Corrosion-resistant wind-vibration-resistant medium-strength aluminum alloy conductor aerial insulation cable production device and working method thereof

A medium-strength aluminum alloy and overhead insulated cable technology, which is applied in the direction of insulated cables, conductor/cable insulation, conductors, etc., can solve the problems of increasing processing costs, secondary transportation costs of raw materials, and unstable material properties, and achieve reduction of two Transportation cost and packaging cost, production control process stability, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

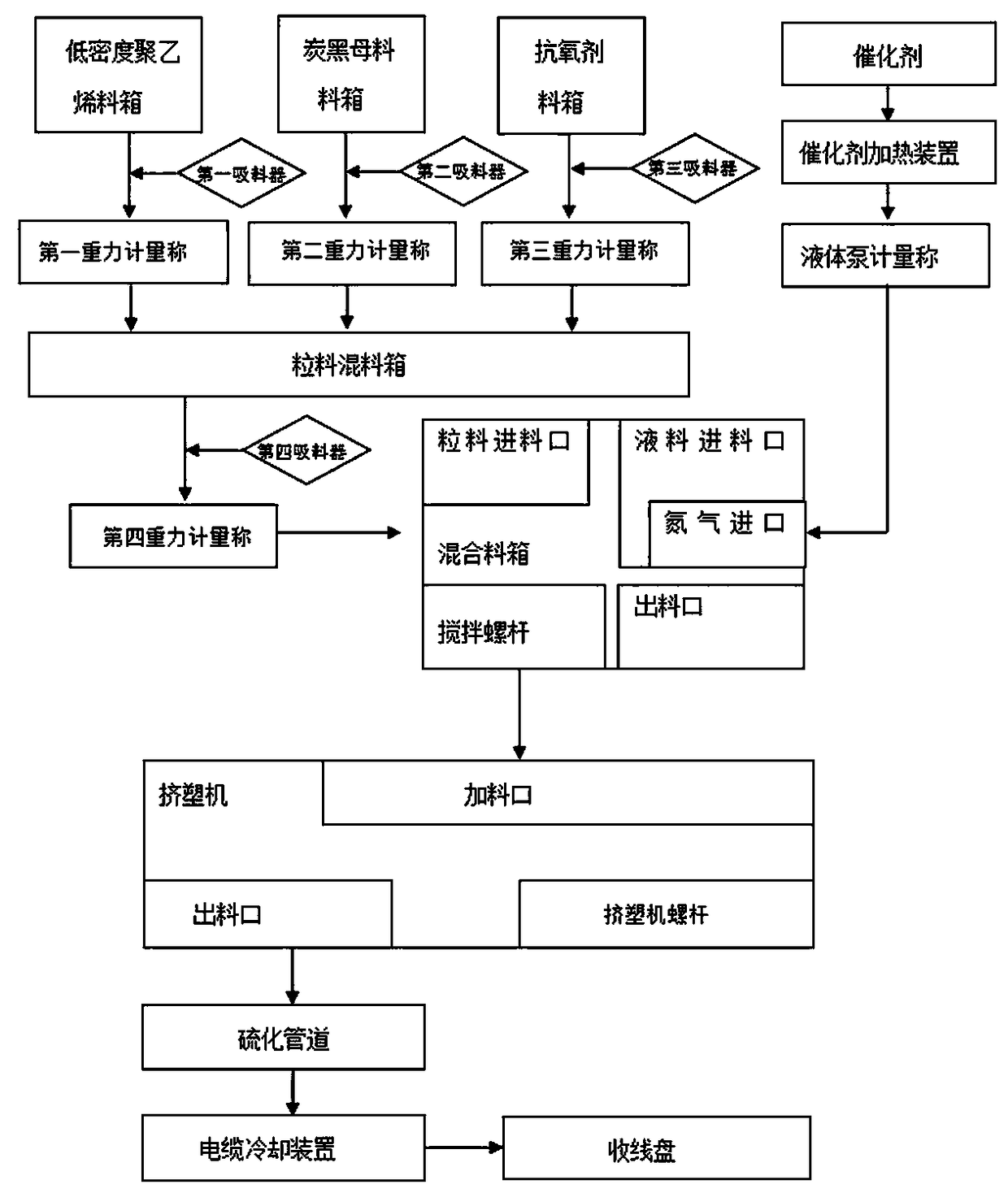

[0025] Such as figure 1 As shown, this embodiment provides a production device for corrosion-resistant and wind-resistant medium-strength aluminum alloy conductor overhead insulated cables, including low-density polyethylene LDPE2220H material box, carbon black masterbatch material box, antioxidant material box, first Gravimetric scale, second gravimetric scale, third gravimetric scale, fourth gravimetric scale, first loader, second loader, third loader, fourth loader, catalyst heating device , liquid pump metering scale, pellet mixing box, mixing box, extruder, extruder screw, mixing screw, vulcanization pipeline, cable cooling device and take-up reel;

[0026] Wherein, the low-density polyethylene material box feeds the low-density polyethylene LDPE2220H in the box to the first gravimetric scale through the first suction device; the carbon black mast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com