Graphene/metal composite thin film and preparation method thereof

A graphene film, metal composite technology, applied in metal material coating process, coating, liquid chemical plating and other directions, can solve the problems of poor time stability of square resistance, prone to agglomeration, complex process, etc., to reduce square resistance , Enhance time stability, save the effect of compound process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of graphene / metal composite film, comprises the following steps:

[0031] A) immersing the growth substrate with the graphene film in the reducing solution to carry out the reduction reaction to obtain a composite film of metal particles / graphene film / growth substrate;

[0032] B) transferring the metal particles / graphene film in the metal particle / graphene film / growth substrate composite film to a target substrate to obtain a graphene / metal composite film of the target substrate / metal particle / graphene film.

[0033] In the invention, firstly, the growth substrate with the graphene film is immersed in the reducing solution to carry out the reduction reaction to obtain the composite film of metal particles / graphene film / growth substrate.

[0034] In the present invention, the growth substrate with graphene film is prepared according to the following method:

[0035] The growth substrate is put into a reaction furnace,...

Embodiment 1

[0057] Putting the copper substrate into a chemical vapor reaction furnace, then introducing hydrogen and methane gas into the chemical vapor reaction furnace, and reacting at 1000°C to obtain a copper substrate with a graphene film, wherein the The volume ratio of hydrogen to methane gas is 10:1.

Embodiment 2

[0064] 1. Prepare 0.5g / L chloroauric acid solution.

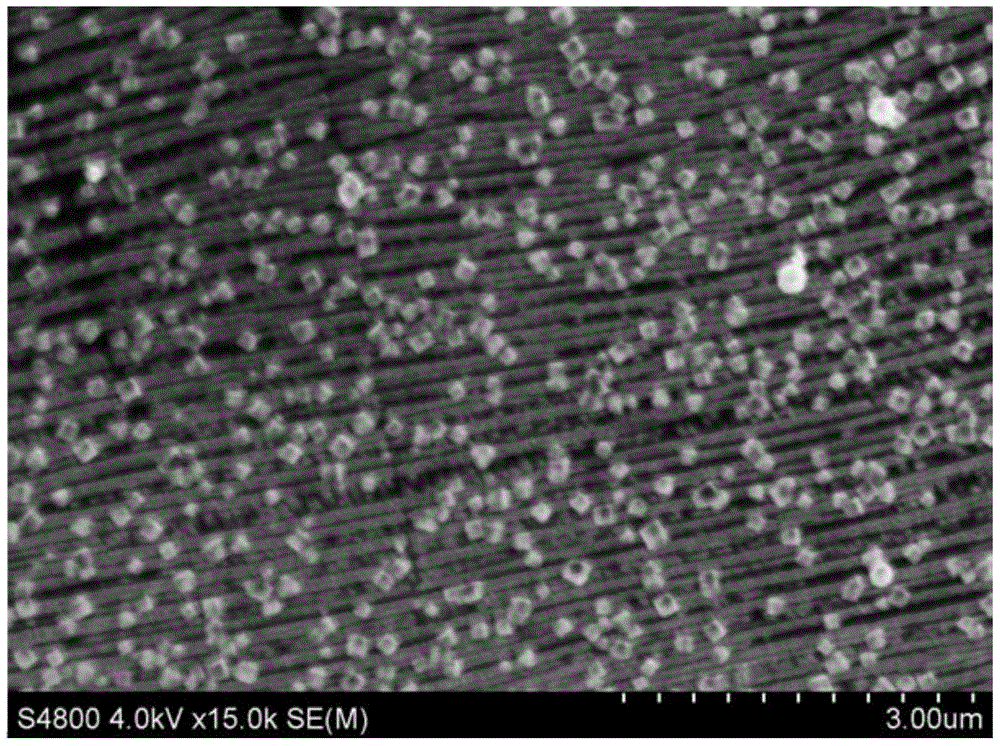

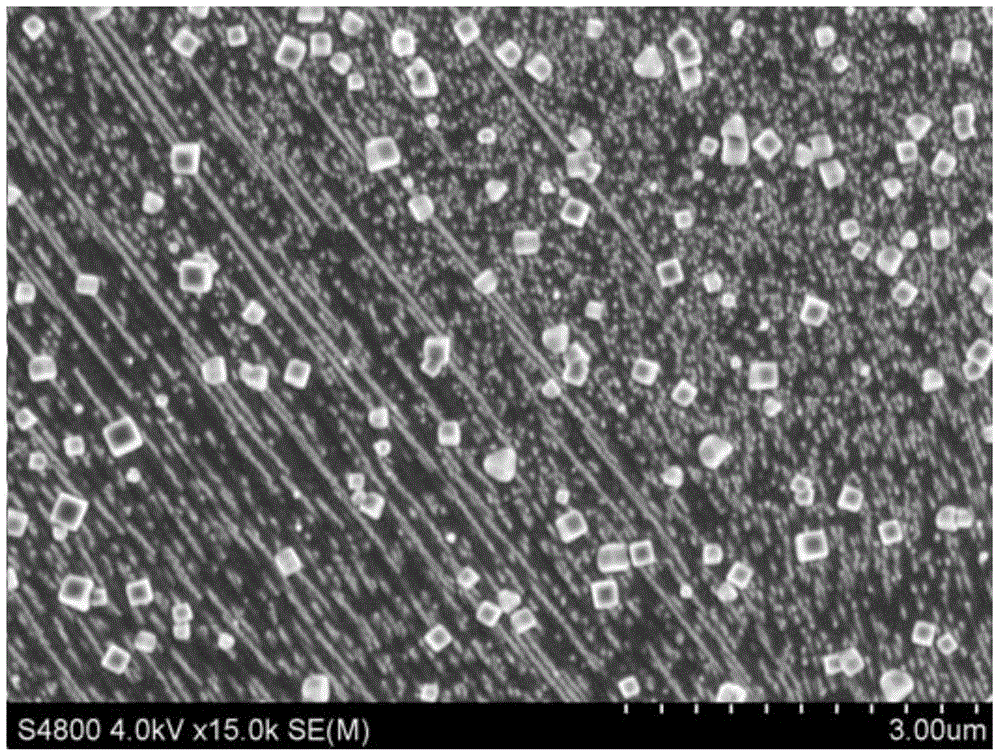

[0065] 2. the copper substrate with the graphene film prepared in embodiment 1 is put into the above-mentioned diluted 0.5g / L chloroauric acid solution, and left to stand for 1 minute to obtain the composite film formed by gold particles / graphene film / copper substrate .

[0066] 3. Take out the above composite film, wash it with deionized water and blow it dry.

[0067] 4. Put the above-mentioned composite film under the condition of 110° C., use hot-melt adhesive as an adhesive, and press it with PET by rollers. A PET / gold particle / graphene film / copper substrate structure is formed.

[0068] 5. Etching the above PET / gold particles / graphene film / copper substrate structure in 10% ammonium persulfate solution.

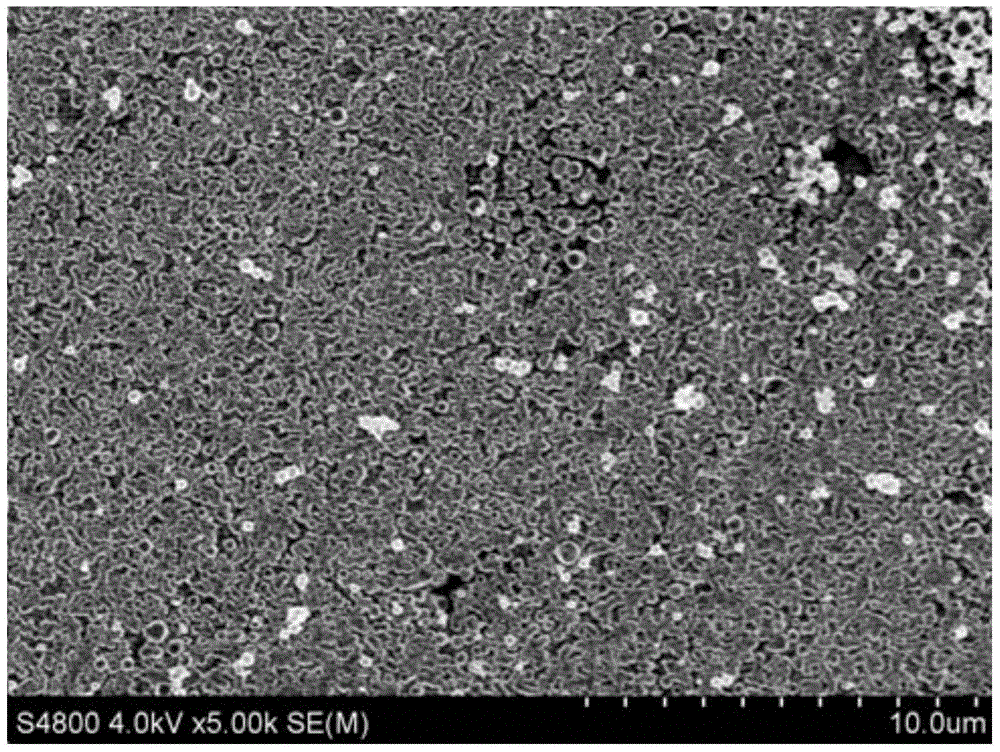

[0069] 6. After the copper is completely etched, a graphene / metal composite film of PET / gold particles / graphene film is obtained, which is washed with deionized water and then dried.

[0070] The graphene / metal co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com