Combined structure and method of light fitting component

A combined structure and lamp technology, applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., to achieve the effects of eliminating damage and light decay of light-emitting array chips, good thermal conductivity, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

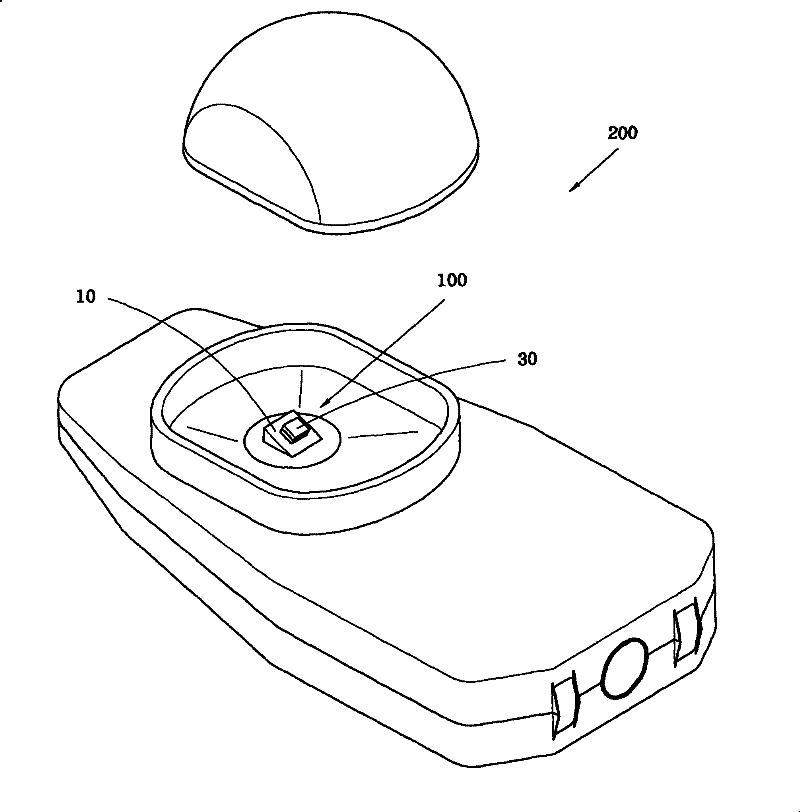

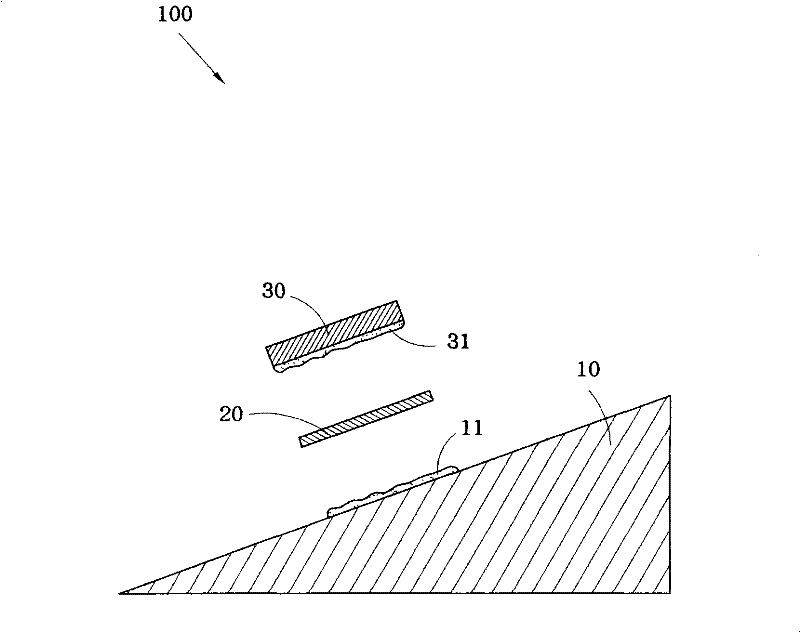

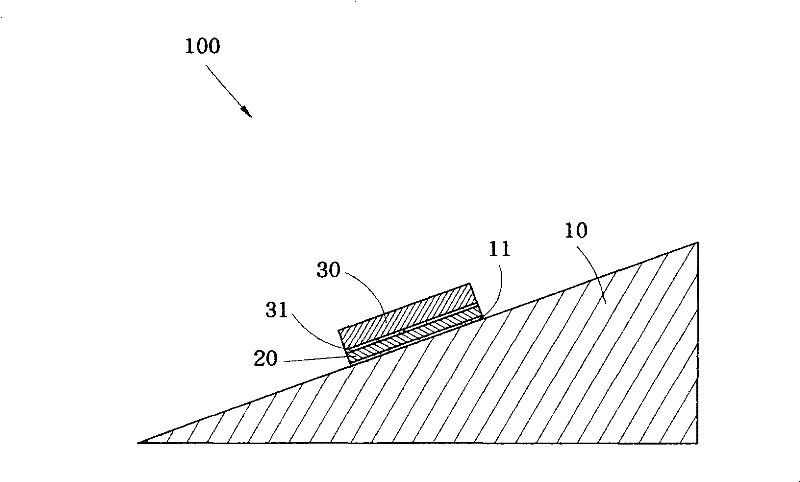

[0044] A luminous array chip 30 is composed of an array of several emitting diode components. The bottom surface of the luminous array chip 30 is combined with the first metal glue layer 31.As an example, the second metal glue layer 31 combines the other side of the above metal film 20, which makes the luminous array chip 30 combined with the surface of the lamp base 10.

[0045] Please cooperate again image 3 Show, the first metal glue layer 11, the first metal glue layer 11, the metal film 20, and the luminous array chip 30 of the lamp base 10 in the combination structure of the present invention can use various hot melt methods to light upThe array chip 30 is firmly combined on the surface of the lamp base 10, and the embodiment of its combination will be clarified in the following combination method steps.

[0046] Please cooperate again Figure 4 As well as Figure 5 and Figure 6 Show, Figure 4 For the implementation step flow chart of the combination of chip combination method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com