Pure iron production method through smelting reduction technique

A reduction method, pure iron technology, applied in the improvement of process efficiency, manufacturing converters, furnace types, etc., can solve the problems of high cost, high value, and difficulty of high-purity iron, achieve stable production process control, excellent product quality, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

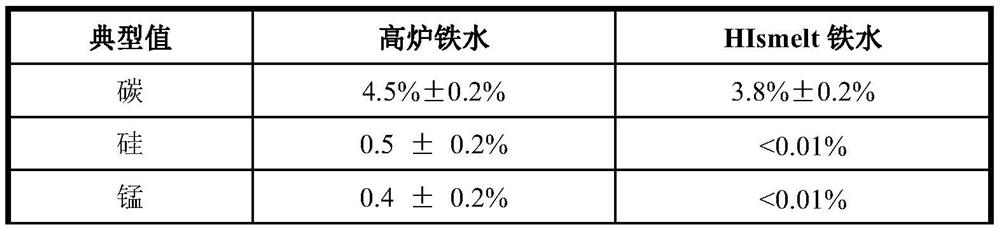

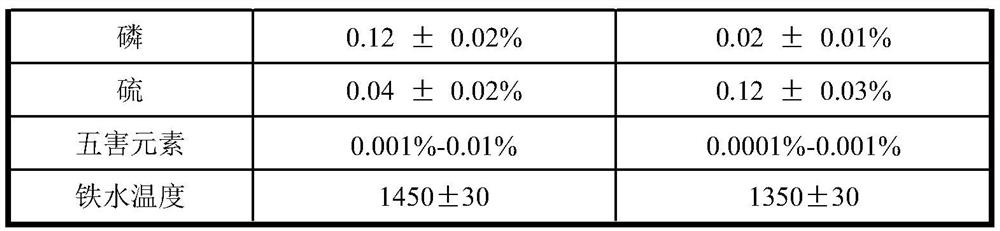

[0077] The primary iron produced has a carbon content of 3.6%, a phosphorus content of 0.010%, a sulfur content of 0.12%, a silicon content of 0.0040%, and a manganese content of 0.001%.

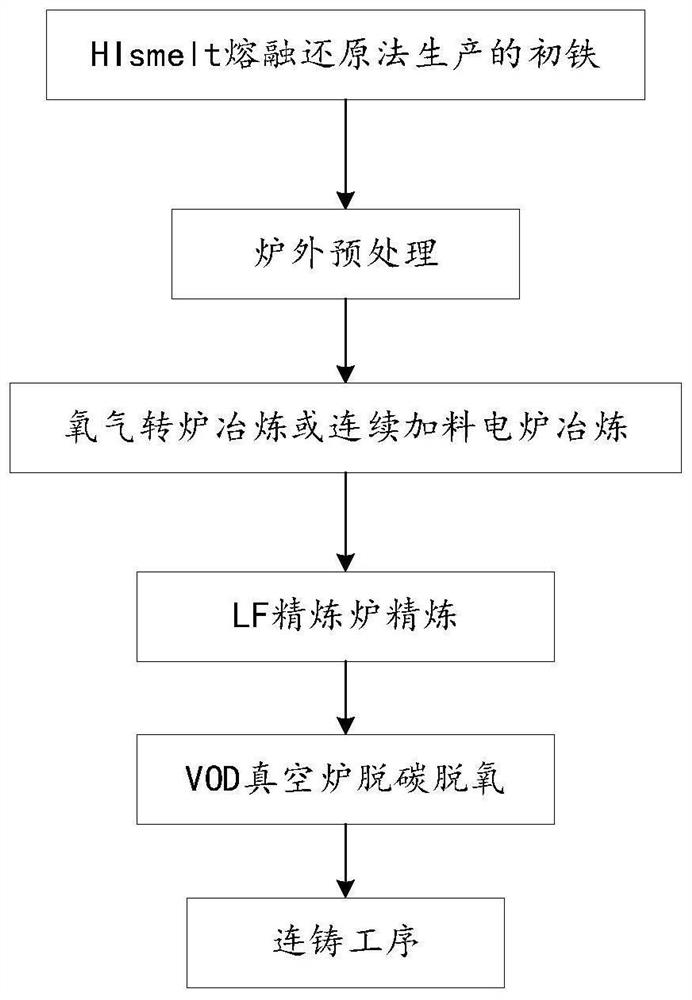

[0078] Primary iron (hot metal temperature 1320°C) is pretreated outside the furnace, smelted in an oxygen converter, refined in an LF refining furnace, and decarburized and deoxidized in a VOD vacuum furnace to produce industrial pure iron of YT4 grade. The specific steps are as follows:

[0079] (1) Pretreatment outside the furnace

[0080] Use compound desulfurizer to carry out desulfurization and carbon adjustment to primary iron, so that the sulfur content of molten iron after desulfurization and carbon adjustment is 0.0010wt%, and carry out slag removal treatment to the molten iron after desulfurization and carbon adjustment until the residual slag in molten iron is less than 5wt% of the total slag;

[0081] The compound desulfurizer includes: 15 parts of magnesium powder, 30 parts of...

Embodiment 2

[0100] The primary iron produced has a carbon content of 3.8%, a phosphorus content of 0.012%, a sulfur content of 0.105%, a silicon content of 0.0042%, and a manganese content of 0.001%.

[0101] Primary iron (hot metal temperature 1360°C) is pretreated outside the furnace, smelted in an oxygen converter, refined in an LF refining furnace, and decarburized and deoxidized in a VOD vacuum furnace to produce industrial pure iron of YT4 grade. The specific steps are as follows:

[0102] (1) Pretreatment outside the furnace

[0103] Use compound desulfurizer to carry out desulfurization and carbon adjustment to the primary iron, so that the sulfur content of the molten iron after desulfurization and carbon adjustment is 0.0008wt%, and carry out slag removal treatment to the desulfurization and carbon adjustment of the molten iron until the residual slag in the molten iron is less than 5wt% of the total slag;

[0104] The compound desulfurizer includes: 18 parts of magnesium powde...

Embodiment 3

[0122] The primary iron produced has a carbon content of 4.0%, a phosphorus content of 0.015%, a sulfur content of 0.09%, a silicon content of 0.0045%, and a manganese content of 0.001%.

[0123] Primary iron (hot metal temperature 1380°C) is pretreated outside the furnace, smelted in an oxygen converter, refined in an LF refining furnace, and decarburized and deoxidized in a VOD vacuum furnace to produce industrial pure iron of YT4 grade. The specific steps are as follows:

[0124] (1) Pretreatment outside the furnace

[0125] Use compound desulfurizer to carry out desulfurization and carbon adjustment to the initial iron, so that the sulfur content of the molten iron after desulfurization and carbon adjustment is 0.0007wt%, and carry out slag removal treatment to the molten iron after desulfurization and carbon adjustment until the residual slag in the molten iron is less than 5wt% of the total slag;

[0126] The compound desulfurizer includes: 20 parts of magnesium powder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com