Silk-screen transparent conductive slurry, preparation method of silk-screen transparent conductive slurry and application of silk-screen transparent conductive slurry

A transparent conductive, paste technology, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, nanotechnology for materials and surface science, etc., can solve the problem of low light transmittance and high haze problem, to achieve the effect of high light transmittance, low haze and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A preparation method for silk screen transparent conductive paste, comprising:

[0050] Material preparation steps: Prepare the raw materials according to the formula ratio; configure the silver nanowires in the formula amount into the silver nano wire dispersion; configure the PEDOT / PSS in the formula amount into the PEDOT / PSS dispersion liquid; configure the adhesive in the formula amount into a binder solution;

[0051] Dispersion steps: Add PEDOT / PSS dispersion, water, and organic solvent to the beaker in turn under stirring at 100-1000r / min at room temperature, and disperse for 15 minutes; then add surface wetting agent, leveling agent, and dispersant in sequence , coupling agent, defoamer, adhesive solution, emulsifier and functional additives, disperse for 15 minutes; then add nano-silver wire dispersion, disperse for 15 minutes, filter with 200-mesh filter to obtain filtrate; finally add thickener , dispersed for 15 minutes, that is, made into transparent condu...

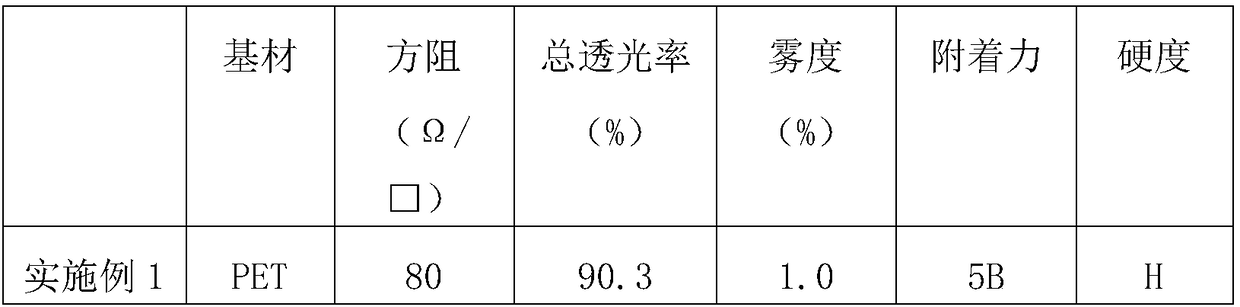

Embodiment 1

[0055] A transparent conductive paste for silk screen printing, prepared from the following raw materials by weight percentage:

[0056] Nano silver wire: 0.25%, PEDOT / PSS: 0.05%, surface wetting agent: 0.03%, leveling agent: 0.01%, dispersant: 0.1%, coupling agent: 0.3%, defoaming agent: 0.01%, viscous Mixture: hydroxypropyl methylcellulose 0.06%, thickener: 0.3%, organic solvent: diacetone alcohol 10%, diethylene glycol dimethyl ether 12%, pH regulator: 0.25%, dimethyl Sulfoxide: 1.0%, water: balance.

[0057] A preparation method for silk screen transparent conductive paste, comprising:

[0058] Material preparation steps: Prepare the raw materials according to the formula ratio; configure the silver nanowires in the formula amount into the silver nano wire dispersion; configure the PEDOT / PSS in the formula amount into the PEDOT / PSS dispersion liquid; configure the adhesive in the formula amount into a binder solution;

[0059] Dispersion steps: Add PEDOT / PSS dispersion,...

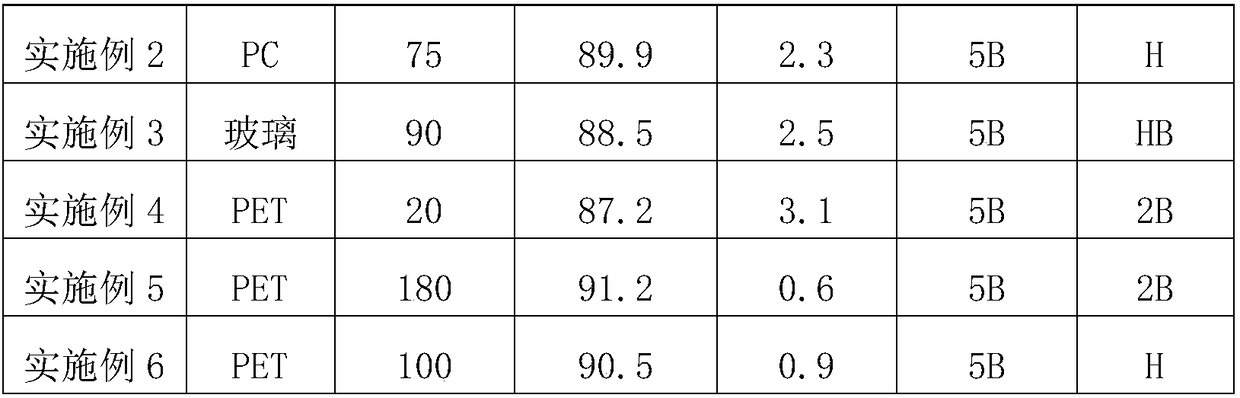

Embodiment 2

[0062] The transparent conductive paste for screen printing and its preparation method are the same as in Example 1.

[0063] An application of screen printing transparent conductive paste, specifically: using PC as the base material, printing the above prepared screen printing conductive paste on different base materials with a 420-mesh screen to prepare transparent conductive patterns, drying at 150°C After 20 minutes in the oven, the conductive coating can be cured after the solvent is completely evaporated, and a patterned transparent conductive coating is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com