Graphene doping material, and preparation method and application of graphene doping material

A technology of doping materials and graphene, which is applied in the direction of cable/conductor manufacturing, carbon-silicon compound conductors, electrical components, etc., which can solve the problems of limiting the application of graphene and reducing the square resistance, so as to achieve easy control of coating thickness and improvement of conductivity , combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

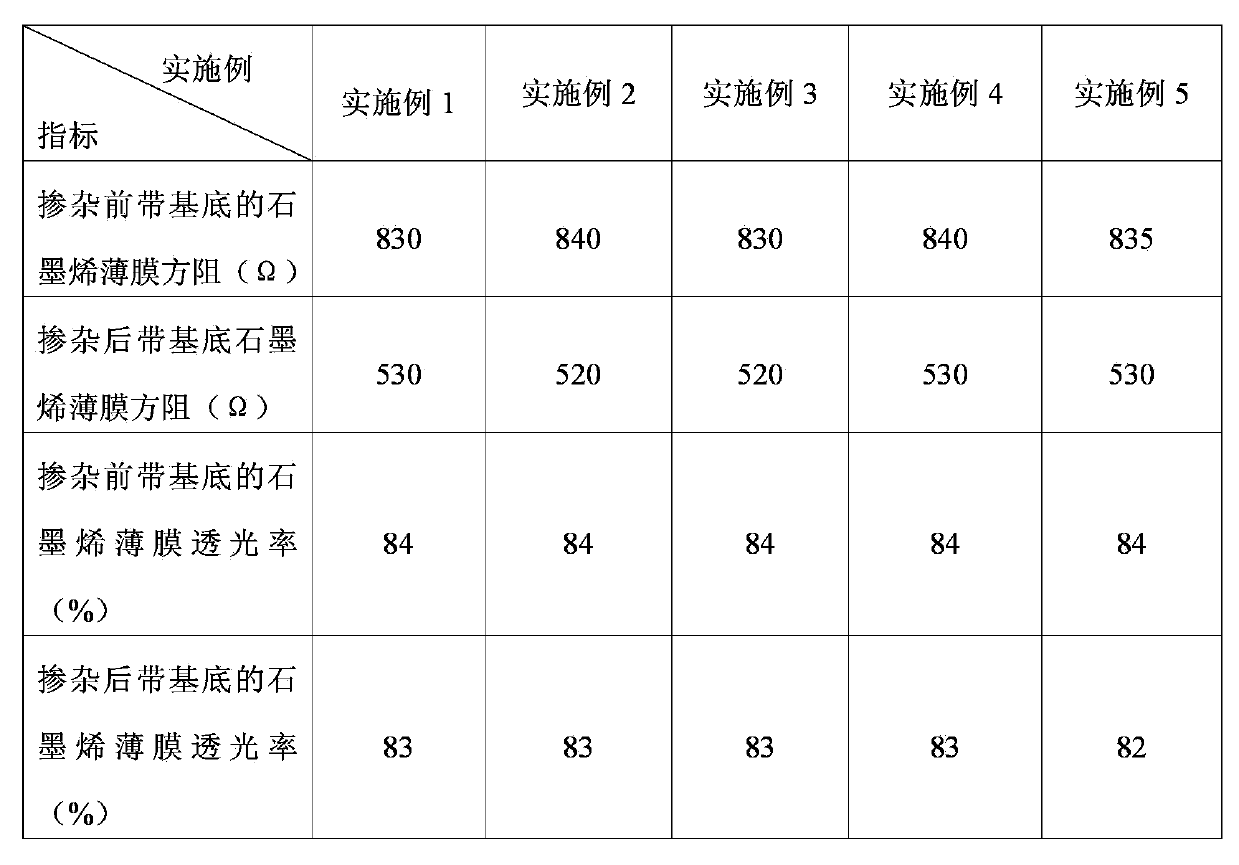

Examples

Embodiment 1)

[0019] Take the graphene film with glass substrate, the number of graphene layers is 2 layers; molybdenum trioxide powder;

[0020] Prepare molybdenum trioxide-doped graphene material according to the following steps: (1) Put the graphene film with the substrate into the vacuum chamber of the thermal evaporation apparatus and then evacuate it, the vacuum degree is 1*10 -4 Pa; (2) Evaporation, adjust the current to 90A to heat and dissolve the molybdenum oxide solid powder, molybdenum trioxide is evaporated and deposited on the graphene film at about 700 ° C, and the molybdenum trioxide is isolated by the baffle of the thermal evaporation apparatus to control the trioxide The thickness of the molybdenum layer is 10 nm in thickness. When in use, the molybdenum trioxide-doped graphene material obtained in this embodiment can be used as the base electrode of the touch screen.

Embodiment 2)

[0022] Get graphene film with PET substrate, graphene layer number is 3 layers; Potassium bromide powder;

[0023] Prepare potassium bromide-doped graphene materials according to the following steps: (1) Put the graphene film with the substrate into the vacuum chamber of the thermal evaporation apparatus and then evacuate it, and the vacuum degree is 1*10 -5 Pa; (2) Evaporation, adjust the current to 100A to heat and dissolve the solid powder of potassium bromide, the potassium bromide is evaporated and deposited on the graphene film at about 730°C, and the potassium bromide is isolated by the baffle of the thermal evaporation instrument to control the bromine The thickness of the potassium oxide layer is 10 nm in thickness. When in use, the potassium bromide-doped graphene material obtained in this embodiment can be used as the base electrode of the touch screen.

Embodiment 3)

[0025] Take the graphene film with glass substrate, the number of graphene layers is 2 layers; molybdenum dioxide powder;

[0026] Prepare molybdenum dioxide-doped graphene materials according to the following steps: (1) Put the glass substrate into the vacuum chamber of the thermal evaporation apparatus and then evacuate it, adjust the current to 100A to heat and dissolve the dopant molybdenum dioxide powder and evaporate it with a thermal evaporation apparatus Plating a molybdenum dioxide layer with a thickness of 20 nanometers to form a molybdenum dioxide glass substrate; (2) transfer the graphene film on the aforementioned molybdenum dioxide glass substrate; Anneal for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com