Process for three-dimensional printing, particularly for the production of windows, plate-shaped elements for floors or the like

A technology for 3D printing and flooring, applied in manufacturing, household components, manufacturing auxiliary devices, etc., can solve the problems of complex and expensive decoration technology, impossibility of high-strength polymeric materials, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

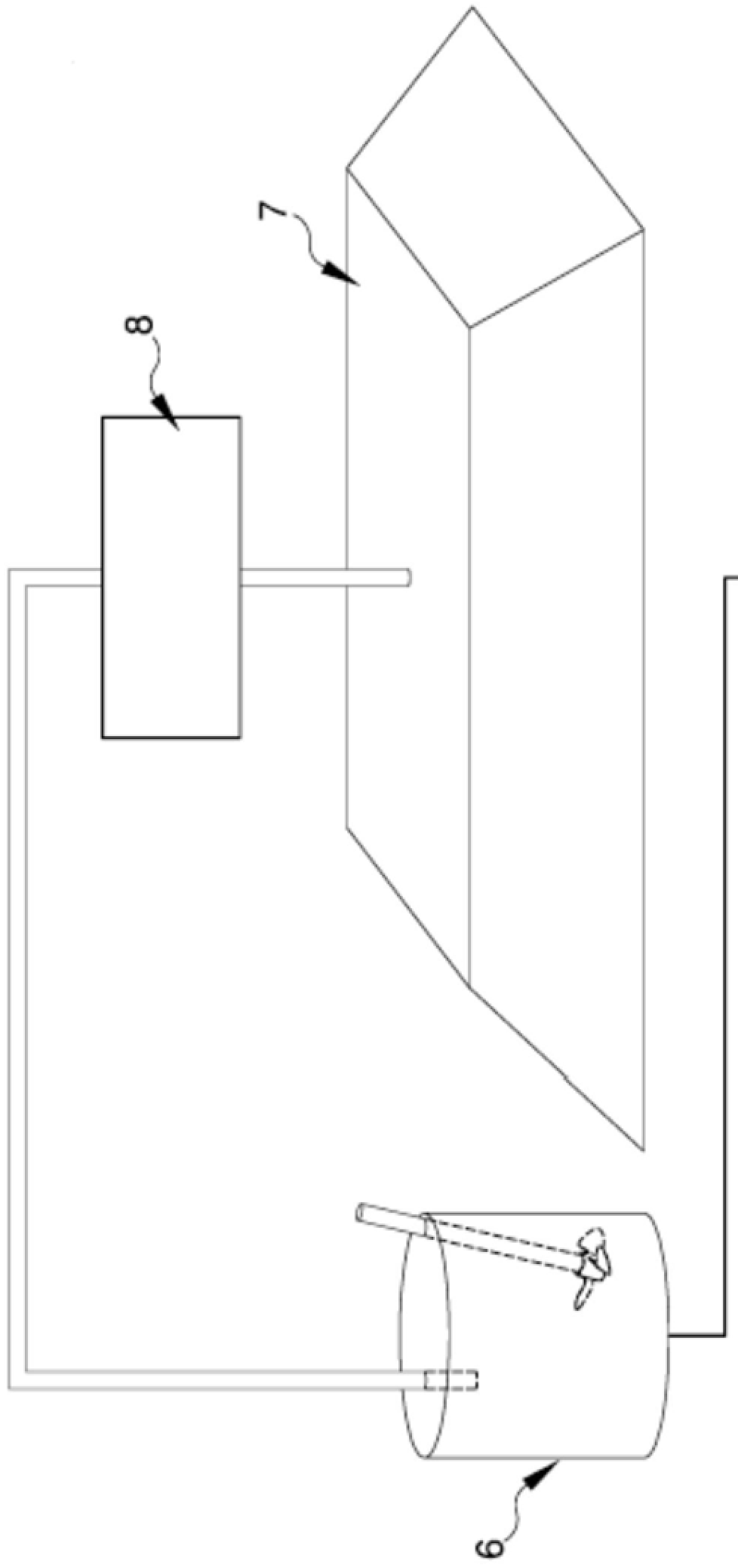

[0031] Method for three-dimensional printing, especially for the manufacture of windows, for floors or similar plate-shaped elements, comprising:

[0032] - at least one step of providing PVC and at least one solvent, wherein PVC is soluble;

[0033] - at least one step of mixing said PVC and said solvent to obtain a mixture of at least one liquid phase;

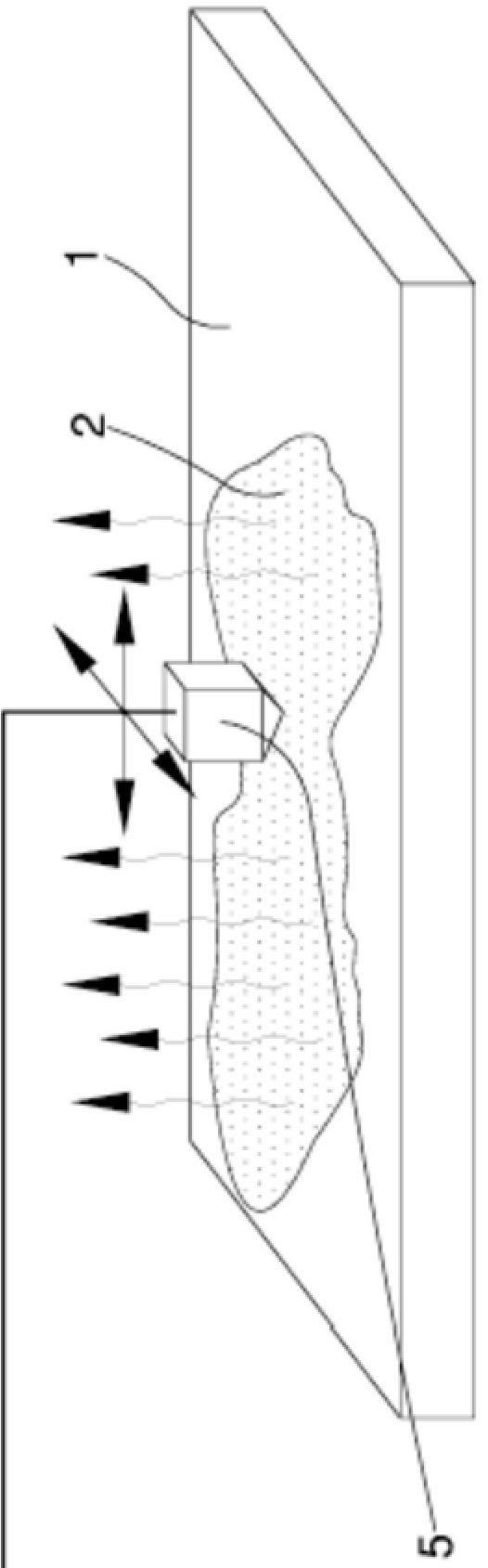

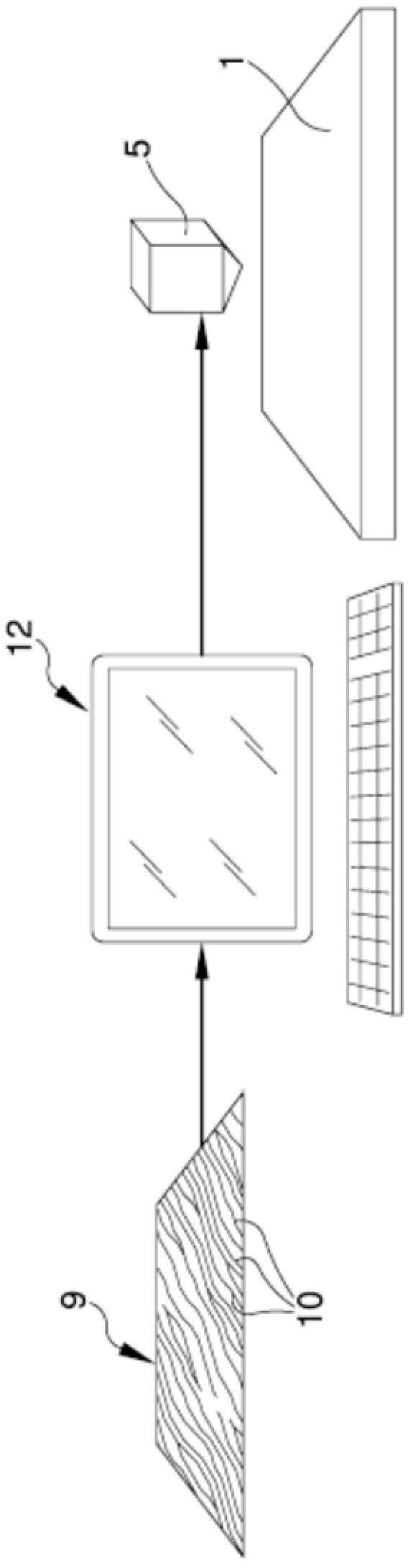

[0034] - at least one step of dispersing said mixture onto at least one deposition surface 1;

[0035] - at least one evaporation step of said solvent to obtain at least one PVC layer 2 of at least one finished product 3, which is followed by said dispersion step.

[0036] According to the invention, said method also includes repeating said dispersion step and said evaporation step to obtain a plurality of overlapping layers 2 of PVC forming said finished product 3 .

[0037] Usefully, the finished product 3 obtained according to the method is a decorative surface part for a window frame profile member 4a, or alternatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com