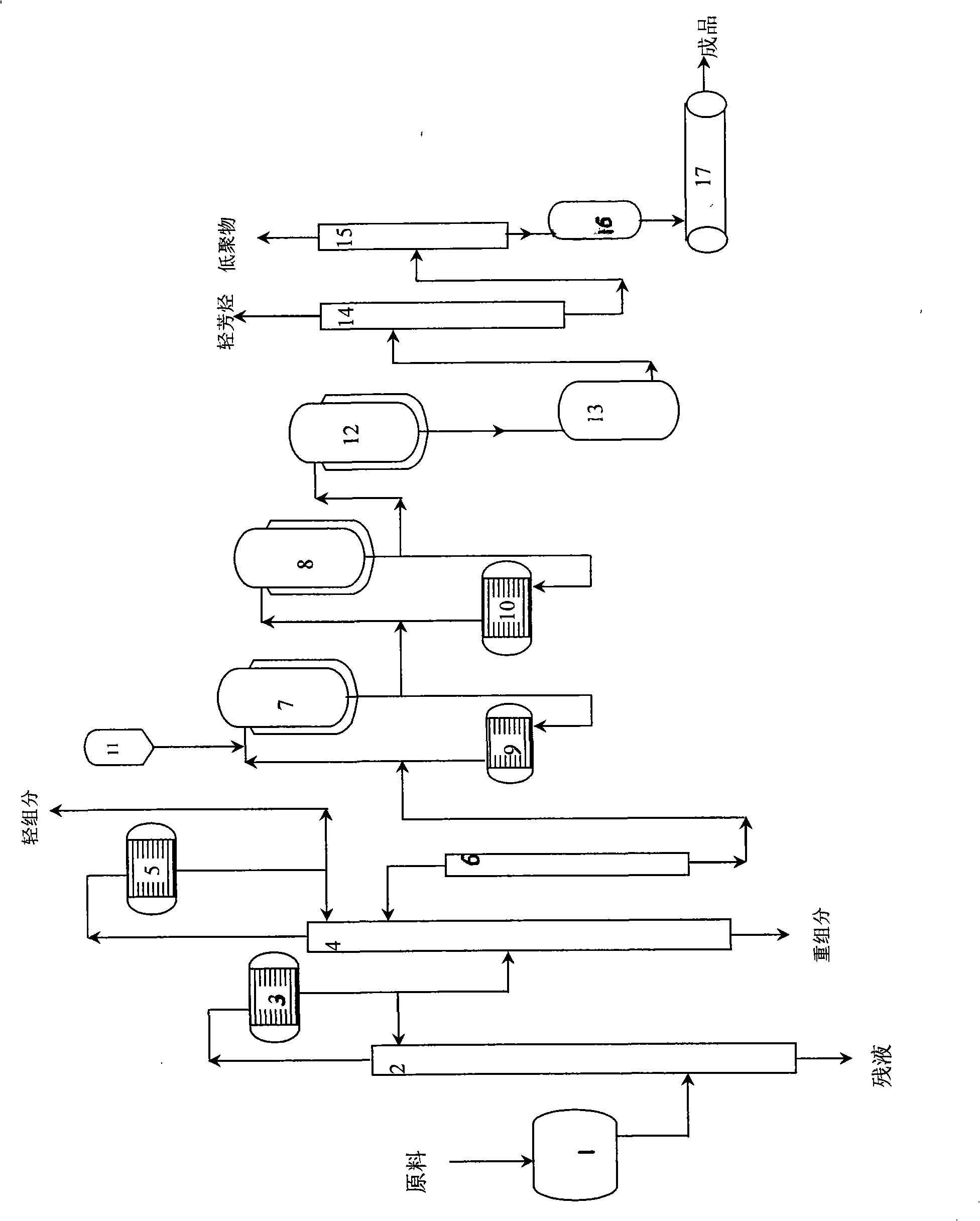

Process and equipment for continuous catalytic polymerization aggregation of C9 petroleum resin

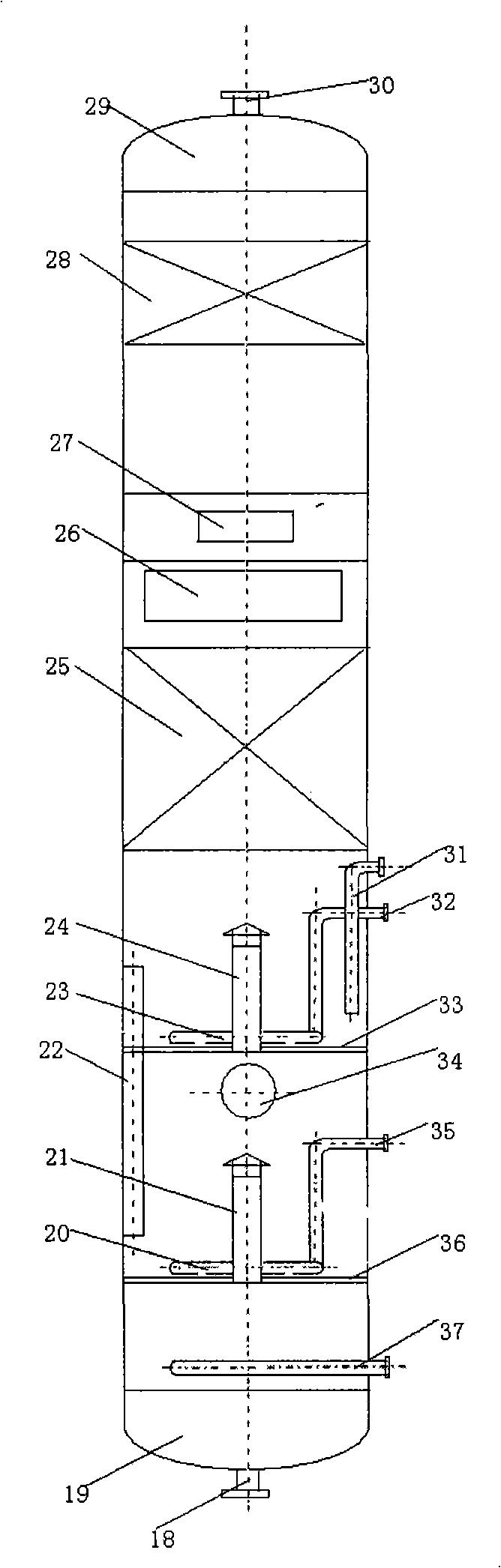

A petroleum resin and catalytic polymerization technology, which is applied in the continuous catalytic polymerization integration process and equipment field of carbon nine petroleum resin, can solve the problems of resin hue deterioration, unstable quality, coking and other problems, so as to increase the flash contact heat exchange time, improve the Flash evaporation effect, the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. C9 raw material pretreatment system

[0039] Cracked C9 passes through the cracked C9 raw material tank 1, and feeds the material to the rectification tower 2 at a feed rate of 2 to 7 tons per hour. The rectification tower is rectified under negative pressure, and the pressure at the top of the tower is controlled at a vacuum degree of 0.03 to 0.05 MPa. After being condensed by the rectification tower condenser 3, the top gas phase components partly reflux in the rectification tower, and part of them enter the separation tower 4, and the light components at the top of the separation tower are recovered and utilized after being condensed by the separation tower condenser 5; the temperature of the separation tower is controlled at between 50 and 180°C; the vacuum at the top of the tower is controlled at 0.05 to 0.08MPa, light carbon nine is extracted from the side line of the separation tower and enters the stripping tower 6, and the temperature of the side extraction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com