Sample preparation method capable of realizing quick detection of nitrogen composition

A rapid and casting technology, applied in the field of sample preparation for rapid detection of nitrogen components, can solve the problems of inability to adapt to rapid production requirements, long sample preparation time, long detection time, etc., to ensure integrity, short sample preparation time, meet The effect of rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Furnace charge ratio is carried out according to the requirements of the production grade, and the prepared charge is placed in the intermediate frequency furnace for melting. When the charge is melted to four-fifths, ferromanganese, copper, and ferrosilicon are added according to the target amount of molten iron. .

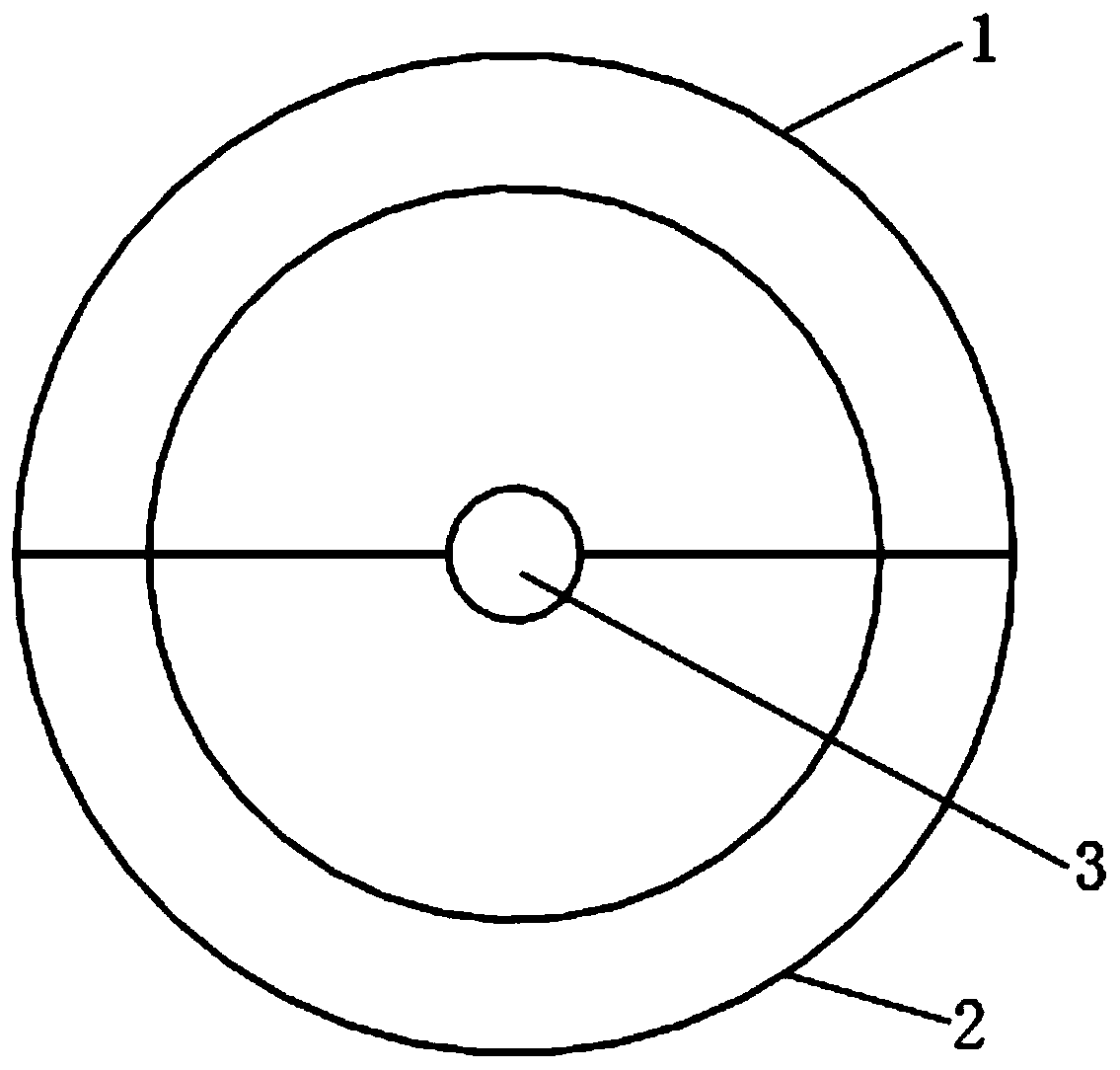

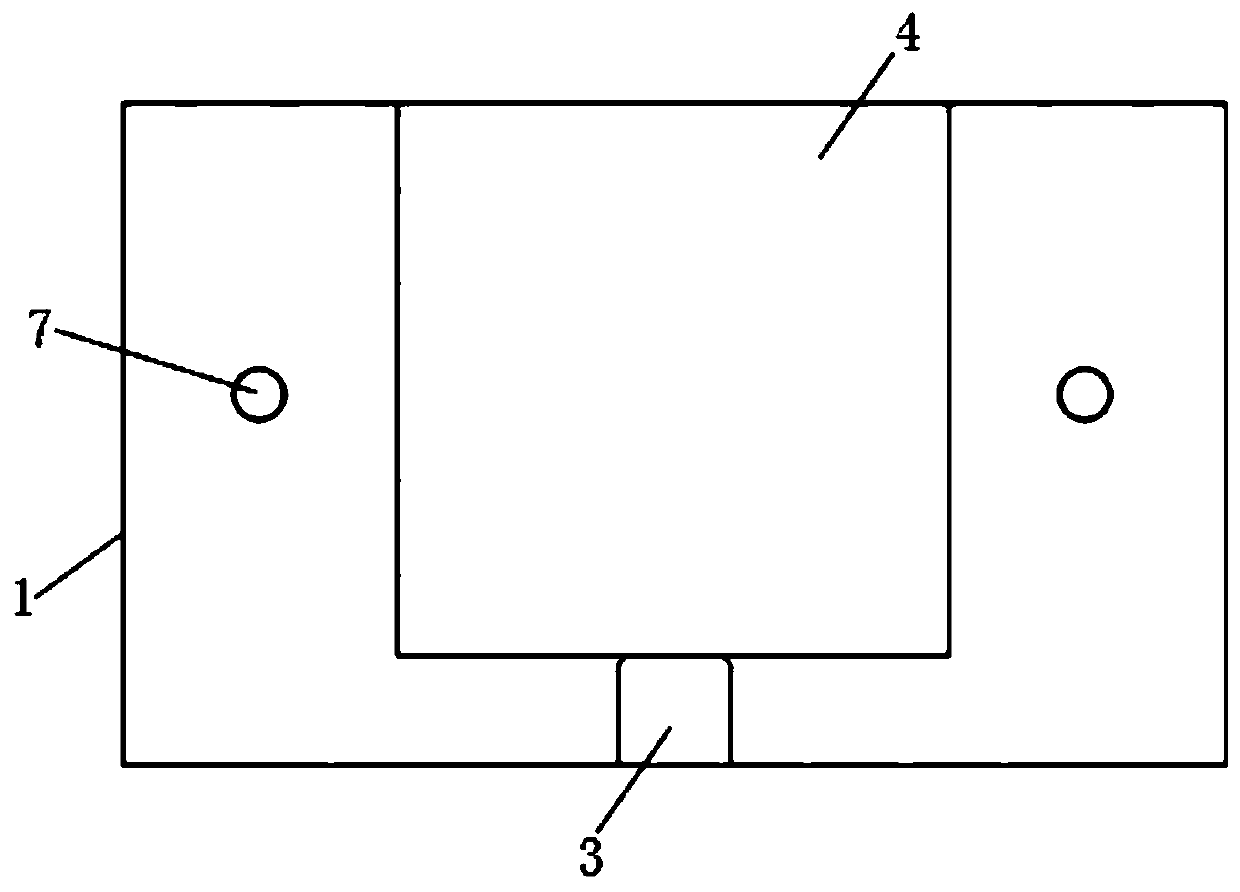

[0031] (2) After the molten iron smelting is completed, the temperature of the molten iron is controlled between 1350-1400 °C, and the molten iron is quickly poured into a specific mold for nitrogen detection.

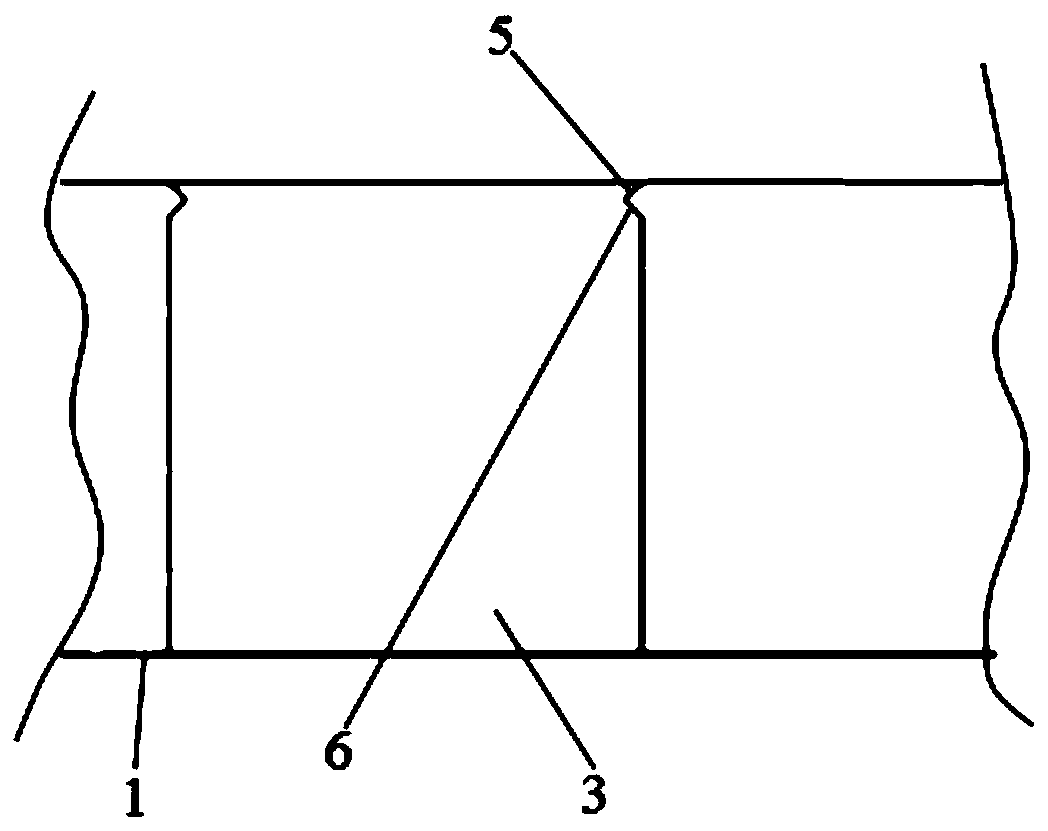

[0032] (3) Wait for the sample to solidify, and after naturally cooling to 600 degrees, take out the sample from the box, and after naturally cooling to room temperature, knock off the tail of the sample directly.

[0033] (4) Take the tail of the knocked-off sample, scrub the surface with alcohol to remove the oxide layer on the surface, put it on a clean white paper to dry, and complete the production of the nitrogen detection sample.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com