Ultraviolet light source system with light intensity automatic feedback correction function and application thereof

An ultraviolet light source and automatic feedback technology, which is applied in the field of ultraviolet light source system, can solve the problems of imperfect UV LED manufacturing process, affecting the use effect of ultraviolet LED, and fast light intensity attenuation and attenuation speed, so as to eliminate its own light attenuation and power supply current Changes, the effect of ensuring effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

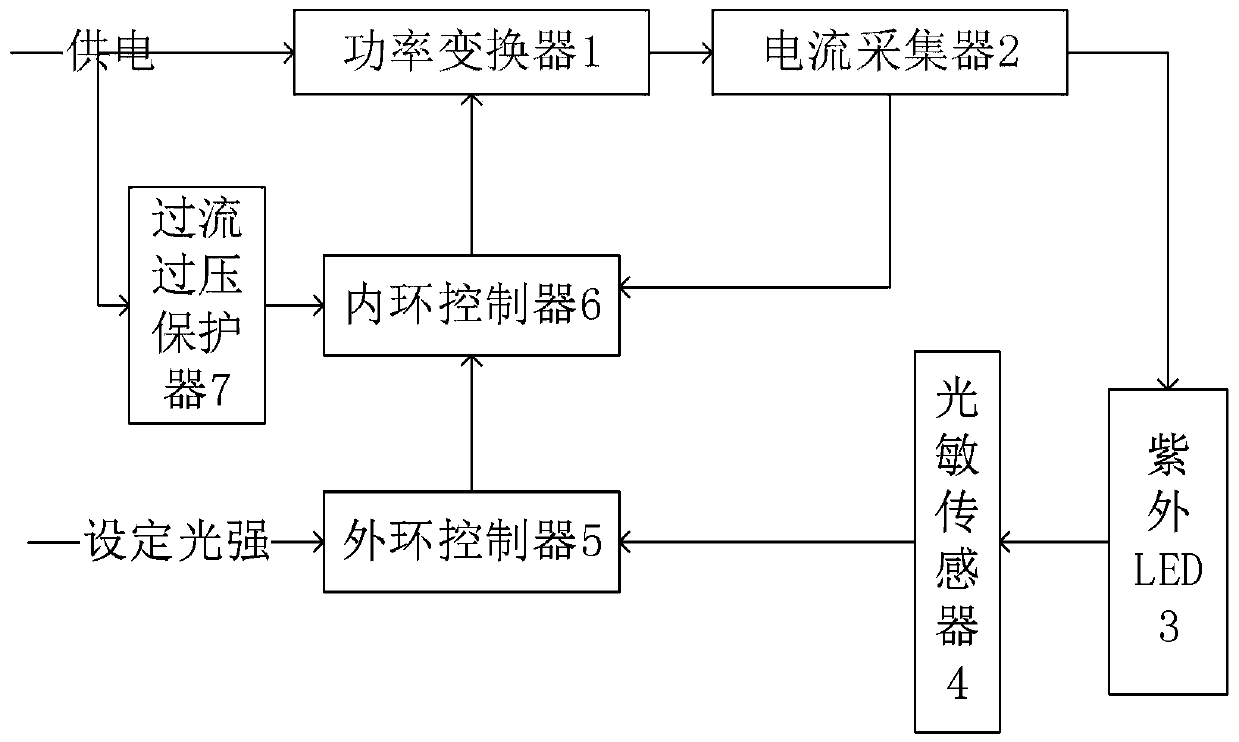

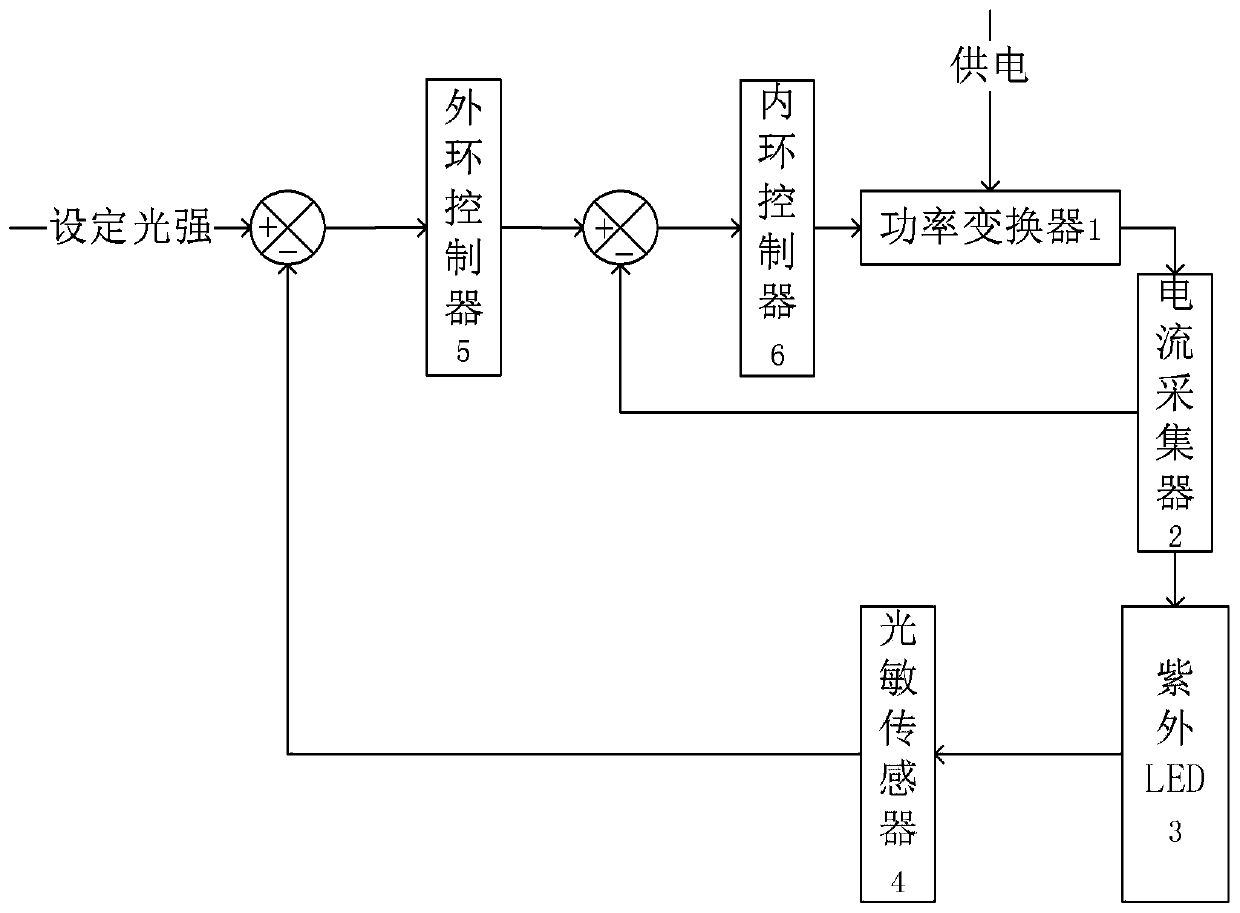

[0021] The invention discloses an ultraviolet light source system with a light intensity automatic feedback correction function, comprising:

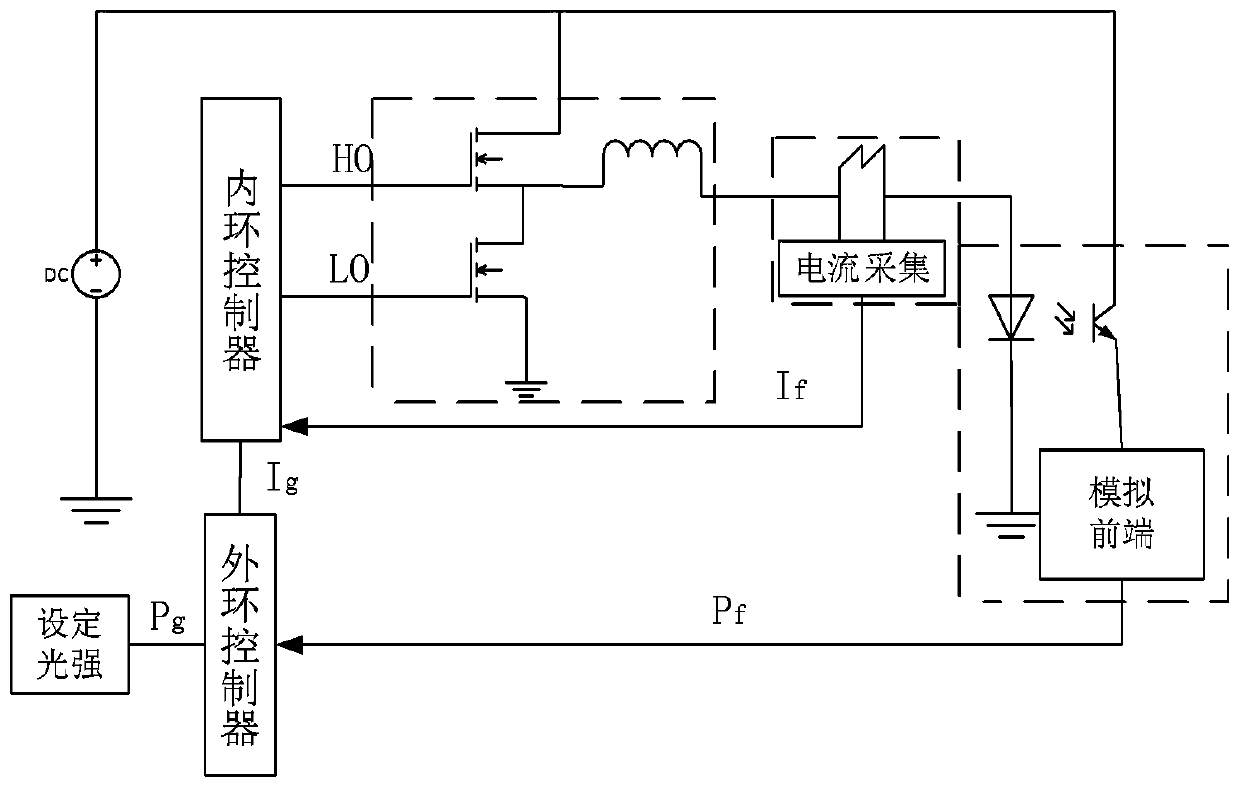

[0022] The power converter converts the electric energy of the power supply into an adjustable current for the ultraviolet light source;

[0023] A current collector, used to detect the input current value and feed it back to the inner loop controller;

[0024] Ultraviolet light source, emitting light intensity signal;

[0025] Photosensitive sensor, which converts the light intensity signal into an electrical signal and amplifies it and feeds it back to the outer loop controller;

[0026] The outer loop controller outputs the electric signal fed back by the photosensitive sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com