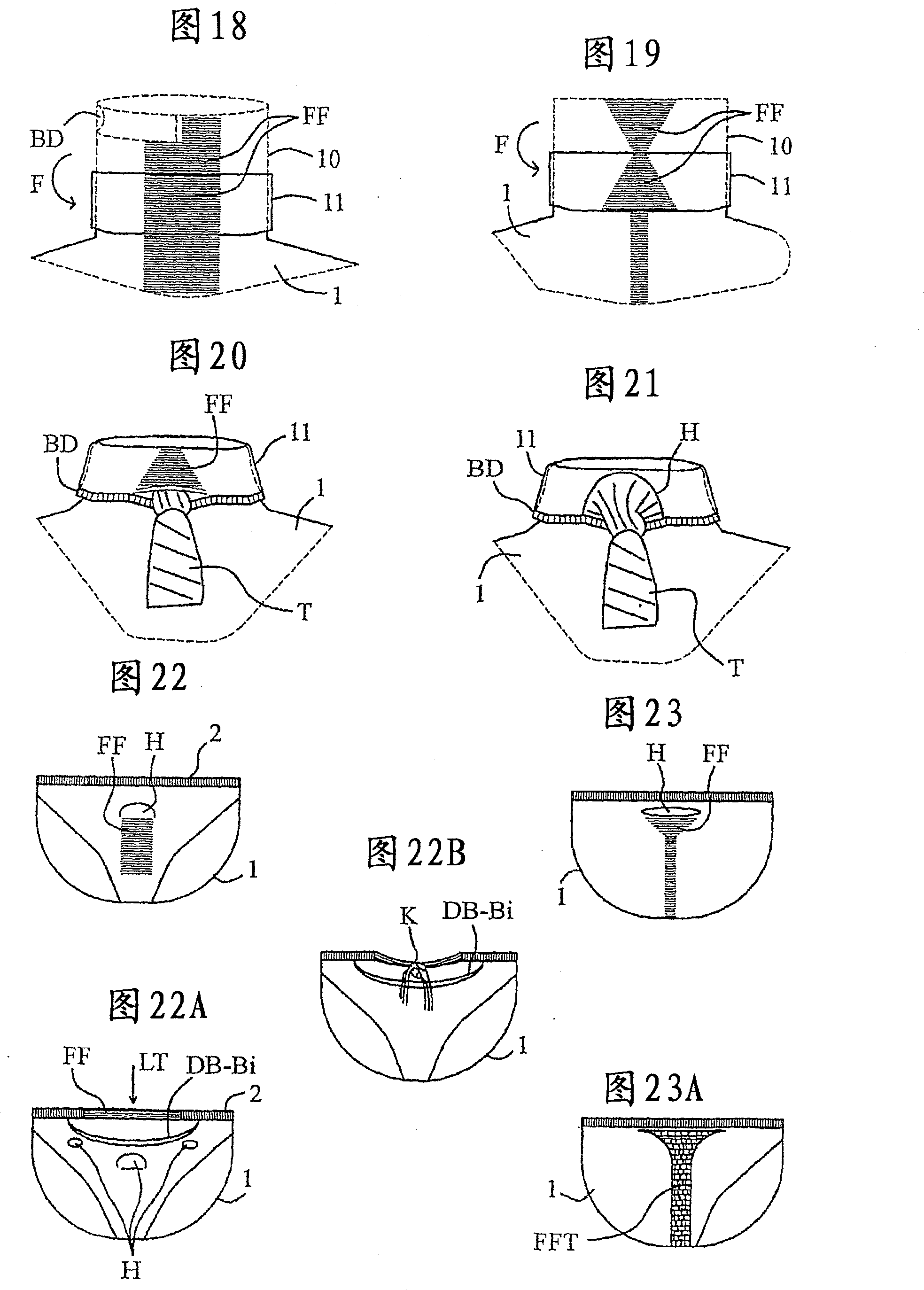

Method for producing tubular knitwear items and products obtained thereby

The invention relates to tubular knitwear with automatically obtained suitable openings or holes (H) for shoulder straps (SS, SD), neck (GC), belts, cords, strips, knots (K), endless belts, etc., that are used for various uses and purposes, such as structural support, aesthetics, and connection functions. The present invention also relates to weaving with other manufactured products. The present invention makes an appropriate selection of the needles (A) according to the design of the jacquard machine and the working cycle of the knitting machine, and enables to temporarily stop the knitting process of the limited fabric area and the needles, and then to let go of the loops, followed by the creation of new fabric loops, and the needles Ditch and float yarn (FF) for sheer effects and fringes.

Owner:弗朗哥・夏卡

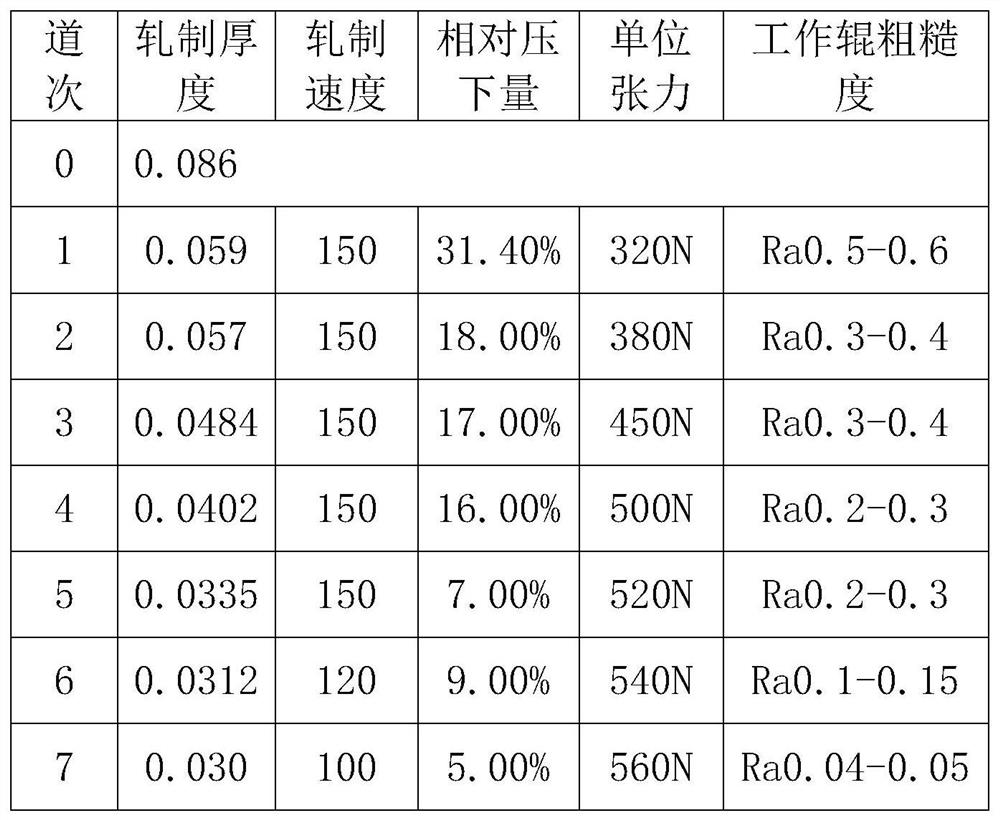

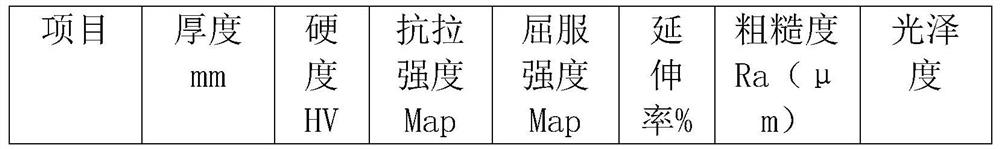

Preparation method of metal belt for manufacturing backlight plate of folding screen mobile phone

The invention discloses a preparation method of a metal belt for manufacturing a backlight plate of a folding screen mobile phone. The preparation method comprises the following steps: S1, primary rolling; S2, primary solution annealing; S3, secondary rolling; S4, secondary solution annealing; S5, tertiary rolling, wherein a semi-finished steel belt with the thickness of 0.086 mm is rolled into a finished steel belt with the thickness of 0.03 mm through seven passes of rolling by adopting a 20-roller rolling mill; S6, finished product cleaning; S7, finished product withdrawal and straightening; and S8, finished product slitting. According to the invention, a steel belt with the thickness of 0.5 mm is sequentially subjected to primary rolling, primary solution treatment, secondary rolling, secondary solution treatment, tertiary rolling, finished product cleaning, finished product withdrawal and straightening and finished product slitting treatment, wherein in the three times of rolling steps, a sand blasting surface working roller is adopted for small-pressure multi-pass rolling, and a large-inclination and small-extension flattening technology is adopted for finished product withdrawal and straightening; and the manufactured stainless steel belt is an ultra-thin and ultra-flat stainless steel belt with the thickness of 0.03 mm.

Owner:江苏贯森新材料科技有限公司

Supply packs and methods and systems for manufacturing supply packs

InactiveUS20140319280A1Easily air droppedImprove distributionWrappingFreight handlingManufactured suppliesEngineering

A cost-effective pack adapted to be distributed from an aircraft in the event of a natural, military, political, or other disaster includes an outer package, at least one item in the outer package for aerial delivery, and at least one aerodynamic component formed on the outer package and methods and systems for making the pack.

Owner:THE SKYLIFE COMPANY

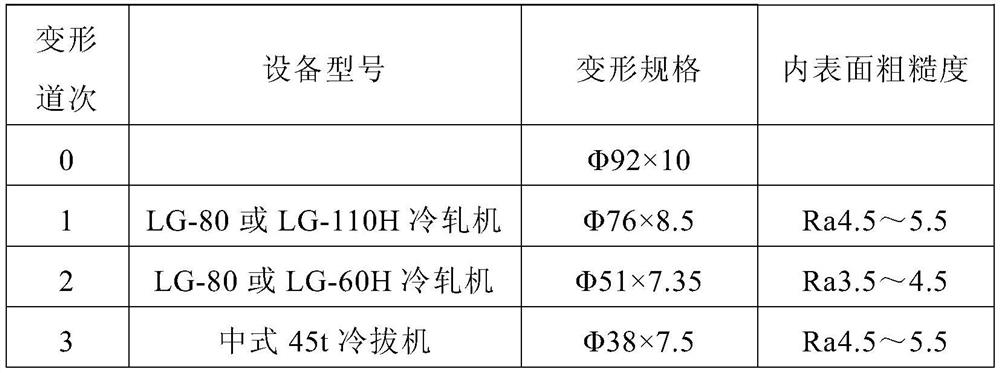

Cold rolling pipe manufacturing method for improving roughness quality of inner wall of stainless steel seamless pipe for power station boiler

ActiveCN111940518AQuality improvementImprove performanceRoll mill control devicesMetal rolling arrangementsPower stationPunching

A cold rolling pipe manufacturing method for improving the roughness quality of the inner wall of a stainless steel seamless pipe for a power station boiler adopts a two-pass cold rolling deformationprocess to roll to obtain finished pipes for delivery, that is, an LG-80 or LG-110H cold rolling mill is adopted for cogging rolling and an SKW-75 high-speed cold rolling mill is adopted for rolling to obtain the finished products. Meanwhile, by optimizing parameters such as a roller device, a hole pattern and a core rod related to cold rolling deformation and taking measures such as increasing the diameter of the core rod, widening a hole pattern opening and reducing a movement gap, the cold rolling pipe making quality and efficiency of the stainless steel seamless pipe for the power stationboiler are improved. On the basis of meeting the technical requirements for cold rolling of the boiler pipe of the power station, the quality loss of the roughness of the inner wall caused by abnormalworking conditions such as "top punching" and "insufficient rotation" of a pipe blank is reduced, the yield is increased, and the production cost is reduced.

Owner:宝武特种冶金有限公司

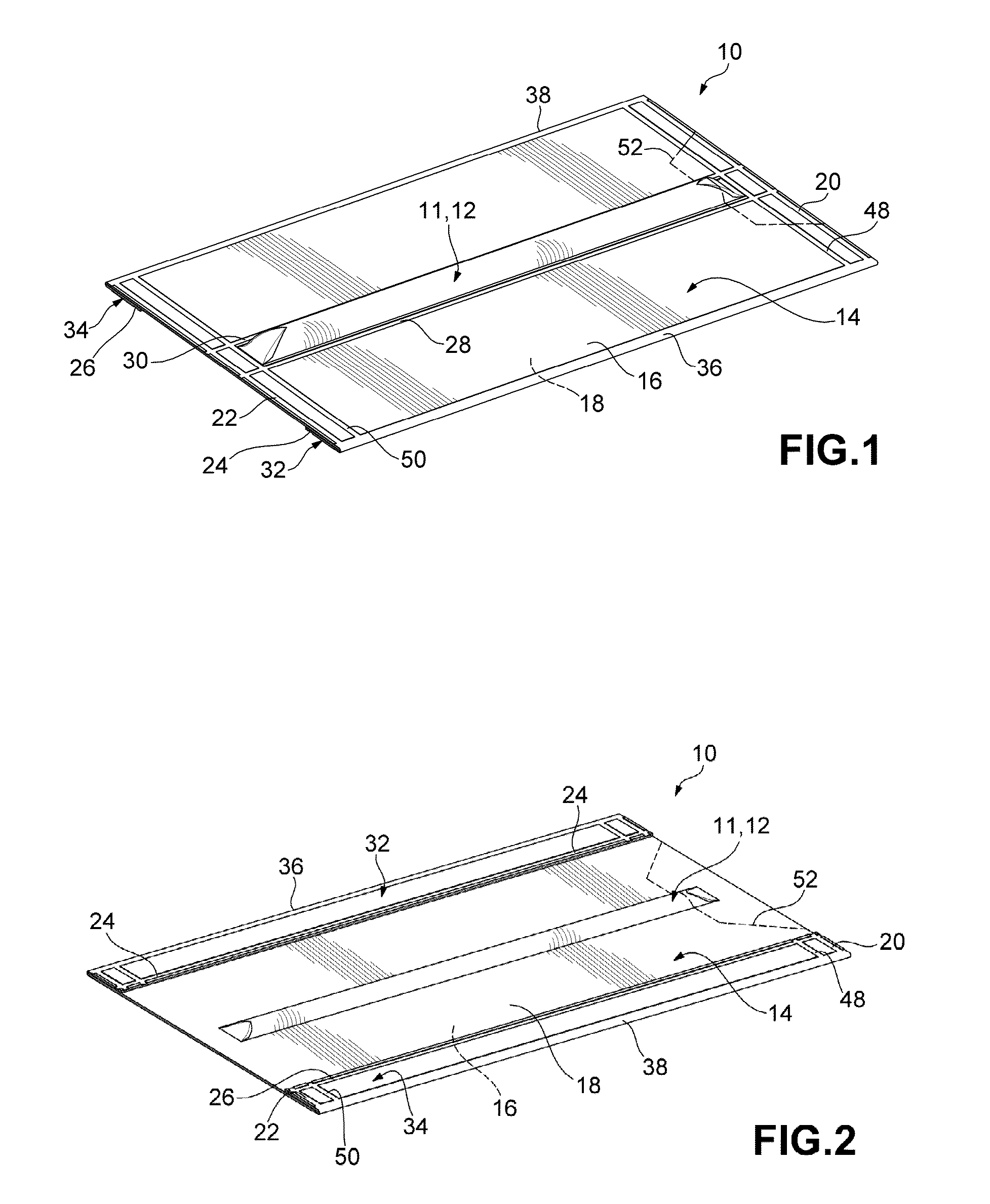

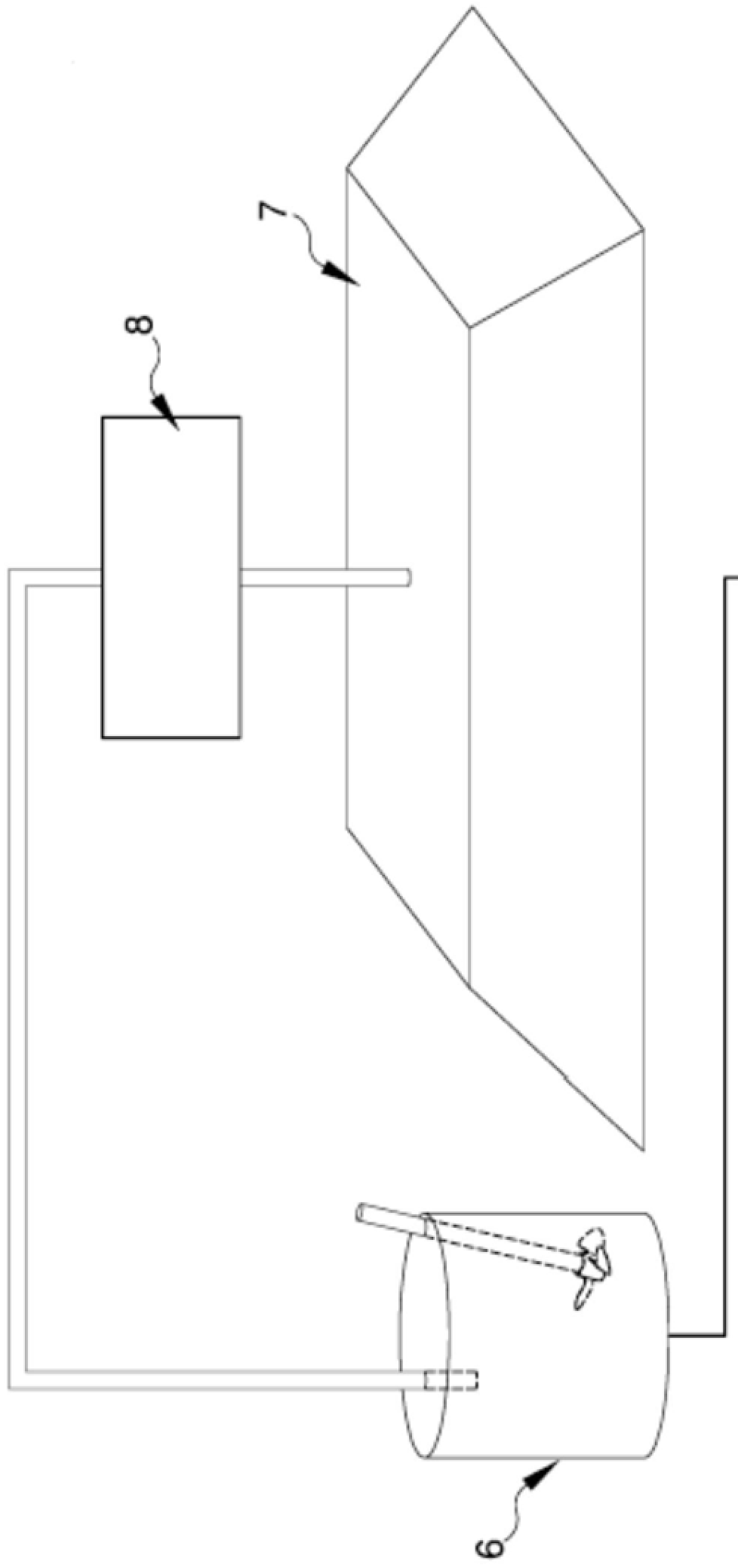

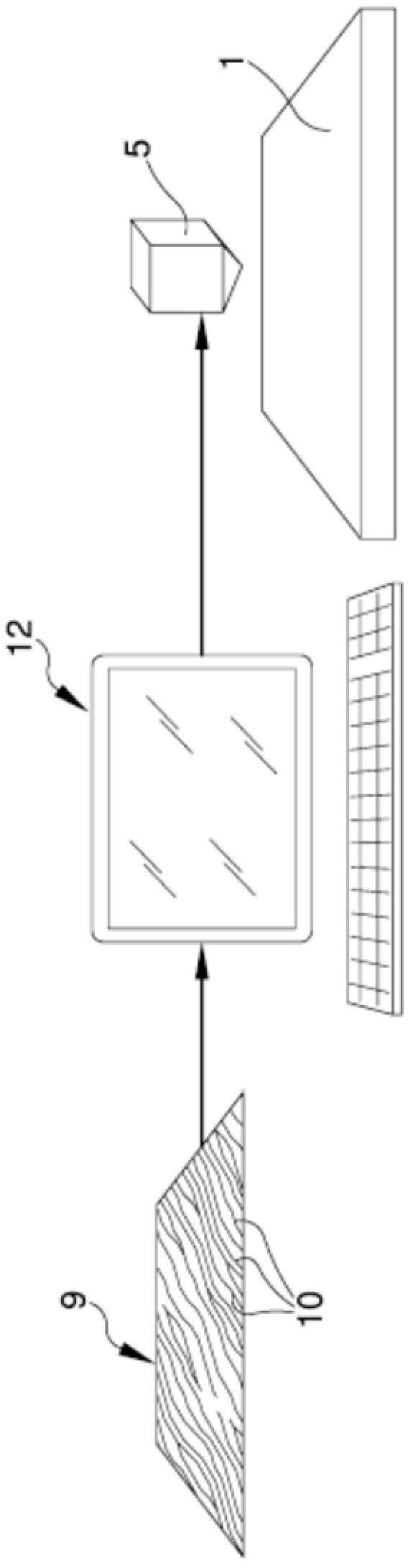

Process for three-dimensional printing, particularly for the production of windows, plate-shaped elements for floors or the like

ActiveCN110582391AAdditive manufacturing apparatusAdditive manufacturing with liquidsEvaporation (deposition)Physical chemistry

A process for three-dimensional printing, particularly for the production of windows, plate-shaped elements for floors or the like, comprises: a supply step of PVC and of a solvent in which the PVC issoluble; a mixing step of the PVC and of the solvent to obtain a mixture in the liquid phase; a distribution step of the mixture onto a deposition surface (1); an evaporation step of the solvent forobtaining a layer of PVC (2) of a manufactured article (3), wherein the evaporation step is subsequent to the distribution step; and repeating the distribution step and the evaporation step to obtaina plurality of overlapping layers of PVC (2) forming the manufactured article (3).

Owner:GRAF SYNERGY

An industrial textile product conveying device

ActiveCN112376185BReduce wrinklesEliminate wrinklesTextile treatment by spraying/projectingTextile shapingManufactured suppliesMechanical engineering

Owner:华睿(无锡)知识产权运营有限公司

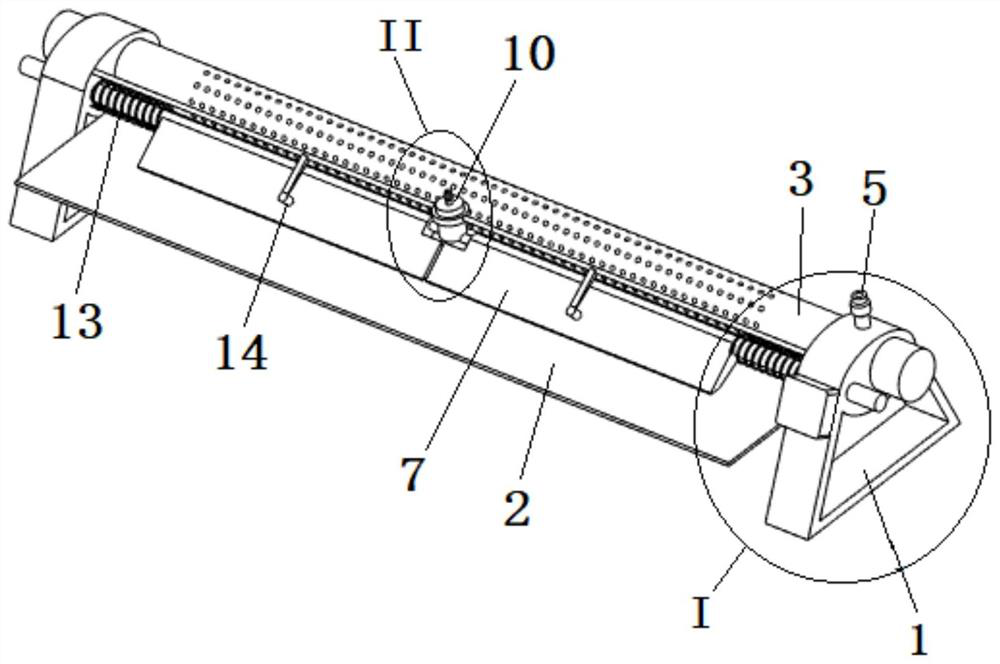

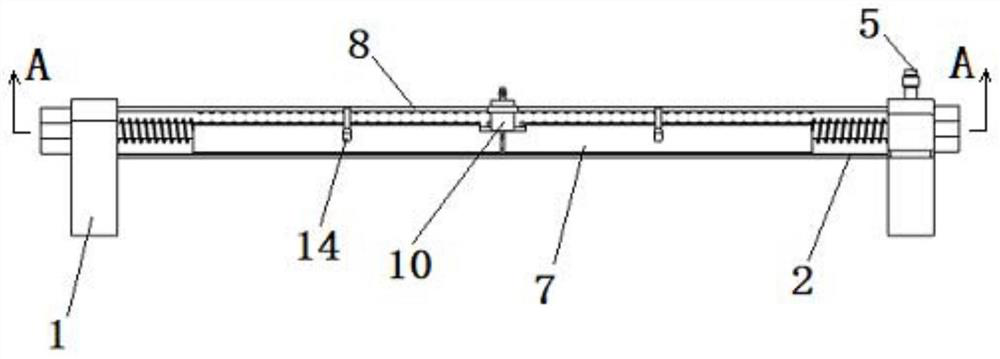

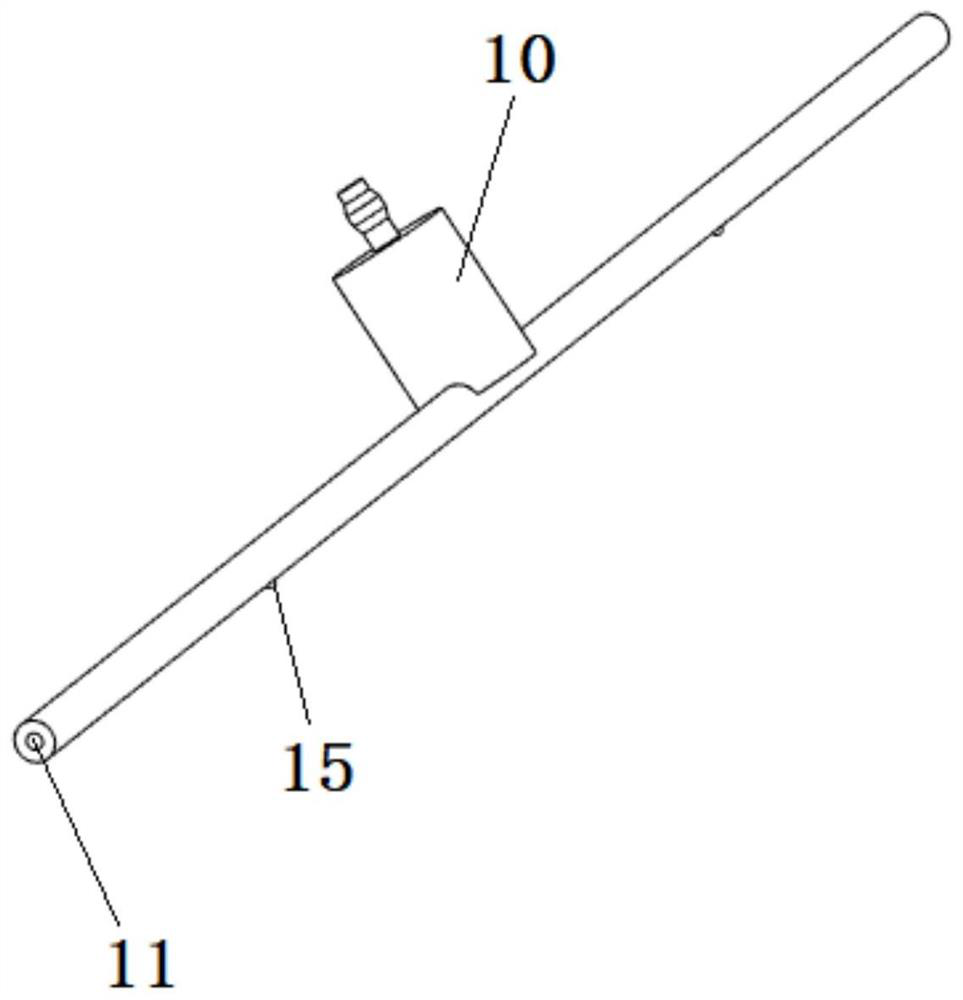

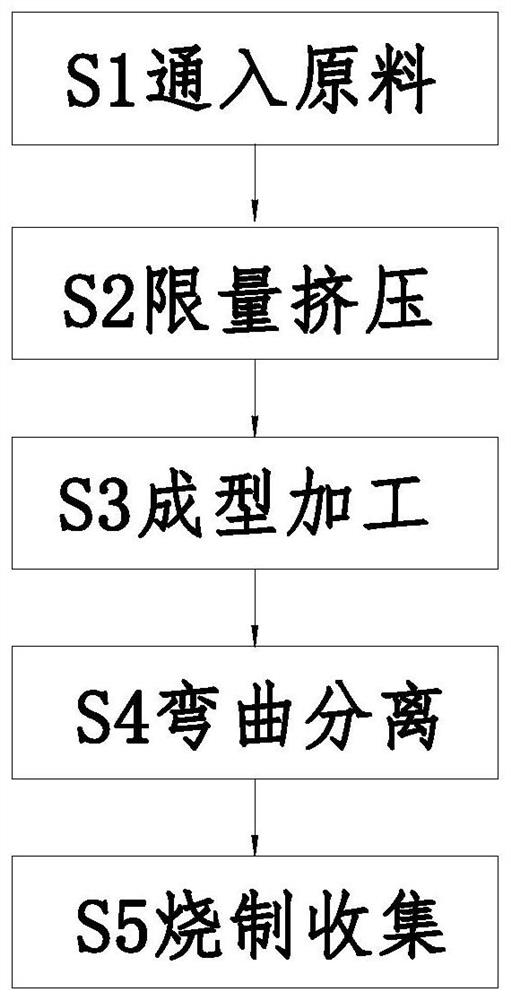

High-performance ceramic filler preparation method

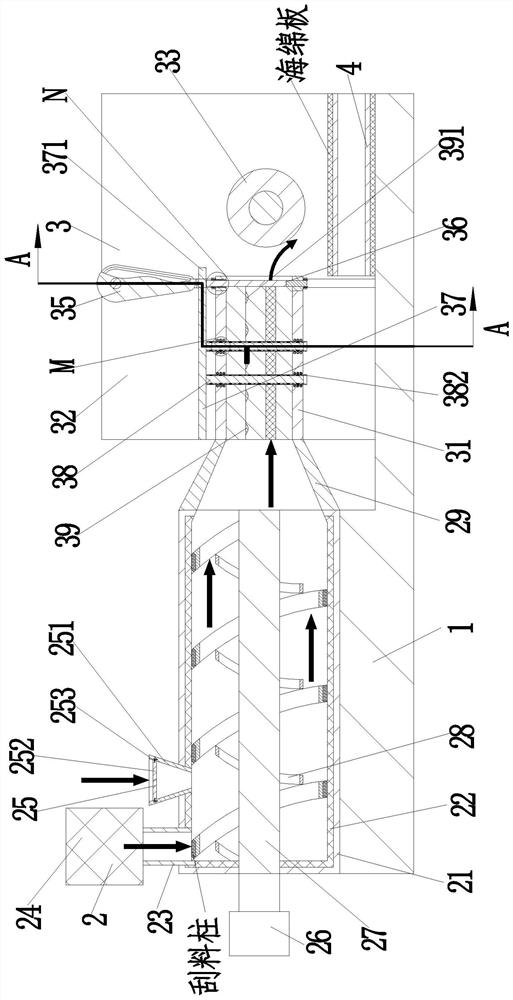

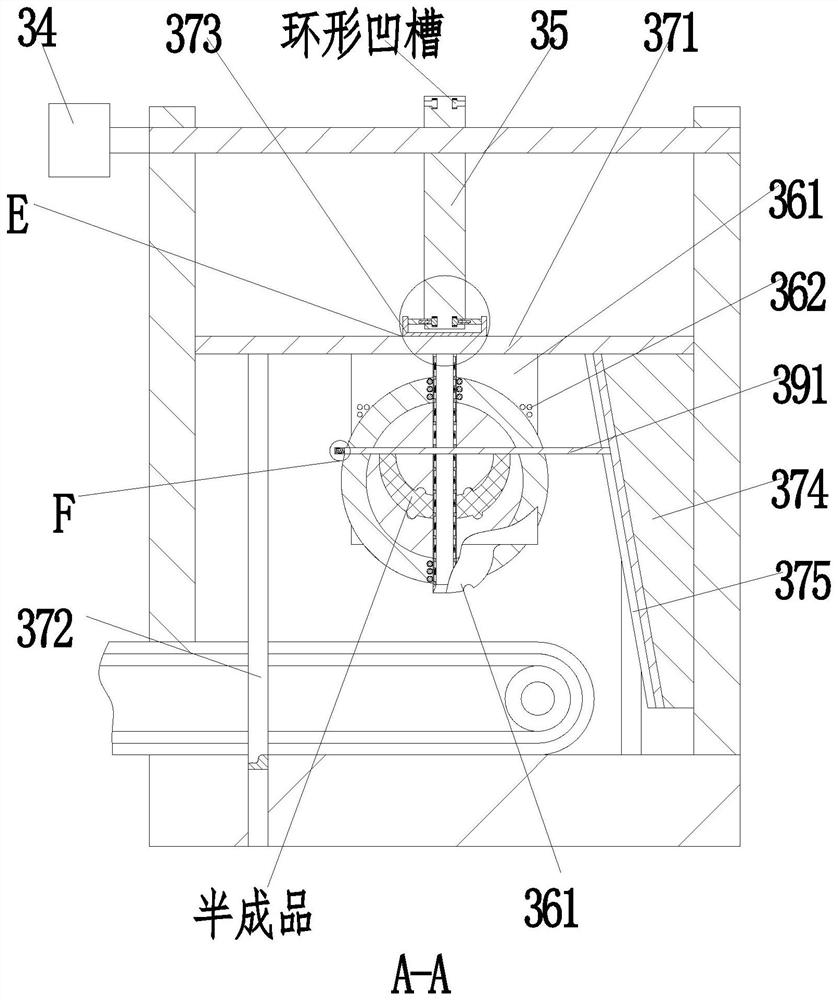

ActiveCN113119277AAvoid damageImprove processing efficiencyCeramic shaping apparatusCeramic materials productionManufactured suppliesBelt conveyor

The invention relates to a high-performance ceramic filler preparation method. High-performance ceramic filler preparation equipment comprises a fixed table, a treatment device, a material extruding device and a belt conveyor, the treatment device, the material extruding device and the belt conveyor are fixedly mounted on the upper end face of the fixed table from left to right, and sponge plates are uniformly and fixedly mounted on the outer end face of the belt conveyor in the circumferential direction. According to the high-performance ceramic filler preparation method, uniformly stirring and extruding in a limited mode are carried out on raw materials through the treatment device, processing and preparing are carried out on the ceramic filler through the material extruding device, manual transportation is not needed to be carried out on the ceramic filler in the whole processing process, manual control over separation treatment between finished products and semi-finished products is not needed, and therefore the processing efficiency of the equipment is improved; and the processing device cooperates with the material extruding device and the belt conveyor, and therefore the whole processing process of the ceramic filler is cyclically carried out, interruption control is not needed, damage caused by repeated switching on and switching off of the equipment is reduced, and finally the service life of the equipment is prolonged.

Owner:萍乡市恒升特种材料有限公司

A method for producing thin-gauge, low-alloy, high-strength checkered plates based on csp process

ActiveCN110639950BSolve batch stability productionStable production controlTemperature control deviceWork cooling devicesProduction lineTemperature control

The invention discloses a method for producing a thin-specification low-alloy high-strength diamond plate based on a CSP process. The method comprises the steps of 1, controlling heating temperature,specifically, the charging temperature and the tapping temperature are controlled; 2, controlling threading speeds, specifically, the different threading speeds are controlled according to different thicknesses of rolled finished products; 3, controlling rolling pressure, specifically, rolling force parameters are adjusted according to different thickness specifications; and 4, controlling roll shifting, specifically, after roll changing calibration is finished, circulating roll shifting from a zero point position with steps of 20 mm, 25 mm and 30 mm is started. According to the method, by controlling the heating temperature, the threading speeds, the rolling pressure, and the roll shifting and by adopting a laminar cooling mode for control, the pattern integrity and the plate shape of thelow-alloy high-strength diamond plate are ensured, the related standards and user requirements are met, the stable batch supply is formed, the production process is controlled stably, no production accidents such as scrap steel, and broken casting occur, and the stable batch production of the thin-specification low-alloy high-strength diamond plate produced by the CSP production line is realized.

Owner:武汉钢铁有限公司

Method and finished product of a composite soft and hard collection book

The invention discloses a manufacturing method of a composite soft and hard collection book and a manufactured product. The composite soft and hard collection book comprises a soft book at the front part, a hard card book at the back part, and a transition page pasted between the soft book and the hard card book, wherein the size of the edge of the transition page is 1 to 5 mm smaller than the size of edges of the soft book and the hard card book; and the transition page has a standard gram number which is the closest to the average of the sum of gram numbers of the soft book and the hard card book. According to the collection book, through the utilization of the transition page, the durability and utilization flexibility of the manufactured product are improved, and paper stamps, paper notes and coins are collected in the same book; through the utilization of hot melt films on the two sides of the transition page, bonding planes are guaranteed to be flat, smooth, firm and reliable; and the entire composite soft and hard collection book is good in applicability and convenient to use, and can be widely utilized by various collectors.

Owner:北京东方之彩印刷有限公司

Automatic ultrasonic welding production line for a paper cover

PendingCN112894119AReduce laborIncrease productivityDomestic articlesNon-electric welding apparatusProduction lineUltrasonic welding

The invention provides an automatic ultrasonic welding production line for a paper cover. The automatic ultrasonic welding production line comprises a support and a first conveying line, a cover paper feeding device, a pressing device and a removing device which are installed at the upper end of the support, and a cover frame feeding device, the cover paper feeding device, the pressing device, the removing device and the first conveying line are all in signal connection with a controller. According to the automatic ultrasonic welding production line for the paper cover, a PLC is arranged in the controller, the PLC controls the cover frame feeding device to convey a cover frame to the first conveying line, the PLC controls the cover paper feeding device to assemble cover paper into the cover frame on the first conveying line, and then the cover frame and the cover paper are pressed into an integrated structure through the pressing device. The PLC recognizes the bad products through the removing device, the bad finished products on the first conveying line are removed, the production process of the paper covers is automatic production, labor is reduced, and production efficiency is improved.

Owner:TIANJIN HUIYUAN PRINTING

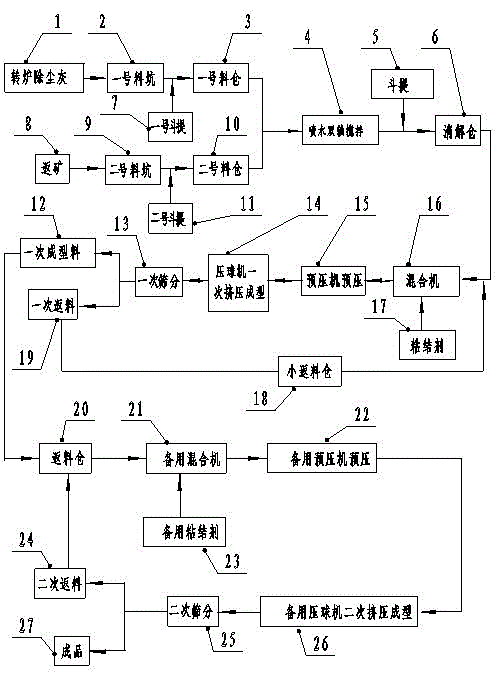

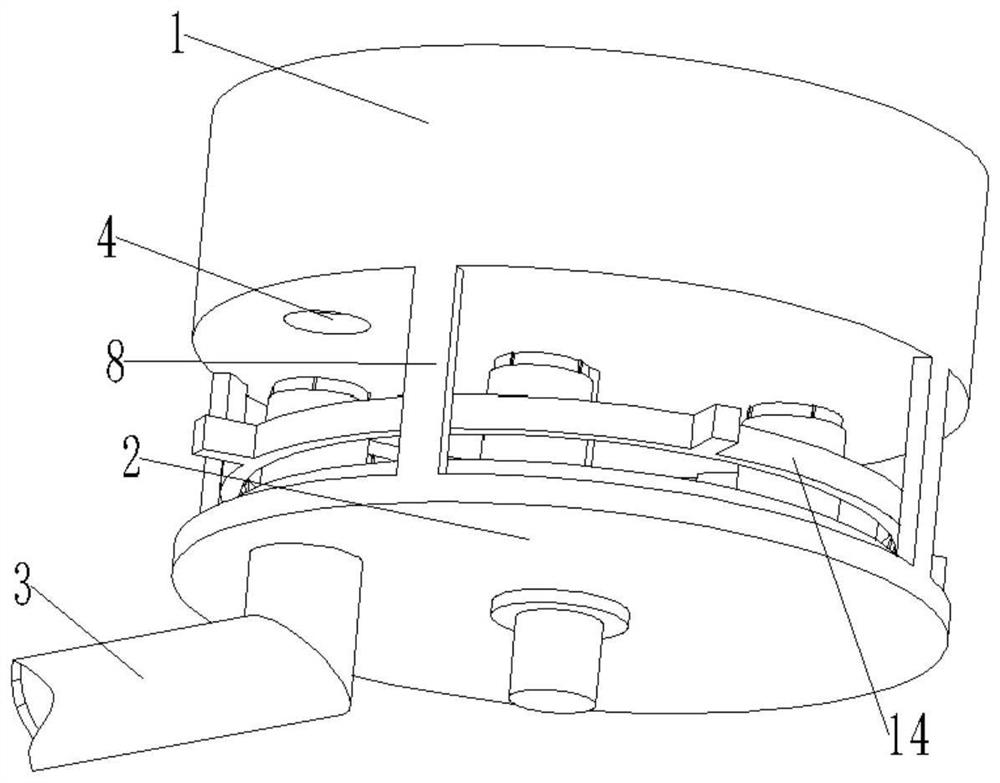

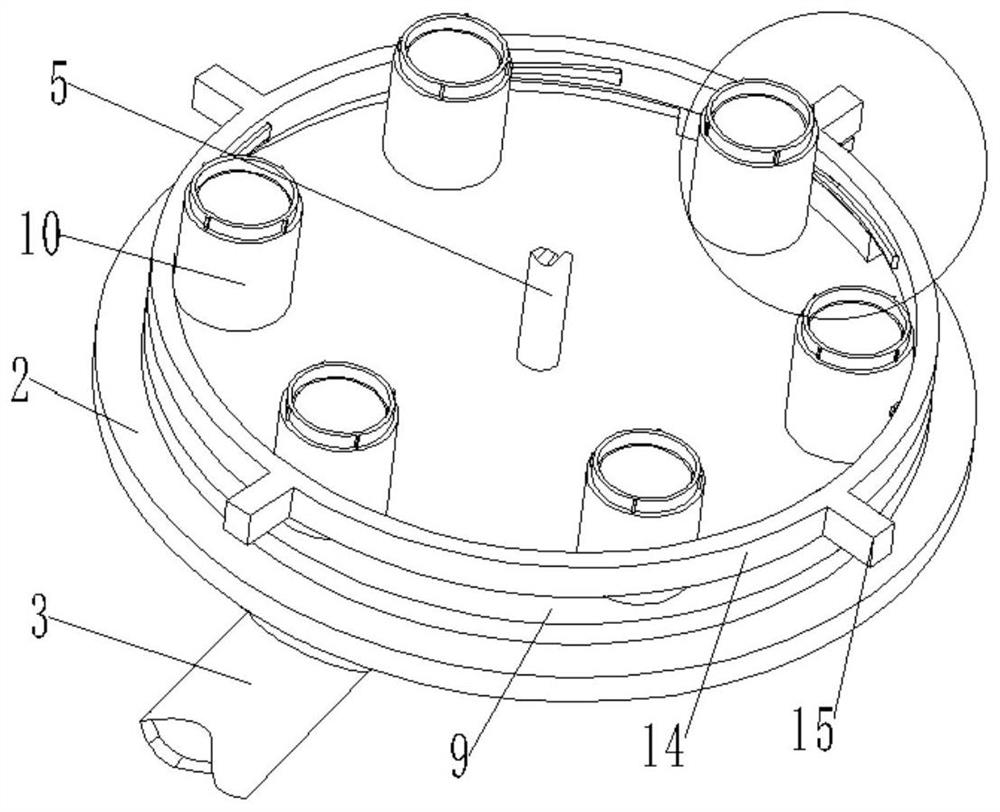

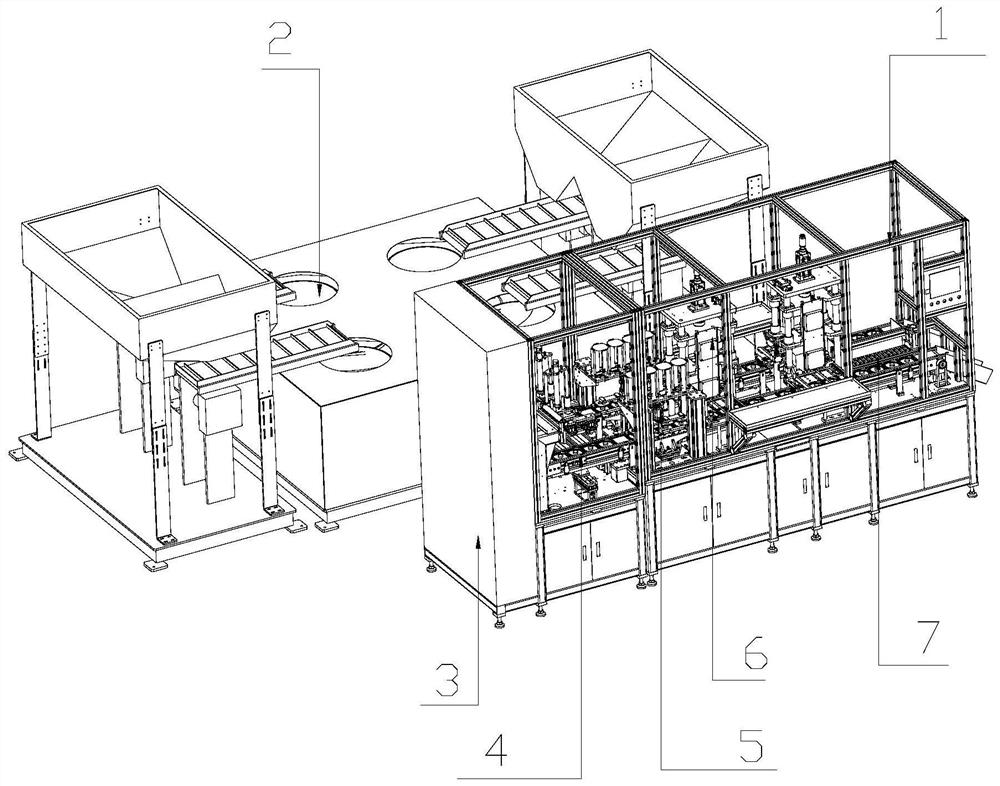

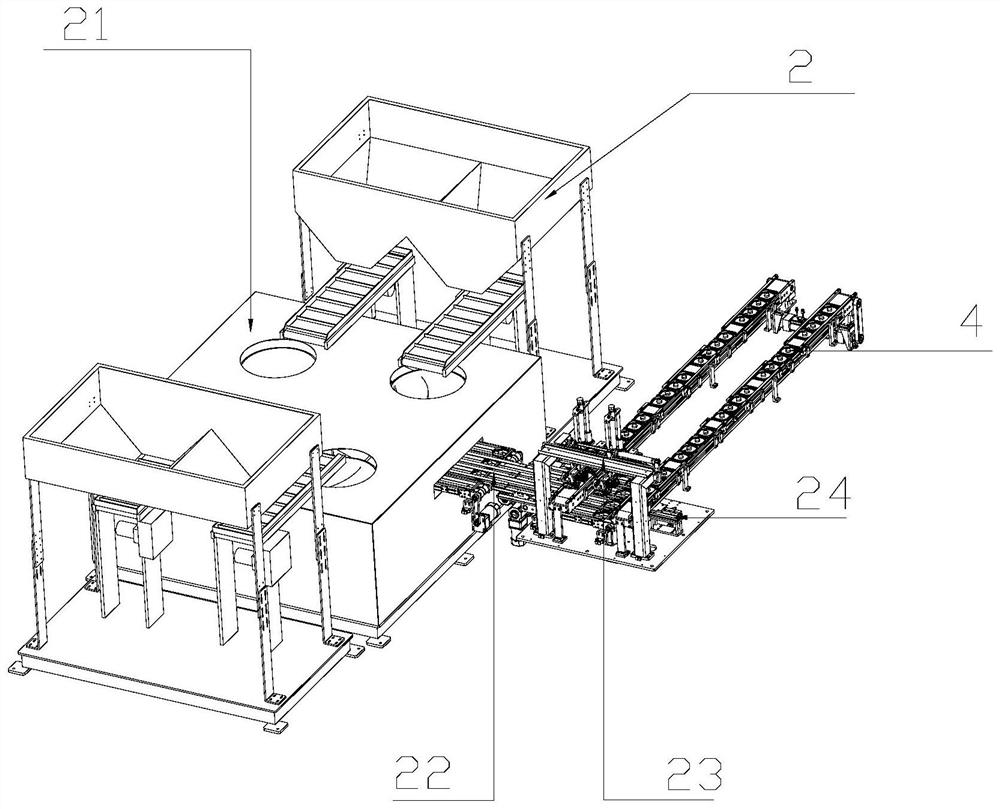

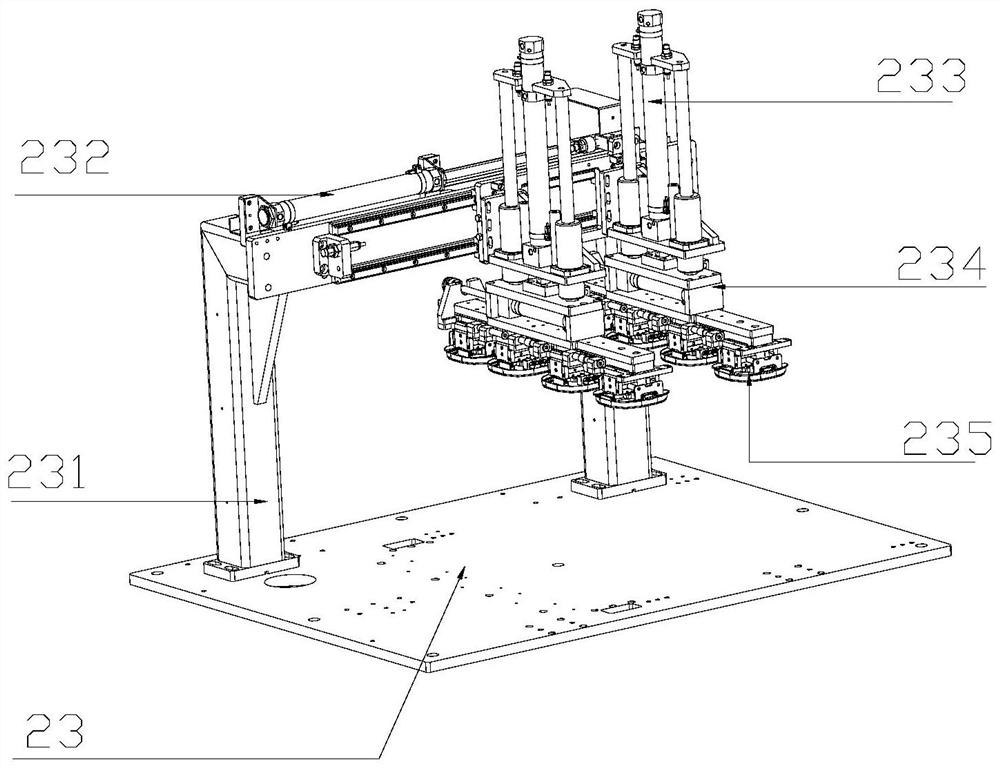

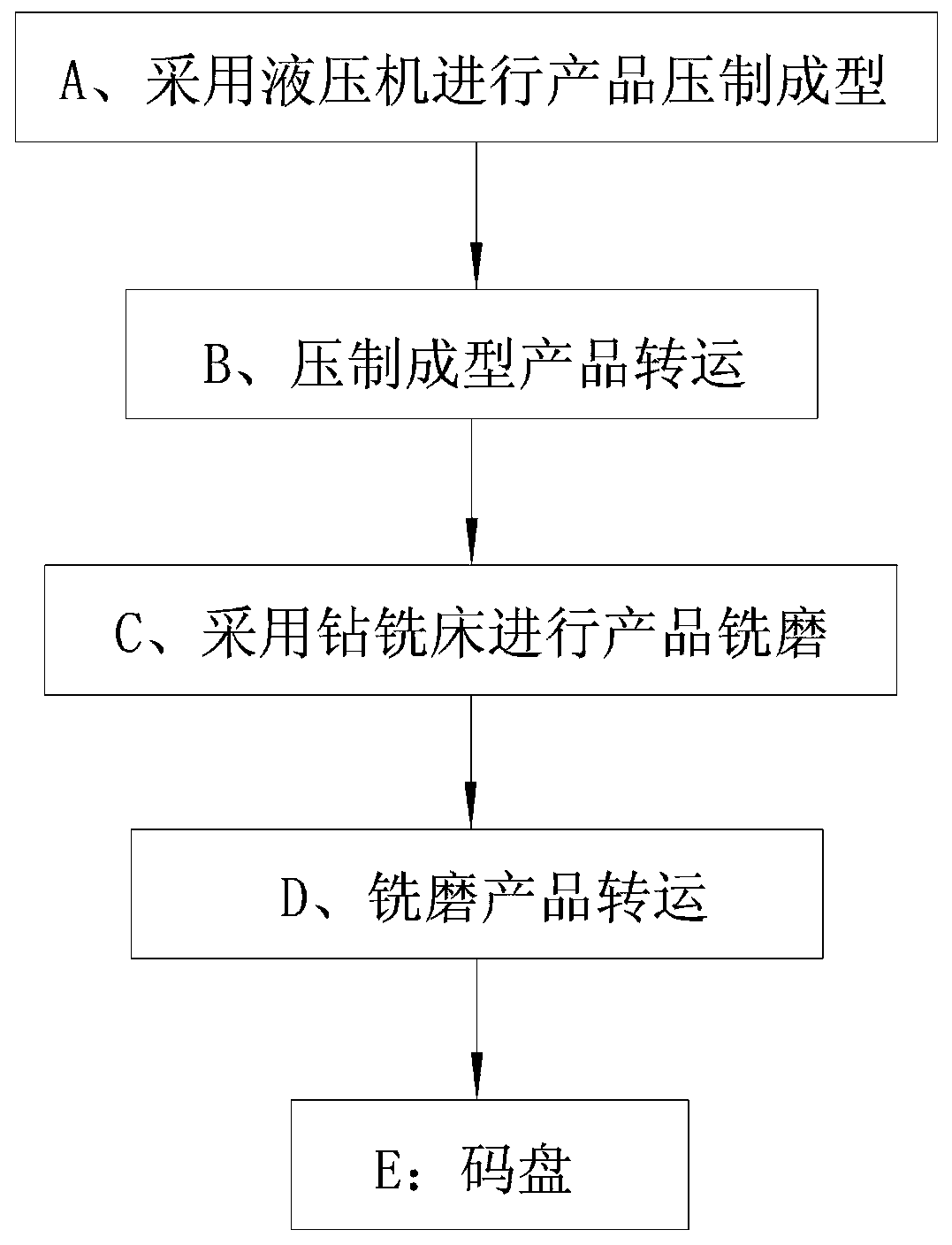

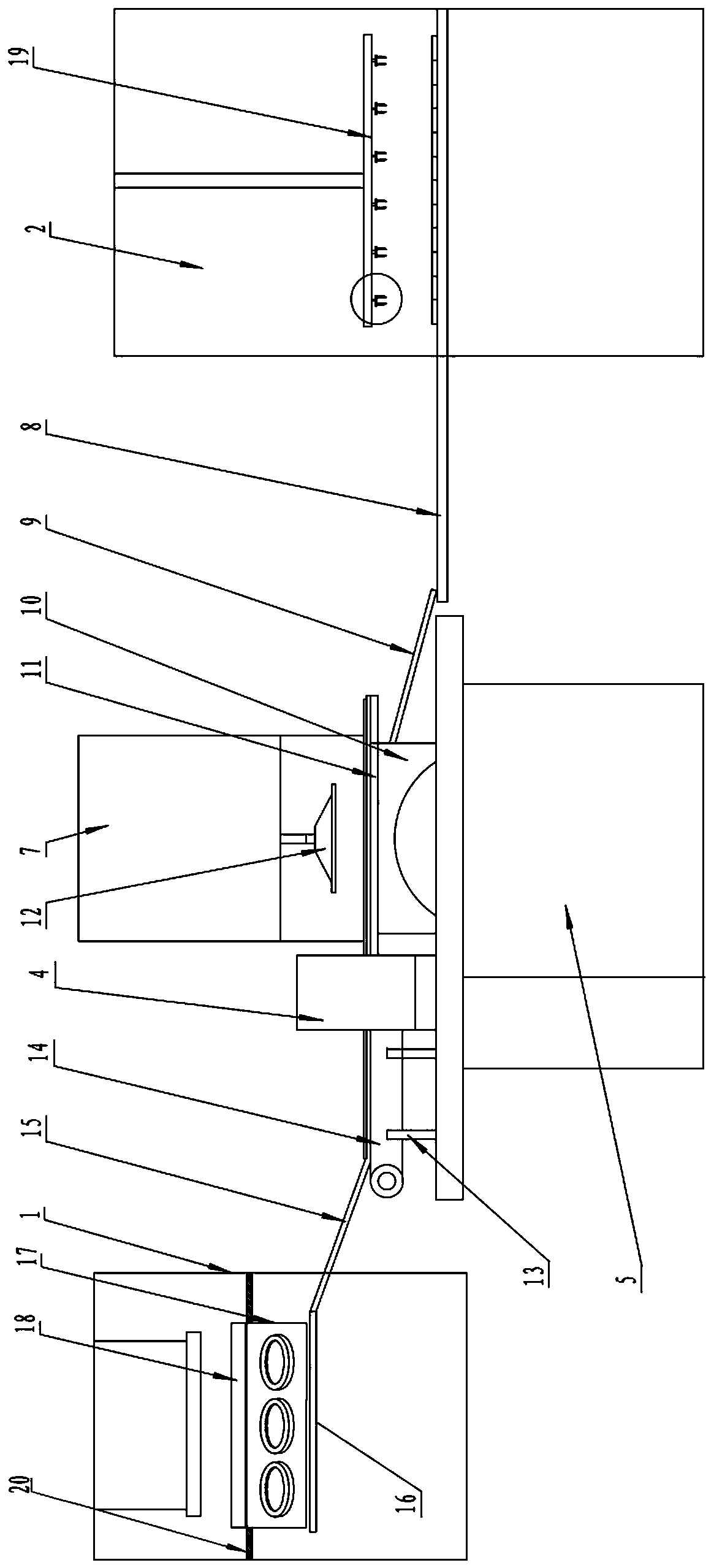

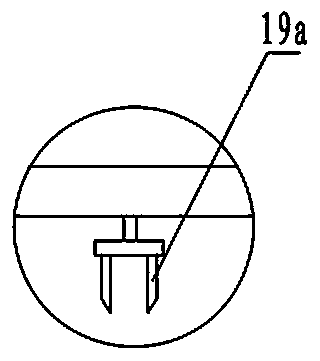

An integrated production process and production system of an annular thin-walled powder product

ActiveCN108994679BReduce transshipmentEliminate duplication of effortGrinding feedersPress ramManufactured suppliesProcess engineering

The invention discloses an integrated production process of annular thin-walled powder products, and a production system thereof. The integrated production process comprises the major steps that a hydraulic press is adopted for product pressing molding; pressing-molded products are transferred; product milling is conducted through a drilling and milling machine; the milled products are transferred; and stacking is conducted. Automatic integration of pressing, milling and stacking of the products is achieved, the number of transferring and stacking times is decreased, repetitive work is eliminated, labor consumption is lowered, and the duration of the whole production process is greatly shortened; and meanwhile, the production system used for the production process can automatically conveyand mill the pressing-molded products, acting force is gentle during milling, the products are not prone to being damaged, the pressing-molded products do not need to be cured, while automatic millingand transferring of the products are achieved, the duration of the working procedure is shortened, the production efficiency is improved, the product pass rate is increased, and material waste is reduced.

Owner:河南中南工业有限责任公司

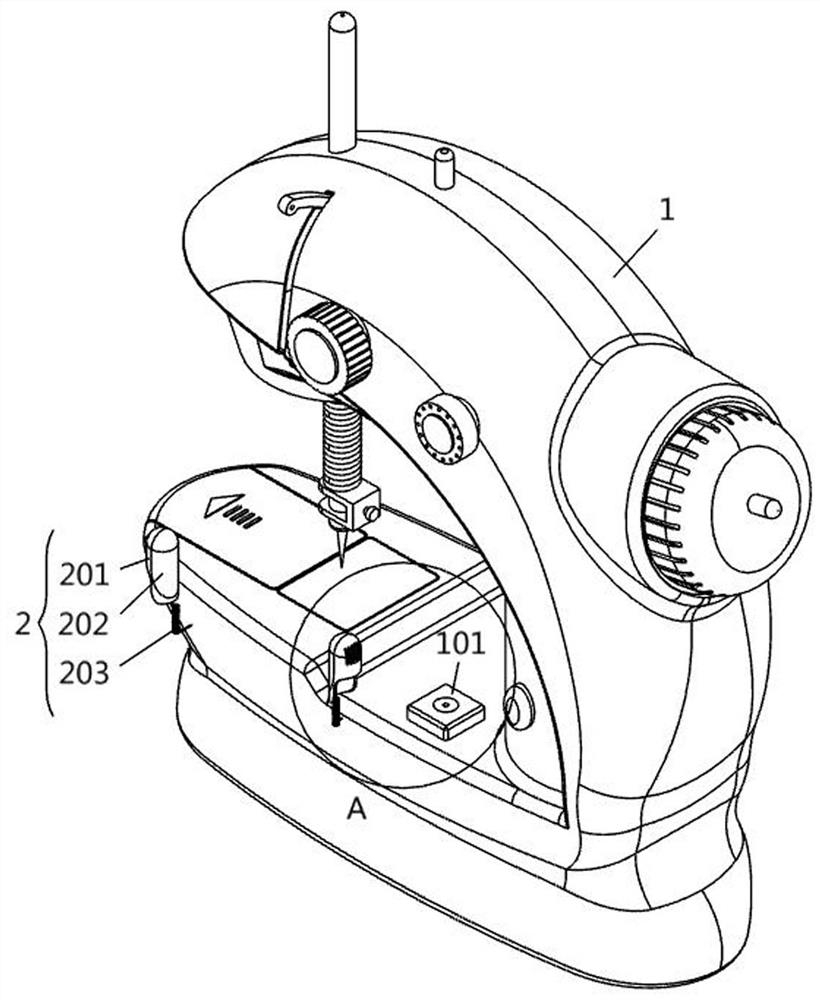

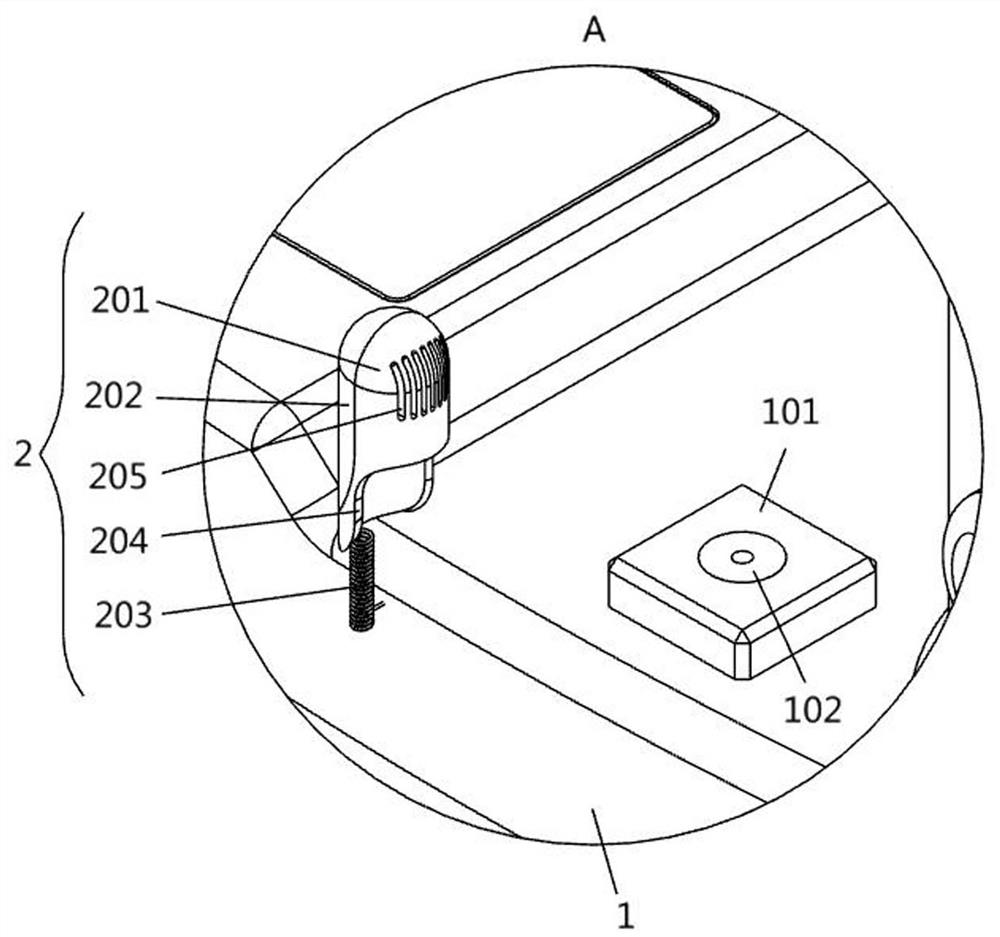

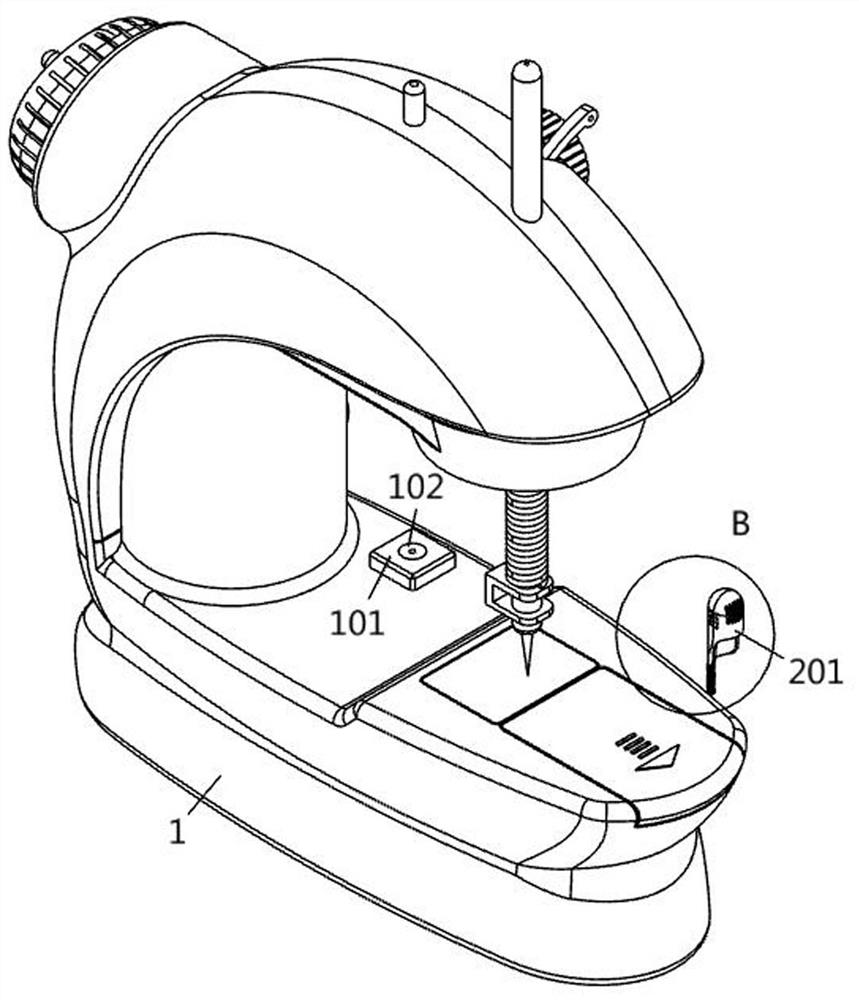

Protection device for sewing machine based on textile finished product manufacturing

ActiveCN113652811AImplement mandatory operationsEnsure safetySafety devices for sewing-machinesPlastic materialsManufactured supplies

The invention provides a protection device for a sewing machine based on textile finished product manufacturing, relates to the technical field of sewing machine protection, and solves the problem that an existing textile finished product manufacturing factory is generally provided with a corresponding protection device, but the protection device does not have a forcing function and cannot be forced to be worn by a sewing machine worker, so that potential safety hazards exist in practical application of the protection device. The protection device for the sewing machine based on textile finished product manufacturing comprises an electric sewing machine and a protection mechanism; the overall structure of a protection cover body is in a fingerstall shape; the protection cover body is made of a plastic material; a storage groove is formed in the position, corresponding to the bottom of a hemispherical area, of the inner circumferential face of the protection cover body; an infrared sensor is installed in the bottom face of the inner end of the storage groove in an embedded mode; and the sensing end of the infrared sensor faces the right upper portion. By means of the mode, the forcing operation is achieved for the sewing machine worker, and the worker is forced to work only by wearing a protection mechanism, so that the safety of the sewing machine worker is guaranteed.

Owner:南通语森家纺科技有限公司

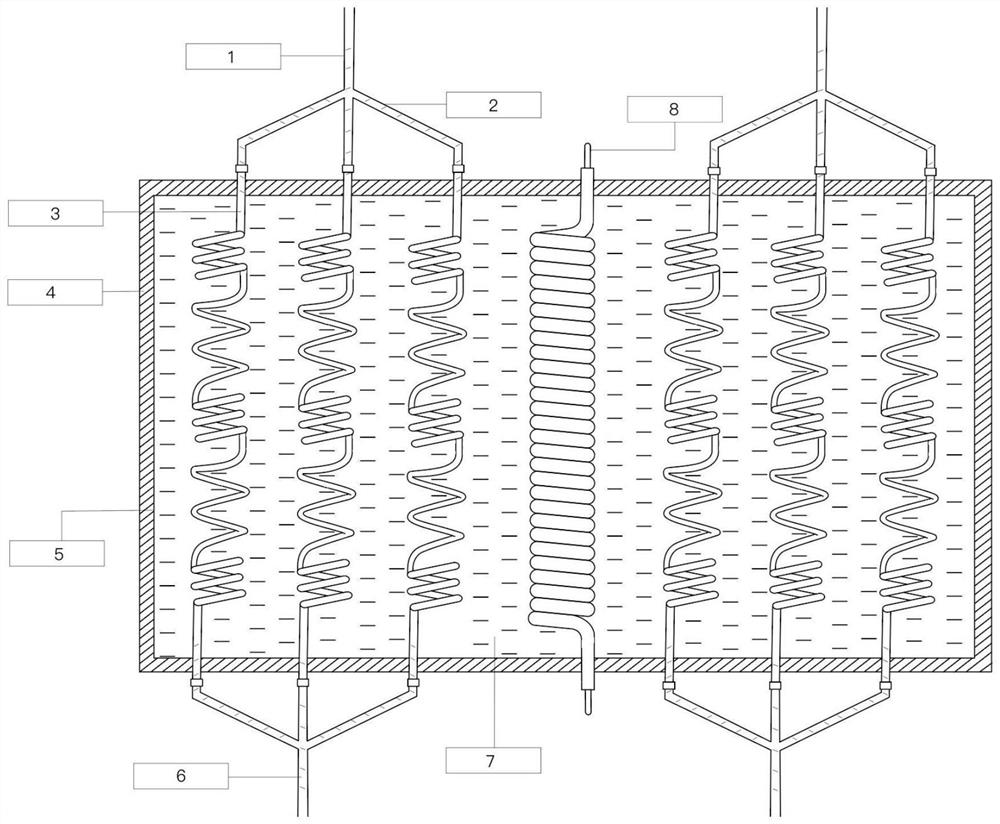

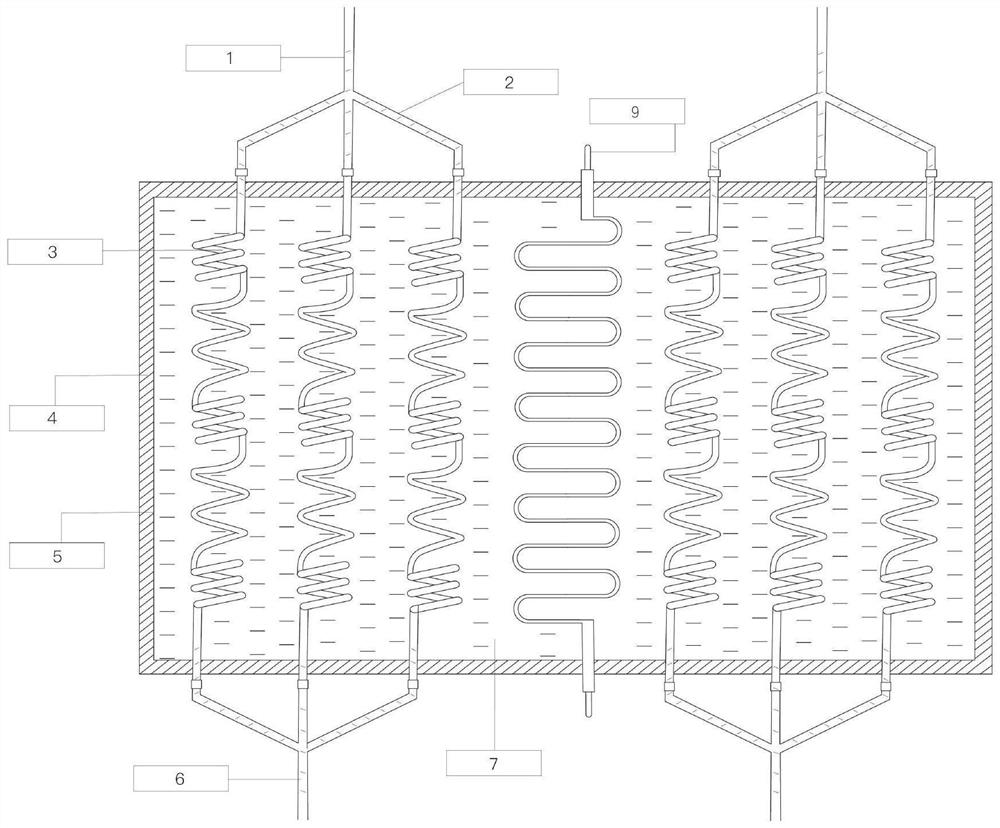

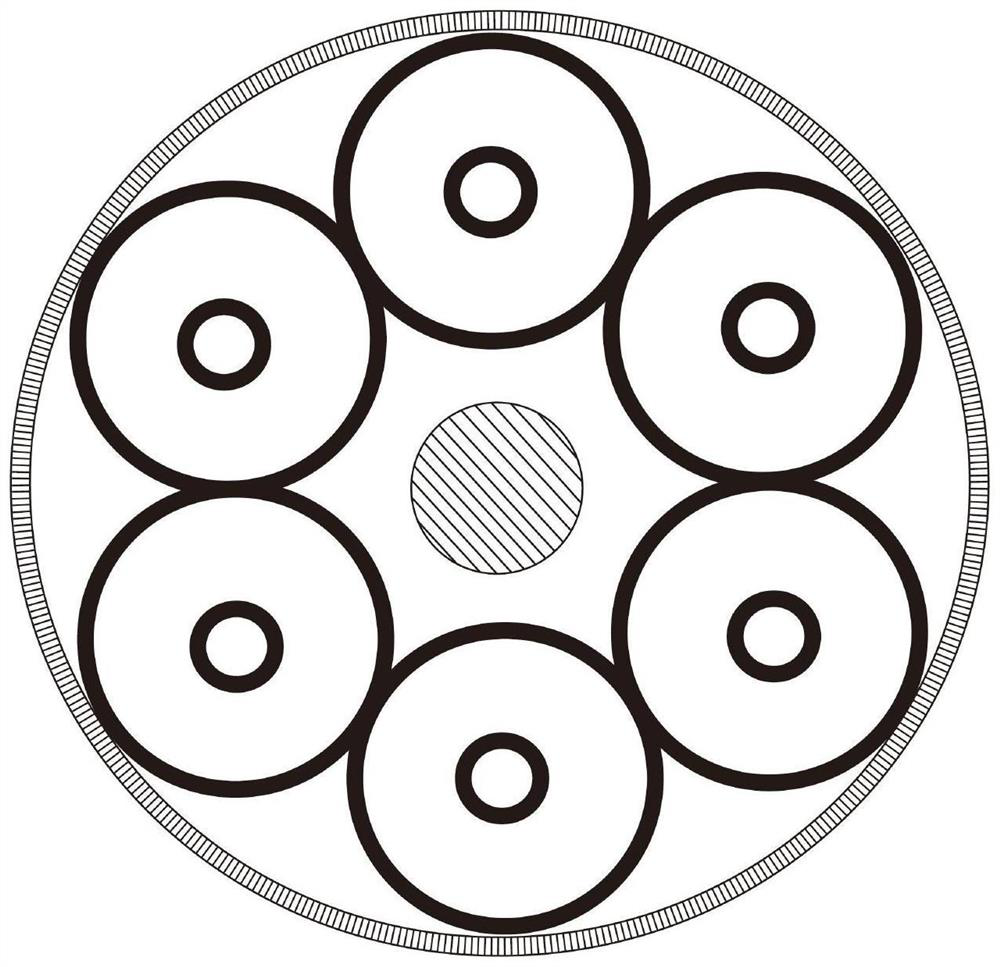

Temperature adjusting device for instant beverage

InactiveCN114391758AReduce logistics costsScale upBeverage vesselsWarming devicesTemperature controlManufactured supplies

The instant beverage temperature adjusting device comprises a feeding port, the feeding port is connected with a four-way pipe, the four-way pipe is connected with a temperature adjusting pipe network set, the temperature adjusting pipe network set is installed in a temperature adjusting box, a cavity is formed in the inner side of the temperature adjusting box, a metal inner container is arranged on the cavity, the bottom of the temperature adjusting box is connected with the four-way pipe, and a discharging port is formed in the four-way pipe. The temperature adjusting box is filled with temperature conduction liquid, and a temperature control heater is installed in the middle of the temperature adjusting box. Compared with the prior art, the beverage machine has the advantages that a novel beverage machine can be developed, and the beverage machine can adapt to beverage finished products produced by various beverage manufacturers. New household and commercial beverage specifications can be added for beverage manufacturers, large-package beverage packaging materials can be changed, the overall logistics cost of the beverage can be reduced, more new beverage varieties can be created due to the perfect heating and refrigerating functions, and the overall scale of the beverage market can be expanded.

Owner:梁晖琳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com