Submerged arc refining slag for billet lf refining and its production process and equipment

A technology for production equipment and refining slag, which is applied in the field of metallurgy, can solve the problems of noise pollution, long refining time, high power consumption, etc., and achieve the effect of improving the ball pressing efficiency and speeding up the screening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Refer figure 1 , A billet LF refinery refined refinery, the weight percentage group of raw materials is: Caco 3 50%, MgO is 20%, SIO 2 5%, Baco 3 10%, NA 2 CO 3 5%, SiC is 5%, CAF 2 5%;

[0046] Caco 3 Can be synthetic or natural limestone; Baco 3 It can be a commercially available waste; NA 2 CO 3 For industrial pure base; MGO can be any of magnesium oxide, lightly magnesium, magnesium dolomite or diamond mite; SiC can be any of industrial smelted silicon carbide or carbide waste; SiO2 can be silica Any one of quartz sand or bentonite.

[0047] The present invention is mainly used for buried arcs in the LF refining process, using carbonates (Caco 3 , Baco 3 NA 2 CO 3 , MGCO 3 ), Etc. 2 Bubble, simultaneous SiC, C, CAC 2 Waiting and Co 2 The reaction generates CO, thereby obtaining a large amount of bubbles to achieve a buried arc;

[0048] The present invention also provides a production process of refined slag for a billet LF refining, including the following steps;

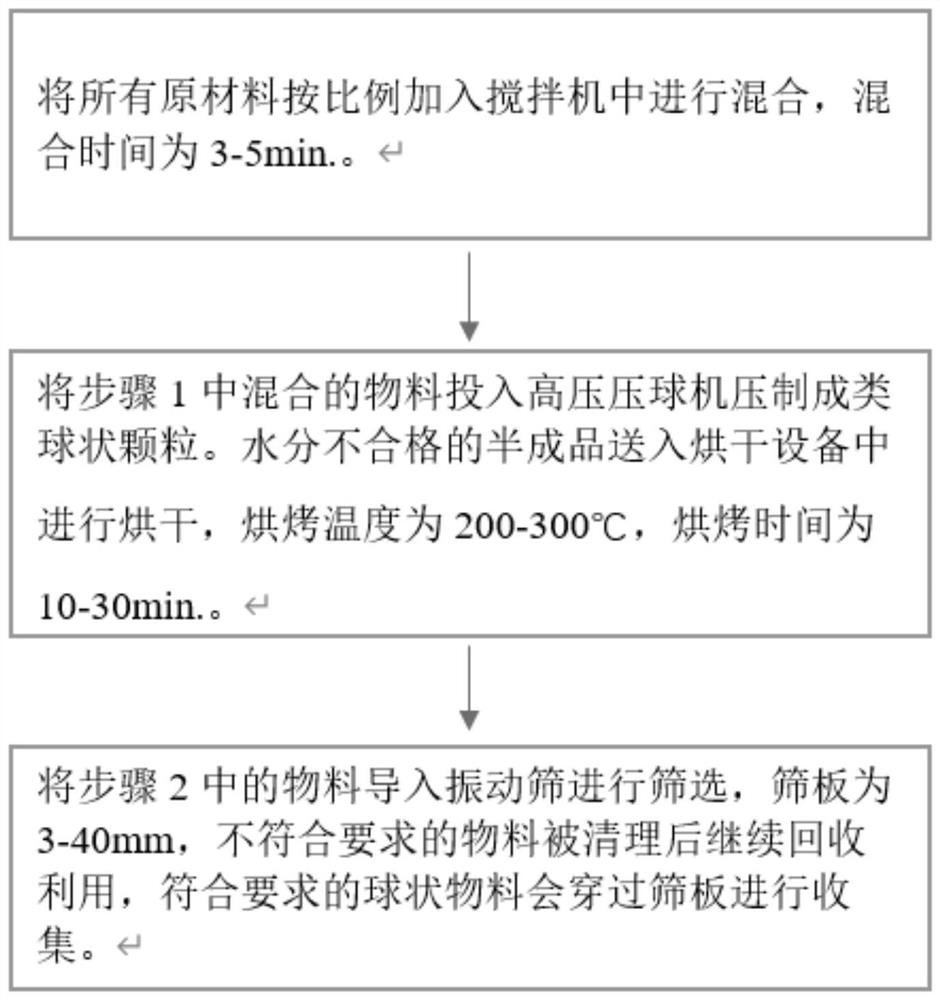

[00...

Embodiment 2

[0054] Refer figure 1 As another preferred embodiment of the present invention, the difference from Embodiment 1 is that the weight percentage of the raw material is: Caco 3 65%, MgO is 10%, SIO 2 5%, Baco 3 10%, NA 2 CO 3 3%, SiC is 3%, CAF 2 4%;

[0055] Caco 3 Can be synthetic or natural limestone; Baco 3 It can be a commercially available waste; NA 2 CO 3 For industrial pure base; MGO can be any of magnesium oxide, lightly magnesium, magnesium dolomite or diamond mite; SiC can be any of industrial smelted silicon carbide or carbide waste; SiO2 can be silica Any one of quartz sand or bentonite.

[0056] The present invention is mainly used for buried arcs in the LF refining process, using carbonates (Caco 3 , Baco 3 NA 2 CO 3 , MGCO 3 ), Etc. 2 Bubble, simultaneous SiC, C, CAC 2 Waiting and Co 2 The reaction generates CO to obtain a large amount of bubbles to achieve the purpose of buried arc.

[0057] The present invention also provides a production process of refined slag for...

Embodiment 3

[0063] During the preparation of synthetic slag, it is necessary to mix the material, and the prior art mixer is mixed and stirred, and the material is uniformly mixed, and the material is uniform, the agitation effect is not ideal; in addition, the material is rolled into the material through the opposite When the slag is generally squeezed with two pressure rolls, the material is not limited to the contact range of the material and the pressure roller, and the material cannot be pressed to the material.

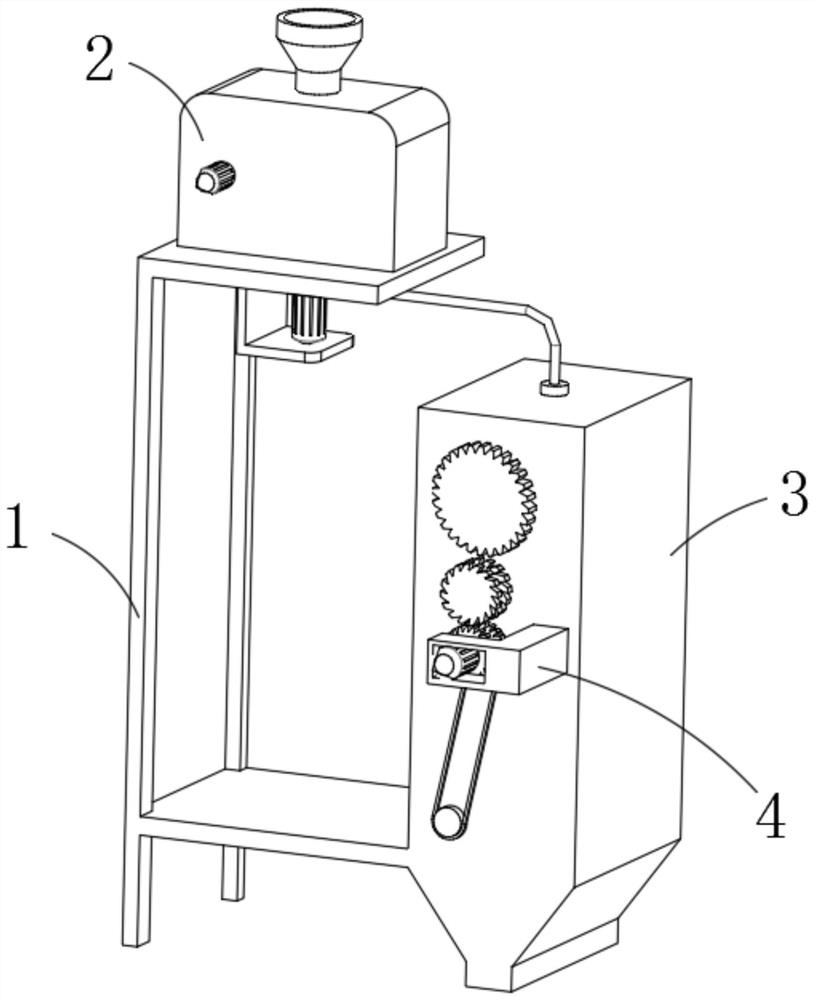

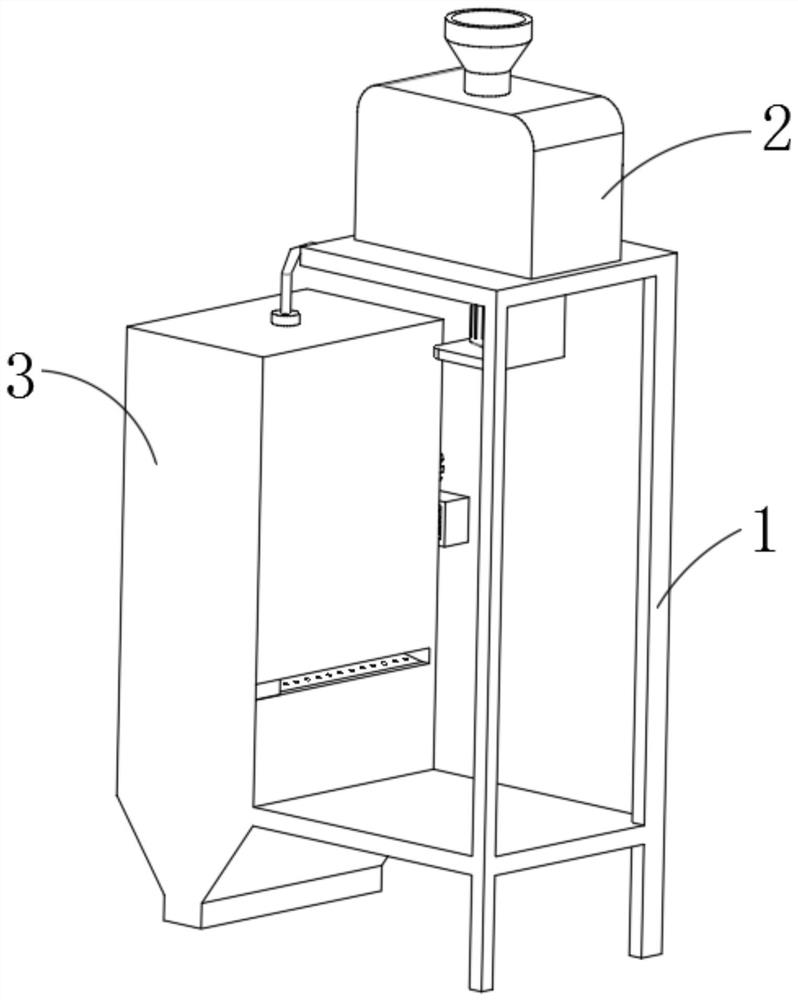

[0064] Refer Figure 2-11 A production apparatus for refining of a billet LF refining, including mounting frame 1, mixing mechanism 2, pressure ball mechanism 3, and drive mechanism 4, mixing mechanism 2 mounted at the top end of the mounting frame 1, a pressure ball mechanism 3 The outlet end of the mixing mechanism 2 is mounted, the drive mechanism 4 is mounted on the outside of the pressurized mechanism 3;

[0065] The mixing mechanism 2 includes a mixing tank 21, the feed ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com