Maltol Grignard section intermediate purification method

A purification method and intermediate technology, which are applied in the field of maltol Grignard section intermediate purification, can solve the problems affecting the yield and output of maltol, low quality, and low furfuryl alcohol yield, etc., so as to facilitate production control, increase yield and improve production efficiency. Effect of quality, solvent consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

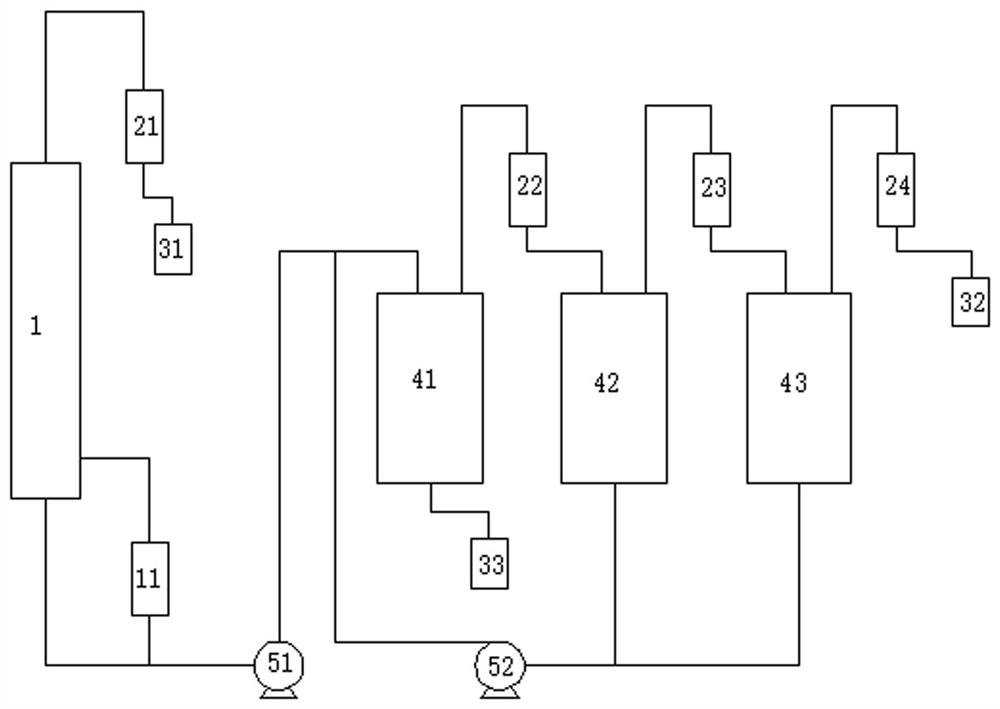

[0020]A method for purifying maltol Grignard process intermediates, which is characterized in that it comprises the following steps:

[0021](1) Intermediate press 2m3The flow rate of / h enters the rectification tower for rough separation of furfuryl alcohol and solvent. The bottom temperature of the rectification tower is 60℃, and the top temperature is 40℃;

[0022](2) Then it is extracted from the bottom of the rectification tower into the first-level flash distillation kettle, and the extraction flow is 1.5m3 / h, the temperature of the first-level flash vaporizer is 85℃, the gas phase of the first-level flash vaporizer enters the second-level flash vaporizer after condensing, the temperature of the second-level flash vaporizer is 65℃, and the gaseous phase of the second-level flash vaporizer enters the third after condensing The temperature of the three-stage flash tank is 60℃. The temperature of the three-stage flash tank is collected after the gas phase condensation. The temperature ...

Embodiment 2

[0026]A method for purifying maltol Grignard process intermediates, which is characterized in that it comprises the following steps:

[0027](1) Intermediate press 2m3The flow rate of / h enters the rectification tower for rough separation of furfuryl alcohol and solvent. The bottom temperature of the rectification tower is 60℃, and the top temperature is 40℃;

[0028](2) Then it is extracted from the bottom of the rectification tower into the first-level flash distillation kettle, and the extraction flow is 1.5m3 / h, the temperature of the first-level flash vaporizer is 85℃, the gas phase of the first-level flash vaporizer enters the second-level flash vaporizer after condensing, the temperature of the second-level flash vaporizer is 65℃, and the gaseous phase of the second-level flash vaporizer enters the third after condensing The temperature of the three-stage flash distillation kettle is 60℃. The temperature of the three-stage flash distillation reactor is collected after gas phase con...

Embodiment 3

[0032]A method for purifying maltol Grignard process intermediates, which is characterized in that it comprises the following steps:

[0033](1) Intermediate press 2m3The flow rate of / h enters the rectification tower for rough separation of furfuryl alcohol and solvent. The bottom temperature of the rectification tower is 60℃, and the top temperature is 40℃;

[0034](2) Then it is extracted from the bottom of the rectification tower into the first-level flash distillation kettle, and the extraction flow is 1.5m3 / h, the temperature of the first-level flash vaporizer is 85℃, the gas phase of the first-level flash vaporizer enters the second-level flash vaporizer after condensing, the temperature of the second-level flash vaporizer is 65℃, and the gaseous phase of the second-level flash vaporizer enters the third after condensing The temperature of the three-stage flash tank is 60℃. The temperature of the three-stage flash tank is collected after gas phase condensation. The temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com