Submerged arc refining slag for square billet LF refining and production process and equipment thereof

A production equipment and refining slag technology, applied in the field of metallurgy, can solve problems such as unstable current transmission, high power consumption, and graphite electrode breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

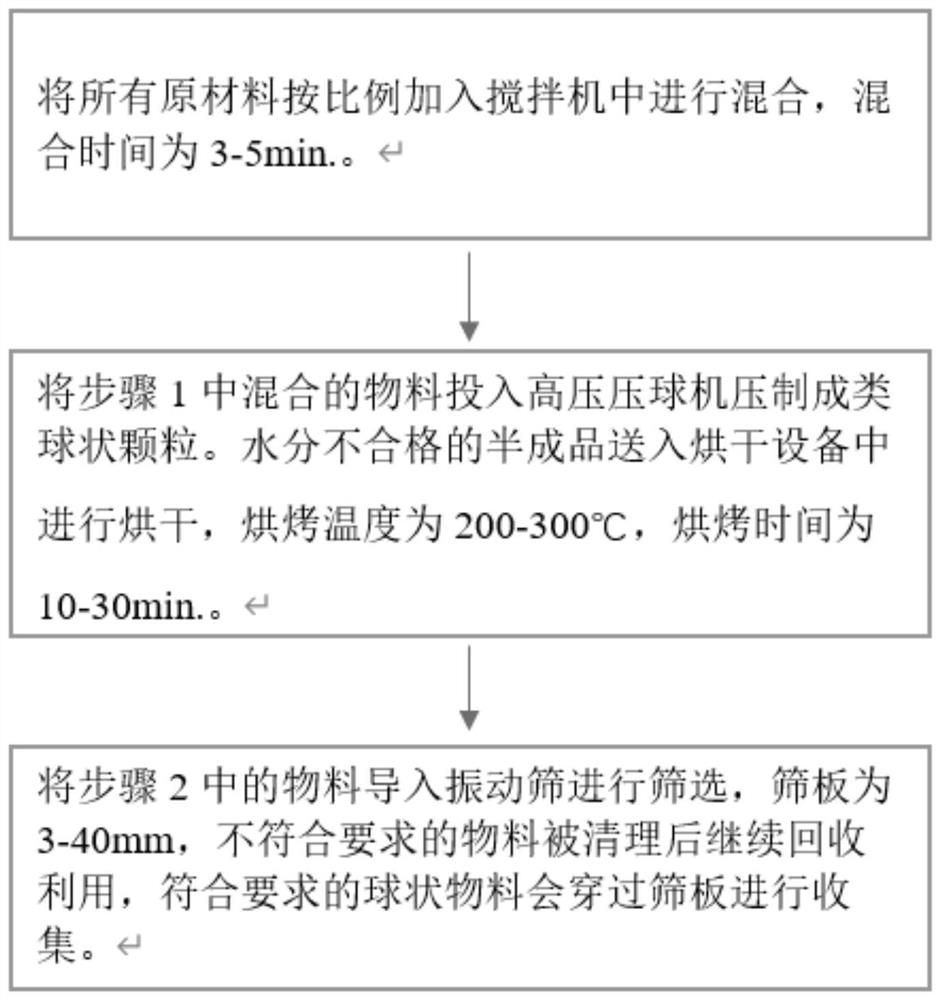

Image

Examples

Embodiment 1

[0045] refer to figure 1 , a kind of submerged arc refining slag for billet LF refining, its raw material weight percentage composition is: CaCO 3 50% parts, MgO 20% parts, SiO 2 5% parts, BaCO 3 10%, Na 2 CO 3 5% for SiC, 5% for CaF 2 5% portion;

[0046] CaCO 3 Can be synthetic or natural limestone; BaCO 3 Can be commercially available or waste containing barium; Na 2 CO 3 It is industrial soda ash; MgO can be any one of magnesia, light burnt magnesia, magnesia dolomite or magnesite; SiC can be any one of industrial smelting grade silicon carbide or silicon carbide-containing waste; SiO2 can be silica , any one of quartz sand or bentonite.

[0047] The present invention is mainly used for the submerged arc of the billet in the LF refining process, using carbonate (CaCO 3 、BaCO 3 、Na 2 CO 3 , MgCO 3 ) etc. as the main raw materials, carbonates decompose due to high temperature after entering the molten steel, producing a large amount of CO 2 Bubbles, SiC, C, C...

Embodiment 2

[0054] refer to figure 1 , as another preferred embodiment of the present invention, the difference with embodiment 1 is that its raw material weight percent composition is: CaCO 3 65% parts, MgO 10% parts, SiO 2 5% parts, BaCO 3 10%, Na 2 CO 3 3% for SiC, 3% for CaF 2 for 4% parts;

[0055] CaCO 3 Can be synthetic or natural limestone; BaCO 3 Can be commercially available or waste containing barium; Na 2 CO 3 It is industrial soda ash; MgO can be any one of magnesia, light burnt magnesia, magnesia dolomite or magnesite; SiC can be any one of industrial smelting grade silicon carbide or silicon carbide-containing waste; SiO2 can be silica , any one of quartz sand or bentonite.

[0056] The present invention is mainly used for the submerged arc of the billet in the LF refining process, using carbonate (CaCO 3 、BaCO 3 、Na 2 CO 3 , MgCO 3 ) etc. as the main raw materials, carbonates decompose due to high temperature after entering the molten steel, producing a larg...

Embodiment 3

[0063] In the process of preparing synthetic slag, it is necessary to mix and stir the materials. The stirring shaft in the fixed position of the mixer in the prior art rotates and stirs, which cannot make the materials evenly mixed, and the stirring effect is not ideal; When removing slag, two pressure rollers are generally used to squeeze the material, so that the contact range between the material and the pressure roller is limited, and the material cannot be ball-pressed to the greatest extent;

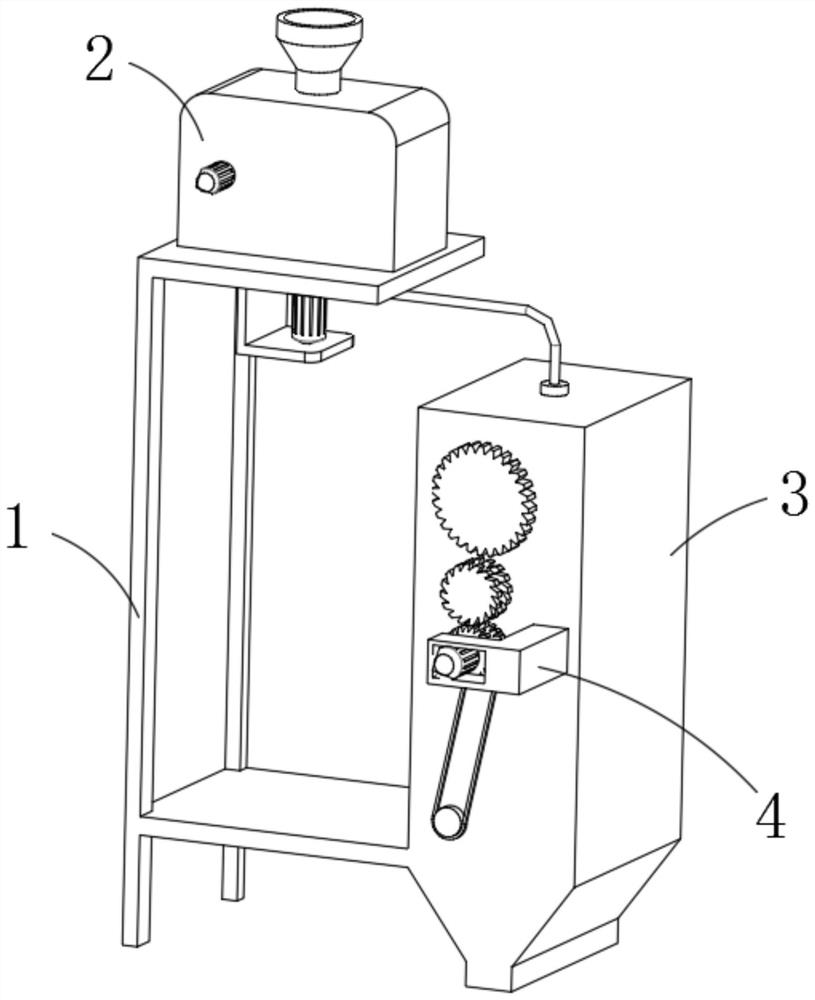

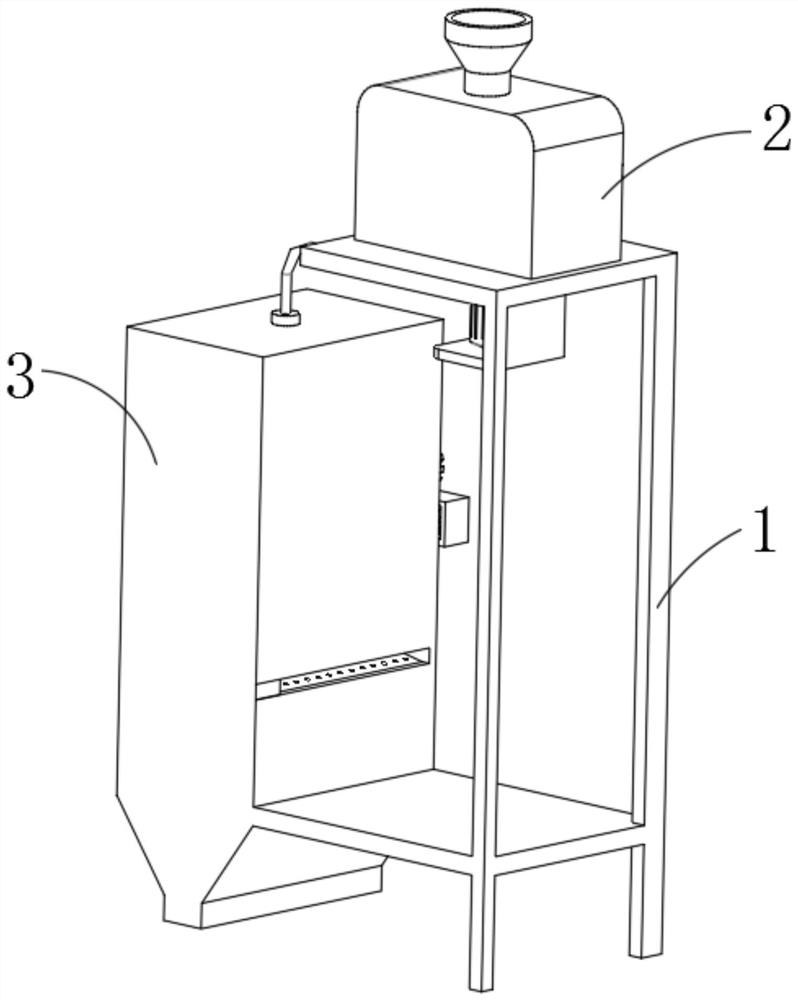

[0064] refer to Figure 2-11 , a submerged arc refining slag production equipment for billet LF refining, including a mounting frame 1, a mixing mechanism 2, a ball pressing mechanism 3 and a driving mechanism 4, the mixing mechanism 2 is installed on the top of the mounting frame 1, and the ball pressing mechanism 3 Installed at the outlet end of the mixing mechanism 2, the drive mechanism 4 is installed outside the ball pressing mechanism 3;

[0065] Mixing mechanism 2 comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com