A lead smelting method using pulverized coal as injection fuel for Isa furnace

An Isa furnace and pulverized coal technology, which is applied in the field of smelting lead, can solve the problems of high cost of crude lead, expensive diesel oil, and large consumption, and achieve the effect of sufficient redox reaction, favorable matching, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

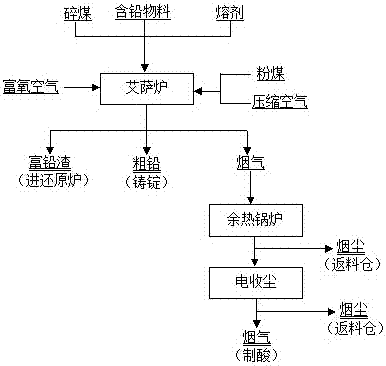

Method used

Image

Examples

Embodiment 1

[0026] Take the input material 10.5t / h as an example.

[0027] A method for smelting lead by using pulverized coal as the injection fuel of the Isa furnace, the specific steps are:

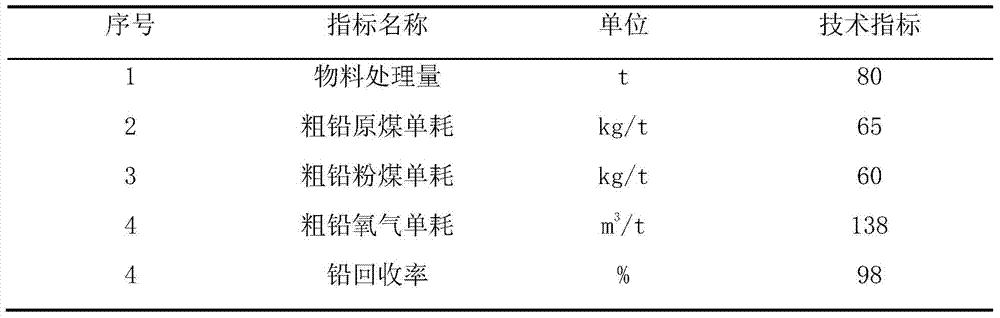

[0028] 1) Put 5t of lead concentrate, 1.5t of high-lead fumes, 4t of roasted lead slag, and appropriate proportions of flux and crushed coal into the furnace from the charging port on the top of the furnace through a quantitative feeder and a belt conveyor to control the dust. The coal volume is 1.4-1.9t / h, and the process air volume is 6-8m 3 / s, the pressure is 160±10KPa; the oxygen consumption is 0.5-2.0m 3 / s, the pressure is 200-240KPa, according to SiO 2 / Fe=0.6-1.0, CaO / SiO 2 =0.3-0.7 to control the amount of flux added. The crushed coal is controlled according to different stages of smelting; during the control process, pay attention to controlling the position of the spray gun to ensure that the spray gun is in a proper position in the molten pool. Quality requirements for pulverized...

Embodiment 2

[0033] Take the input material 47.5t / h as an example.

[0034] A method for smelting lead by using pulverized coal as the injection fuel of the Isa furnace, the specific steps are:

[0035] 1) Put 25t of lead concentrate, 7.5t of high-lead fume, 15t of roasted lead slag, together with appropriate proportion of flux and crushed coal, through the quantitative feeder and belt conveyor, and put them into the furnace from the charging port on the top of the furnace to control the dust. The coal volume is 1.4-1.9t / h, and the process air volume is 6-8m 3 / s, the pressure is 160±10KPa; the oxygen consumption is 0.5-2.0m 3 / s, the pressure is 200-240KPa, according to SiO 2 / Fe=0.6-1.0, CaO / SiO 2 =0.3-0.7 to control the amount of flux added. The crushed coal is controlled according to different stages of smelting; during the control process, pay attention to controlling the position of the spray gun to ensure that the spray gun is in a proper position in the molten pool. Quality re...

Embodiment 3

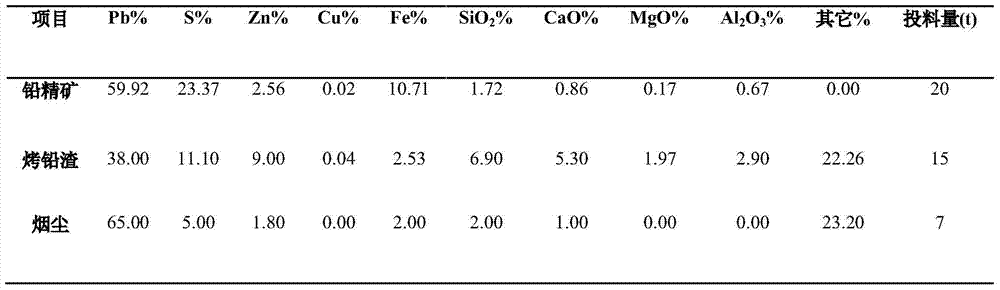

[0040] Taking the input material 42t / h as an example, its composition is shown in Table 1.

[0041] Table 1 Composition of materials input to ISA furnace

[0042]

[0043] A method for smelting lead by using pulverized coal as the injection fuel of the Isa furnace, the specific steps are:

[0044] 1) Put 20t of lead concentrate, 7t of high-lead fumes, 15t of roasted lead slag, together with an appropriate proportion of flux and crushed coal, through the quantitative feeder and belt conveyor, and add them into the furnace from the charging port on the top of the furnace to control the pulverized coal The volume is 1.4-1.9t / h, and the process air volume is 6-8m 3 / s, the pressure is 160±10KPa; the oxygen consumption is 0.5-2m 3 / s, the pressure is 200-240KPa, according to SiO 2 / Fe=0.6-1.0, CaO / SiO 2 =0.3-0.7 to control the amount of flux added. The crushed coal is controlled according to different stages of smelting; during the control process, pay attention to controll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com