Process for purifying trichlorosilane and silicon tetrachloride

A technology for purifying trichlorosilane and silicon tetrachloride, applied in halogenated silicon compounds, halogenated silanes, fractional distillation, etc., can solve the problems of insufficient quality, poor product yield, large amounts of frozen water, etc., and achieve stable production control and personnel. The effect of labor intensity reduction, application and benefit improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

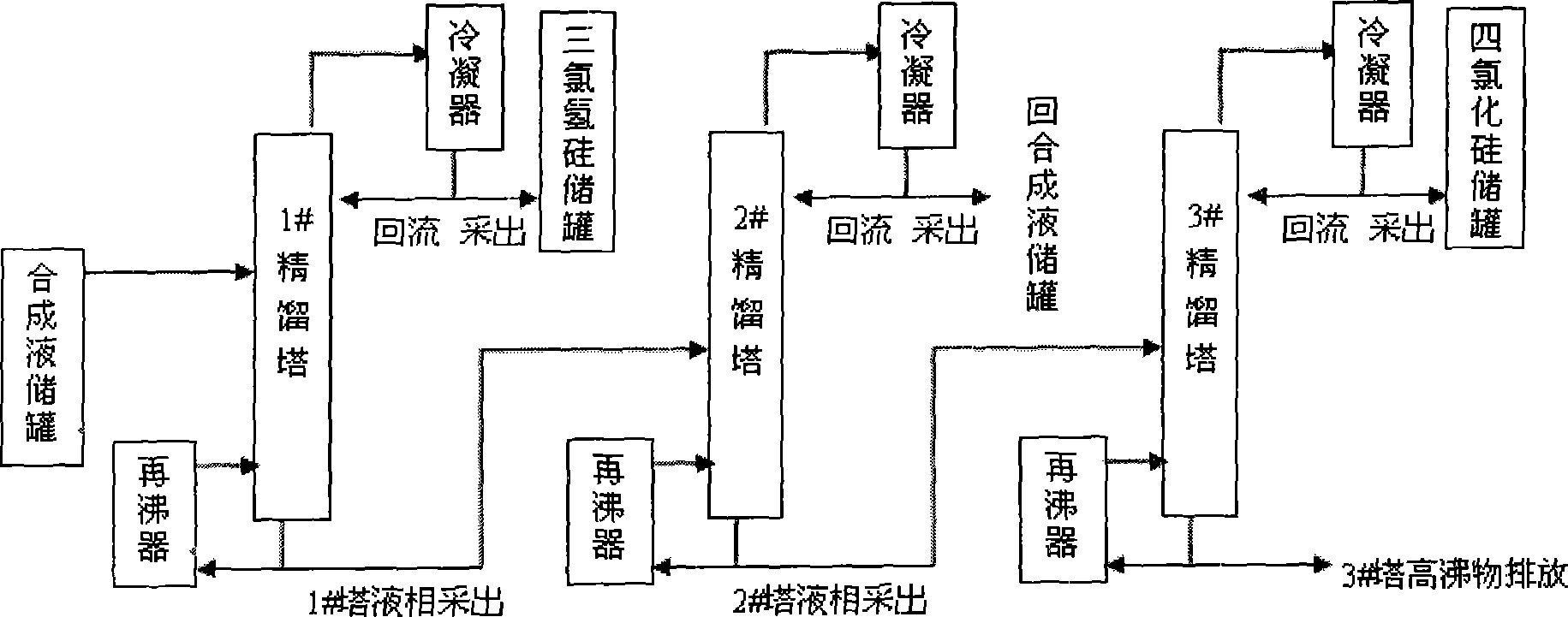

[0022] Such as figure 1 As shown, the trichlorosilane liquid raw material enters the middle part of the 1# rectification tower with a pressure of 0.35MPa from the synthetic liquid storage tank with a pressure of 0.50MPa under the action of the pressure difference. 110°C, maintain the set pressure and temperature in the tower; the refrigerant of the condenser is ordinary circulating water, the gas phase at the top of the 1# rectification tower is extracted and refluxed after being condensed by the condenser, and the rest of the high-purity trichlorosilane is stored in Trichlorosilane storage tank; the bottom of the tower is connected to the reboiler, and the temperature in the adjustment tower is maintained by heating part of the liquid phase in the rectification tower; the liquid phase of the 1# rectification tower is produced to contain a small amount of trichlorohydrogen Silicon tetrachloride solution of silicon, the solution enters the middle part of the 2# rectification to...

Embodiment 2

[0024] The trichlorosilane liquid raw material enters the middle part of the 1# rectification tower with a pressure of 0.40MPa from the synthetic liquid storage tank with a pressure of 0.55MPa under the action of pressure difference. The temperature at the top of the tower is 80-85°C and the temperature at the bottom of the tower is 120-130°C Maintain the set pressure and temperature in the tower; the refrigerant in the condenser is ordinary circulating water, the gas phase at the top of the 1# rectification tower is extracted and condensed by the condenser, and part of it is refluxed, and the rest of the high-purity trichlorosilane is stored in trichlorohydrogen Silicon storage tank; the bottom of the tower is connected with the reboiler, and the temperature in the adjustment tower is maintained by heating part of the liquid phase in the rectification tower; the liquid phase of the 1# rectification tower is produced as tetrachloride containing a small amount of trichlorosilane ...

Embodiment 3

[0026]The trichlorosilane liquid raw material enters the middle part of the 1# rectification tower with a pressure of 0.30MPa from the synthetic liquid storage tank with a pressure of 0.60MPa under the action of pressure difference. The temperature at the top of the tower is 60-62°C, and the temperature at the bottom of the tower is 90-105°C Maintain the set pressure and temperature in the tower; the refrigerant in the condenser is ordinary circulating water, the gas phase at the top of the 1# rectification tower is extracted and condensed by the condenser, and part of it is refluxed, and the rest of the high-purity trichlorosilane is stored in trichlorohydrogen Silicon storage tank; the bottom of the tower is connected with the reboiler, and the temperature in the adjustment tower is maintained by heating part of the liquid phase in the rectification tower; the liquid phase of the 1# rectification tower is produced as tetrachloride containing a small amount of trichlorosilane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com