A method for producing thin-gauge, low-alloy, high-strength checkered plates based on csp process

A thin-gauge, low-alloy technology, used in metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as uneven cooling, edge pattern groove damage, obstruction, etc., to achieve stable production process control and ensure The effect of pattern integrity and plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

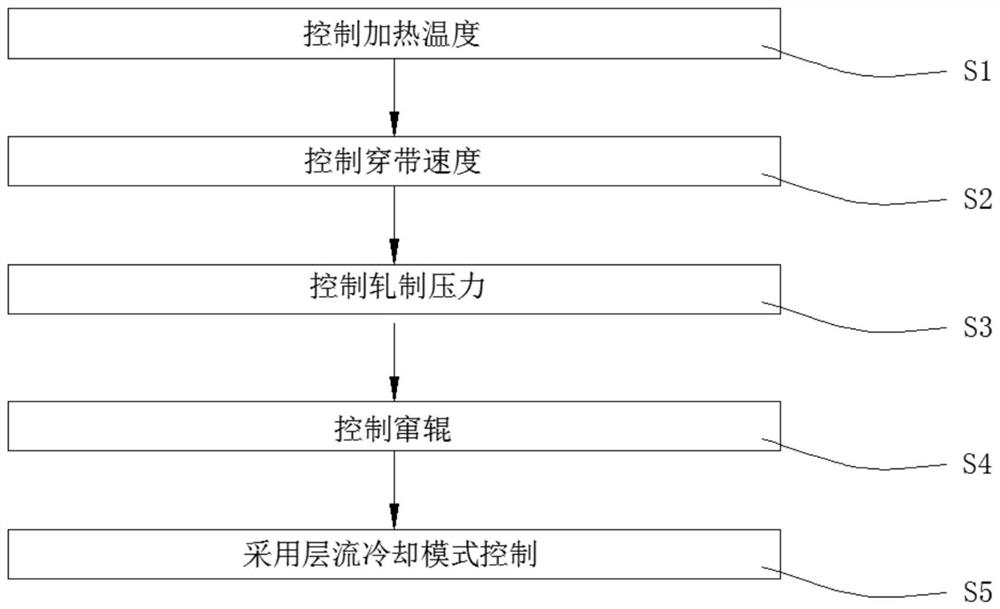

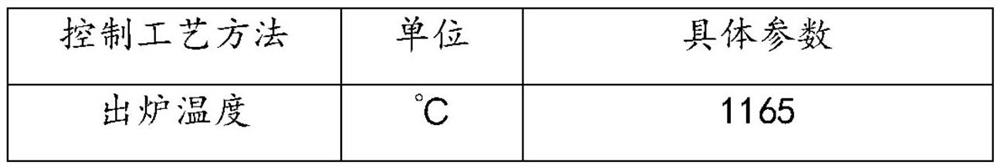

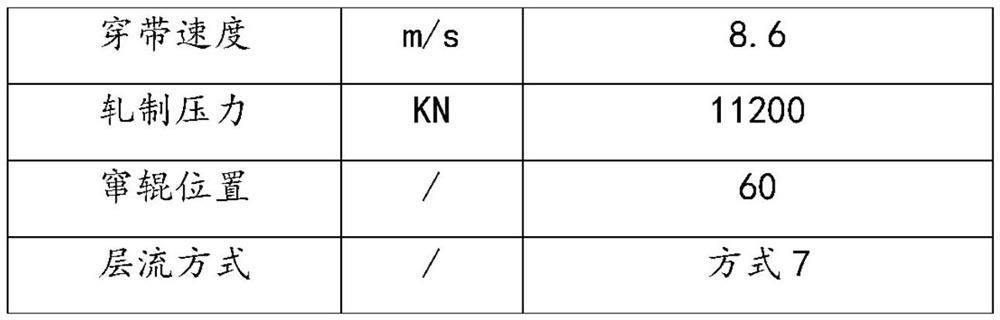

[0029] The present invention provides such as figure 1 A method for producing a thin-gauge, low-alloy, high-strength checkered plate based on a CSP process as shown includes the following steps:

[0030] S1. Control the heating temperature: control the furnace entry temperature and the furnace exit temperature;

[0031] S2. Control the threading speed: according to the thickness of the rolled product, control the threading speed;

[0032] S3. Control the rolling pressure: adjust the rolling force parameters according to different thickness specifications;

[0033] S4. Control roll shifting: after changing rolls and calibrating, starting from 0 point, the roll shifting cycle starts at 20mm, 25mm, and 30mm respectively. The range of roll shifting is (-100, 100), and the frequency of roll shifting is every 2 pieces of steel move once;

[0034] S5. Adopt laminar flow cooling mode control: laminar flow cooling is set to mode 7.

[0035] Specifically in the present invention: in...

Embodiment 2

[0060] The present invention also provides figure 1 A method for producing a thin-gauge, low-alloy, high-strength checkered plate based on the CSP flow shown is different from Embodiment 1 in that:

[0061] The temperature into the furnace is 900°C.

[0062] When the thickness of the rolled product is in the interval of 1.4mm

[0063] When rolling a 1000mm section, the rolling pressure range is 10500KN; when rolling a 1250mm section, the rolling pressure range is 12000KN; when rolling a 1500mm section, the rolling pressure range is 13000KN.

Embodiment 3

[0065] The present invention also provides figure 1 A method for producing a thin-gauge, low-alloy, high-strength checkered plate based on the CSP flow shown is different from Embodiment 1 in that:

[0066] The temperature into the furnace is 950°C.

[0067] When the thickness of the rolled product is in the interval of 1.4mm

[0068] When rolling a 1000mm section, the rolling pressure range is 11500KN; when rolling a 1250mm section, the rolling pressure range is 13000KN; when rolling a 1500mm section, the rolling pressure range is 14000KN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com