Manufacturing method of converter fly ash pressed balls

A converter dust removal and manufacturing method technology, applied in the direction of improving process efficiency, etc., can solve the problem of low ball pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

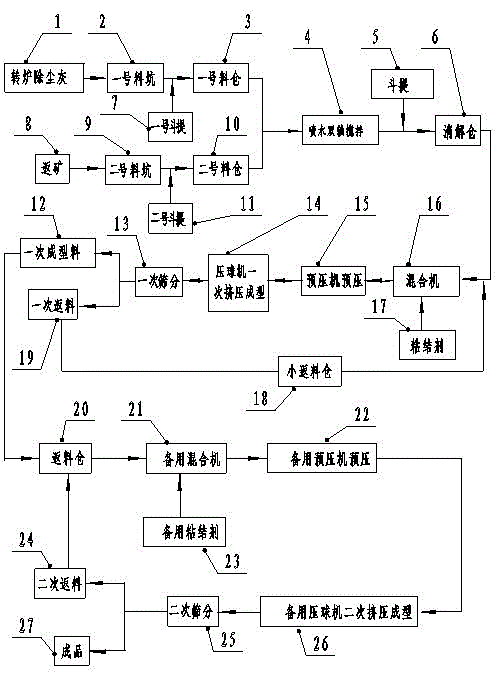

Image

Examples

Embodiment

[0034] (1) 70 tons of converter dedusting ash 1 enters the No. 1 material pit 2, and lifts 7 into the No. 1 material bin 3 through the No. 1 bucket;

[0035] 12 tons of sintered returned ore 8 enters the No. 2 material pit 9, and enters the No. 2 material bin 10 through the No. 2 bucket lift 11;

[0036] (The mass ratio of converter ash to sintered ore-returning briquetting balls is: 85%:15%. No. 1 bunker 3 can store 80 tons of converter dedusting ash, No. Bucket elevator 7 and No. 2 bucket elevator 11 will continuously replenish materials to the silo)

[0037] (2) Converter dedusting ash 1 in No. 1 silo 3 and returned ore 8 from No. 2 silo 10 enter the 5.25-meter-long water-spraying twin-shaft agitator 4 through the lower material opening of the silo for stirring, and the amount of water pumped is 11~ 20%, and then enter the digestion chamber 6 for digestion through the bucket elevator 5. Digestion bin 6 can store 50 tons of materials. It takes half an hour to fill the dig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com