Production technique and device of high-water-soluble-phosphorus sulfur-base compound fertilizer

A production process and water-soluble technology, which is applied to the production process and device field of highly water-soluble phosphorus-sulfur-based compound fertilizers, can solve the problems of low water-soluble phosphorus content of sulfur-based compound fertilizers and cannot meet customer needs, etc., to increase the quality The effect of advantages, increasing popularity, and strong competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

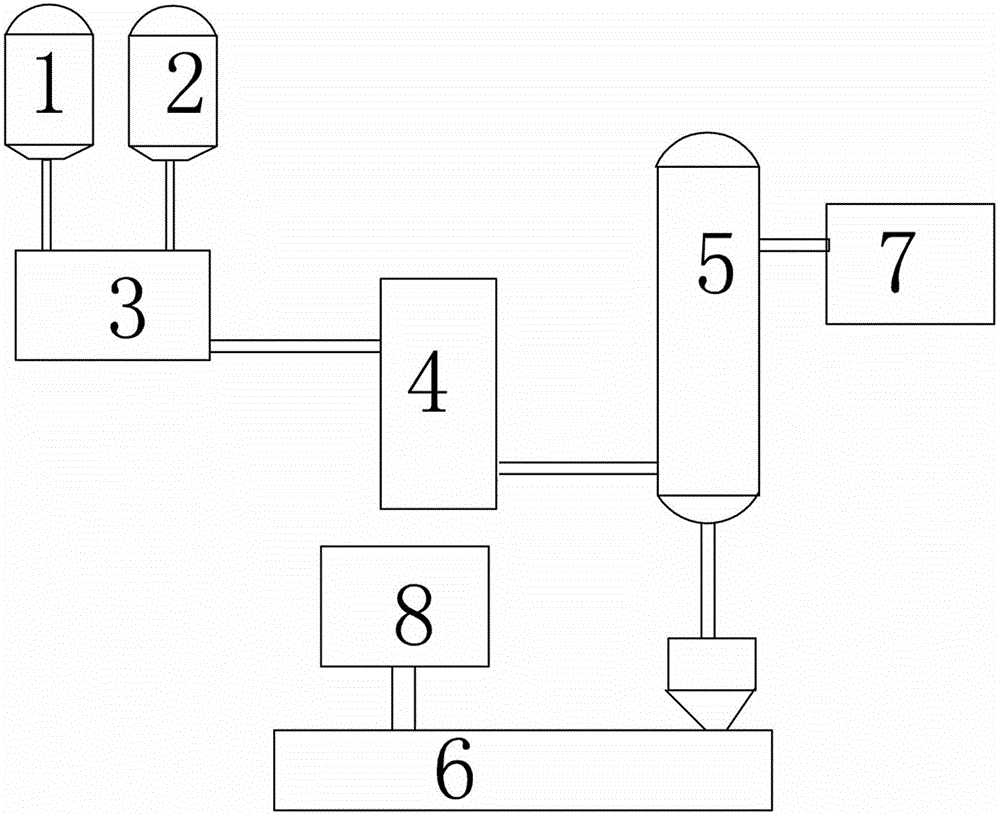

Image

Examples

Embodiment 1

[0024] A kind of production technology of highly water-soluble phosphorus-sulfur-based compound fertilizer, concrete steps are:

[0025] 1) In parts by weight, mix dilute phosphoric acid with a mass concentration of 20%~25% and the mother liquor in an industrial monoammonium phosphate plant at a ratio of 2:1, then add 0.8 parts of concentrated sulfuric acid with a mass concentration of 98%, 0.5 parts Potassium chloride was reacted for 4 hours;

[0026] 2) Neutralize the solution obtained in step 1) with ammonia gas when passing through the tubular reactor, adjust the amount of ammonia in time according to the degree of neutralization and the viscosity of the slurry until the neutralization degree of the slurry is 1.10, and then proceed to manufacture granules to obtain a sulfur-based compound fertilizer with a water-soluble phosphorus content of 89.6%.

Embodiment 2

[0028] A kind of production technology of highly water-soluble phosphorus-sulfur-based compound fertilizer, concrete steps are:

[0029] 1) In parts by weight, mix dilute phosphoric acid with a mass concentration of 20%~25% and the mother liquor in an industrial monoammonium phosphate plant at a ratio of 4:1, then add 1 part of concentrated sulfuric acid with a mass concentration of 98%, 1.5 parts Potassium chloride was reacted for 6 hours;

[0030] 2) Neutralize the solution obtained in step 1) with ammonia gas when passing through the tubular reactor, adjust the amount of ammonia in time according to the degree of neutralization and the viscosity of the slurry until the neutralization degree of the slurry is 1.50; then granulate , to obtain a phosphorus-sulfur-based compound fertilizer with a water-soluble phosphorus content of 92.3%.

[0031] The composition of the mother liquor in the said industrial monoammonium phosphate unit has a nitrogen content of 4-6%, water-solubl...

Embodiment 3

[0034] A kind of production technology of highly water-soluble phosphorus-sulfur-based compound fertilizer, concrete steps are:

[0035] 1) In parts by weight, mix dilute phosphoric acid with a mass concentration of 20%~25% and the mother liquor in an industrial monoammonium phosphate plant at a ratio of 3:1, then add 0.88 parts of concentrated sulfuric acid with a mass concentration of 98%, 1.0 parts Potassium chloride was reacted for 5 hours;

[0036] 2) Neutralize the solution obtained in step 1) with ammonia gas when passing through the tubular reactor, adjust the amount of ammonia in time according to the degree of neutralization and the viscosity of the slurry until the neutralization degree of the slurry is 1.50; then granulate , to obtain a phosphorus-sulfur-based compound fertilizer with a water-soluble phosphorus content of 93.5%.

[0037] In the above examples, the components of the mother liquor in the industrial monoammonium phosphate plant have a nitrogen conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com