Nitrobenzene hydrogenation aniline preparation catalyst for fluidized bed

A catalyst, nitrobenzene technology, applied in the direction of physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, amino compound preparation, etc., can solve the problem of catalyst composition and temperature, different adsorption properties, unfavorable mass production and other problems, to achieve the effect of reducing catalyst unit consumption, single composition, and stable production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

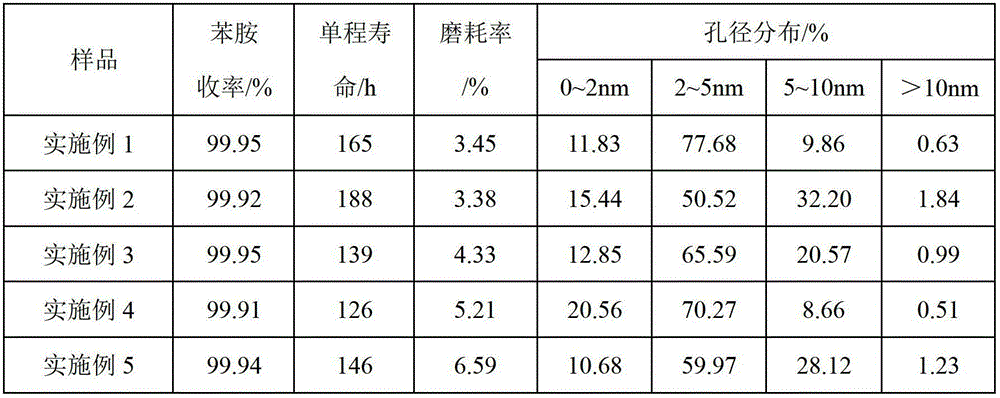

Embodiment 1

[0022] Catalyst preparation is carried out in a closed reactor, and it is implemented in the following steps. ① Preparation of cuproammonia solution: Take 100ml of 10M ammonia water and add it to 500ml of 0.5M copper nitrate solution to prepare a clear cuproammonia complex solution, then add 600 ml of ionized water and stir. ②Impregnation: Take 200g of silica gel and add it to the cuproammonia complex solution in ①, keep it under vacuum at 70℃ for 3 hours while stirring, and the impregnation is completed. ③Separation, washing and drying: Separating the impregnated materials into solid and liquid, washing the solid materials until neutral, and then drying them to obtain the finished catalyst. The copper content of the catalyst is 15.5%, and the specific surface area is 380.5m 2 / g, pore volume 0.72ml / g, average pore diameter 3.5nm.

Embodiment 2

[0024] Catalyst preparation is carried out in an airtight reactor, according to the following steps to implement. ① Preparation of copper ammonia solution: Take 200ml of 10M ammonia water and add it to 500ml of 0.5M copper nitrate solution to prepare a clear copper ammonia complex solution. ②Impregnation: Take 200g of silica gel and add it to the copper ammonia complex solution in ①, stir and vacuumize at 90°C for 4 hours, and the impregnation is completed. ③Separation, washing and drying: Separating the impregnated materials into solid and liquid, washing the solid materials until neutral, and then drying them to obtain the finished catalyst. The copper content of the catalyst is 19.5%, and the specific surface area is 445.4m 2 / g, pore volume 0.82ml / g, average pore diameter 3.8nm.

Embodiment 3

[0026] Catalyst preparation is carried out in an airtight reactor, according to the following steps to implement. ① Preparation of copper ammonia solution: Take 100ml of 10M ammonia water and add it to 500ml of 0.5M copper nitrate solution to prepare a clear copper ammonia complex solution. ②Impregnation: Take 200g of silica gel and add it to the cuproammonia complex solution in ①, and keep it in a vacuum at 80°C for 4 hours while stirring, and the impregnation is completed. ③Separation, washing and drying: Separating the impregnated materials into solid and liquid, washing the solid materials until neutral, and then drying them to obtain the finished catalyst. The copper content of the catalyst is 20.6%, and the specific surface area is 463.5m 2 / g, pore volume 0.63ml / g, average pore diameter 3.1nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com