Efficient line scanning photo-curing imaging device and method

An imaging device and light curing technology, applied in the field of 3D printing, can solve the problems of low scanning speed, aging, heating display screen, etc., and achieve the effect of high amplitude and frequency stability, stable oscillation frequency, and small moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

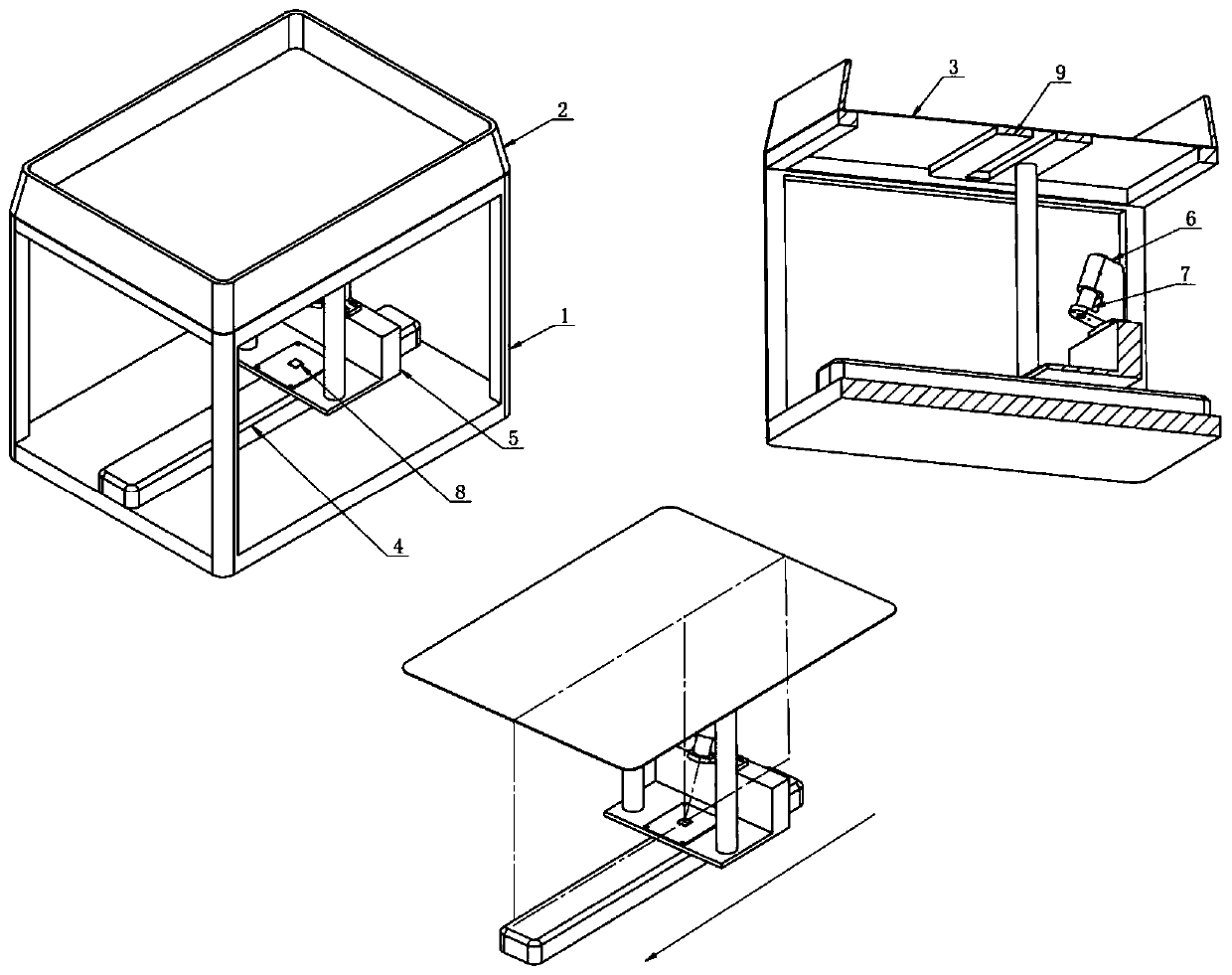

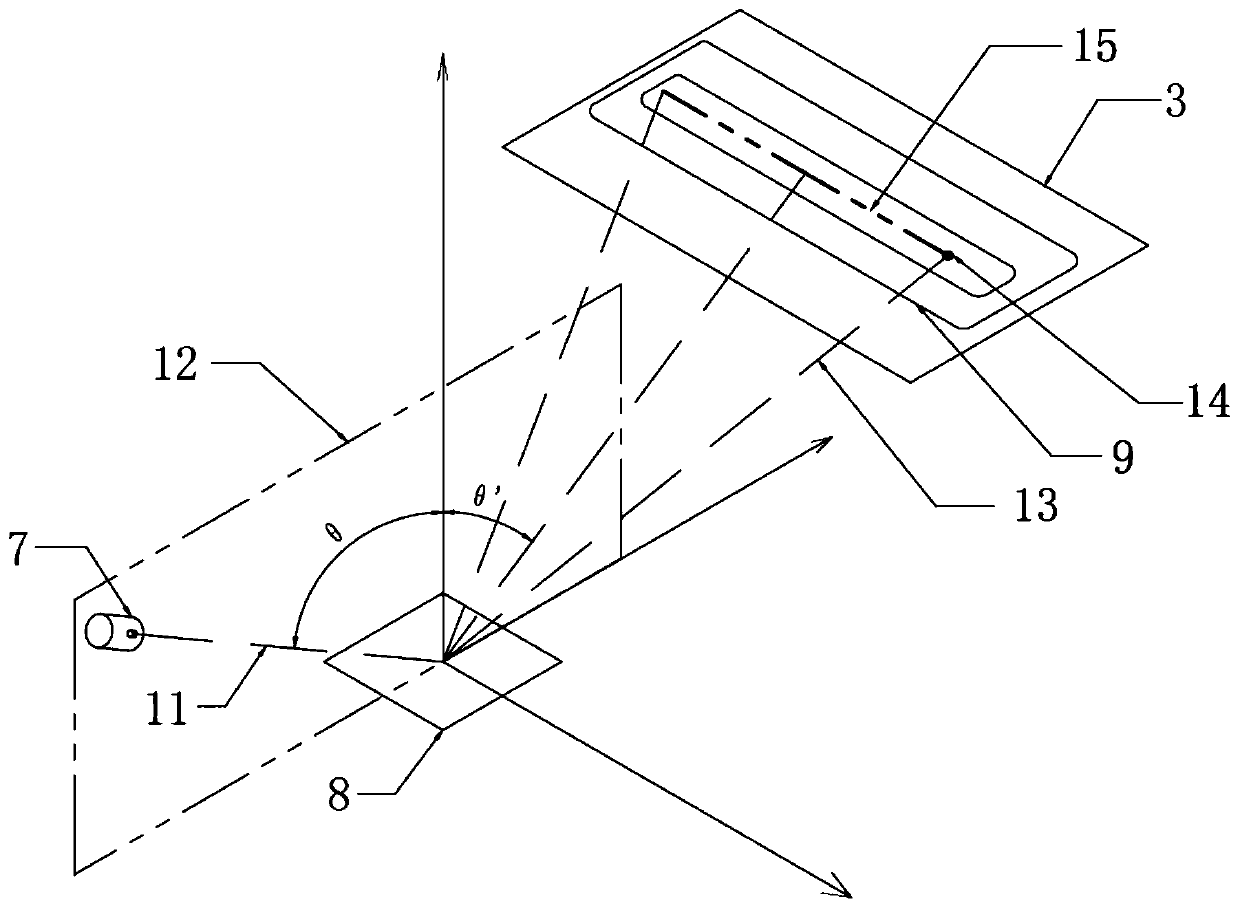

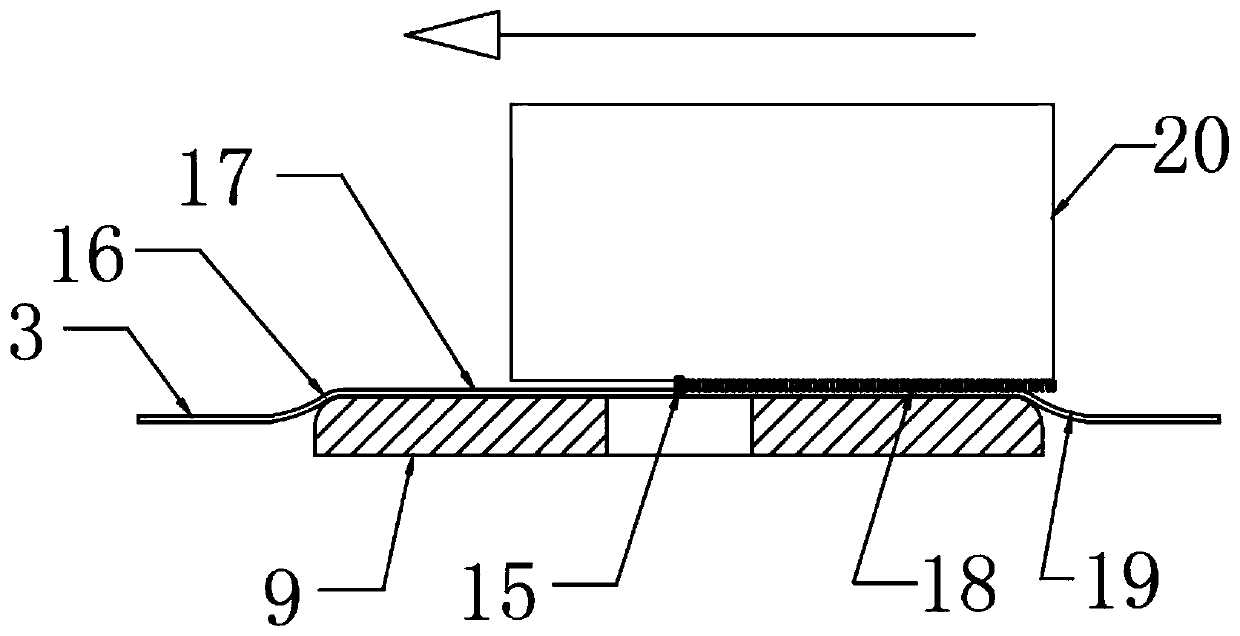

[0023] Example: such as figure 1 , a high-efficiency line-scan photocuring imaging device, comprising a frame 1, a liquid tank 2 is arranged above the frame 1, a photosensitive resin is arranged in the liquid tank 2, a flexible transparent bottom 3 is arranged at the bottom of the liquid tank 2, and a linear Module 4, the linear module 4 is provided with a mobile platform 5, the moving direction of the mobile platform 5 is parallel to the longitudinal direction of the flexible transparent bottom 3, the mobile platform 5 is provided with a support 6, and the support 6 is provided with a laser light source 7, a resonant micro The electromechanical mirror 8 and the rigid narrow linewidth window 9, the light beam 11 emitted by the laser light source 7 just strikes the resonant microelectromechanical mirror 8, the deflection axis of the resonant microelectromechanical mirror 8 is parallel to the longitudinal direction of the flexible transparent bottom 3, and Coincident with the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com