Patents

Literature

37results about How to "Stable production control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing silk protein composite cellulose fibers

ActiveCN102505170AHigh recycling valueLow viscosityArtificial filaments from viscoseProtein solutionSulfonate

The invention discloses a method for preparing silk protein composite cellulose fibers, which includes steps: firstly, adding degummed waste silk into LiBr solution, dissolving the waste silk to prepare silk protein solution in which silk protein accounts for 3-15%, by weight; secondly, adding the silk protein solution into sodium hydroxide solution with cellulose sulfonate to obtain blended solution of silk protein and cellulose, wherein blended silk protein solution accounts for 5-50% of that of the sodium hydroxide with cellulose sulfonate by weight; and thirdly, spinning the blended solution by coagulating bath and obtaining the silk protein composite cellulose fibers by post-processing. By the method, recovery value of the waste silk is improved greatly, special effects of whitening and skin caring of the silk protein composite cellulose fibers can be realized, and the fibers are smooth and soft to touch as silk, and have the skin caring and whitening effects that the effects of protein powder fibers or blended fibers of protein powder and cellulose solution cannot match.

Owner:赛得利(盐城)纤维有限公司

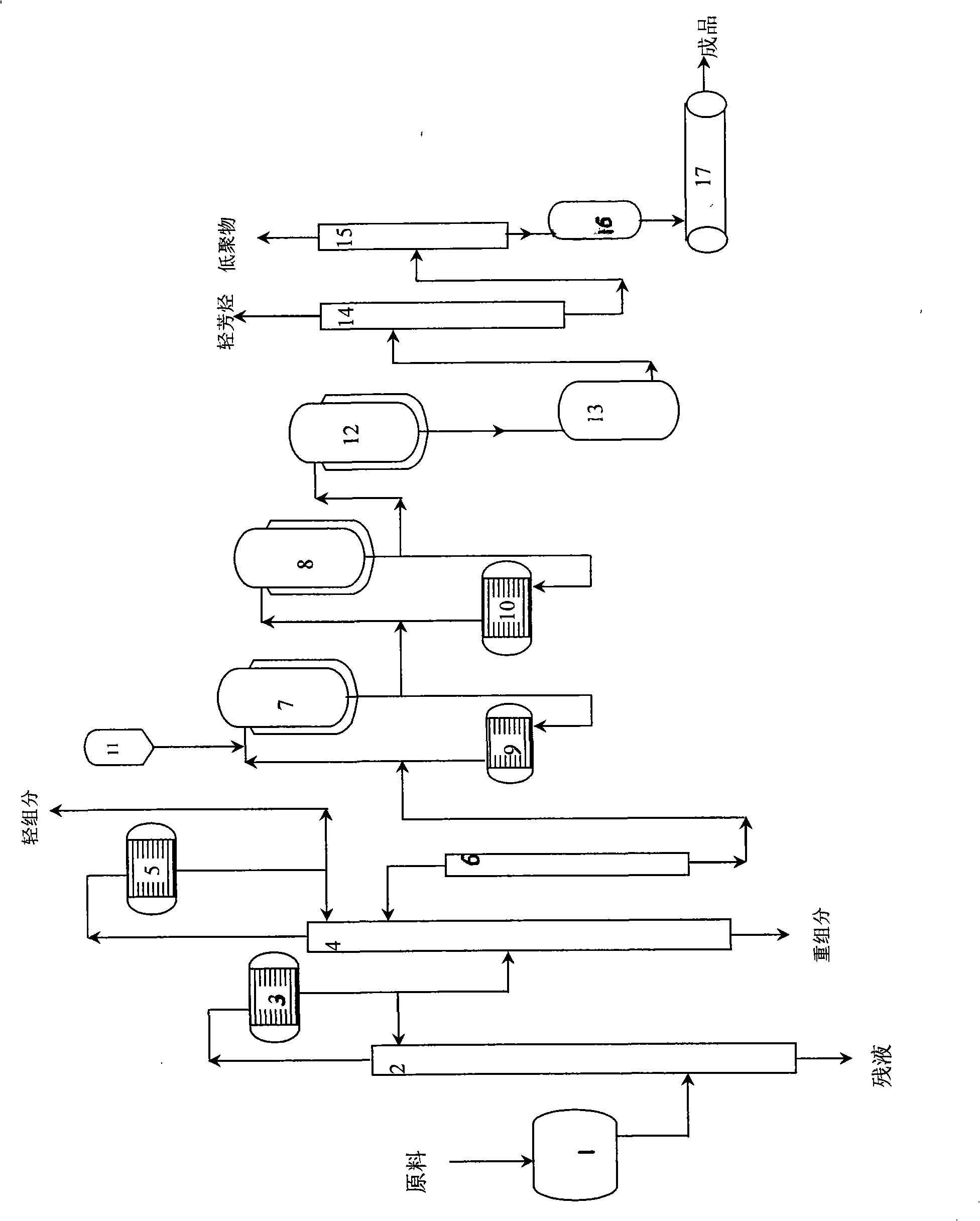

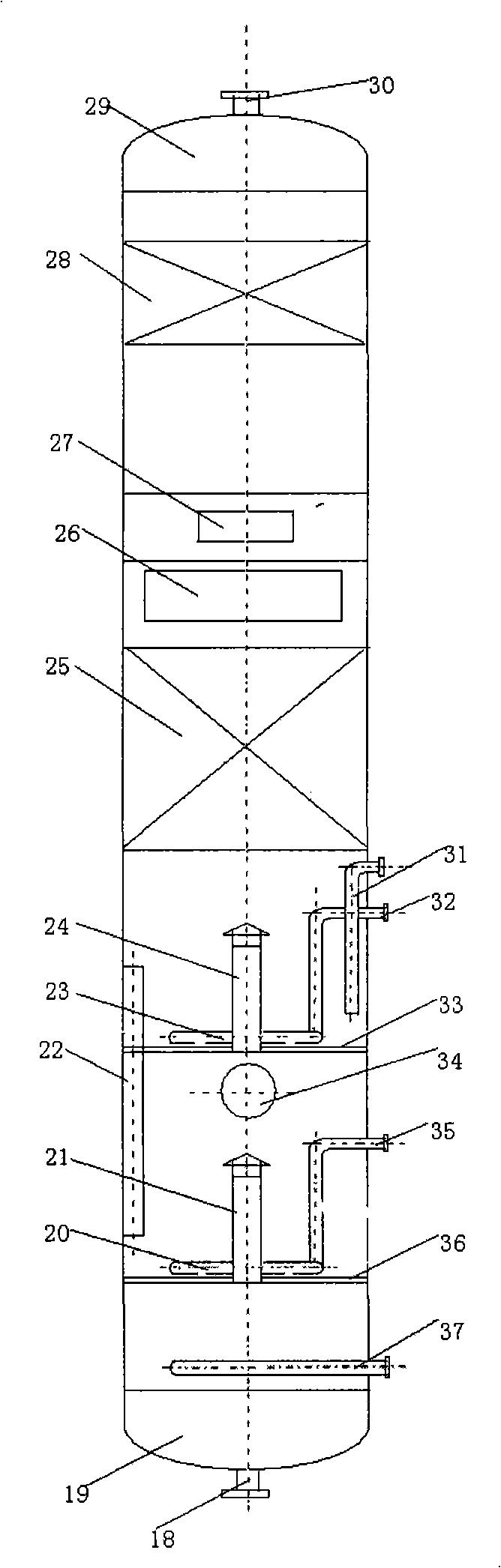

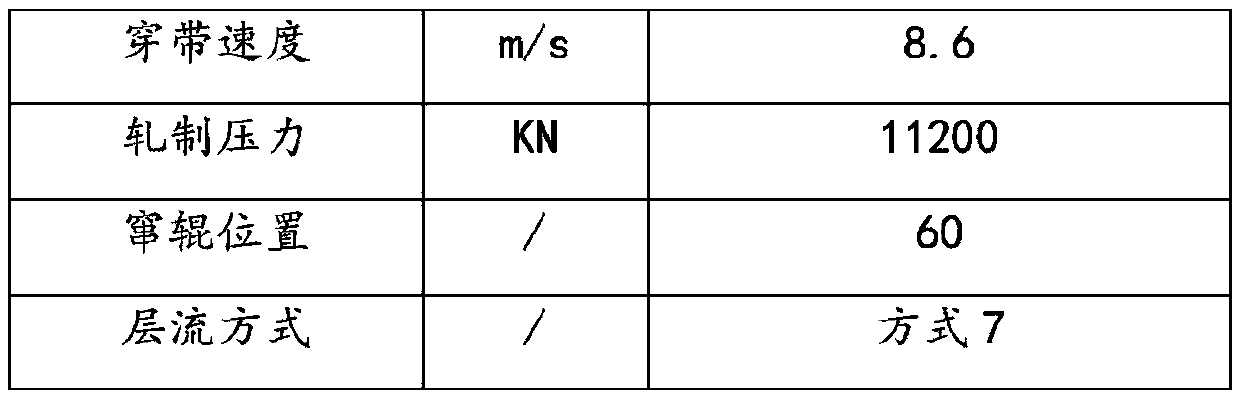

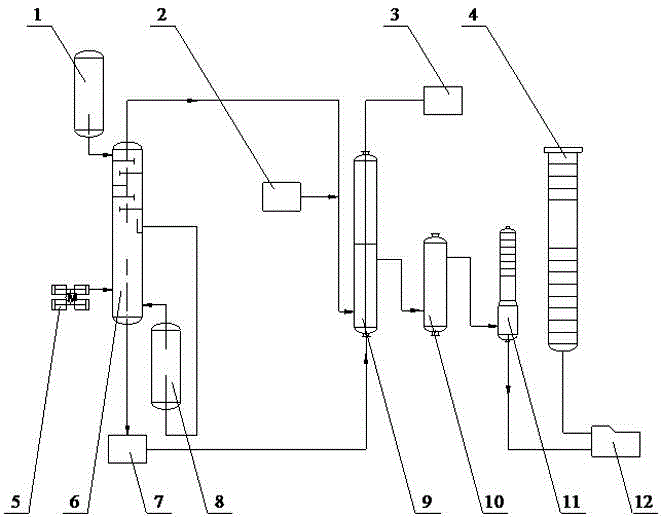

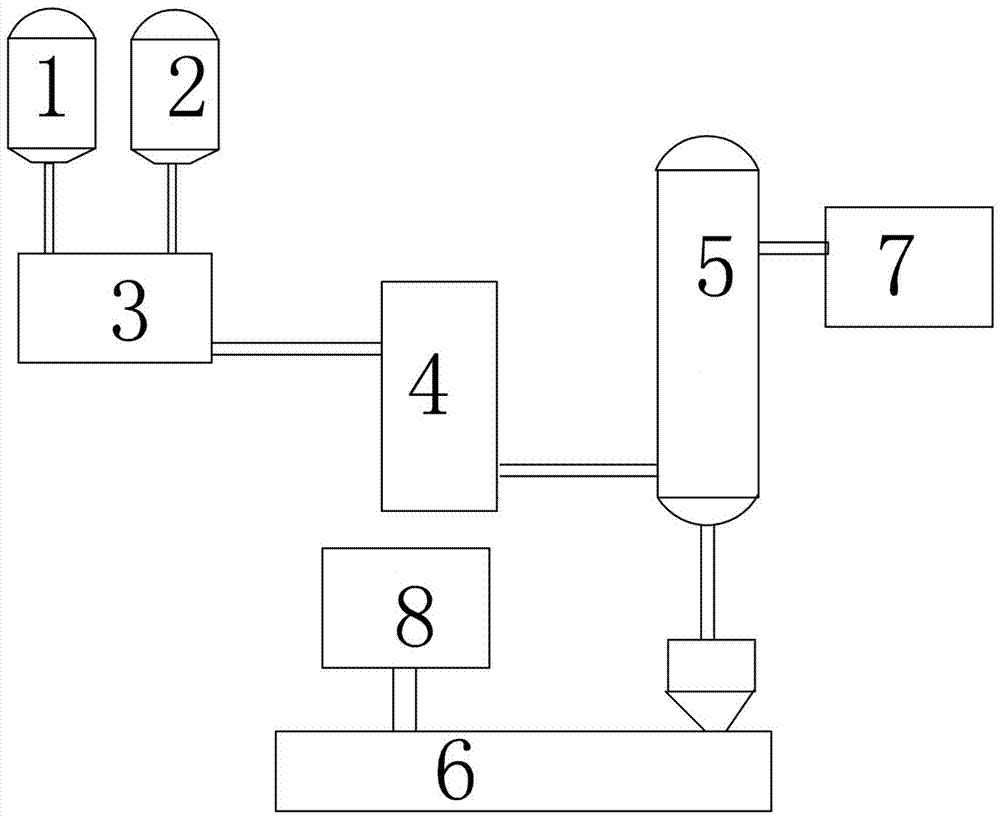

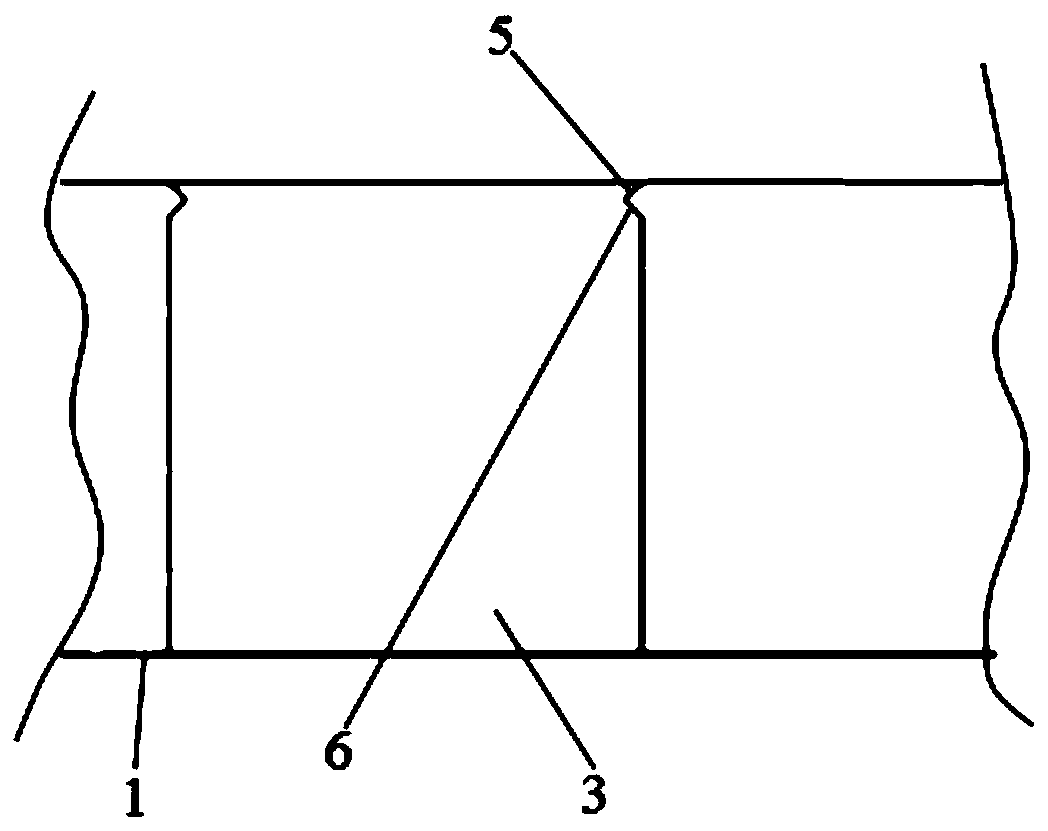

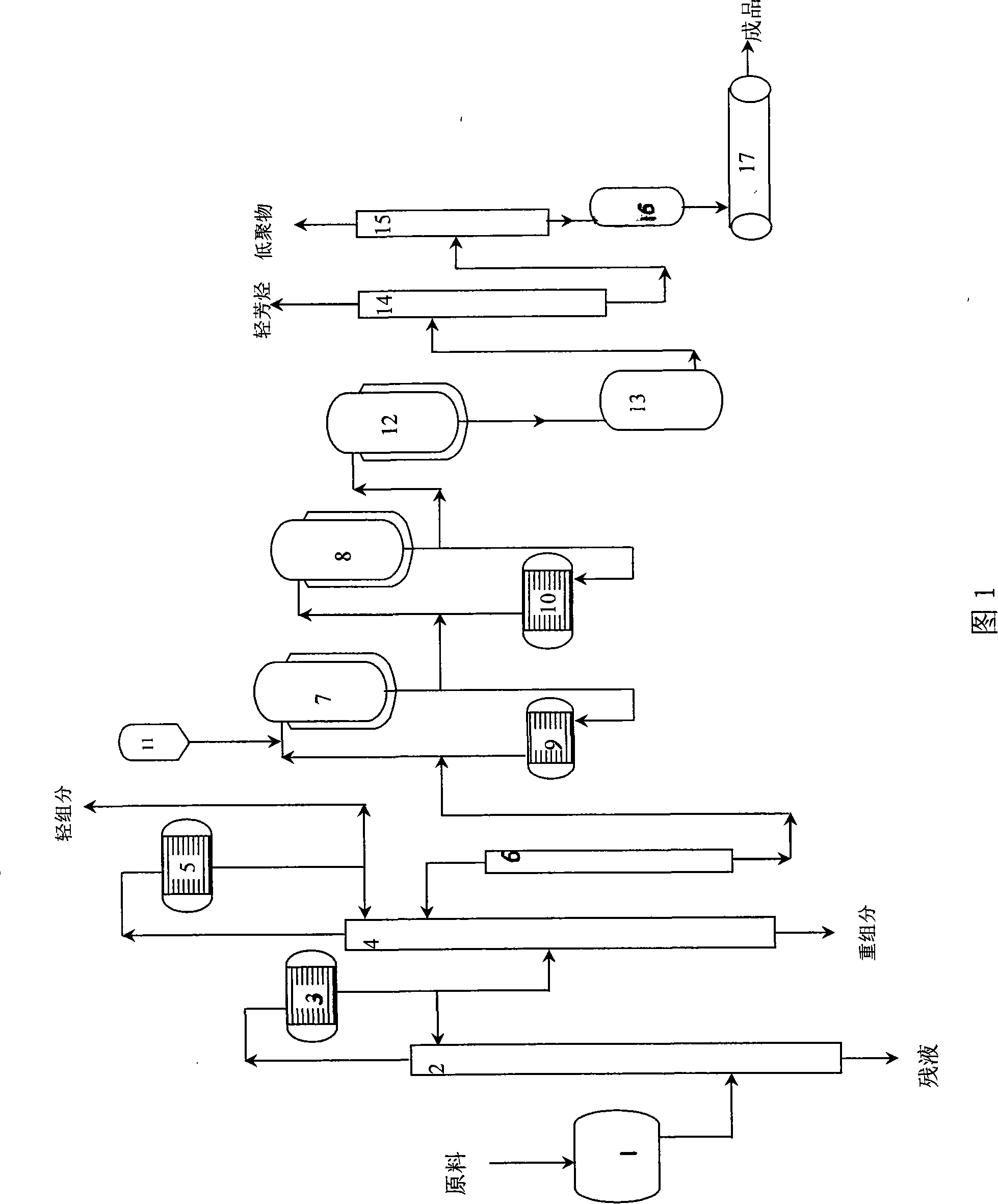

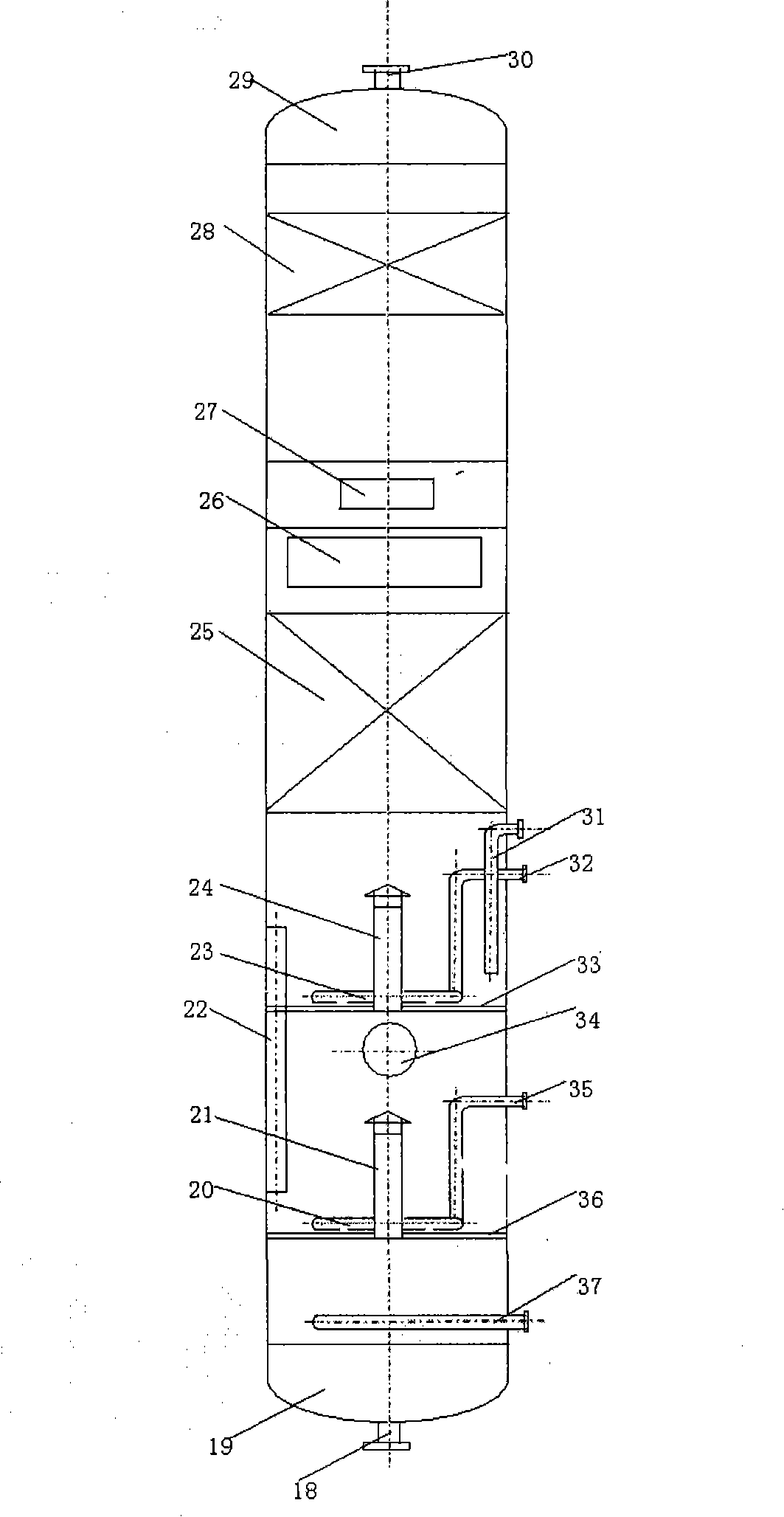

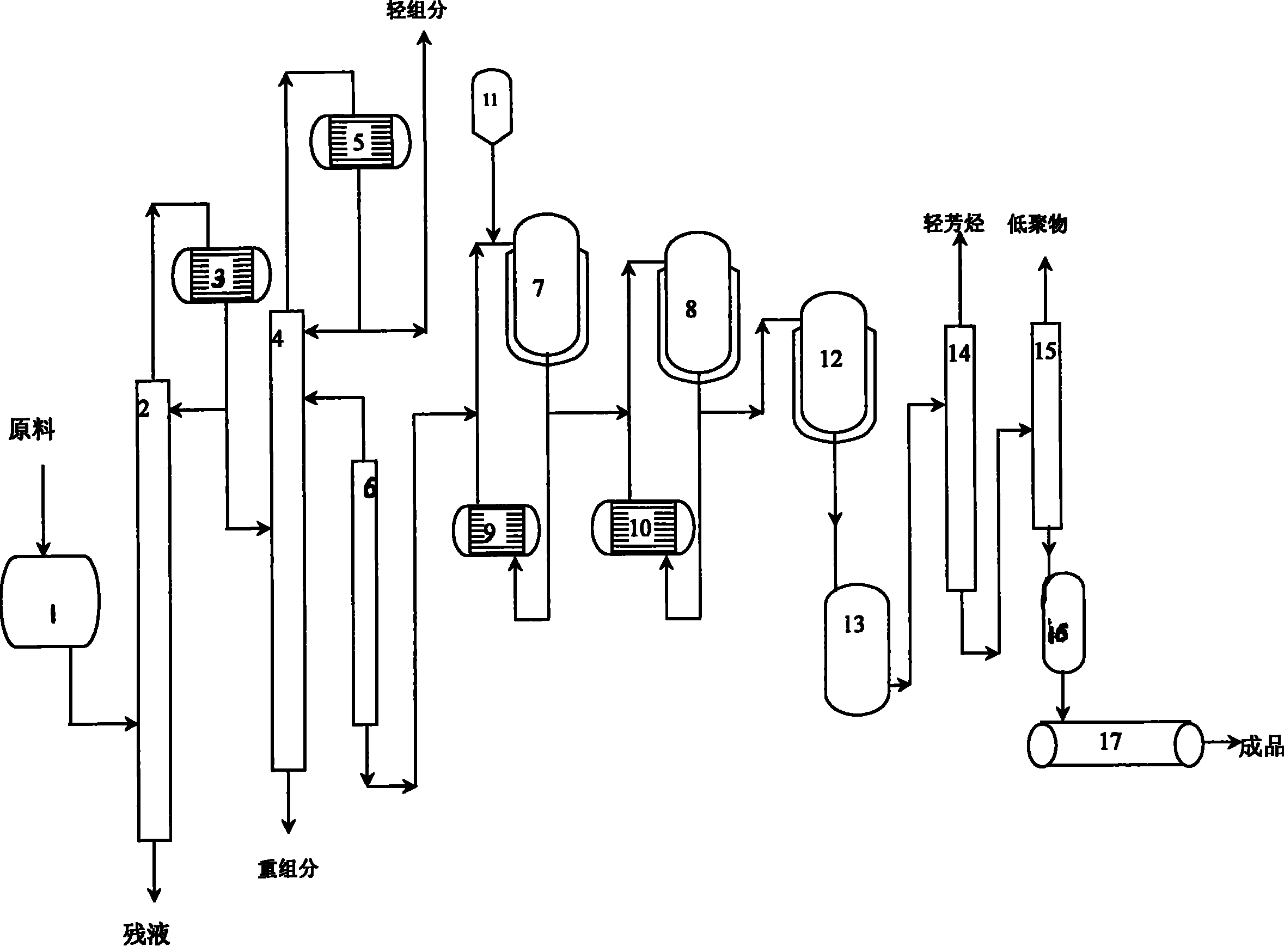

Process and equipment for continuous catalytic polymerization aggregation of C9 petroleum resin

The invention relates to a process and equipment for the continuous catalytic polymerization aggregation of C9 petroleum resin. The process adopts multi-tower refining for separating and refining C9 raw materials, and adopts a continuous catalytic polymerization technique and a solvent and low polymer stripping technique for realizing automatic continuous large-scale production, wherein a stripping tower used in the stripping technique comprises two major parts, namely a distilling section and a stripping section; the distilling section is provided with a plurality of layers of fillers for better separating gas and liquid components; and the stripping section adopts a multi-stage stripping device for stripping. The process and the equipment can overcome the drawbacks in the production process of the conventional process such as uneasy stable control, high energy consumption and unstable product quality. The C9 petroleum resin produced by the process and the equipment is improved in color phase and resin softening point.

Owner:DAQING HUAKE

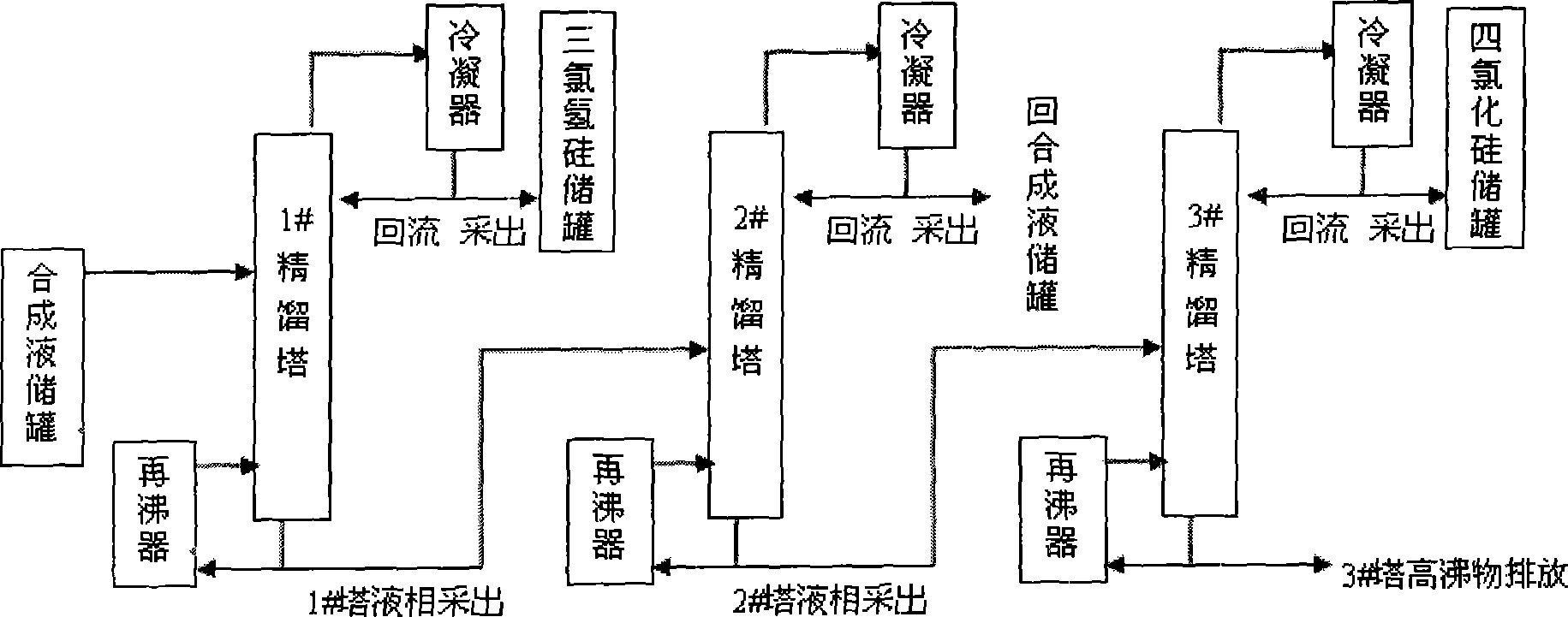

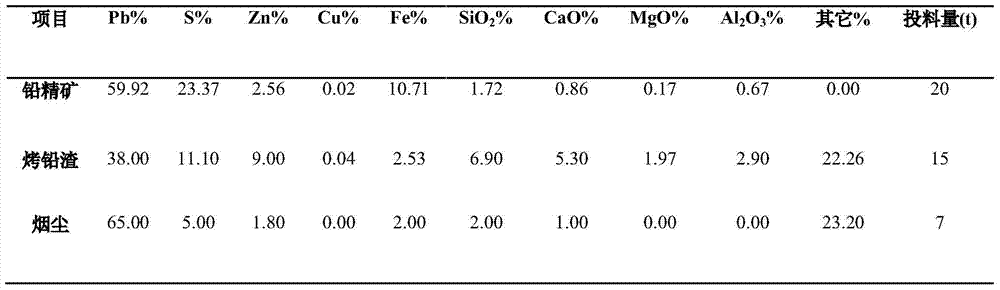

Process for purifying trichlorosilane and silicon tetrachloride

InactiveCN101519206AHigh purityHigh yieldHalogenated silanesFractional distillationContinuationGas phase

The invention discloses a process for purifying trichlorosilane and silicon tetrachloride. The process purifies the trichlorosilane and the silicon tetrachloride by means of three-tower continuous rectification and comprises: setting two towers as three-tower continuation; by adjusting process conditions, extracting high-purity trichlorosilane at the top of a rectifying tower 1 by gas phase, while extracting a silicon tetrachloride solution containing a small amount of the trichlorosilane by liquid phase, and feeding the solution into a rectifying tower 2; completing gas phase extraction of residual trichlorosilane and a small amount of the silicon tetrachloride at the top of the rectifying tower 2, and returning the extracts to a synthetic fluid intermediate tank after condensation; and feeding the silicon tetrachloride and high-boiling saline obtained through liquid phase extraction in the rectifying tower 2 into a rectifying tower 3; and carrying out purification on the silicon tetrachloride and the high-boiling saline by the rectifying tower 3 to obtain the high-purity silicon tetrachloride at the top of the tower. The process increases the product yield, the quality, the application and benefits, and realizes stable production control and greatly reduces labor intensity.

Owner:山东齐泉硅业有限公司

Mica treatment process for preparing lithium carbonate by utilizing lepidolite

ActiveCN106636615ALi2O content decreasedHigh recovery rateProcess efficiency improvementSlagEvaporation

The invention discloses a mica treatment process for preparing lithium carbonate by utilizing lepidolite. The process comprises the following steps: putting lepidolite and diluted sulfuric acid into a reaction kettle in a certain ratio at high temperature and normal pressure to react; adding the reacted slurry into a silica sand byproduct which is dried in workshop, and mixing the materials; drying and roasting the mixed powder in a kiln; directly adding water into the roasted material to perform a leaching reaction at a certain temperature; performing cooling crystallization, centrifugal separation, neutralized impurity removal, evaporation concentration and lithium depositing production processes on the leached slurry to prepare battery grade lithium carbonate and industrial lithium carbonate. The process has the advantages that gypsum byproduct in the process can be reduced by more than or equal to 35 percent in comparison with that in the prior art, the overall recovery of lithium carbonate is greatly increased, the quality of lithium carbonate is slightly improved in comparison with that of existing products, and each index can reach the national standard; and the problem of material attachment of a kiln can be solved after the acid leached slurry is added into and mixed with the workshop dried silica slag.

Owner:宜春银锂新能源有限责任公司

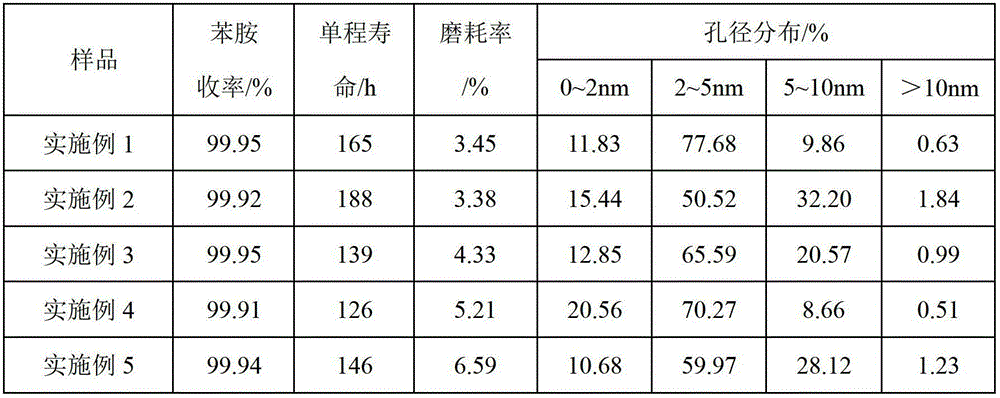

Nitrobenzene hydrogenation aniline preparation catalyst for fluidized bed

InactiveCN102744066AReduce churnReduce unit consumptionOrganic compound preparationAmino compound preparationFluidized bedNitrobenzene

The present invention belongs to the technical field of catalyst preparation, and provides a nitrobenzene hydrogenation aniline preparation catalyst for a fluidized bed. The catalyst provided by the present invention has the following characteristics that: composition is single, the catalyst only contains an active ingredient copper, introduction of a multi-element component to the catalyst is not required, and physicochemical properties of the catalyst are: an average specific surface area of ??350-500 m<2> / g, an average pore size of 2.5-4.0 nm, and an average pore volume of 0.55-0.85 ml / g. In addition, a mass content of the active ingredient copper in the catalyst is 10-25%; a mass percentage of the catalyst with particle size distribution of 125-600 mum is 80-98%, and a mass percentage of the catalyst with particle size distribution less than 125 mum is less than 2%; and the catalyst has characteristics of high activity, uneasy pore clogging, long service life, high selectivity, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

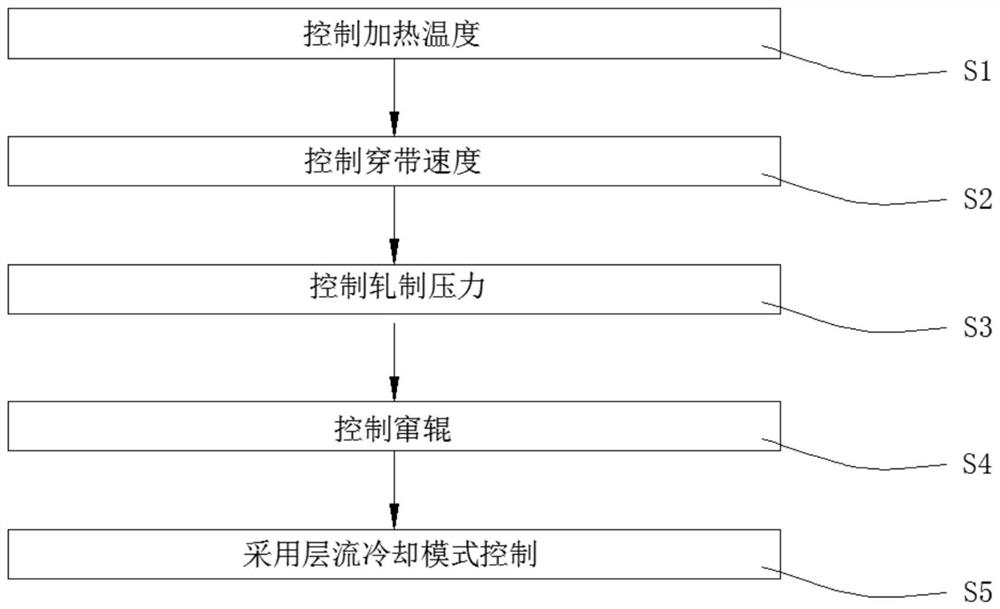

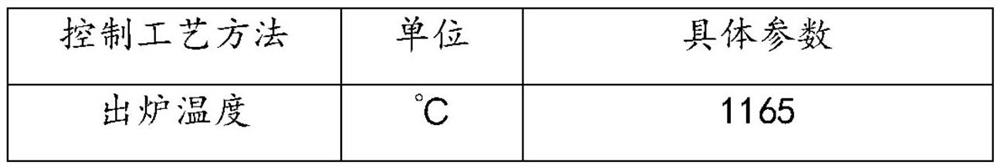

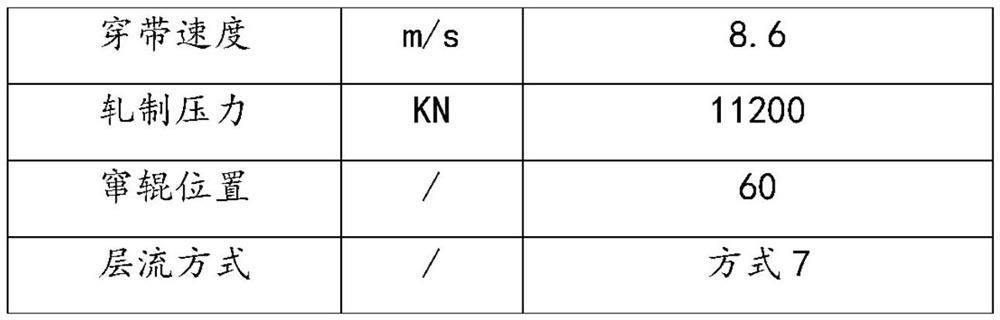

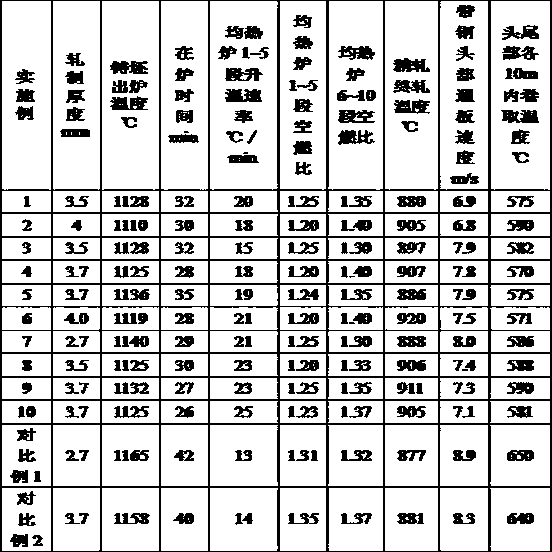

Method for producing thin-specification low-alloy high-strength diamond plate based on CSP process

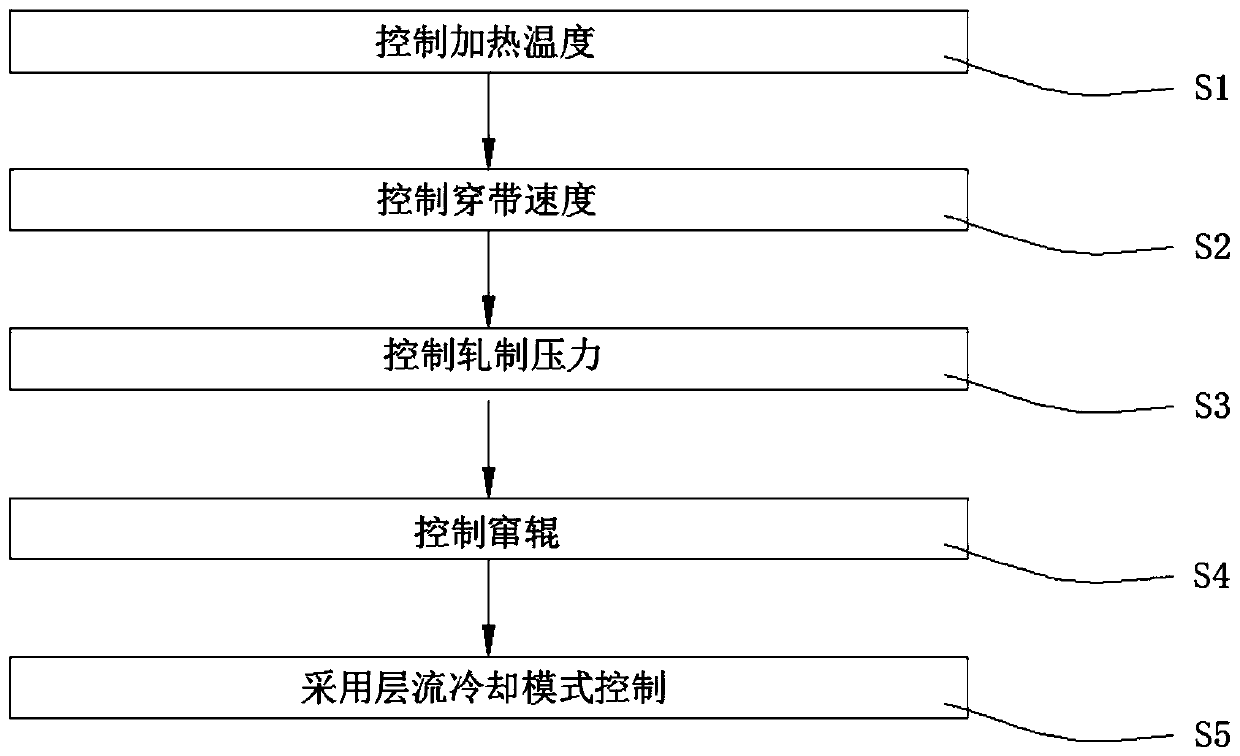

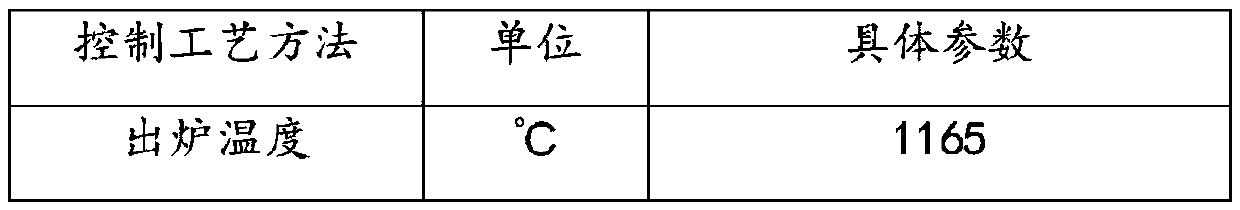

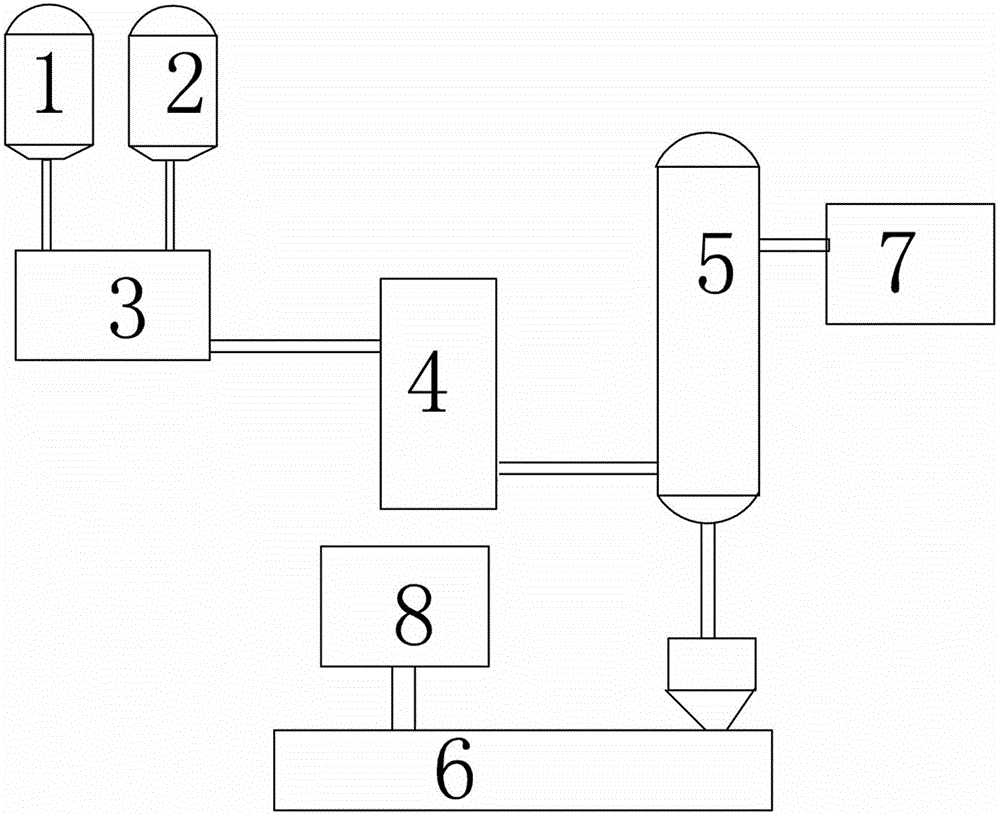

ActiveCN110639950ASolve batch stability productionStable production controlTemperature control deviceWork cooling devicesProduction lineTemperature control

The invention discloses a method for producing a thin-specification low-alloy high-strength diamond plate based on a CSP process. The method comprises the steps of 1, controlling heating temperature,specifically, the charging temperature and the tapping temperature are controlled; 2, controlling threading speeds, specifically, the different threading speeds are controlled according to different thicknesses of rolled finished products; 3, controlling rolling pressure, specifically, rolling force parameters are adjusted according to different thickness specifications; and 4, controlling roll shifting, specifically, after roll changing calibration is finished, circulating roll shifting from a zero point position with steps of 20 mm, 25 mm and 30 mm is started. According to the method, by controlling the heating temperature, the threading speeds, the rolling pressure, and the roll shifting and by adopting a laminar cooling mode for control, the pattern integrity and the plate shape of thelow-alloy high-strength diamond plate are ensured, the related standards and user requirements are met, the stable batch supply is formed, the production process is controlled stably, no production accidents such as scrap steel, and broken casting occur, and the stable batch production of the thin-specification low-alloy high-strength diamond plate produced by the CSP production line is realized.

Owner:武汉钢铁有限公司

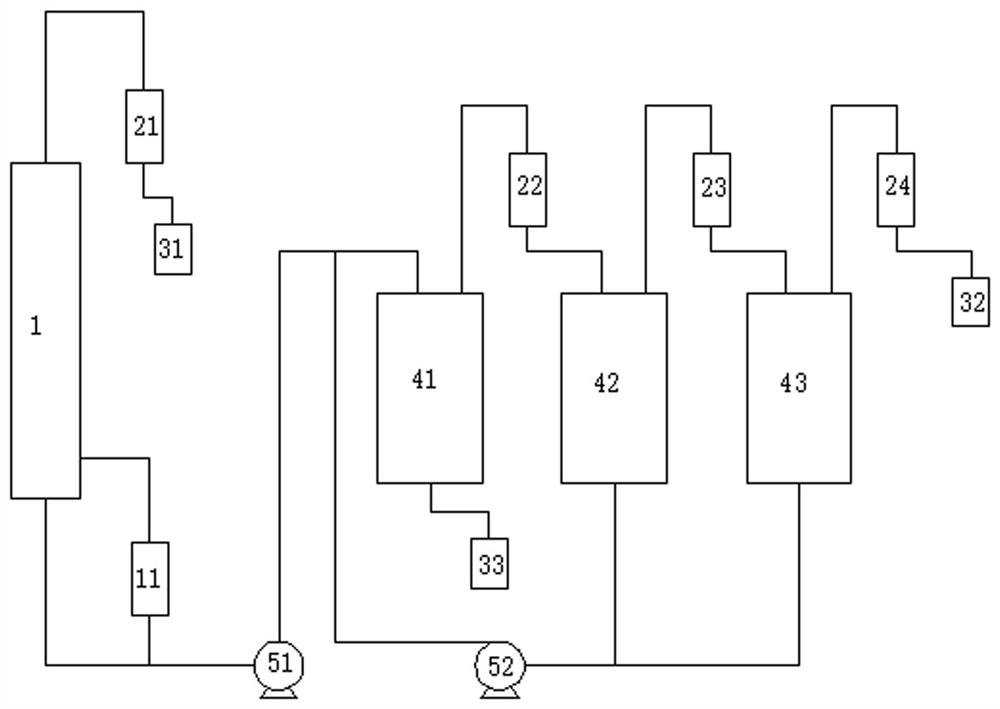

Production technique and device of high-water-soluble-phosphorus sulfur-base compound fertilizer

The invention discloses a production technique of a high-water-soluble-phosphorus sulfur-base compound fertilizer, which comprises the following steps: mixing 20-25 wt% dilute phosphoric acid with a mother solution in an industrial monoammonium phosphate device according to the mass ratio of (2-4):1, and adding 0.88 part of 98 wt% concentrated sulfuric acid and 1.0 part of potassium chloride to react for 4-6 hours; and neutralizing and granulating to obtain the sulfur-base compound fertilizer in which the water-soluble phosphorus content can reach 88% above. The invention also discloses a device for producing the high-water-soluble-phosphorus sulfur-base compound fertilizer by using the technique. The high-water-soluble-phosphorus sulfur-base compound fertilizer has the advantages of smooth appearance and uniform granules. The sulfur-base compound fertilizer device is easy to operate and steady in production control in the granulation process, and can maximally display the productivity.

Owner:HUBEI SANNING CHEM

Method for preparing silk protein composite cellulose fibers

ActiveCN102505170BHigh recycling valueLow viscosityArtificial filaments from viscoseProtein solutionSulfonate

Owner:赛得利(盐城)纤维有限公司

Device and technique for recovering melamine exhaust by using urea unit

ActiveCN104370775ASolve the use problemImprove Primary UtilizationUrea derivatives preparationProductsPulp and paper industryTower

The invention provides a device and technique for recovering melamine exhaust by using a urea unit, relating to the technical field of melamine exhaust recovery treatment. The device comprises an exhaust compressor and a urea unit with a primary decomposing tower, wherein the side wall of the primary decomposing tower corresponding to the bottom of the lower separating section is provided with an exhaust inlet; and the exhaust compressor is communicated with the primary decomposing tower through the exhaust inlet. The technique comprises the following steps: sending pressurized melamine exhaust to the primary decomposing tower, introducing a urea solution heated by a primary heater into the primary decomposing tower, injecting a urea solution in a preseparator into a pre-rectifying section, controlling the urea solution at the outlet of the primary heater at 155-160 DEG C, and cooling the gas-liquid mixture in a methylamine condenser to 90-100 DEG C. The device and technique can well utilize the heat of the melamine exhaust, are stable in the production process and convenient to control, and do not increase energy consumption generated by the urea unit.

Owner:HUAQIANG CHEM GRP

Preparation method of ethyl silicate

InactiveCN104250259AAchieve recyclingAvoid pollutionChlorine/hydrogen-chlorideSilicon organic compoundsSocial benefitsActivated carbon

The invention relates to a preparation method of ethyl silicate, and the preparation method comprises the following preparation process: (1) first, adding a weighed silicon tetrachloride crude product and an active metal catalyst into a reactor, and adding an ethanol solution into an elevated tank; (2) in a certain vacuum degree, gradually dripping the ethanol into the reactor, after the dripping, rapidly reacting, regulating the reaction speed through control of the amount of the dripped ethanol; after the ethanol is completely dripped, slowly heating the reactor for reflux, using water to absorb HC1 produced during the reaction to produce by-product hydrochloric acid, after about 0.5 to 1 hour of reflux, heating to evaporate out unreacted ethanol; and (3) at the end of the reaction, cooling to room temperature, decolorizing with activated carbon, distilling to remove the ethanol, and collecting 160-180 DEG C fractions. The method can effectively solve and use the silicon tetrachloride crude product, avoids environmental pollution, achieves cleaner production, reduces production cost, improves yield, and has significant economic and social benefits.

Owner:TAICANG GOLDEN ANCHOR CHEM CO LTD

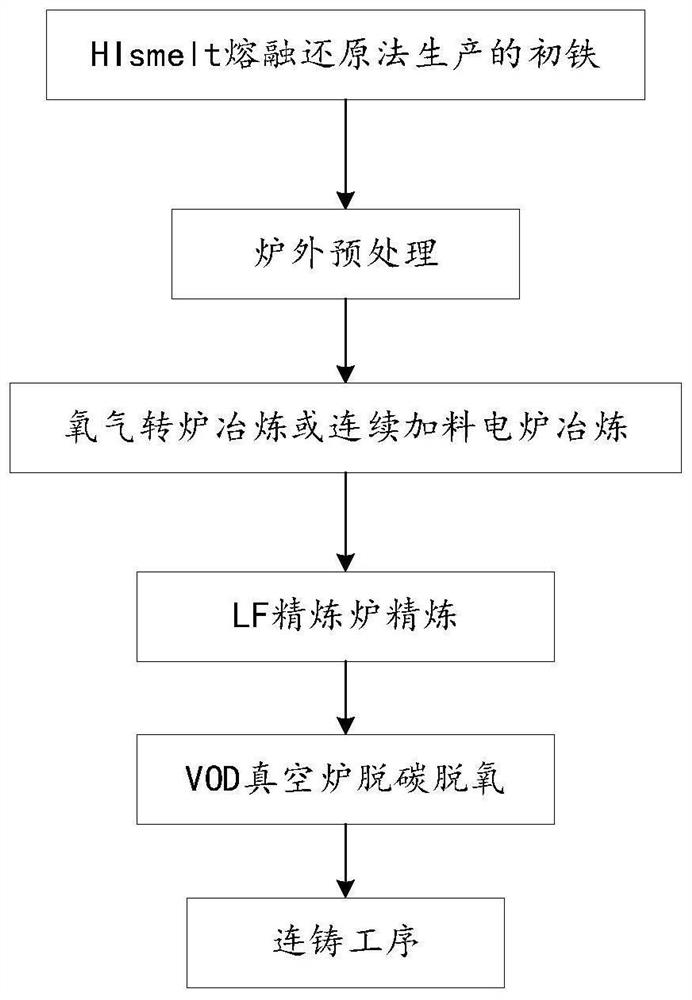

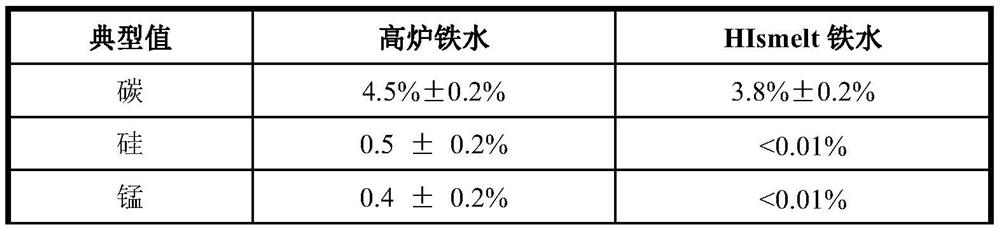

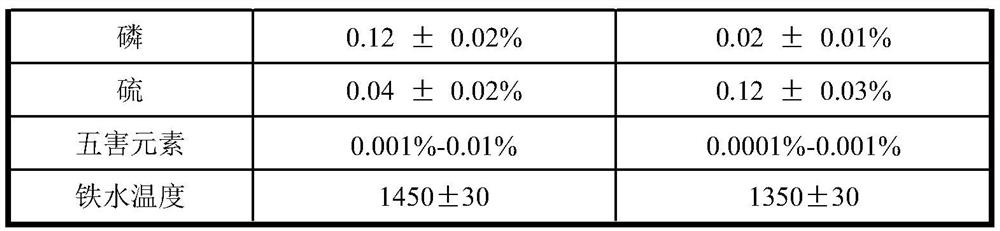

Pure iron production method through smelting reduction technique

ActiveCN111663015ARealize large-scale productionRealize industrialized and stable productionManufacturing convertersProcess efficiency improvementMetalIron content

The invention relates to the technical field of metal smelting, in particular to a pure iron production method through smelting reduction technique. The pure iron production method through smelting reduction technique comprises the process of preparing YT4 pure iron from initial iron, and raw materials are the initial iron produced through an iron bath smelting reduction method. According to products obtained through the method, the iron content can reach 99.95% or above, content requirements of the YT4 industrial pure iron and high-purity iron are met, scale production of the YT4 industrial pure iron can be achieved, the product purity is high, the production cost is low, safety and environment protection are achieved, the quality meets the requirements of the YT4 industrial pure iron andthe high-purity iron, control over the production process is stable, and the product quality is excellent.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

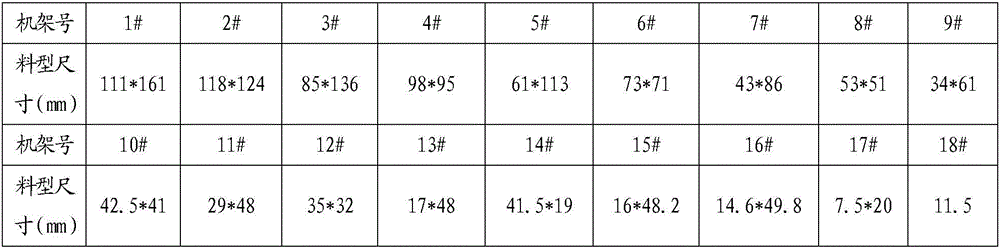

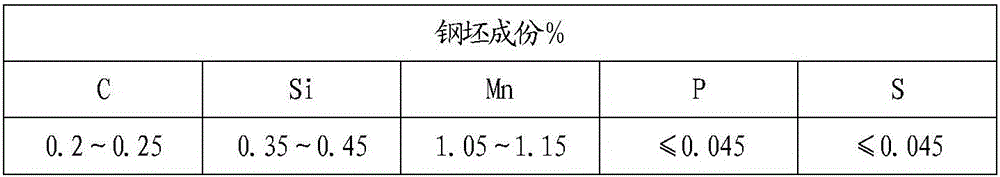

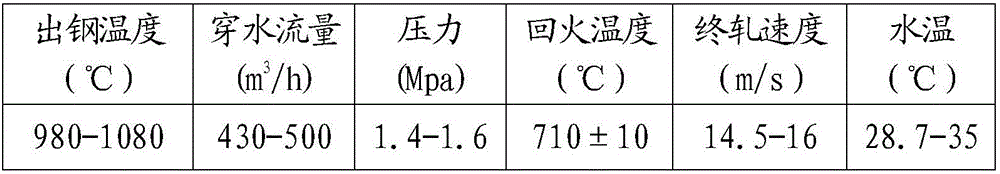

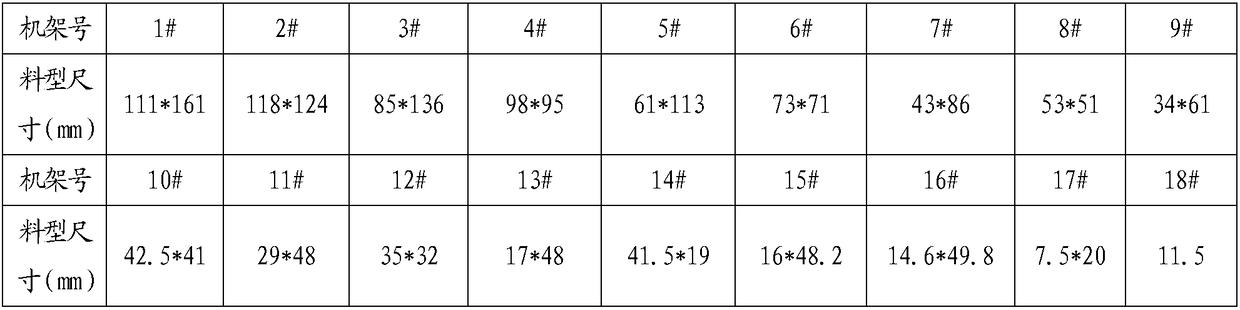

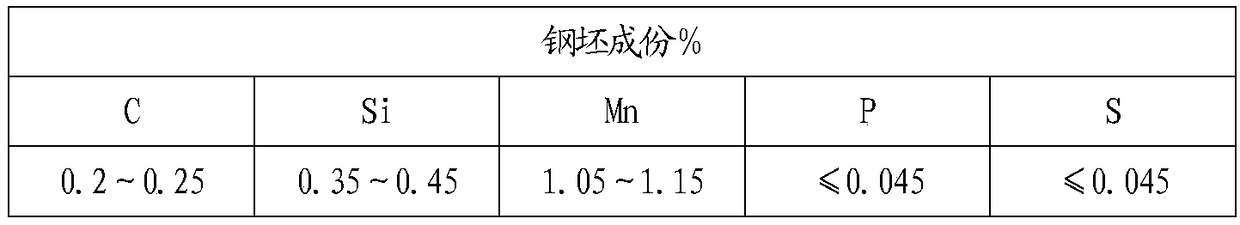

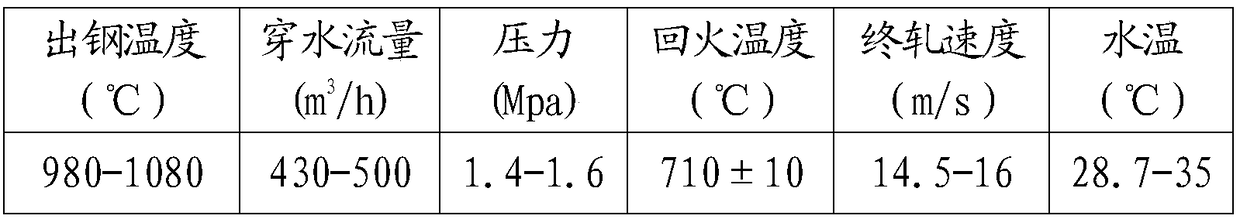

Three-strand splitting rolling method for rebars with diameter phi of 12 mm

ActiveCN106345805AHigh strengthImprove toughnessWork cooling devicesMetal rolling arrangementsStrip millDegrees of freedom

The invention discloses a three-strand splitting rolling method for rebars with the diameter phi of 12 mm. 18 rolling mills are involved in the method. The 18 rolling mills are divided into a roughing mill unit, an intermediate mill unit and a finishing mill unit, wherein the roughing mill unit includes 6 rolling mills, the intermediate mill unit includes 6 rolling mills, and the finishing mill unit includes 6 rolling mills. Billet steel is rolled by the 18 rolling mills in sequence, and the technological material shape and size of the 18 rolling mills are optimized and adjusted. The three-strand splitting rolling method for the rebars with the diameter phi of 12 mm solves the problems that split strips are seriously folded, the three-strand difference is unstable, and the degree of freedom of rolled pieces is controlled, the height, width and side wall slope of hole patterns are reasonably controlled, it is avoided that the rolled pieces deflect and collide with loop rolls or loop side walls when entering loops, and rolling rejects are generated, it is avoided that the rolled pieces get stuck at loop-rising roll gaps, the surface quality of finished products is improved, and the size of the finished products is stabilized.

Owner:YUNNAN DESHENG STEEL CO LTD

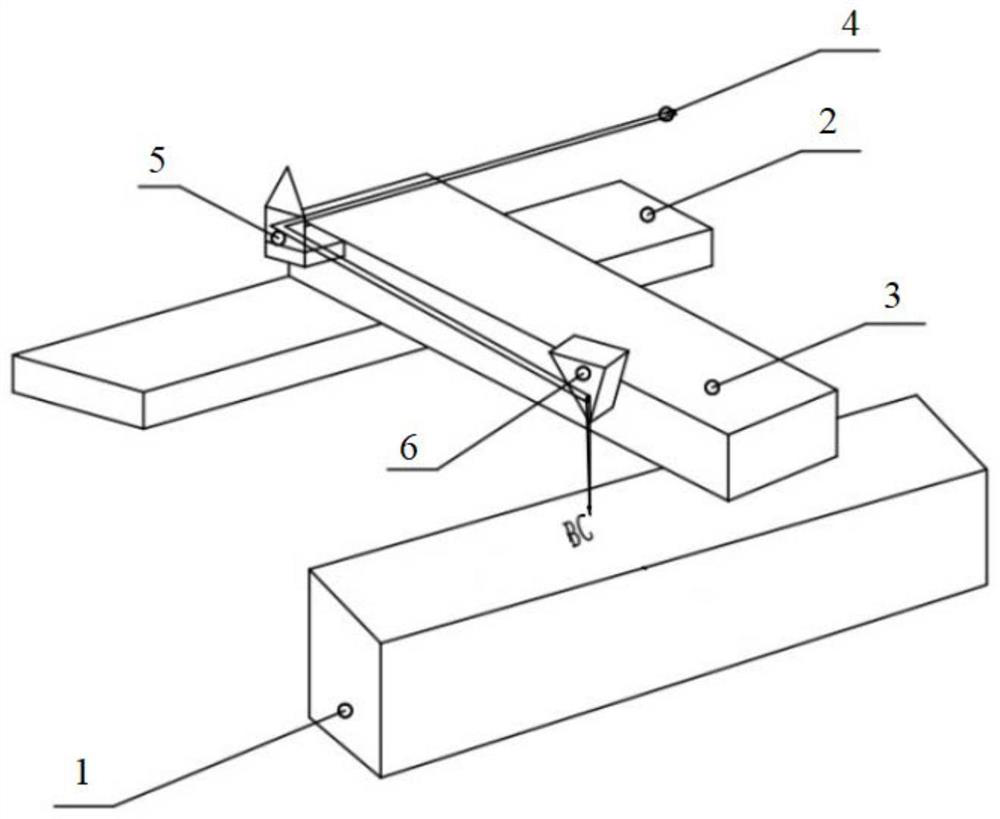

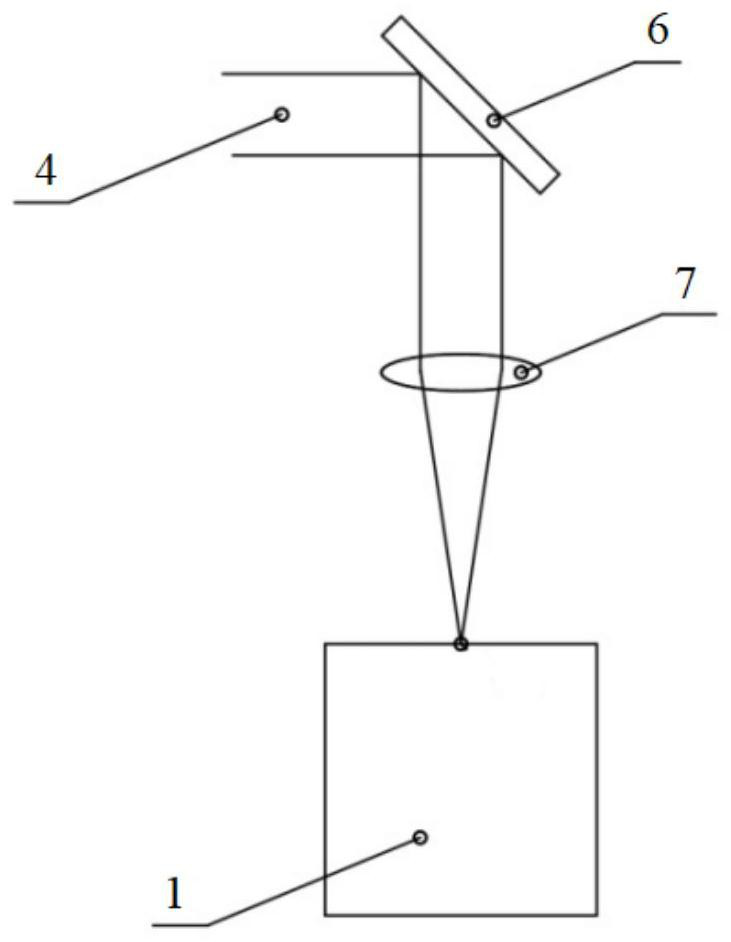

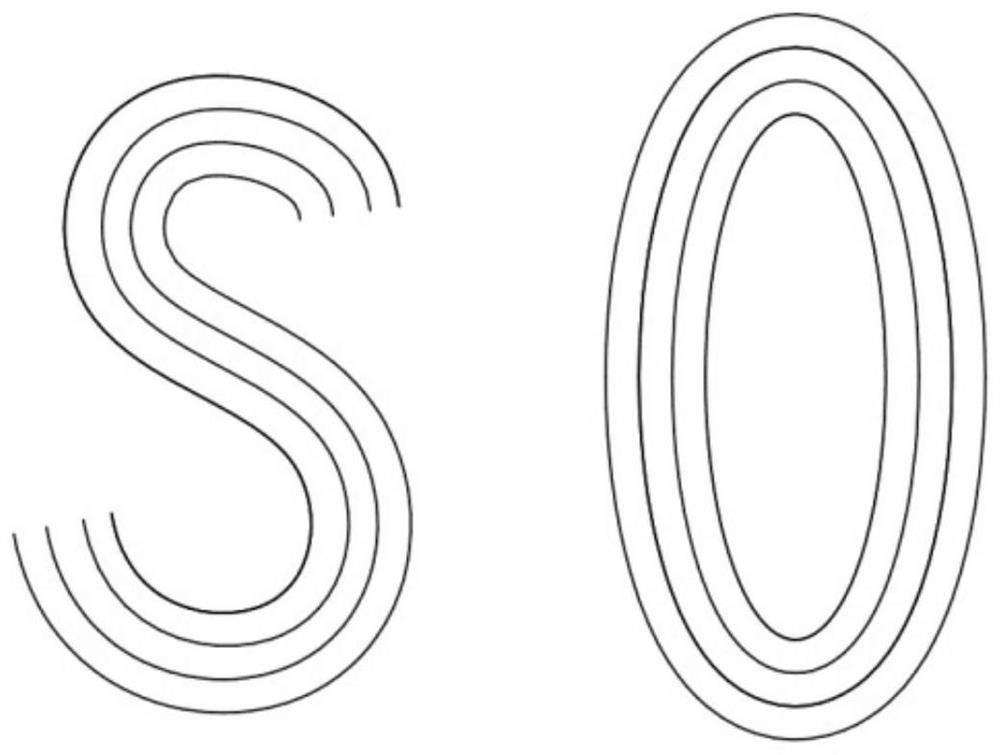

Online laser marking device and method for hot-rolled steel billet

PendingCN113385827AImprove cooling effectImprove sealingWelding/soldering/cutting articlesMetal working apparatusErbium lasersEngineering

The invention provides an online laser marking device and method for a hot-rolled steel billet, and relates to the field of steel production and laser marking. The device comprises a laser, a light guide mechanism, a focusing mechanism, a two-dimensional linear motion mechanism and a control unit, wherein the light guide mechanism is used for guiding the incident direction of laser beams, the focusing mechanism is used for focusing the laser beams into light spots and guiding the light spots to the surface of the steel billet to mark the surface of the steel billet, and the control unit is used for controlling the two-dimensional linear motion mechanism to move according to marking information. The method comprises the steps of mounting, cleaning, positioning, focusing, marking and the like. After the above device is mounted on a production line, an oxide layer on the surface of the steel billet is cleaned, the position and height of the steel billet are determined through a camera and the like, the focusing height of the steel billet is adjusted according to the height, the marking information formed by connecting a plurality of parallel lines or rotating light spots is marked on the surface of the steel billet by using the focused light spots, and air blowing and water cooling are carried out in the marking process, so as to meet the operation requirement in a high-temperature severe environment, and the stability and reliability of the device are ensured.

Owner:安阳睿恒数控机床股份有限公司

Maltol Grignard section intermediate purification method

InactiveCN112409304AIncrease productionQuality improvementOrganic chemistryChemical industryPurification methodsPhysical chemistry

The invention provides a maltol Grignard section intermediate purification method which comprises the following steps that an intermediate enters a rectifying tower according to the flow of 2 m < 3 > / h, the tower bottom temperature of the rectifying tower is 60 DEG C, and the tower top temperature of the rectifying tower is 40 DEG C; then the intermediate enters a primary flash kettle, wherein theextraction flow is 1.5 m < 3 > / h, the temperature of the first-stage flash evaporation kettle is 85 DEG C, the gas phase of the first-stage flash evaporation kettle is condensed and then enters a second-stage flash evaporation kettle, the temperature of the second-stage flash evaporation kettle is 65 DEG C, the gas phase of the second-stage flash evaporation kettle is condensed and then enters athird-stage flash evaporation kettle, and the temperature of the third-stage flash evaporation kettle is 60 DEG C, the condensed gas phase of the three-stage flash kettle is collected, and the flash kettle is distilled under reduced pressure, wherein the vacuum degree is -0.08 MPa; the materials in the second-stage flash evaporation kettle and the third-stage flash evaporation kettle are returnedto the first-stage flash evaporation kettle every 3 hours; and qualified furfuryl alcohol is extracted from the bottom of the first-stage flash evaporation kettle according to the flow of 0.5 m < 3 > / h. According to the method, the furfuryl alcohol content and yield can be improved, meanwhile, intermittent repeated operation is achieved, and the labor intensity of personnel is relieved.

Owner:ANHUI JINGHE IND

NMP lateral extraction method

PendingCN110885305AQuality improvementStable production controlOrganic chemistryProcess engineeringTower

An NMP lateral extraction method comprises the following steps: 1, neutralizing: neutralizing a raw material to adjust the pH value of the raw material to 9; 2, separating in a first rectifying tower:introducing the neutralized raw material into the first rectifying tower, and separating water, light components and impurities azeotropic with water from the raw material in the first rectifying tower; and 3, separating in a second rectifying tower: introducing the separated raw material obtained in the first rectifying tower into the second rectifying tower, arranging an extraction pipeline atone side of the second rectifying tower, connecting a condenser to one side of the extraction pipeline, arranging a reflux pipeline at the top of the second rectifying tower, separating the raw material by the second rectifying tower, performing total reflux through the top reflux pipeline, intermittently extracting water through the extraction pipeline at one side and the condenser, and obtainingan NMP product at the top of the second rectifying tower. The method has the advantages of realization of intermittent extraction of a small amount of water, and stable production control, allows theproduct quality to meet the NMP content of 99.8% or above, and reduces the water content of the recycled NMP to 100 ppm or below.

Owner:镇江新纳环保材料有限公司

High-formation, high-weather resistance, ultra-thin hot-rolled steel plate and its csp production process

Owner:武汉钢铁有限公司

A method for producing thin-gauge, low-alloy, high-strength checkered plates based on csp process

ActiveCN110639950BSolve batch stability productionStable production controlTemperature control deviceWork cooling devicesProduction lineTemperature control

The invention discloses a method for producing a thin-specification low-alloy high-strength diamond plate based on a CSP process. The method comprises the steps of 1, controlling heating temperature,specifically, the charging temperature and the tapping temperature are controlled; 2, controlling threading speeds, specifically, the different threading speeds are controlled according to different thicknesses of rolled finished products; 3, controlling rolling pressure, specifically, rolling force parameters are adjusted according to different thickness specifications; and 4, controlling roll shifting, specifically, after roll changing calibration is finished, circulating roll shifting from a zero point position with steps of 20 mm, 25 mm and 30 mm is started. According to the method, by controlling the heating temperature, the threading speeds, the rolling pressure, and the roll shifting and by adopting a laminar cooling mode for control, the pattern integrity and the plate shape of thelow-alloy high-strength diamond plate are ensured, the related standards and user requirements are met, the stable batch supply is formed, the production process is controlled stably, no production accidents such as scrap steel, and broken casting occur, and the stable batch production of the thin-specification low-alloy high-strength diamond plate produced by the CSP production line is realized.

Owner:武汉钢铁有限公司

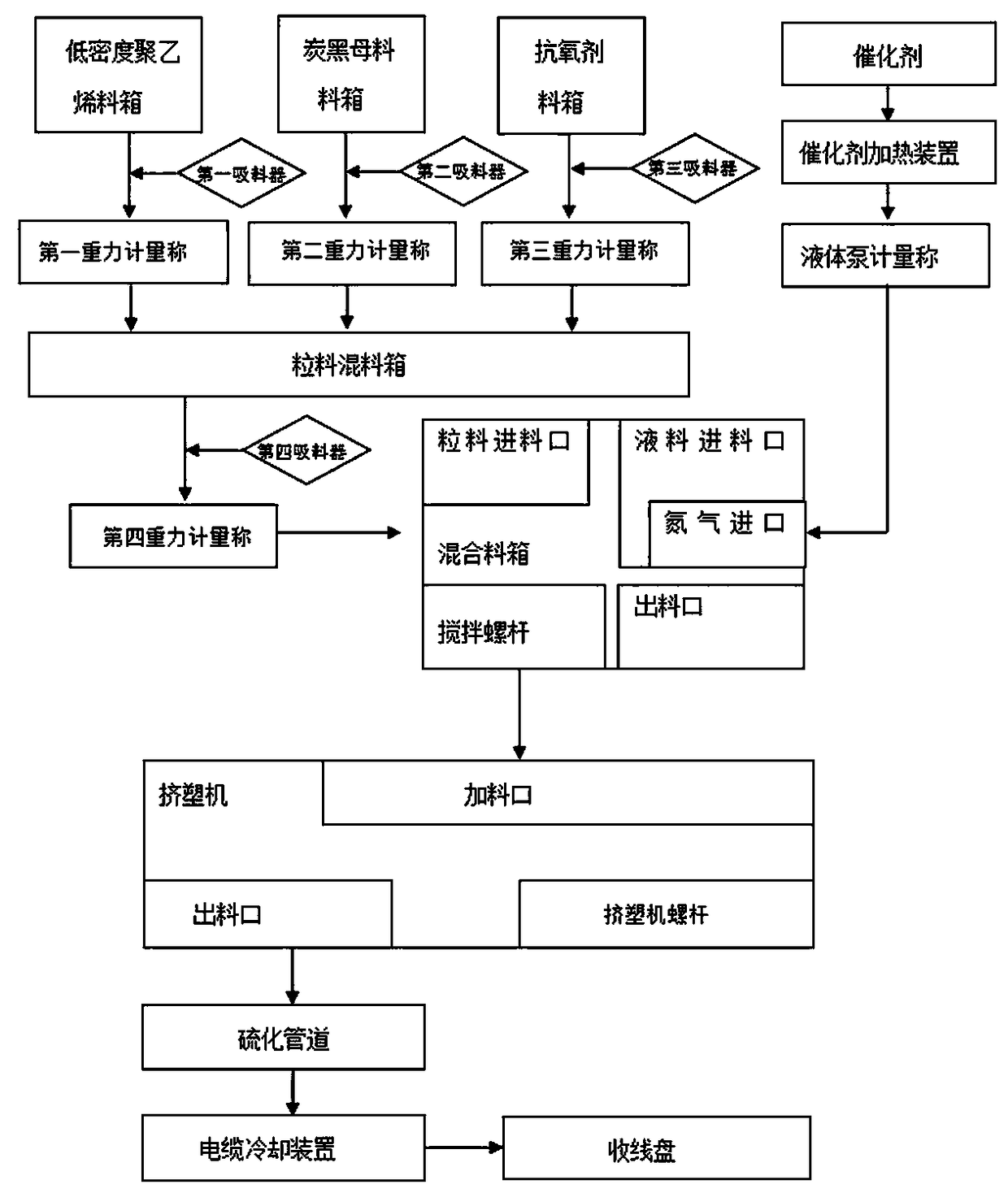

Corrosion-resistant wind-vibration-resistant medium-strength aluminum alloy conductor aerial insulation cable production device and working method thereof

InactiveCN109360694AImprove stabilityReduce manufacturing costPlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethyleneElectrical conductor

The invention relates to a corrosion-resistant wind-vibration-resistant medium-strength aluminum alloy conductor aerial insulation cable production device and a working method thereof. According to anextrusion technological process, linear low-density polyethylene, carbon black masterbatches and an antioxidant are stirred and mixed in a mixing box, and then are mixed with a DCP catalyst added with an accurate weighing system via a gravitational dropping material weighing system, the mixture enters a barrel above a charging area of an extruding machine, and all materials in the barrel enter anextruder screw and are mixed uniformly. An aerial insulation able uses a medium-strength aluminum alloy conductor, compared with a traditional hard aluminum conductor, the medium-strength aluminum alloy conductor has the characteristics of excellent corrosion resistance and wind vibration resistance; by a semiconductor resistance water tape, the corrosion prevention property of the cable can be improved further; and the various component materials are accurately weighed and uniformly mixed, then the mixture is directly added in a peroxide crosslinking extruder and then is extruded out, any secondary processing courses do not exist, the production process is stable, and the obtained cable not only has excellent insulation and weather resistant properties, but also has characteristics of corrosion resistance and wind vibration resistance.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +4

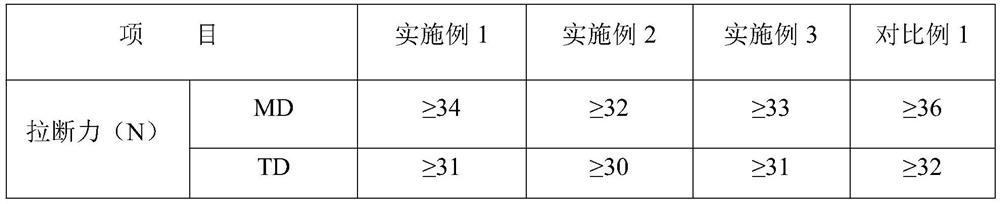

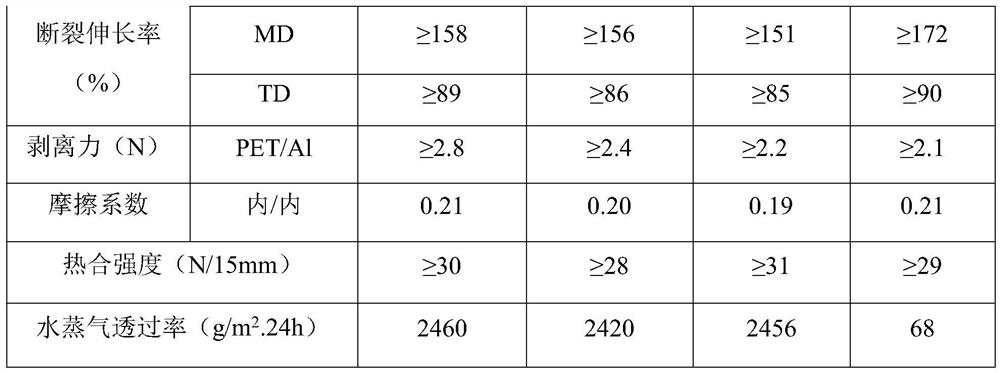

Paper-plastic composite packaging material with high air permeability and preparation method thereof

The invention provides a paper-plastic composite packaging material with high air permeability and a preparation method thereof. The preparation method comprises a film blowing production process, a hot needle micropore process and a hot laminating compounding process;a PE film material with high air permeability is obtained by optimizing a formula of a PE film and performing micropore treatment on the modified PE film; then a conventional adhesive dry compounding mode and a PE particle extrusion compounding mode are avoided, and paper-plastic packaging materials are compounded in a hot laminating manner, so micropores in a modified polyethylene PE film are prevented from being blocked by dry laminating or extrusion laminating; and finally, the PE film material with stable and excellent air permeability is obtained, shows excellent thermal stability, impact resistance, heat sealability and excellent low-temperature adhesive property, is applied to the fields of daily life article packaging, medicine, the clothing industry, electrical elements and the like, and meets the specific requirements of customer markets.

Owner:HUANGSHAN NOVEL

A three-slice rolling method of φ12mm steel bar

ActiveCN106345805BDimensionally stableAvoid getting stuckWork cooling devicesMetal rolling arrangementsStrip millDegrees of freedom

The invention discloses a three-strand splitting rolling method for rebars with the diameter phi of 12 mm. 18 rolling mills are involved in the method. The 18 rolling mills are divided into a roughing mill unit, an intermediate mill unit and a finishing mill unit, wherein the roughing mill unit includes 6 rolling mills, the intermediate mill unit includes 6 rolling mills, and the finishing mill unit includes 6 rolling mills. Billet steel is rolled by the 18 rolling mills in sequence, and the technological material shape and size of the 18 rolling mills are optimized and adjusted. The three-strand splitting rolling method for the rebars with the diameter phi of 12 mm solves the problems that split strips are seriously folded, the three-strand difference is unstable, and the degree of freedom of rolled pieces is controlled, the height, width and side wall slope of hole patterns are reasonably controlled, it is avoided that the rolled pieces deflect and collide with loop rolls or loop side walls when entering loops, and rolling rejects are generated, it is avoided that the rolled pieces get stuck at loop-rising roll gaps, the surface quality of finished products is improved, and the size of the finished products is stabilized.

Owner:YUNNAN DESHENG STEEL CO LTD

Production process and device of a high water-soluble phosphorus-sulfur-based compound fertilizer

ActiveCN104557224BRound appearanceUniform particle sizeFertilizer mixturesO-Phosphoric AcidPhosphate

The invention discloses a production technique of a high-water-soluble-phosphorus sulfur-base compound fertilizer, which comprises the following steps: mixing 20-25 wt% dilute phosphoric acid with a mother solution in an industrial monoammonium phosphate device according to the mass ratio of (2-4):1, and adding 0.88 part of 98 wt% concentrated sulfuric acid and 1.0 part of potassium chloride to react for 4-6 hours; and neutralizing and granulating to obtain the sulfur-base compound fertilizer in which the water-soluble phosphorus content can reach 88% above. The invention also discloses a device for producing the high-water-soluble-phosphorus sulfur-base compound fertilizer by using the technique. The high-water-soluble-phosphorus sulfur-base compound fertilizer has the advantages of smooth appearance and uniform granules. The sulfur-base compound fertilizer device is easy to operate and steady in production control in the granulation process, and can maximally display the productivity.

Owner:HUBEI SANNING CHEM

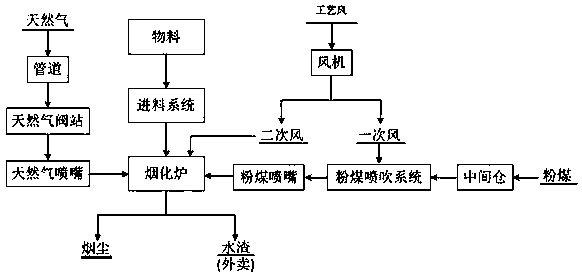

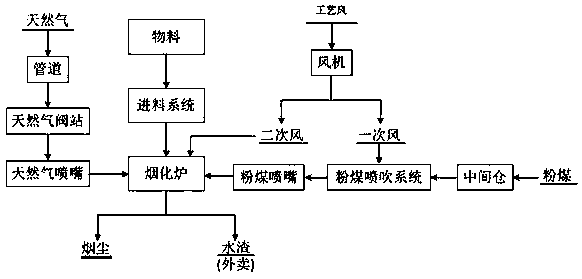

Reduction and volatilization smelting method of a composite fuel fuming furnace

ActiveCN107841625BFlexible operation and easy adjustmentHigh degree of automationProcess efficiency improvementSmelting processFuel supply

The invention relates to a composite fuel fuming furnace reduction and volatilization smelting method and belongs to the technical field of thermometallurgy. The method comprises the steps that pulverized coal and natural gas are adopted as a composite fuel of reduction and volatilization smelting of a fuming furnace, the natural gas is sprayed into the fuming furnace through natural gas spray nozzles, the pulverized coal and primary air are blended in a pulverized coal fuel supply system and then sprayed into the fuming furnace through pulverized coal spray nozzles; and in the reduction and volatilization smelting process, the pulverized coal spray amount and the natural gas spray amount are regulated according to the situation of cold and hot materials of the fuming furnace. By adoptingthe reduction and volatilization smelting method, the temperature rising speed is high, the fuming furnace is flexible to operate, regulation is easy and convenient, the automation degree is high, andthe problems that supply of the pulverized coal or the fuel gas is interrupted and consequentially slag discharging of the fuming furnace is difficult can be effectively prevented; clean and long-period continuous production and operation can be achieved, reduction and volatilization reaction of the fuming furnace is more thorough, and matching with an upstream and downstream operation system isfacilitated; and the production efficiency is high, production control is stable, and stable and refined production control can be achieved easily.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Ethyl polysilicate synthesizing process

The present invention relates to an ethyl polysilicate synthesizing process comprising the following steps: firstly quantitative byproduct silicon tetrachloride and active metal powder are added into a kettle, alcohol is slowly dropwise added at certain negative pressure to be mixed and react, warming and refluxing are carried out after adding is finished for complete reaction, and HCL produced during reaction is absorbed by water; reaction liquid is heated for distillation after reaction is completed, unreacted alcohol is expelled, then residual liquid at the bottom of the kettle is cooled and added with active carbon for decolouration filtering, and the filtrate is the ethyl silicate. Product purity and yield of the ethyl silicate obtained by adopting the process for production can meet market requirements, production control is extremely stable, not only production cost is reduced while improving revenue, but also environmental pollution is avoided, thereby having significant economic benefit and social benefit.

Owner:淄博市临淄齐泉工贸有限公司

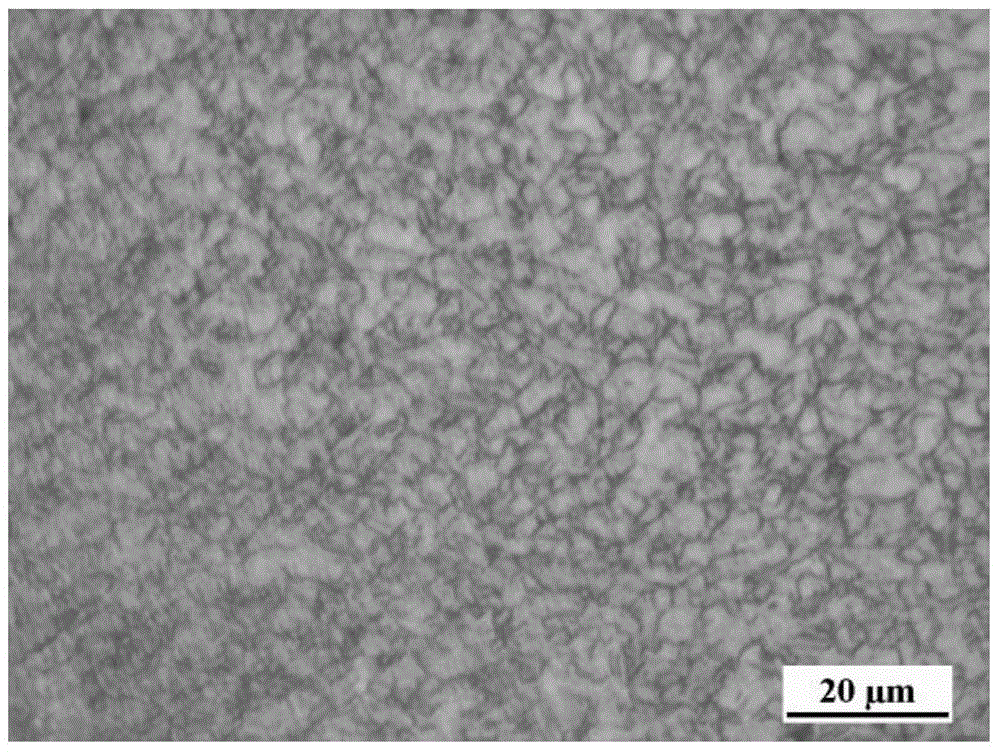

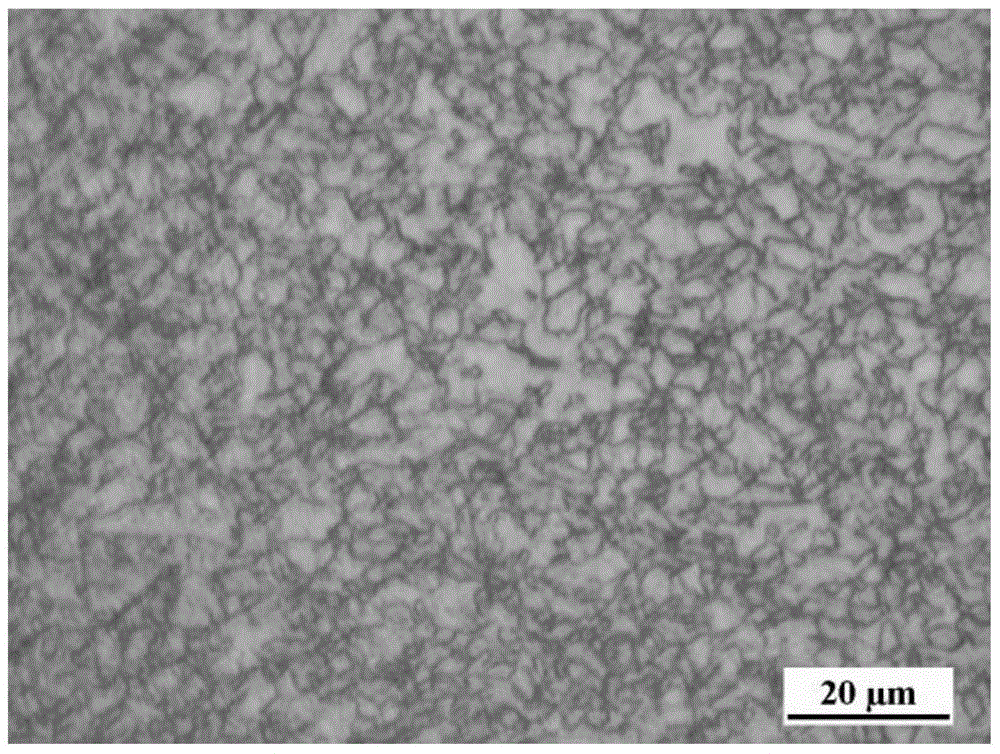

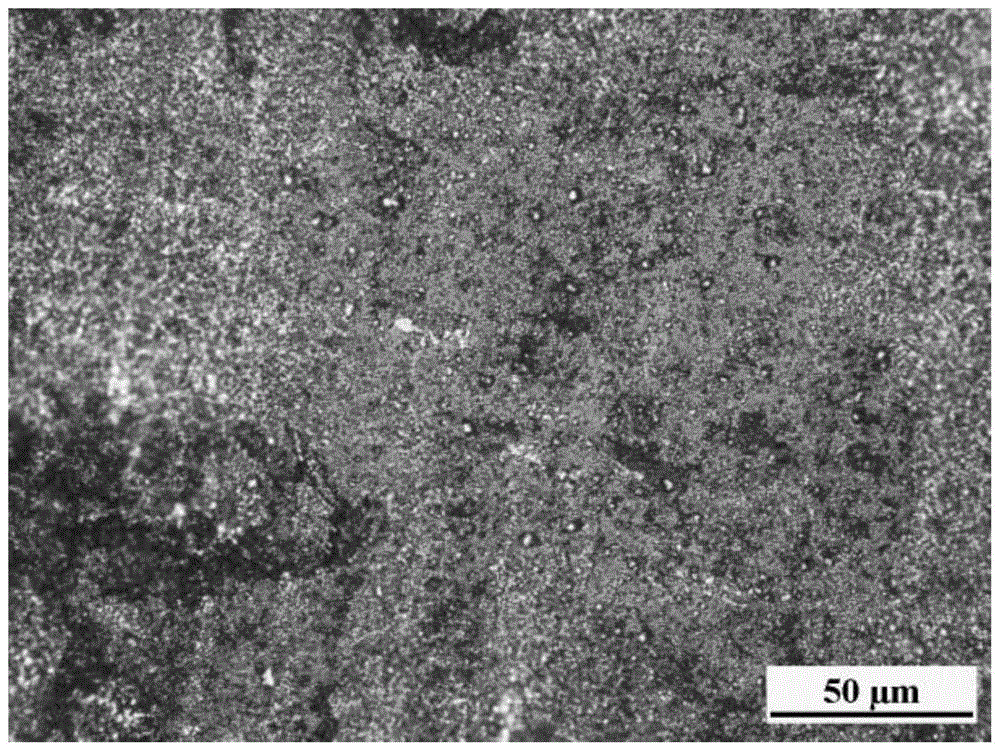

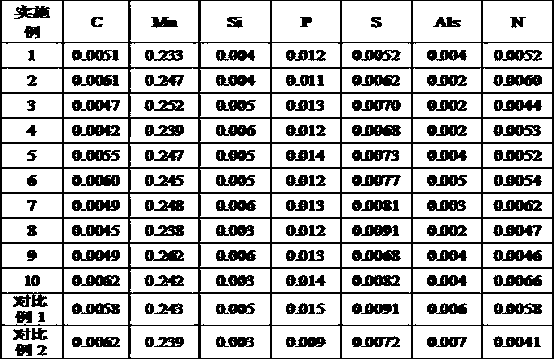

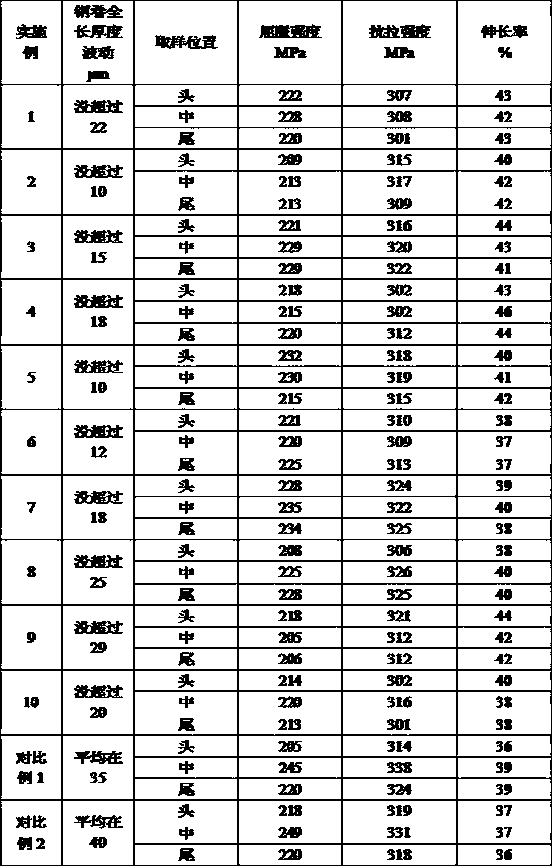

A kind of fin steel with excellent surface quality and its csp production process

ActiveCN107245656BEasy picklingSolve the problem of roller printing defectsLaminar coolingHigh pressure water

Fin steel excellent in surface quality comprises no more than 0.01wt% of C, 0.18-0.30wt% of Mn, 0-0.02wt% of Si, no more than 0.005wt% of Als, 0-0.03wt% of P, 0-0.01wt% of S, and 0.002-0.007wt% of N. A technology of the fin steel comprises the steps that converter smelting is conducted; LF refining is conducted; a casting blank enters a soaking furnace for soaking; scale is removed with high-pressure water; before rolling of machine frames, roll gap cooling water is started, then, a seven-machine-frame unit is adopted for finish rolling; laminar cooling is conducted; and reeling is conducted. According to the fin steel excellent in surface quality and the technology, the defects that fin steel has too much scale, and roll marks occur due to the fact that the head and the tail of belt steel impact a reeling and clamping roll in the tension lost state are overcome, the advantages of the short technological process are sufficiently achieved, the thickness precision of a whole produced steel reel fluctuates within 30 [mu]m, and the strength of the whole steel reel in the length direction fluctuates within 20 Mpa.

Owner:武汉钢铁有限公司

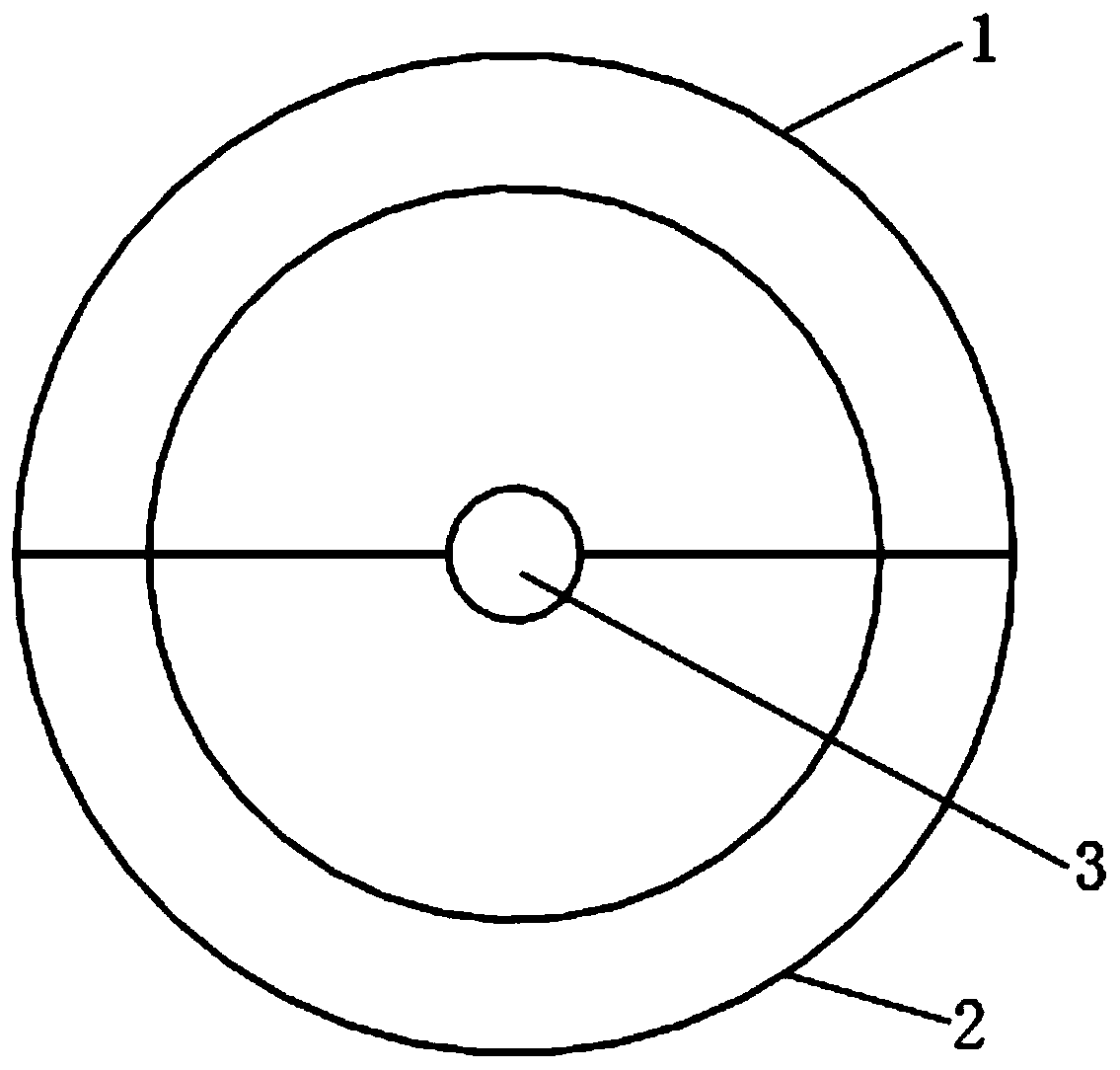

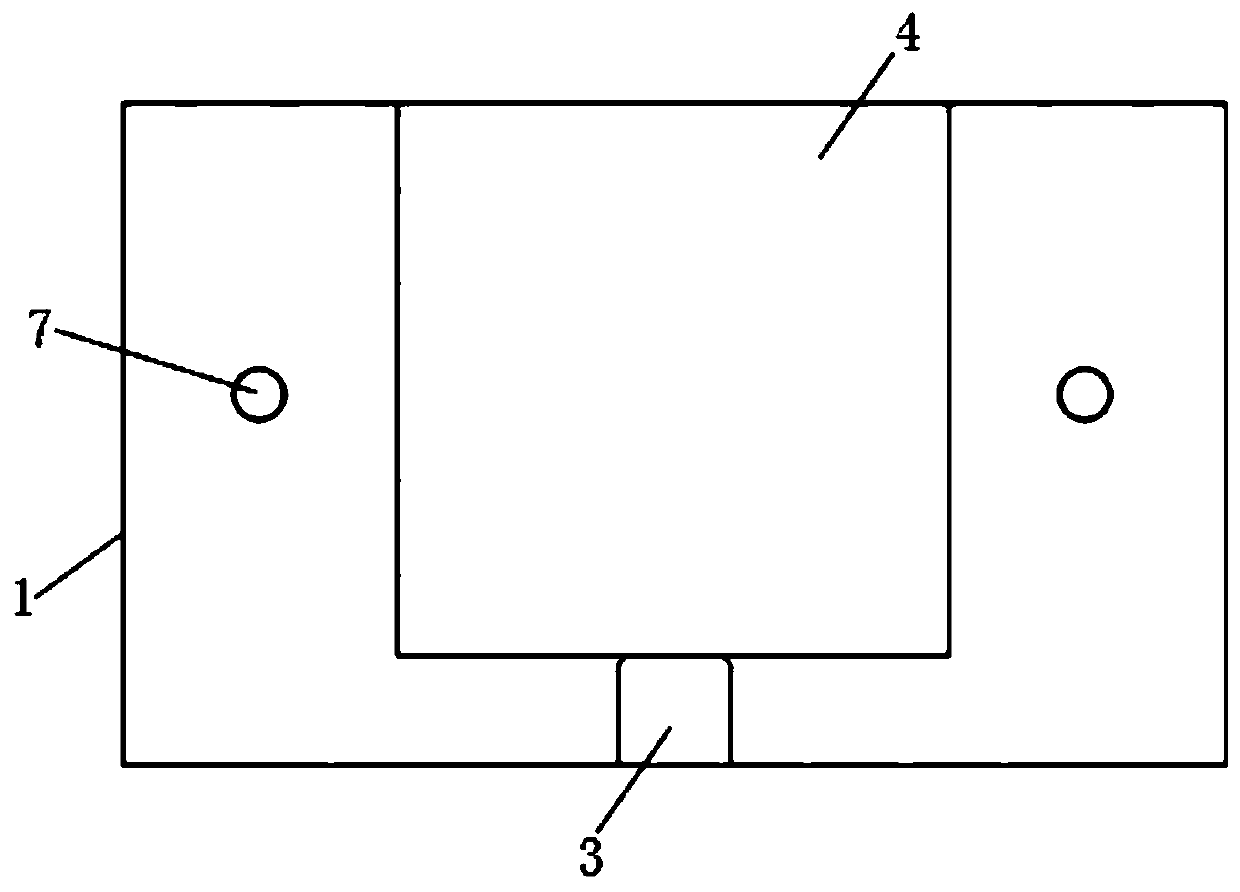

Sample preparation method capable of realizing quick detection of nitrogen composition

InactiveCN110196180AFast preparationRapid Nitrogen CompositionPreparing sample for investigationNitrogenChemistry

The invention discloses a sample preparation method capable of realizing quick detection of nitrogen composition and relates to preparation methods of nitrogen detection samples. Through the sample preparation method, the problems that currently, detection time is long, and a before-furnace rapid production requirement cannot be met are solved. The sample preparation method comprises the steps that after molten iron is smelted, iron liquid is poured into a nitrogen detection mold; after the iron liquid is solidified, the sample is taken out and cooled to normal temperature, and the tail of thesample is knocked off; and an oxide layer on the tail of the sample is removed, and the tail is air-dried. The mold comprises a first mold part and a second mold part which are detachably connected,wherein the first mold part and the second mold part define a sample preparation cavity, one end of the sample preparation cavity is provided with a pouring cavity, the sample preparation cavity is communicated with the pouring cavity, the sample preparation cavity and the pouring cavity are both cylindrical cavities, and the pouring cavity is larger than the sample preparation cavity. When the nitrogen detection sample is prepared through the method, the molten iron is directly taken to be poured to form the nitrogen detection sample, it is not needed to form another sample through pouring and then process the sample into the nitrogen detection sample, the sample can be quickly prepared and used for detection, before-furnace rapid detection of the nitrogen composition is realized, and production control is stabilized.

Owner:GUANGXI YUCHAI MASCH CO LTD

A special admixture for self-compacting concrete for pouring in closed spaces

ActiveCN106587711BSolve the phenomenon of no strength foam layerEliminate Bubble ProblemsSuperplasticizerMaterials science

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

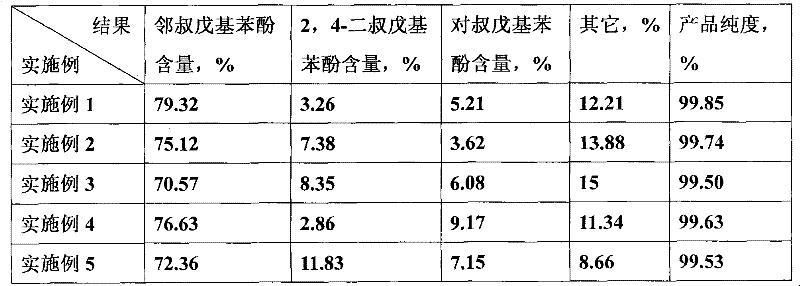

O-tert-pentylphenol production process

ActiveCN101628854BHigh activityHigh selectivityOrganic chemistryOrganic compound preparationAlkyl transferReaction temperature

Owner:ZIBO KEWEI CHEM

Process and equipment for continuous catalytic polymerization aggregation of C9 petroleum resin

ActiveCN101538349BReduce unit consumptionHigh yieldDispersed particle separationOligomerPetroleum resin

Owner:DAQING HUAKE

A device and process for recovering melamine tail gas using a urea plant

ActiveCN104370775BSolve the use problemImprove Primary UtilizationUrea derivatives preparationProductsProcess engineeringMethylamines

The invention provides a device and technique for recovering melamine exhaust by using a urea unit, relating to the technical field of melamine exhaust recovery treatment. The device comprises an exhaust compressor and a urea unit with a primary decomposing tower, wherein the side wall of the primary decomposing tower corresponding to the bottom of the lower separating section is provided with an exhaust inlet; and the exhaust compressor is communicated with the primary decomposing tower through the exhaust inlet. The technique comprises the following steps: sending pressurized melamine exhaust to the primary decomposing tower, introducing a urea solution heated by a primary heater into the primary decomposing tower, injecting a urea solution in a preseparator into a pre-rectifying section, controlling the urea solution at the outlet of the primary heater at 155-160 DEG C, and cooling the gas-liquid mixture in a methylamine condenser to 90-100 DEG C. The device and technique can well utilize the heat of the melamine exhaust, are stable in the production process and convenient to control, and do not increase energy consumption generated by the urea unit.

Owner:HUAQIANG CHEM GRP

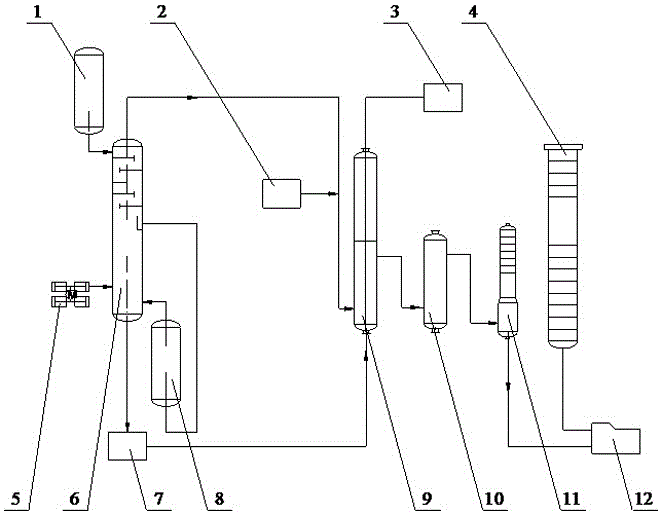

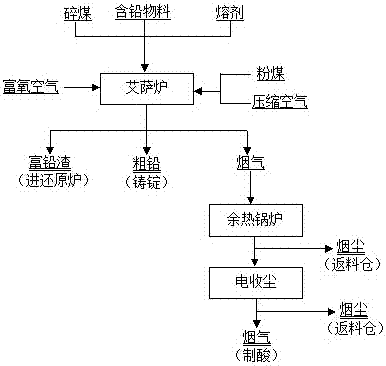

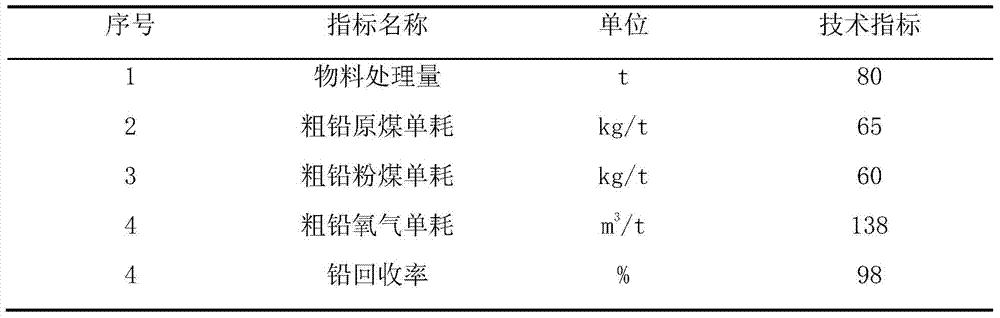

A lead smelting method using pulverized coal as injection fuel for Isa furnace

ActiveCN104775037BImprove energy savingAdaptableProcess efficiency improvementMelting tankLead smelting

The invention relates to a lead smelting method adopting pulverized coal as injection fuel in ISA furnaces, belonging to the technical field of pyrometallurgy. The method adopts the modes of continuous feeding and intermittent slag and lead discharge and comprises the following steps: 1) continuously adding lead concentrate, roasted lead slag, a flux, a slag former and a reducing agent to an oxygen-enriched top blowing furnace to be smelted; 2) sending the fuel in a spray gun into the spray gun by a Clyde pulverized coal system and injecting the fuel into a molten pool via a pulverized coal pipeline to sharply react with oxygen-enriched air to generate heat; 3) mixing loose coal used as the reducing agent with the raw materials and adding the mixture to the furnace; 4) adjusting the pulverized coal injection amount and the lifting height of the spray gun according to the temperature and height of the molten pool; 5) after separating lead and the slag, reducing the addition of the loose coal, adjusting the temperature of the molten pool, entering the stages of slag discharge and lead discharge and sending flue gases to an acid making system after waste heat and smoke dust in the flue gases are recovered by a waste heat boiler and an electric dust collector. As the pulverized coal is adopted as the fuel, the method is economical and low-carbon. The method operates efficiently, is simple to operate and has achieved industrial application.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com