Physical vapor deposition device and method for Nano silicon-crystal thin film of solar battery

A technology of physical vapor deposition and solar cells, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the limitation of photoelectric conversion efficiency and the improvement of service life, and solar cells cannot fundamentally solve the problem of light decay and migration , Diffusion ability is very poor and other problems, to achieve the effects of photoelectric conversion efficiency, large beam current, and wide energy regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

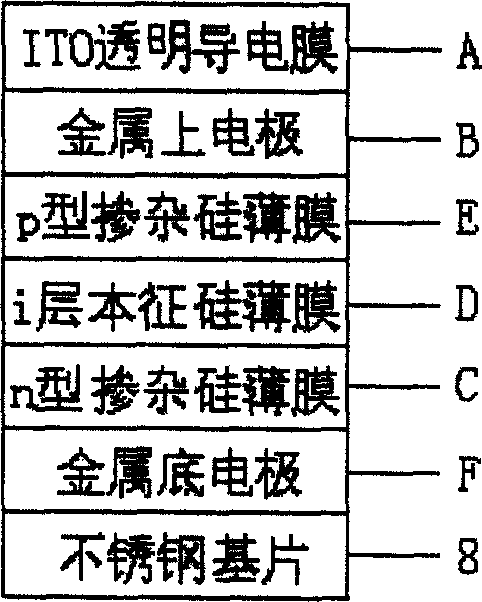

[0055] Example: Take the stainless steel substrate 8 as an example to illustrate the specific implementation process.

[0056] 1. Substrate polishing and cleaning

[0057] The stainless steel substrate 8 is mechanically polished, the surface is smooth and bright without scratches, and the reflection coefficient is >85%. Then it is chemically cleaned, dehydrated and dried for later use.

[0058] 2. Racking

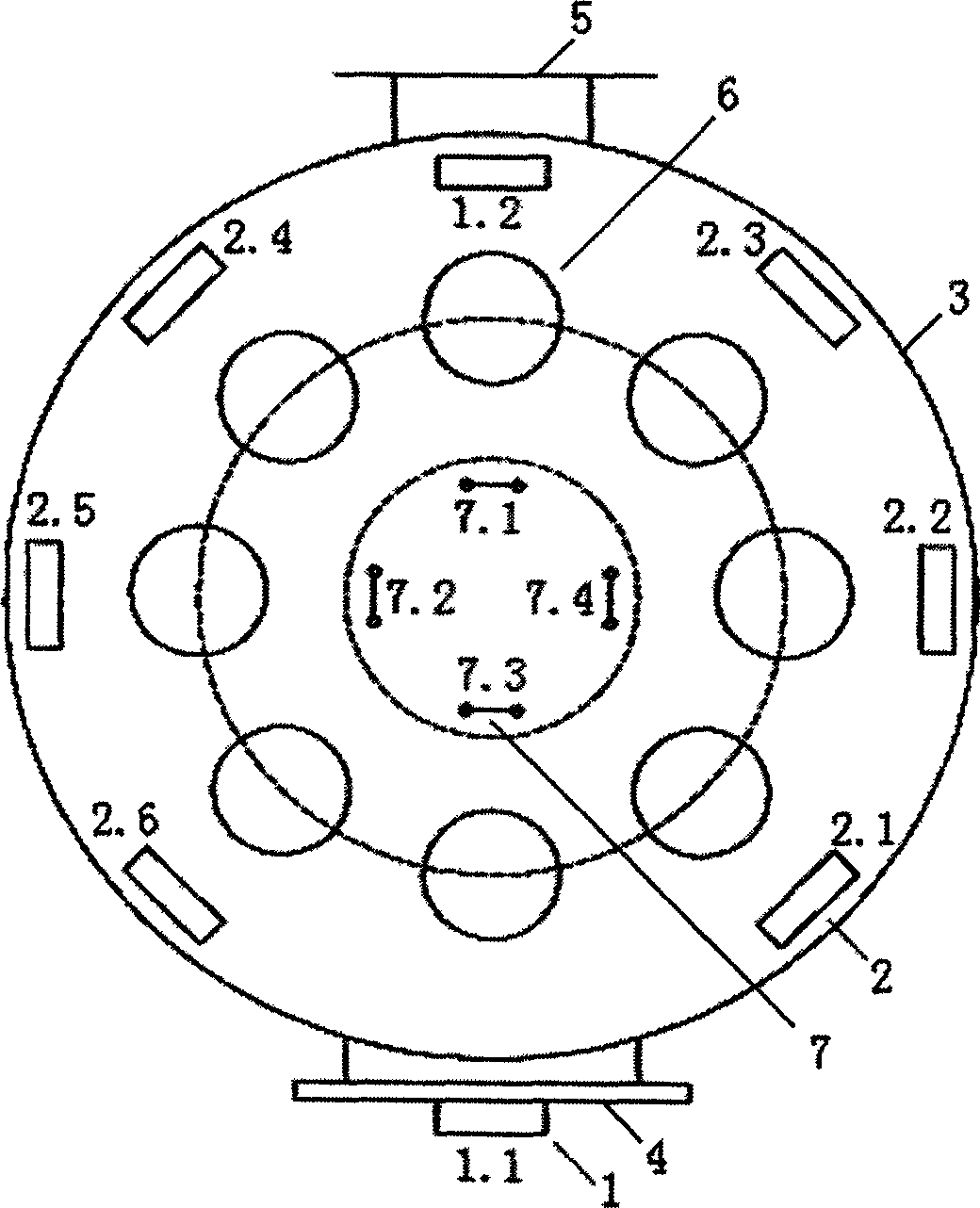

[0059] The cleaned stainless steel substrate 8 is loaded on the workpiece frame 6 and hung on the working rotating shaft in the vacuum chamber 3 . Maintain the cleanliness of the substrate and vacuum chamber components throughout the operation.

[0060] 3. Vacuuming

[0061] Close the furnace door 4, and pump a high vacuum to 3×10 according to the operation regulations of the coating machine. -3 Pa.

[0062] 4. Substrate baking

[0063] Vacuum up to 3×10 -3 After Pa, turn on the baking heating power supply to bake the substrate, control the baking temperature at 280...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com